Introduction

In the ever-evolving landscape of global trade, understanding the nuances between OEM and ODM suppliers is crucial for businesses aiming to thrive. The choice between these two types of manufacturers can significantly impact product quality, development timelines, and overall costs. Grasping the difference between OEM vs ODM suppliers not only informs better decision-making but also fosters strategic partnerships that drive success.

Understanding OEM and ODM Concepts

At their core, Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs) serve distinct roles in the production process. An OEM typically focuses on manufacturing products based on another company's specifications, while an ODM takes it a step further by designing and producing products that can be sold under various brand names. This fundamental difference sets the stage for understanding what’s an OEM? and what about an ODM?, highlighting their unique contributions to product development.

The Importance of Selecting the Right Supplier

Choosing the right supplier is more than just a matter of cost; it's about aligning with a partner who understands your vision and can deliver quality consistently. Selecting between an OEM vs ODM supplier requires careful consideration of factors like design capabilities, production flexibility, and supply chain reliability. Moreover, recognizing potential risks to beware of when choosing a factory—such as communication barriers or quality control challenges—can save businesses from costly missteps down the line.

Why OEMs and ODMs Matter in Global Trade

OEMs and ODMs play pivotal roles in shaping global trade dynamics by enabling companies to leverage specialized manufacturing capabilities across borders. Their ability to provide tailored solutions allows brands to innovate rapidly while maintaining competitive pricing structures in diverse markets. Ultimately, understanding how these entities operate not only enhances product quality but also fortifies business strategies in today's interconnected economy.

What’s an OEM?

An Original Equipment Manufacturer (OEM) produces parts and equipment that may be marketed by another manufacturer. This relationship is crucial in the global trade ecosystem, as it allows companies to leverage specialized manufacturing capabilities while focusing on their core competencies.

Definition and Role of OEMs

The definition of an OEM revolves around its role in the supply chain: they create products or components that are used in another company's end product. Typically, these manufacturers work under contracts that specify how products should be made, often adhering to strict guidelines provided by the client company. The relationship often leads to a seamless integration of parts into finished products, making OEMs indispensable players in industries like automotive, electronics, and consumer goods.

Examples of Leading OEMs

When discussing leading OEMs, names like Foxconn and Pegatron come to mind immediately; they are giants in the electronics sector known for assembling devices for brands like Apple and Microsoft. In automotive manufacturing, companies such as Magna International provide essential components for major car brands worldwide. These examples illustrate how diverse the landscape is when considering different sectors—each with its own set of challenges and opportunities related to quality inspection services in China.

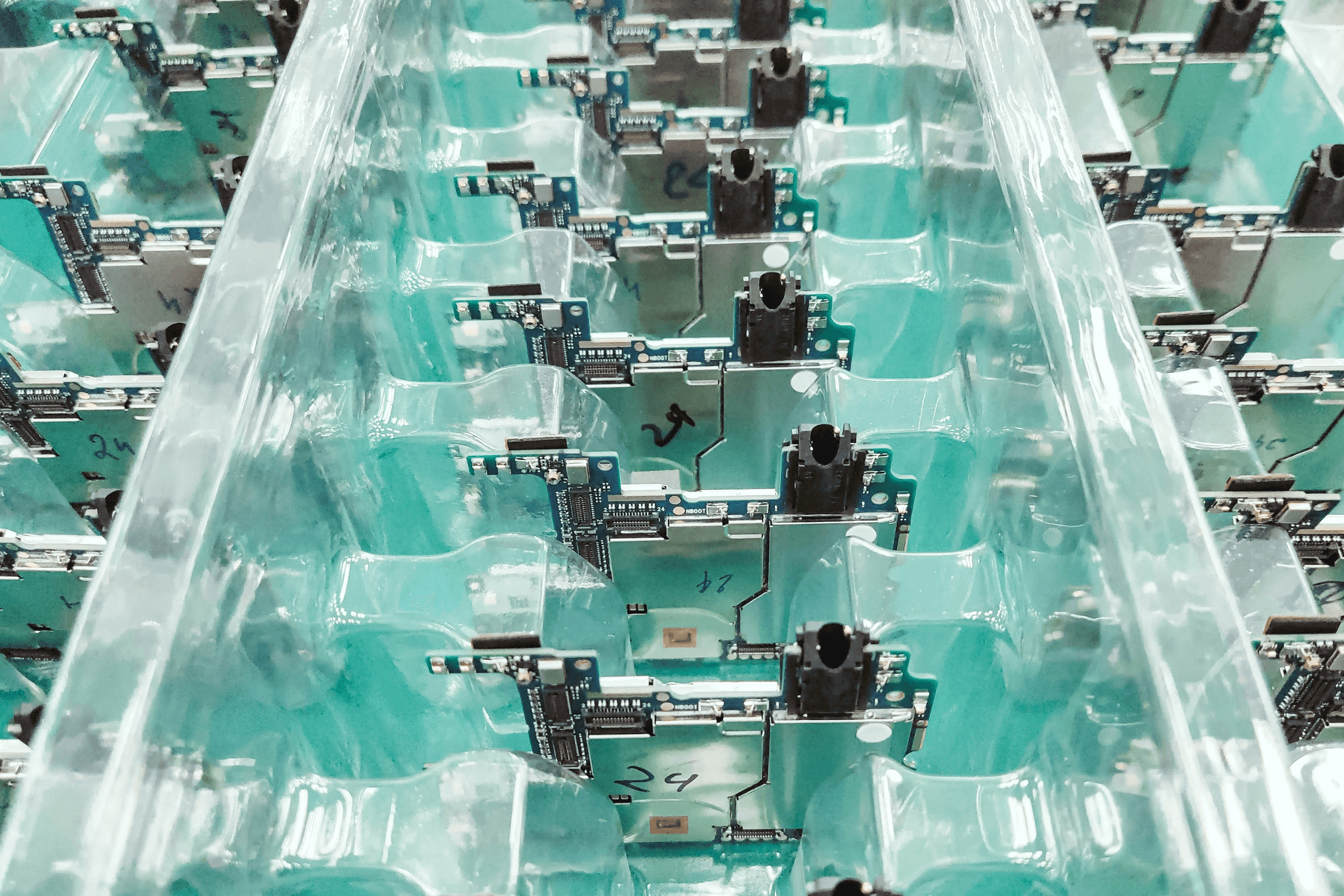

The Manufacturing Process Overview

The manufacturing process for an OEM typically begins with design specifications provided by the client company; this sets the stage for production standards and quality expectations. Once designs are finalized, materials are procured, followed by various stages of assembly where skilled labor and advanced machinery come into play. Finally, quality checks ensure that every component meets industry standards before being shipped off—this is where risks to beware of when choosing a factory become apparent if not managed properly.

What about an ODM?

Definition and Role of ODMs

The primary function of an ODM is to take a concept from a brand and transform it into a tangible product. Unlike OEMs, which focus primarily on manufacturing existing designs, ODMs take on more responsibility by also contributing to the design process. This means they can offer unique solutions tailored to market demands while managing production efficiently, making them invaluable partners in today’s fast-paced global trade environment.

Popular ODM Brands and Their Products

Some well-known brands leverage ODM services to bring their products to market without investing heavily in internal manufacturing capabilities. Companies like Foxconn and Quanta Computer are prime examples; they produce everything from consumer electronics to laptops for major tech giants. By collaborating with these popular ODMs, brands can ensure that their products are not only high-quality but also competitive in terms of price—an essential factor when considering the difference between OEM vs ODM suppliers.

Customization and Flexibility Offered by ODMs

One of the standout features of working with an ODM is the level of customization they provide. Unlike traditional OEM partnerships where designs may be static or limited, many ODMs offer flexible solutions that allow brands to innovate quickly based on consumer trends or feedback. This adaptability can be particularly beneficial when navigating risks to beware of when choosing a factory; having a partner who understands your needs can make all the difference in ensuring quality and timely delivery.

Key Differences Between OEM and ODM

When diving into the world of manufacturing, understanding the key differences between OEM and ODM suppliers can save you a lot of headaches. While both play crucial roles in the supply chain, their business models and responsibilities vary significantly. Knowing these distinctions will help you make informed decisions when selecting a partner for your production needs.

Comparison of Business Models

The business models of OEM vs ODM suppliers are fundamentally different, each catering to specific market needs. An OEM (Original Equipment Manufacturer) typically focuses on producing products based on designs provided by another company, allowing for minimal input in the design phase. In contrast, an ODM (Original Design Manufacturer) takes on a more creative role by designing and manufacturing products that brands can then market under their own names—essentially offering a complete package from concept to finished product.

This distinction leads to varying levels of involvement in product development; while OEMs are often seen as mere manufacturers, ODMs act as partners in innovation. Brands looking for unique offerings may lean toward an ODM due to their ability to customize designs flexibly. However, if you're asking yourself What’s an OEM? you might find that they excel in producing high volumes efficiently while adhering strictly to existing specifications.

Design and Development Responsibilities

An OEM typically relies heavily on the client’s specifications—meaning you provide them with the blueprints or prototypes needed for production. This arrangement works well if your brand has already established its design but may limit creativity and innovation.

On the other hand, what about an ODM? They take charge of both design and manufacturing processes, which allows for greater flexibility in creating new products tailored to market demands or consumer trends. This means that if you're looking for innovative solutions without investing heavily in R&D yourself, partnering with an ODM could be your best bet.

Cost Implications and Pricing Structures

Cost implications also differ significantly when comparing OEM vs ODM suppliers; understanding these nuances is vital for budgeting effectively. Generally speaking, working with an OEM can be more cost-effective if you have established designs since they specialize in mass production based on those existing plans—leading to economies of scale that drive down unit costs.

However, choosing an ODM often involves higher upfront costs due to their comprehensive services encompassing design through production; this investment can pay off if it results in unique products that stand out in competitive markets. Remember that while price is essential when considering risks to beware of when choosing a factory, quality should never be compromised—especially when it comes to inspection in China or utilizing quality inspection services China before finalizing any orders.

Risks to Beware of When Choosing a Factory

Navigating the world of manufacturing can be a minefield, especially when it comes to selecting the right factory for your needs. The risks involved are numerous, and understanding these challenges is crucial for anyone considering an OEM vs ODM supplier relationship. In this section, we'll dive into some significant risks you should be aware of when choosing a factory.

Quality Control Challenges

Quality control is often cited as one of the biggest hurdles in the manufacturing process, particularly when dealing with overseas suppliers. The difference between OEM vs ODM suppliers can lead to varying standards in quality assurance practices, which may leave you vulnerable to inconsistencies in your product output. Without robust quality inspection services in China, you might find yourself facing defective products that could tarnish your brand's reputation and bottom line.

Communication Issues with Overseas Manufacturers

Communication can be another sticky point when working with factories abroad, especially if there are language barriers or cultural differences at play. Misunderstandings about product specifications or timelines can arise quickly, leading to frustrations on both sides of the equation. This is particularly critical when considering what’s an OEM? versus what about an ODM?—as each type may have different expectations and operational procedures that need clear articulation.

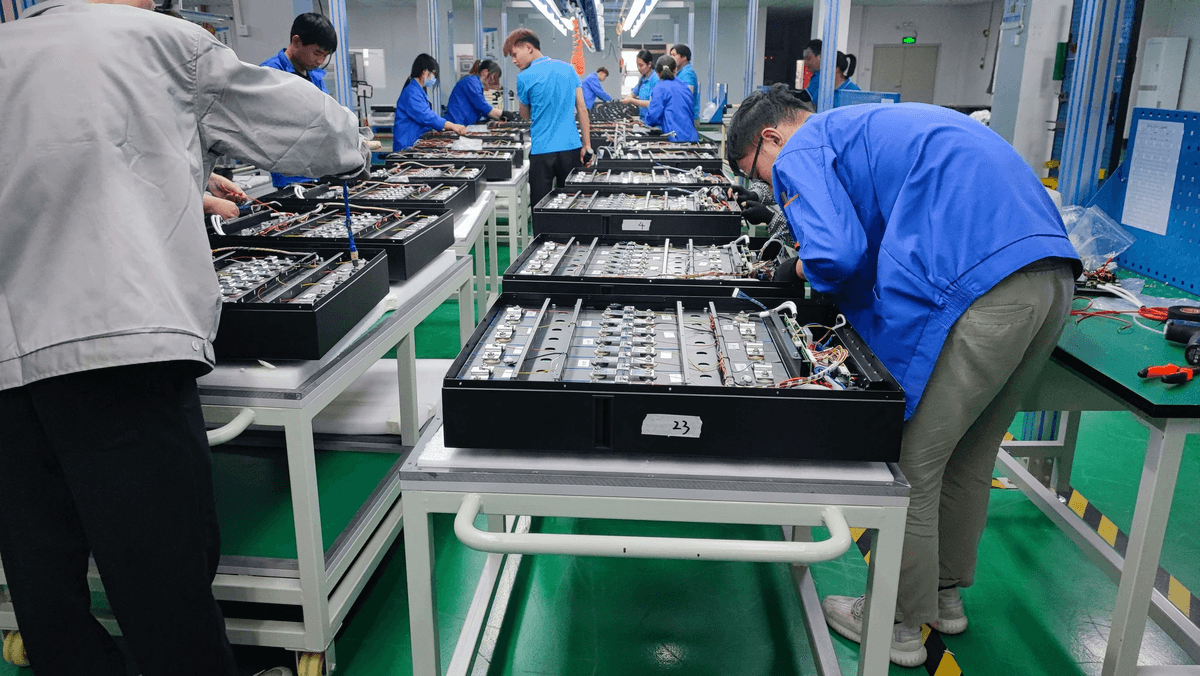

Importance of Using Quality Inspection Services in China

To mitigate these risks effectively, it's essential to employ quality inspection services in China as part of your manufacturing strategy. These services provide an extra layer of assurance by monitoring production processes and ensuring compliance with agreed-upon standards before products leave the factory floor. By integrating quality inspections into your supply chain management, you can build trust with your OEM vs ODM supplier and significantly reduce potential issues down the line.

The Role of China Inspection Pro

In the intricate world of global trade, particularly when dealing with OEM vs ODM suppliers, ensuring product quality is paramount. This is where China Inspection Pro steps in, providing essential services that help mitigate risks associated with manufacturing abroad. By utilizing their expertise in quality inspection services in China, businesses can navigate the complexities of overseas production with greater confidence.

How Inspection Services Mitigate Risks

When evaluating the difference between OEM vs ODM suppliers, understanding how inspection services can mitigate risks becomes crucial. Quality control challenges often arise during production, leading to potential losses if not addressed promptly. With professional inspection services in place, companies can identify defects early on and ensure that their products meet the required standards before they hit the market.

Moreover, these inspection services act as a bridge between businesses and manufacturers by facilitating clear communication and expectations. This helps to reduce misunderstandings that could arise due to language barriers or cultural differences when working with overseas factories. Ultimately, leveraging quality inspection services in China provides peace of mind and protects investments.

Real-Time Quality Assurance Processes

The beauty of partnering with a service like China Inspection Pro lies in their real-time quality assurance processes. In an era where speed often trumps all else, having immediate feedback on production quality is invaluable for any business relying on OEMs or ODMs. This proactive approach allows companies to make necessary adjustments on-the-fly rather than waiting until after production has concluded.

Through systematic checks and balances throughout the manufacturing process, clients can rest assured that their products align with specifications outlined during design discussions—whether they’re working with an OEM or an ODM supplier. This level of oversight significantly reduces risks to beware of when choosing a factory and enhances overall product reliability.

Building Trust in Legal Trade Agreements

Trust is a vital currency in international trade relationships; hence building it through reliable practices cannot be overstated—especially when navigating the OEM vs ODM supplier landscape. By employing comprehensive quality inspection services in China from reputable firms like China Inspection Pro, businesses can foster transparency within their supply chain operations.

These inspections provide documented evidence supporting compliance with agreed-upon standards—an essential component for legal trade agreements between parties from different countries. When both sides know there’s a reliable system monitoring product quality, it strengthens partnerships and encourages long-term collaboration beneficial for all involved.

Conclusion

In the ever-evolving landscape of global trade, making informed decisions is crucial for businesses looking to thrive. Choosing the right partner can significantly impact your product's success in the market, especially when deciding between an OEM vs ODM supplier. Understanding what’s an OEM? and what about an ODM? will help you align your business goals with the capabilities of your chosen manufacturer.

Choosing the Right Partner for Your Needs

Selecting between an OEM and ODM supplier is not a decision to be taken lightly; it requires careful consideration of your product requirements and business strategy. The difference between OEM vs ODM suppliers often boils down to whether you need a custom design or are looking to leverage existing products with minor modifications. By evaluating these factors, you can find a partner that aligns well with your vision and operational needs.

Long-Term Implications of OEM vs ODM Decisions

The long-term implications of choosing either an OEM or ODM can shape your brand's future trajectory. An OEM may provide you with more control over design and production but might require more investment in development resources upfront. On the other hand, opting for an ODM could expedite time-to-market but may limit some customization options; understanding these trade-offs is essential for sustainable growth.

Enhancing Product Quality Through Strategic Selection

Enhancing product quality starts with strategic selection—choosing a factory that emphasizes quality control measures is paramount in today’s competitive environment. Risks to beware of when choosing a factory include potential communication barriers and quality inconsistencies; this makes inspection in China essential for ensuring that products meet your standards before they reach consumers. Utilizing quality inspection services in China can provide peace of mind, allowing you to focus on scaling your business while maintaining high-quality outputs.