Introduction

In today's competitive landscape, effective quality assurance is paramount for businesses aiming to deliver top-notch products consistently. A key component of this process is understanding AQL sampling fundamentals, which serve as a cornerstone for ensuring product quality through systematic inspection methods. By mastering the intricacies of AQL sampling tables, companies can streamline their quality control process and enhance overall product inspection accuracy.

Understanding AQL Sampling Fundamentals

AQL, or Acceptable Quality Level, is a statistical measure used in quality control to determine the maximum number of defective items considered acceptable in a sample batch. This method allows businesses to make informed decisions regarding product acceptance or rejection based on predefined quality standards. Understanding AQL sampling fundamentals not only aids in maintaining high-quality products but also helps organizations mitigate risks associated with poor-quality goods.

Importance of Quality Control in Industries

Quality control plays a crucial role across various industries by ensuring that products meet specific standards and customer expectations. Implementing robust QC processes minimizes waste and reduces the likelihood of costly recalls that can tarnish a brand's reputation. By focusing on effective quality inspection practices, companies can foster trust among consumers and build long-lasting relationships that drive business success.

Navigating AQL Sampling Tables

Navigating AQL sampling tables may seem daunting at first glance, but they are invaluable tools for streamlining the inspection process. These tables provide clear guidelines on how many samples to inspect based on batch size and desired defect rates, making it easier for quality control companies to perform accurate assessments. With proper understanding and application of these tables, organizations can enhance their QC practices while ensuring compliance with industry standards.

What is AQL Sampling?

AQL, or Acceptable Quality Level, is a statistical quality control method used to determine the maximum number of defective items considered acceptable in a sample batch. This technique plays a crucial role in ensuring that products meet predefined quality standards before they reach consumers. By utilizing AQL sampling tables, businesses can streamline their quality control process and enhance the reliability of their product inspections.

Definition and Purpose of AQL

The definition of AQL revolves around establishing thresholds for defects within a production lot. Essentially, it sets the bar for what is deemed acceptable during product inspection, allowing companies to maintain consistent quality assurance without rejecting entire batches unnecessarily. The purpose of AQL is to provide a systematic approach to quality control that balances cost-effectiveness with customer satisfaction.

The Role of AQL in Quality Assurance

AQL serves as an essential component in the broader framework of quality assurance by helping organizations identify and mitigate risks associated with defective products. It provides a structured methodology for inspecting samples rather than examining every single item, thus saving time and resources while still ensuring high standards are met. By implementing effective AQL sampling techniques, businesses can foster trust with their clients and stakeholders through consistent delivery of quality products.

How AQL Sampling Benefits Product Inspection

A key benefit of using AQL sampling in product inspection lies in its ability to enhance efficiency without compromising on quality standards. When companies adopt this method, they can quickly assess large quantities of goods while focusing on critical defects that could impact customer satisfaction or safety. Furthermore, integrating AQL into the quality control process allows organizations to make informed decisions based on statistical data derived from their inspections—ultimately leading to improved product reliability and brand reputation.

Key Concepts of AQL Levels

Understanding the key concepts of AQL levels is crucial for effective quality assurance and product inspection. These levels serve as benchmarks that guide quality control companies in determining acceptable defect rates during inspections. By grasping the nuances of AQL levels, businesses can enhance their quality control process and ensure product reliability.

Explanation of AQL Levels

AQL, or Acceptable Quality Level, refers to the maximum number of defective items considered acceptable during a random sampling inspection. It allows companies to balance quality assurance with production efficiency by setting specific thresholds for defects. In essence, AQL levels help organizations minimize risks while maintaining high standards in their qc quality control efforts.

The concept revolves around statistical sampling techniques where a predetermined level of defects is accepted based on the total quantity produced. This systematic approach not only streamlines the inspection process but also provides a clear framework for assessing product quality. By utilizing aql sampling tables, businesses can make informed decisions about whether to accept or reject batches based on their defect rates.

Common AQL Levels Used in Industries

In various industries, common AQL levels typically range from 0.65% to 2.5%, depending on the nature of the products and customer requirements. For instance, critical defects may warrant an AQL level as low as 0.1%, while minor defects might be acceptable at higher thresholds like 2.5%. Understanding these common levels helps organizations tailor their quality inspection processes to meet industry standards and customer expectations effectively.

Different sectors may adopt distinct practices; electronics manufacturers often use stricter AQLs due to safety concerns, while textiles might allow slightly more leeway in defect rates. It's essential for businesses to identify which AQL level aligns best with their product type and market demands to ensure optimal outcomes in their inspections. By leveraging aql sampling tables effectively, companies can navigate these nuances with confidence.

Importance of Selecting the Right AQL Level

Selecting the right AQL level is paramount for ensuring that products meet both regulatory standards and consumer satisfaction expectations during inspections. Choosing an inappropriate level can lead to excessive waste or missed defects that could harm brand reputation and customer trust in qc quality control efforts. Therefore, understanding your specific market needs and aligning them with suitable aql sampling parameters is crucial for success.

An overly lenient AQL might result in unacceptable defect rates slipping through into consumers' hands, while an overly stringent one could lead to unnecessary rejections and increased costs for manufacturers during the quality control process. Striking this balance ensures not only compliance but also enhances overall product reliability through effective quality inspection practices tailored specifically for each business context.

When partnering with experienced firms like China Inspection Pro, organizations can benefit from expert guidance on selecting appropriate AQL levels tailored to their unique requirements—ensuring robust results throughout manufacturing and shipping processes while building trust within global trade networks.

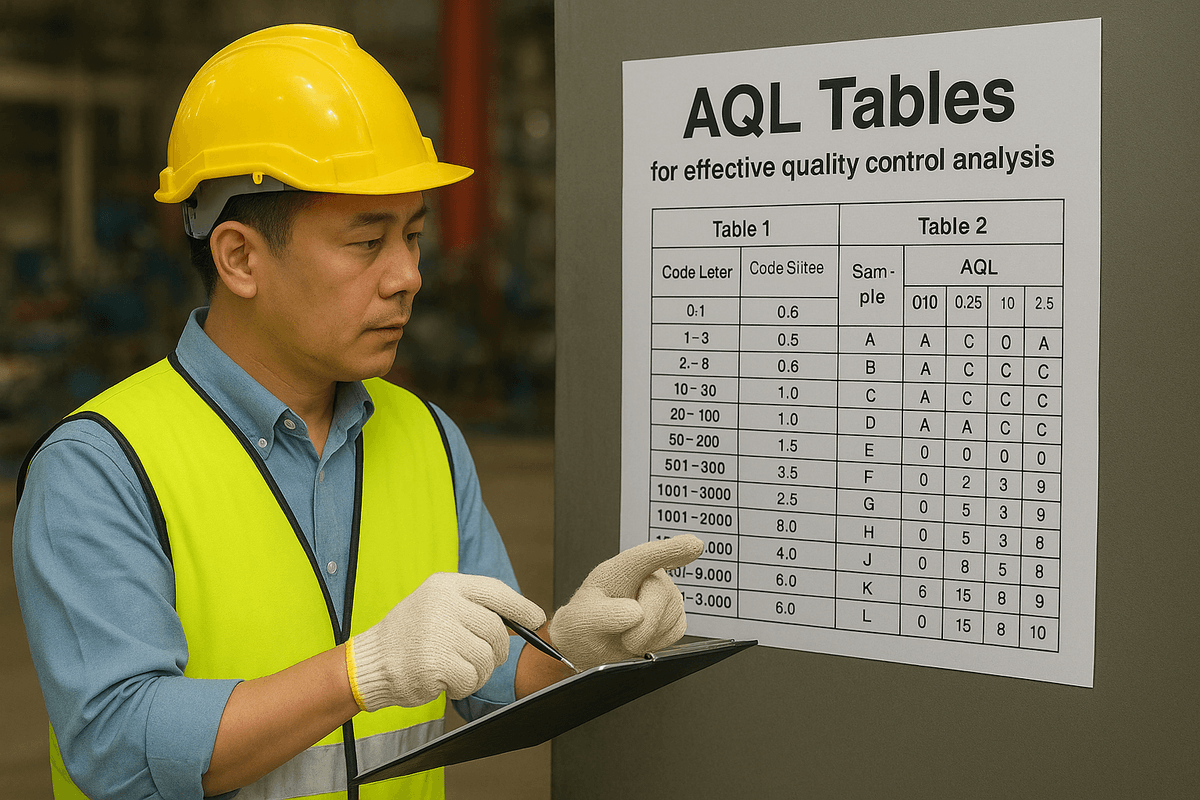

AQL Sampling Tables Demystified

AQL sampling tables are essential tools in the realm of quality assurance, providing a structured approach to determining acceptable quality levels for products. These tables help streamline the quality control process by offering clear guidelines on how many items to inspect and what constitutes an acceptable defect rate. By utilizing AQL sampling tables, businesses can enhance their product inspection efforts, ensuring that they meet industry standards while minimizing risks associated with poor quality.

Overview of AQL Sampling Tables

AQL sampling tables consist of various columns and rows that detail sample sizes and acceptance criteria based on specific AQL levels. The primary function of these tables is to inform quality control companies about how many units should be inspected from a batch and the maximum allowable defects for those units. Understanding these tables is crucial for effective QC quality control, as they provide a systematic way to evaluate product inspection results against predefined standards.

How to Read AQL Tables Effectively

Reading AQL sampling tables effectively requires familiarity with their structure and terminology, which can initially seem daunting. Start by identifying the lot size—this determines which row you will reference in the table—and then locate your chosen AQL level across the top row. The intersection point will give you both the sample size needed for inspection and the maximum number of defects allowed, making it easier to implement your findings into your overall quality control process.

Real-World Applications of AQL Tables

In practice, AQL sampling tables are widely used across various industries, including manufacturing, electronics, textiles, and food production. For instance, a company might use these tables during its final product inspection phase to ensure that their goods meet customer expectations before shipping them out globally. By partnering with experienced firms like China Inspection Pro, businesses can leverage these tools effectively within their QC processes—ensuring consistent quality while building trust in global trade.

Implementing AQL in Quality Control Process

Implementing AQL (Acceptable Quality Level) in the quality control process is essential for maintaining high standards in product inspection. This section will guide you through the steps involved in conducting effective AQL sampling, how to integrate AQL into your quality control companies, and provide case studies that illustrate successful inspections. By mastering these aspects, businesses can enhance their quality assurance efforts and build trust with partners and customers alike.

Steps for Conducting AQL Sampling

Conducting AQL sampling begins with defining the inspection lot size, which is crucial for determining the sample size from the aql sampling tables. Next, select an appropriate AQL level based on your product's criticality and customer expectations; this choice directly impacts your quality control process. Once you have your sample size and level defined, proceed with inspecting the selected items to identify any defects or non-conformities.

After gathering inspection data, compare the results against your established acceptance criteria from the aql sampling tables to make informed decisions about product acceptance or rejection. If defects are within acceptable limits, you can confidently move forward with shipping; if not, corrective actions must be taken promptly to address any issues identified during quality inspection. This systematic approach not only streamlines your QC quality control efforts but also enhances overall product reliability.

Integrating AQL in Quality Control Companies

Integrating AQL into quality control companies requires a strategic approach that aligns with both company policies and industry standards for effective quality assurance. Training employees on interpreting aql sampling tables is vital; they should understand how to select appropriate sample sizes and levels based on specific products or client requirements. Furthermore, establishing clear protocols for conducting inspections will ensure consistency across all departments involved in the QC process.

Collaboration between different teams—such as production, logistics, and customer service—is key when implementing an efficient quality control process that incorporates AQL principles. Regular audits of both processes and results can help identify areas for improvement while reinforcing accountability within teams responsible for maintaining product standards during inspections. By fostering a culture of continuous improvement centered around effective use of aql sampling methods, companies can enhance their competitive edge.

Case Studies of AQL in Successful Inspections

Examining case studies where companies effectively implemented AQL provides valuable insights into best practices within quality inspection processes. For instance, one electronics manufacturer adopted rigorous aql sampling procedures after facing significant returns due to defective products—this led them to revise their acceptance criteria using updated aql sampling tables tailored specifically for their unique production needs. As a result of these changes, they significantly reduced defect rates while improving customer satisfaction scores.

Another example involves a textile company that faced challenges meeting international compliance standards before integrating AQL into its QC practices effectively. By training staff on proper usage of aql sampling techniques and emphasizing thorough inspections at each stage of production, they were able to elevate their overall product quality dramatically while minimizing waste associated with rejected batches during final inspections—a win-win situation! These case studies showcase how implementing structured approaches through effective use of AQL can lead to substantial improvements across various industries.

Choosing the Right Quality Control Partner

When it comes to ensuring your products meet quality standards, selecting the right quality control partner is crucial. A reliable partner can streamline your quality assurance process and enhance product inspection accuracy, ultimately saving you time and money. With numerous quality control companies available, understanding their strengths can make a world of difference for your business.

Why Work with China Inspection Pro

China Inspection Pro stands out as a premier choice for businesses seeking top-notch quality inspection services. Their commitment to maintaining consistent product quality throughout manufacturing and shipping processes ensures that you receive real-time, accurate inspections tailored to your specific needs. By leveraging their expertise in AQL sampling tables, you can navigate the complexities of quality control with confidence.

Working with China Inspection Pro means you gain access to seasoned professionals who understand the nuances of QC quality control in various industries. Their meticulous approach helps identify potential issues before they escalate into costly problems, allowing you to focus on growing your business instead of worrying about product defects. In an increasingly competitive market, partnering with a reputable inspection company like China Inspection Pro gives you an edge by enhancing trust with customers through proven reliability.

Benefits of Third-Party Quality Inspections

Third-party quality inspections provide an unbiased perspective on your products, ensuring that they meet industry standards without any internal bias clouding judgment. This objectivity is essential for maintaining high-quality assurance levels and helps build credibility within your supply chain. By utilizing third-party services like those offered by China Inspection Pro, businesses can rest assured that their products undergo thorough evaluation using established AQL sampling methodologies.

Moreover, third-party inspections often lead to significant cost savings by identifying defects early in the production process before they become widespread issues during shipping or distribution. This proactive approach not only minimizes waste but also enhances overall efficiency within the quality control process. Ultimately, investing in third-party inspections allows businesses to uphold a reputation for excellence while reducing risks associated with subpar products.

Questions to Ask Quality Control Companies

When evaluating potential quality control companies for your needs, asking the right questions is key to finding a suitable partner for effective product inspection and AQL sampling processes. Inquire about their experience with specific industries and whether they utilize standardized AQL sampling tables tailored to those sectors—this will give you insight into their proficiency in handling unique challenges related to your products.

Additionally, ask about their approach toward integrating QC quality control measures into existing workflows; this will help determine how seamlessly they can enhance your current practices without causing disruption or delays. Finally, don’t hesitate to request case studies or references from previous clients—successful partnerships speak volumes about a company's ability to deliver consistent results over time.

Conclusion

In the realm of quality assurance, mastering AQL sampling is not just a recommendation; it’s a necessity. Understanding how to effectively utilize AQL sampling tables can significantly enhance your quality control process, ensuring that every product inspection meets rigorous standards. When businesses prioritize these practices, they not only improve their operational efficiency but also foster lasting relationships with clients and stakeholders.

Mastering AQL for Better Quality Assurance

To truly master AQL for better quality assurance, companies need to grasp its fundamental principles and applications. By integrating AQL sampling into the quality control process, organizations can systematically identify defects and ensure compliance with industry standards. This proactive approach minimizes risks associated with poor-quality products and ultimately leads to greater customer satisfaction.

Enhancing Product Inspection Accuracy

Enhancing product inspection accuracy relies heavily on the effective use of AQL sampling tables. These tables provide clear guidelines for determining acceptable defect levels, allowing quality control companies to carry out thorough inspections without sacrificing efficiency. With precise data at their fingertips, inspectors can make informed decisions that uphold product integrity and reliability.

Building Trust Through Consistent Quality Control

Building trust through consistent quality control is essential in today’s competitive market landscape. Companies like China Inspection Pro exemplify this commitment by offering professional third-party inspections that ensure adherence to established quality standards throughout manufacturing and shipping processes. By partnering with reliable quality control companies, businesses can mitigate risks and cultivate enduring trust among their customers.