Introduction

In the fast-paced world of fashion, apparel inspection has become a cornerstone of successful production. With the growing demand for quality clothing, ensuring that every piece meets stringent standards is vital. This not only protects brand reputation but also fosters consumer trust in company clothing.

Importance of Apparel Inspection

Apparel inspection plays a crucial role in maintaining the integrity of the manufacturing process. By systematically checking each stage, companies can identify defects early and avoid costly reworks or returns later on. This proactive approach not only enhances product quality but also streamlines operations, ultimately leading to greater customer satisfaction.

The Role of Quality Control

Quality control is the backbone of effective apparel inspection, ensuring that every garment adheres to established standards before reaching consumers. Implementing robust quality inspection protocols helps brands mitigate risks associated with defective products while also reinforcing their commitment to excellence. In an industry where trends change rapidly, maintaining high-quality benchmarks can set a company apart from its competitors.

Stages of the Apparel Manufacturing Process

The apparel manufacturing process consists of several key stages that require diligent oversight and thorough quality checks. From initial fabric checking to final product inspections, each phase contributes to the overall quality assurance strategy. Understanding these stages allows businesses to implement targeted inspection services tailored to their specific needs and challenges.

Understanding the Apparel Manufacturing Process

The apparel manufacturing process is a multifaceted journey that requires meticulous attention to detail at each stage. From the initial design to the final product, quality control plays a pivotal role in ensuring that every piece of clothing meets established standards. Understanding this process is essential for effective apparel inspection and maintaining the integrity of quality clothing.

Key Stages in Production

The production of apparel typically unfolds through several key stages: designing, sourcing materials, cutting, sewing, finishing, and finally, shipping. Each stage presents unique challenges and opportunities for quality inspection to ensure that company clothing meets consumer expectations. By implementing robust quality control measures at every step, manufacturers can significantly reduce defects and enhance overall product reliability.

Importance of Fabric Checking

Fabric checking is not just a formality; it’s a critical aspect of the apparel manufacturing process that directly influences the final product's quality. The choice of fabric affects everything from durability to comfort, making it essential for inspectors to assess fabric characteristics thoroughly before production begins. Skipping this step can lead to costly mistakes down the line—think mismatched patterns or unexpected wear-and-tear—so diligent fabric checking is non-negotiable.

The Impact of Quality Clothing Standards

Quality clothing standards serve as benchmarks for manufacturers aiming to produce garments that satisfy consumer needs while adhering to industry regulations. These standards guide every aspect of production—from raw material selection to final inspections—and help maintain consistency across various lines of company clothing. By embracing these standards through comprehensive inspection services, brands can foster trust with consumers and build long-lasting relationships in an increasingly competitive market.

Pre-Production Inspection

Pre-production inspection is a crucial phase in the apparel manufacturing process that sets the tone for quality control throughout production. It ensures that everything from fabric quality to supplier reliability meets the standards necessary for producing high-quality clothing. By implementing thorough inspection services at this stage, companies can significantly reduce the risk of defects later on, saving time and resources.

Evaluating Apparel Labels

Evaluating apparel labels is essential for ensuring compliance with industry standards and consumer expectations. Labels provide critical information about fabric composition, care instructions, and country of origin, which all contribute to quality inspection processes. By meticulously checking these labels before production begins, companies can prevent costly errors and ensure their company clothing aligns with branding guidelines.

In addition to verifying label accuracy, it’s important to ensure that they adhere to legal requirements and ethical practices such as proper labeling of materials. This not only enhances customer trust but also plays a significant role in maintaining brand reputation in a competitive market. The details on apparel labels can make or break a sale; thus, effective label evaluation should never be overlooked during pre-production inspections.

Supplier Verification Techniques

Supplier verification techniques are vital for establishing a reliable supply chain in apparel manufacturing. Companies must assess their suppliers' capabilities through audits, certifications, and past performance records before committing to any contracts. This proactive approach ensures that only those who meet stringent quality control measures are chosen to provide materials or services.

Moreover, building strong relationships with verified suppliers fosters transparency and collaboration throughout the production process. Regular communication about expectations regarding fabric checking and delivery timelines can further enhance overall efficiency. By prioritizing supplier verification techniques within pre-production inspections, businesses can mitigate risks associated with subpar materials or unreliable sources.

Conducting Initial Quality Inspector Visits

Conducting initial quality inspector visits allows companies to gain firsthand insights into their suppliers’ operations and capabilities before production begins. These visits serve as an opportunity for inspectors to evaluate facilities, machinery, and workforce competence while identifying potential areas for improvement early on. When inspectors engage directly with suppliers during these visits, they foster stronger partnerships based on mutual understanding of quality expectations.

During these visits, attention should be paid not just to processes but also to workplace conditions—after all, happy employees often lead to better-quality output! Inspectors should also review samples of fabrics intended for use in company clothing; this hands-on approach enables them to assess material integrity right away rather than waiting until later stages of production when issues may arise unexpectedly. Ultimately, initial quality inspector visits play an integral role in setting the stage for successful apparel inspection throughout subsequent phases.

In-Process Quality Inspection

In-process quality inspection is a crucial phase in the apparel manufacturing process that ensures products meet established standards before they reach the final stages. It involves continuous monitoring and assessment of the production line, which helps in identifying any potential issues early on. By implementing effective quality control measures during this stage, companies can significantly reduce waste, enhance customer satisfaction, and maintain their reputation for high-quality clothing.

Monitoring the Production Line

Monitoring the production line is essential for effective apparel inspection and quality control. This involves regularly checking various stages of garment assembly to ensure that everything aligns with approved specifications and apparel labels. By keeping a close eye on processes like stitching, cutting, and finishing, inspectors can catch discrepancies that may lead to defects or inconsistencies in quality clothing.

Regular audits during production also help identify areas where efficiency can be improved without compromising quality inspection standards. For example, if certain machines are consistently producing faulty seams or if workers are not adhering to fabric checking protocols, timely adjustments can be made to rectify these issues. Ultimately, diligent monitoring fosters a culture of accountability among workers and reinforces the importance of maintaining high-quality standards throughout the manufacturing process.

Common Defects and Their Solutions

Despite best efforts in monitoring production lines, common defects often arise during garment manufacturing that require immediate attention. These may include issues such as uneven stitching, misaligned patterns on fabrics, or incorrect sizing—problems that could easily compromise the integrity of company clothing if left unchecked. Understanding these defects allows quality inspectors to implement targeted solutions swiftly.

For instance, if uneven stitching is detected during an in-process inspection, it could be resolved by adjusting machine tension settings or retraining operators on proper sewing techniques. Similarly, misalignment of patterns might necessitate recalibration of cutting machines or additional training for staff involved in fabric checking processes. Identifying these common pitfalls enables manufacturers to take corrective measures before garments move further down the production line.

Importance of Timely Interventions

Timely interventions are vital in maintaining high standards during in-process quality inspections; they prevent small problems from escalating into significant issues later on. When defects are identified early through rigorous monitoring practices and effective communication within teams about apparel inspection findings, corrective actions can be applied promptly without causing major disruptions to production schedules.

Moreover, addressing issues as they arise helps reinforce trust between manufacturers and suppliers while ensuring compliance with industry standards for quality clothing. Companies utilizing thorough inspection services not only enhance their reputation but also build lasting relationships with customers who appreciate consistent product excellence over time. Ultimately, fostering an environment where timely interventions are prioritized leads to improved overall efficiency and reduced costs associated with rework or returns.

Final Product Inspection

When it comes to the final product inspection, ensuring compliance with quality standards is paramount. This stage acts as the last line of defense against defects that could tarnish a company’s reputation or lead to financial loss. Through meticulous apparel inspection, businesses can confirm that their products meet both internal and external quality benchmarks, ultimately safeguarding customer satisfaction.

Ensuring Compliance with Quality Standards

Quality control is not just a buzzword; it's an essential part of the apparel manufacturing process. During final product inspections, quality inspectors rigorously check for adherence to established quality clothing standards, including fabric checking and overall garment construction. This attention to detail ensures that every piece of company clothing is not only aesthetically pleasing but also durable and functional.

Effective Quality Control Measures

Implementing effective quality control measures during final inspections can significantly reduce the likelihood of defects reaching consumers. Inspectors often utilize checklists tailored to specific apparel labels, ensuring that every aspect from stitching to color consistency is scrutinized. By fostering a culture of accountability and precision in these measures, companies can enhance their reputation for producing high-quality clothing.

Utilizing Third-Party Inspection Services

In many cases, companies opt for third-party inspection services to add an extra layer of assurance during final product inspections. These independent auditors bring expertise and objectivity that internal teams may lack, providing comprehensive reports on quality inspection outcomes. By leveraging the knowledge and resources of specialized firms in apparel inspection, businesses can ensure their products not only meet but exceed industry standards.

Post-Production and Shipping Checks

Once the apparel has been manufactured and is ready for shipping, conducting thorough post-production checks becomes critical. This phase ensures that the quality control measures implemented throughout the production process are upheld right until the garments leave for their final destination. Effective packaging and labeling play a significant role in maintaining quality clothing standards during transit.

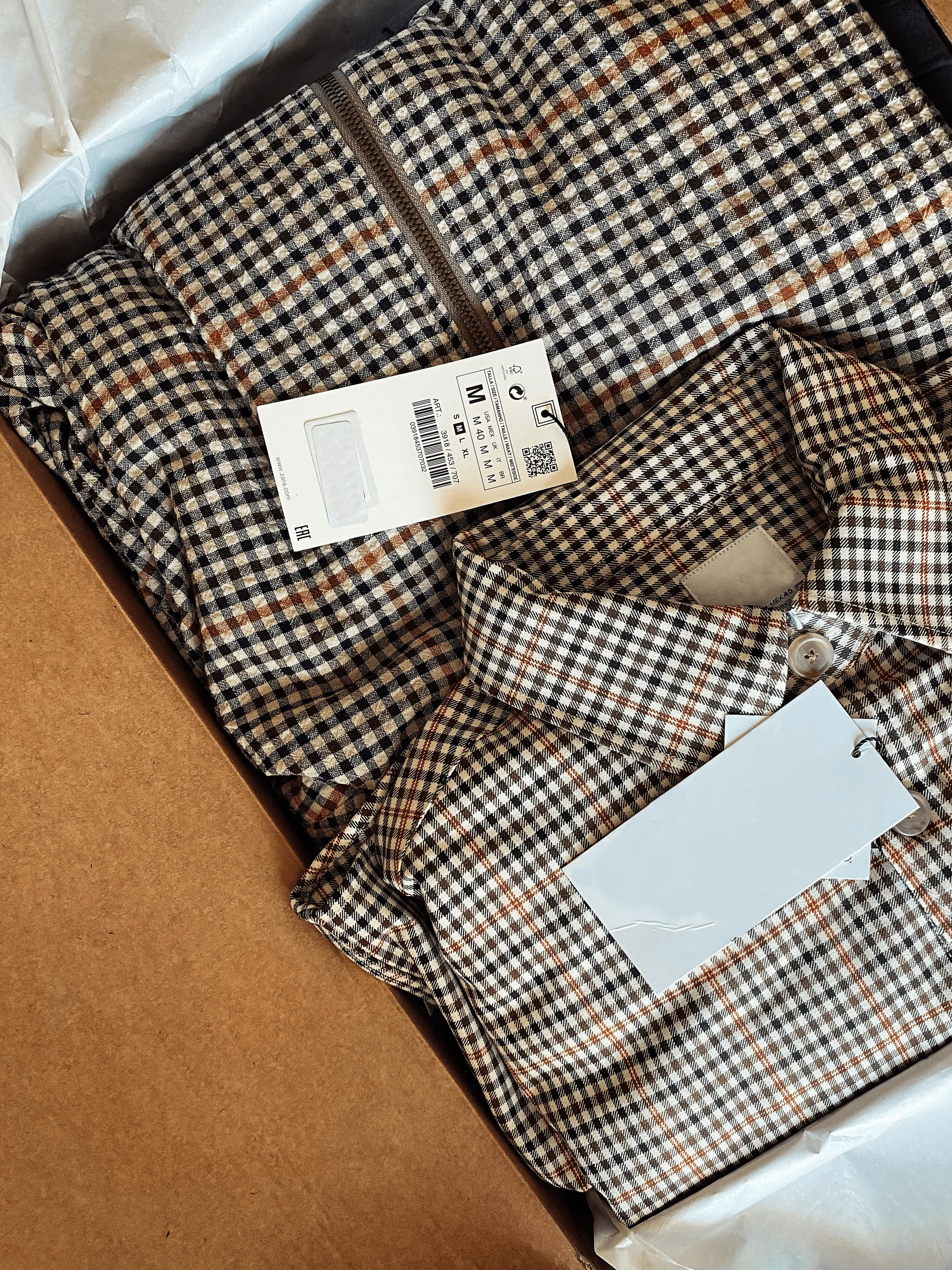

Importance of Packaging and Labeling

Packaging is not just about aesthetics; it serves to protect quality clothing from damage during shipping. Proper labeling also ensures that every piece of apparel is easily identifiable, which simplifies inventory management upon arrival. When apparel labels are accurate and clear, they help avoid confusion at retail outlets, enhancing customer satisfaction.

In addition to protecting garments, effective packaging can also reflect a company's commitment to quality control. Well-packaged items suggest that every detail matters, from fabric checking to final inspections before shipment. Ultimately, good packaging practices contribute significantly to a positive brand image in the competitive apparel market.

Final Quality Clothing Assessment

The final quality inspection is crucial before sending products out into the world; it’s like giving each garment a last check-up before its big debut! Inspectors look for any defects or inconsistencies that may have slipped through earlier stages of quality inspection. This assessment guarantees that only top-notch apparel reaches consumers, reinforcing trust in the brand.

During this stage, inspectors evaluate various aspects such as stitching integrity, color consistency, and overall finish of each piece of clothing. By prioritizing thorough assessments at this point in the process, companies can minimize returns due to defects or dissatisfaction with their products. After all, nothing tarnishes a brand’s reputation faster than subpar items being delivered to customers!

Role of Companies like China Inspection Pro

Companies like China Inspection Pro specialize in providing comprehensive inspection services tailored specifically for the apparel industry. Their expertise in quality control helps ensure that manufacturers adhere to high standards throughout production and shipping processes alike. With their assistance in fabric checking and final assessments, businesses can confidently present their products to global markets.

Moreover, these inspection services often include detailed reports on any identified issues along with recommendations for improvements—helping brands stay ahead of potential pitfalls before they escalate into larger problems down the line! By partnering with experienced firms like China Inspection Pro, companies can maintain consistent product quality while navigating international trade complexities seamlessly.

Conclusion

In the fast-paced world of fashion, comprehensive apparel inspection services are not just a luxury; they are a necessity. With the increasing demand for quality clothing, brands must prioritize quality control to ensure their products meet consumer expectations. By investing in thorough quality inspection processes, companies can mitigate risks and enhance their reputation in the competitive apparel market.

Benefits of Comprehensive Inspection Services

Comprehensive inspection services provide numerous benefits that extend beyond mere compliance with standards. They help identify potential issues early in the manufacturing process, allowing for timely interventions that save time and money. Additionally, rigorous fabric checking ensures that only high-quality materials are used, which ultimately leads to better end products and satisfied customers.

Moreover, these inspection services play a crucial role in evaluating apparel labels to ensure they meet regulatory requirements and consumer preferences. This attention to detail not only enhances product quality but also builds brand loyalty as consumers increasingly seek transparency from their favorite companies. Ultimately, a robust quality control system through comprehensive inspections can be the difference between success and failure in today’s global apparel trade.

Maintaining Trust in Global Apparel Trade

Trust is paramount in the global apparel trade, where brands rely on suppliers from various regions to deliver consistent quality clothing. Effective quality control measures foster this trust by ensuring that each stage of production adheres to established standards through meticulous quality inspections. When brands can confidently assure customers of their product integrity, it strengthens relationships with both suppliers and consumers alike.

Furthermore, maintaining trust necessitates transparency throughout the supply chain—something that comprehensive apparel inspection services can facilitate effectively. By employing third-party inspectors who specialize in assessing production processes and final outputs, companies can reinforce their commitment to high-quality standards while minimizing risks associated with overseas manufacturing partnerships. The result is a more resilient supply chain built on mutual respect and reliability.

Future Trends in Quality Control and Inspection

Looking ahead, several trends will shape the future of quality control and apparel inspection services within the industry. One significant trend is the integration of technology into inspection processes—think AI-driven analytics that provide real-time data on fabric checking or automated systems for monitoring production lines for defects before they escalate into larger issues. Embracing such innovations will enhance efficiency while ensuring higher levels of accuracy during inspections.

Additionally, as sustainability becomes increasingly important to consumers worldwide, companies must adapt their quality control practices accordingly by focusing on eco-friendly materials and ethical production methods during inspections. This shift will not only cater to changing consumer preferences but also position brands as leaders committed to responsible practices within the global market for company clothing. As we move forward, staying ahead of these trends will be essential for maintaining competitiveness while upholding high-quality standards across all facets of apparel manufacturing.