Introduction

Quality control in the garment industry is more than just a buzzword; it’s the backbone that supports the entire manufacturing process. With the ever-increasing demands for high-quality products, brands cannot afford to cut corners when it comes to quality inspection. A robust quality control system ensures that garments meet established quality standards, ultimately leading to customer satisfaction and brand loyalty.

Importance of Quality Control in Garment Industry

In an industry where fashion trends change at lightning speed, maintaining quality is crucial for survival. Quality control not only prevents defects but also enhances brand reputation and reduces costs associated with returns and rework. By prioritizing quality assurance, companies can ensure that their products stand out in a competitive marketplace.

Common Missteps in Quality Assurance

Despite its importance, many organizations stumble when implementing effective quality assurance practices. Common missteps include inadequate training of quality assurance specialists and neglecting to establish clear quality standards from the outset. These errors can lead to significant financial losses and damage a brand's credibility in an already saturated market.

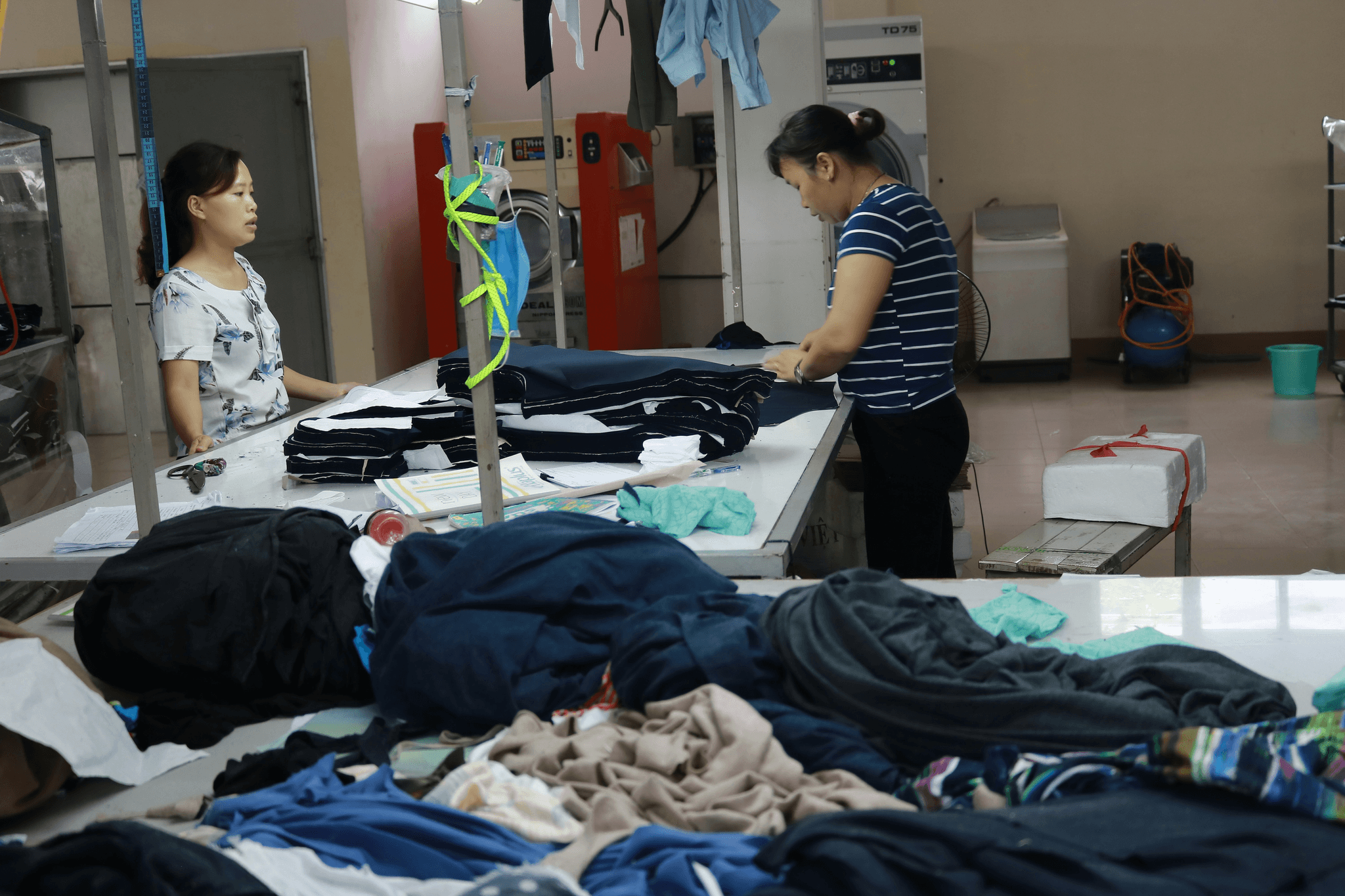

The Role of Quality Inspectors

Quality inspectors play a pivotal role in upholding the integrity of garments produced on the factory floor. Their expertise not only involves conducting thorough inspections but also collaborating with production teams to identify potential issues before they escalate into costly problems. As gatekeepers of quality control in manufacturing, these professionals are essential for ensuring compliance with both internal standards and external regulations.

Understanding Quality Standards

Quality standards serve as the backbone of the garment industry, ensuring that products meet customer expectations and regulatory requirements. In a sector where aesthetics and functionality are paramount, quality control in garment industry practices helps maintain brand integrity and consumer trust. By grasping these standards, manufacturers can avoid pitfalls that lead to costly errors and dissatisfied customers.

Defining Quality Control in Garment Industry

Quality control in the garment industry encompasses a series of processes designed to ensure that clothing meets specific standards before reaching consumers. This involves systematic inspections throughout production phases, from raw materials to finished products. A quality assurance specialist plays a critical role here, utilizing various techniques to identify defects and ensure compliance with established quality standards.

Essential Quality Standards for Clothing

Essential quality standards for clothing include durability, safety, fit, and overall appearance. Each piece must undergo rigorous quality inspection to assess stitching integrity, fabric strength, colorfastness, and sizing accuracy. Adhering to these standards not only enhances customer satisfaction but also fortifies a brand's reputation in an increasingly competitive market.

Regulatory Bodies and Their Impact

Regulatory bodies play an influential role in shaping quality control practices within the garment industry by establishing guidelines that manufacturers must follow. Organizations such as ASTM International or ISO set forth benchmarks for safety and performance that directly impact production methods. Compliance with these regulations is crucial; failure to do so can result in penalties or even product recalls—an absolute nightmare for any manufacturer focused on maintaining high-quality assurance inspector protocols.

The Pitfalls of Poor Quality Control

In the fast-paced world of fashion, where trends come and go in the blink of an eye, the importance of quality control in the garment industry cannot be overstated. Poor quality control can lead to a cascade of issues that not only affect a brand's reputation but also its bottom line. From dissatisfied customers to costly recalls, the consequences of inadequate quality inspection are far-reaching and can leave a lasting impact on businesses.

Consequences of Inadequate Quality Inspection

When quality control fails, the repercussions can be severe. First and foremost, consumers may receive defective products that do not meet their expectations or adhere to established quality standards. This not only leads to financial losses due to returns and refunds but also damages customer trust—an invaluable asset in today’s competitive market.

Moreover, inadequate quality inspection can result in legal ramifications if products fail safety regulations or standards set by regulatory bodies. Brands may find themselves facing lawsuits or fines that further erode their profits. Ultimately, neglecting effective quality auditing practices can transform a thriving business into one struggling for survival amidst public backlash and legal woes.

Common Errors Made by Quality Assurance Specialists

Even seasoned quality assurance specialists can stumble into common pitfalls that compromise product integrity. One prevalent error is relying too heavily on visual inspections without employing comprehensive testing methods; this approach often overlooks hidden defects that could lead to significant issues down the line. Additionally, failing to stay updated with evolving industry standards means that quality assurance inspectors might inadvertently approve subpar products.

Miscommunication within teams is another frequent issue; when expectations aren’t clearly defined among production staff and inspectors, it creates gaps in understanding what constitutes acceptable quality control in manufacturing processes. Furthermore, overlooking documentation during inspections can lead to discrepancies between what was promised and what is delivered—a surefire way to create chaos in supply chains and customer relationships alike.

Case Studies of Quality Failures in Fashion

History has shown us that even high-profile brands are not immune to the pitfalls associated with poor quality control in garment industry practices. Take for instance a major fashion label that faced backlash after releasing a clothing line with serious stitching flaws; this oversight resulted not only in massive recalls but also tarnished their brand image for years. Such incidents serve as cautionary tales about how critical effective quality inspection is for maintaining reputation and consumer loyalty.

Another notable case involved a popular athletic wear company whose leggings were found to be see-through during rigorous testing phases—an embarrassing blunder that led to widespread ridicule on social media platforms. The fallout from these failures highlights just how essential it is for companies to prioritize robust training programs for their quality assurance inspectors so they’re equipped with both knowledge and skills necessary for effective audits.

In conclusion, while no one sets out intending for poor quality control practices to damage their business, it happens more often than we’d like to admit—especially when corners are cut or communication falters among teams responsible for ensuring product excellence.

Implementing Effective Quality Auditing

When it comes to quality control in the garment industry, effective quality auditing is crucial for maintaining high standards and ensuring customer satisfaction. A systematic approach not only helps identify defects but also enhances overall production processes. By integrating robust auditing practices, manufacturers can significantly reduce errors and elevate their quality assurance efforts.

Steps for Successful Quality Auditing

Successful quality auditing involves a series of well-defined steps that help ensure compliance with established quality standards. First, it's essential to define the scope of the audit clearly, which includes identifying specific areas within the manufacturing process that require scrutiny. Next, a thorough inspection plan should be developed—this plan will guide quality assurance specialists through each phase of the audit while providing a framework to evaluate adherence to quality control protocols.

Once the inspection plan is in place, auditors should conduct on-site evaluations using checklists tailored to specific garments or processes. This systematic approach allows quality assurance inspectors to gather data effectively and pinpoint areas needing improvement. Finally, after completing the audit, it's vital to compile findings into a comprehensive report that outlines both strengths and weaknesses in current practices—this feedback loop is essential for continuous improvement in quality control.

Tools for Quality Assurance Inspectors

Quality assurance inspectors have access to various tools designed specifically for enhancing accuracy during inspections. Among these are digital measuring devices, which ensure precise measurements of fabric dimensions and garment specifications—no more guesswork! Additionally, software applications tailored for tracking defects can streamline communication between teams and facilitate real-time reporting on quality issues.

Another invaluable tool is statistical process control (SPC) software; this technology enables inspectors to analyze trends over time and identify potential problem areas before they escalate into larger issues. Coupling these tools with regular training sessions ensures that all team members are proficient in utilizing them effectively within their roles as quality assurance specialists. Ultimately, leveraging advanced technology aids in elevating overall performance in quality control within manufacturing settings.

Best Practices in Quality Control for Manufacturing

Implementing best practices in quality control is integral to achieving excellence within the garment industry. One key practice involves establishing clear communication channels among all stakeholders—from designers and production teams to sales representatives—to ensure everyone understands their role in maintaining high-quality standards throughout the supply chain. Regular meetings can foster collaboration and create a culture of accountability around quality inspection processes.

Additionally, conducting frequent training workshops helps keep staff updated on current trends and techniques related to effective auditing methods—a well-informed team is a successful team! Another best practice is adopting an iterative approach toward improvements; by continuously reviewing processes based on feedback from audits or inspections, companies can adapt quickly while maintaining high levels of product integrity.

In conclusion, implementing effective quality auditing requires thoughtful planning combined with practical tools and best practices tailored specifically for the garment industry’s unique challenges. By embracing these strategies wholeheartedly, organizations will not only enhance their reputation but also contribute positively towards advancing overall standards within this dynamic sector.

Collaborating with Third-Party Inspectors

In the dynamic world of the garment industry, collaborating with third-party inspectors has become a strategic move for ensuring quality control. Quality assurance specialists often find that these partnerships can enhance their ability to meet stringent quality standards while also streamlining processes. By leveraging external expertise, manufacturers can focus on production without compromising on quality inspection.

Benefits of Hiring China Inspection Pro

Hiring a reputable firm like China Inspection Pro brings numerous benefits to your quality control in the garment industry. Firstly, they offer specialized knowledge and experience that can significantly improve your quality auditing processes. Secondly, their presence in manufacturing hubs allows for timely inspections, ensuring that any issues are caught early before they escalate into costly problems.

Moreover, using a third-party inspector helps maintain objectivity in the evaluation process; after all, an unbiased set of eyes can catch flaws that internal teams might overlook due to familiarity with the product. This not only enhances accountability but also fosters greater trust among stakeholders regarding adherence to established quality standards.

How to Choose a Quality Control Partner

Selecting the right quality control partner is crucial for effective collaboration in the garment industry. Start by evaluating potential partners based on their track record and expertise in conducting thorough quality inspections specific to your product type and market needs. Look for certifications and testimonials from other clients as indicators of reliability and professionalism.

It's also essential to assess their communication skills and responsiveness; a good partnership thrives on clear dialogue about expectations and results related to quality assurance practices. Lastly, ensure that they align with your company's values regarding sustainability and ethical practices—after all, integrity should be at the heart of any successful collaboration.

Integrating Third-Party Inspections into Processes

Integrating third-party inspections into existing manufacturing processes requires careful planning but can yield significant rewards in terms of enhanced quality control outcomes. Begin by establishing clear protocols outlining when and how these inspections will occur throughout production cycles—this ensures consistency in applying quality standards across all products.

Next, foster an environment where internal teams collaborate closely with external inspectors; this synergy promotes knowledge sharing and continuous improvement within your organization's approach to quality assurance. Finally, regularly review inspection results together to identify trends or recurring issues—this data-driven approach will help refine both your internal practices and those of your chosen inspection partner.

Training and Development for Quality Teams

In the fast-paced world of the garment industry, the significance of training and development for quality teams cannot be overstated. Quality control in manufacturing hinges on having well-trained quality assurance specialists who can identify potential issues before they escalate into costly problems. This proactive approach not only enhances the overall quality standards but also fosters a culture of excellence within the organization.

Importance of Skills Training for Quality Inspectors

Quality inspectors play a pivotal role in maintaining high-quality standards throughout the production process. Skills training is essential to equip these professionals with the latest techniques and tools necessary for effective quality inspection. By investing in ongoing education, companies can ensure their quality assurance inspectors are adept at spotting defects, understanding complex regulations, and implementing best practices in quality auditing.

Furthermore, skilled inspectors are more likely to contribute positively to team dynamics and overall productivity. When quality assurance specialists are confident in their abilities, they can make informed decisions that lead to improved outcomes in garment production. Ultimately, continuous skills training not only enhances individual performance but also strengthens the entire quality control framework within an organization.

Continuous Improvement in Quality Assurance

The principle of continuous improvement is fundamental to effective quality assurance practices in the garment industry. Regularly evaluating existing processes allows teams to identify areas that require enhancement or adjustment, ensuring that standards remain relevant and effective. Embracing a mindset focused on ongoing improvement leads to more efficient workflows and higher levels of product consistency.

Moreover, fostering an environment where feedback is encouraged promotes innovation among quality teams. When employees feel empowered to share insights or suggest changes related to quality control processes, organizations can adapt swiftly to shifting market demands or emerging trends. This agile approach not only boosts morale but significantly elevates the overall standard of quality control across all manufacturing stages.

Developing a Quality-Centric Culture

Creating a culture centered around quality is vital for long-term success in any garment manufacturing operation. A commitment from leadership down through every level ensures that everyone understands their role in achieving high-quality standards during production cycles. Such dedication cultivates an atmosphere where employees take pride in their work as part of a cohesive effort towards excellence.

Integrating regular training sessions focused on best practices and innovations related to quality inspection helps reinforce this culture consistently over time. Additionally, recognizing and rewarding individuals or teams who exemplify outstanding adherence to established guidelines encourages others to follow suit. Ultimately, by embedding a strong focus on quality control into every aspect of operations, organizations position themselves as leaders within the competitive landscape of the garment industry.

Conclusion

In the fast-paced world of fashion, ensuring high-quality products is no longer just a nice-to-have; it’s a necessity. Effective quality control in the garment industry not only safeguards brand reputation but also enhances customer satisfaction and loyalty. By implementing robust quality standards and rigorous quality inspections, businesses can minimize defects and streamline their production processes.

Strategies for Enhancing Quality Control

Enhancing quality control involves a multifaceted approach that begins with setting clear quality standards tailored to specific product lines. Training programs for quality assurance specialists should focus on the latest inspection techniques and technologies, ensuring they remain adept at identifying potential issues before they escalate. Regular audits can also help maintain compliance with these standards, allowing manufacturers to adapt quickly to any changes in regulations or market demands.

Avoiding Common Quality Control Mistakes

Common pitfalls in quality control often stem from inadequate training or lack of communication among team members. Quality assurance inspectors must be well-versed in both the technical aspects of garment production and the expectations set forth by regulatory bodies. By fostering an environment where feedback is encouraged and mistakes are viewed as learning opportunities, companies can significantly reduce errors that compromise their quality assurance efforts.

The Future of Quality Control in Garment Industry

The future of quality control in the garment industry looks promising, especially with advancements in technology such as AI-driven inspections and data analytics tools that enhance decision-making processes. As consumer expectations continue to rise, brands will increasingly rely on sophisticated quality auditing practices that ensure consistency across all products while minimizing waste. Ultimately, the integration of innovative solutions into traditional practices will redefine how we perceive quality control, making it more proactive rather than reactive.