Introduction

In an increasingly interconnected world, the significance of factory audits cannot be overstated. A factory audit in China serves as a vital tool for businesses looking to ensure that their suppliers adhere to quality standards and operational efficiency. By conducting thorough audits, companies can gain insights into supplier capabilities, ultimately fostering stronger relationships and enhancing product quality.

The Importance of Factory Audits

Factory audits play a pivotal role in maintaining the integrity of supply chains, especially when sourcing from regions like China. They help identify potential risks and ensure compliance with industry regulations, which is crucial for safeguarding brand reputation. Moreover, regular audits contribute to effective quality control measures by pinpointing areas that require improvement or attention.

Understanding Supplier Capabilities

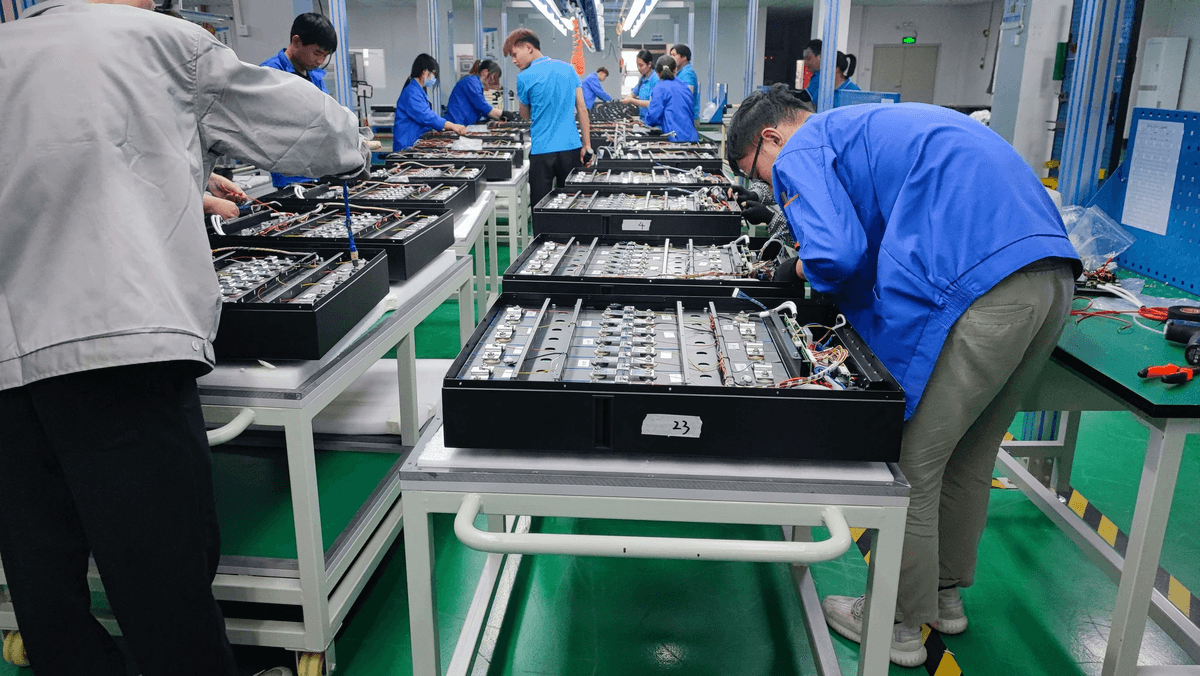

Understanding supplier capabilities is essential for any business aiming to streamline its operations and enhance product offerings. A comprehensive factory audit provides detailed insights into a supplier's production processes, workforce skills, and technological advancements. This knowledge not only aids in selecting the right partners but also ensures that quality management systems are robust enough to meet demand.

The Role of Quality Control

Quality control is the backbone of successful manufacturing processes; it ensures that products meet predetermined standards before reaching consumers. Through effective quality inspection procedures during factory audits, businesses can detect inconsistencies early on, reducing the likelihood of costly recalls or customer dissatisfaction later on. Ultimately, prioritizing quality management through regular audits fosters trust and reliability within global supply chains.

What is a Factory Audit?

When discussing the landscape of global manufacturing, a factory audit emerges as a crucial tool for ensuring quality and compliance. It serves as a systematic examination of a factory's operations, focusing on quality control processes and overall management practices. The purpose of these audits is to identify any discrepancies in production standards, thereby safeguarding the integrity of the supply chain.

Definition and Purpose

A factory audit can be defined as an assessment conducted to evaluate a supplier’s capabilities, processes, and adherence to quality standards. The ultimate goal is not just to check boxes but to provide actionable insights that enhance quality management practices within the manufacturing environment. By implementing regular audits, businesses can mitigate risks associated with poor quality inspection outcomes and ensure that products meet both regulatory requirements and customer expectations.

Types of Factory Audits

Factory audits come in various forms, each tailored to specific needs within the manufacturing process. Common types include pre-production audits, during-production audits (DPA), and post-production audits (PPA). Each type focuses on different stages of production; for instance, pre-production audits assess readiness for manufacturing while DPA evaluates ongoing processes—ensuring that quality control measures are effectively implemented throughout.

Key Components of an Effective Audit

An effective factory audit encompasses several key components that contribute to its overall success. First, thorough preparation is essential; this includes defining clear objectives and criteria for evaluation based on industry standards. Second, onsite evaluation techniques must be employed systematically—this could involve direct observation of production lines or interviews with staff—to gather comprehensive data regarding quality inspection procedures in place. Lastly, an exhaustive document review should analyze records related to production efficiency and compliance with established quality management protocols.

The Process of Conducting a Factory Audit

Conducting a factory audit is a crucial step in ensuring that suppliers meet quality standards and comply with regulations. This process involves systematic planning, thorough evaluation techniques, and comprehensive document analysis to assess the factory's capabilities. By following these steps, businesses can enhance their quality control measures and strengthen supplier relationships.

Preparing for the Audit

Preparation is key to a successful factory audit in China. Before you step foot in the facility, it's essential to define the scope of the audit clearly—this includes identifying specific areas of focus such as quality management systems and production processes. Gathering background information about the supplier's operations, previous audit results, and any relevant certifications will also help you tailor your approach and set realistic expectations for quality inspection outcomes.

Once you've established your objectives, it’s time to assemble an audit team equipped with expertise in quality control protocols. Assign roles based on each member’s strengths—some may focus on technical evaluations while others dive into documentation analysis. Finally, communicate with your supplier ahead of time; this ensures they are prepared for your visit and understand what aspects will be evaluated during the factory audit.

Onsite Evaluation Techniques

When it comes to onsite evaluation techniques during a factory audit, observation is your best friend. Start by conducting a walkthrough of the facility to assess production workflows and identify any potential bottlenecks or inefficiencies that could impact quality management practices. Pay close attention to safety protocols as well; an unsafe work environment can lead to compromised product quality.

Interviews with staff members are another valuable technique for gathering insights into their understanding of quality control processes. Engaging employees at various levels can reveal how deeply ingrained quality inspection practices are within the company culture. Additionally, utilizing checklists tailored to specific industry standards can help ensure that all critical areas are covered during your assessment.

Document Review and Analysis

After completing onsite evaluations, it’s time to turn your attention towards document review and analysis—a vital component of any thorough factory audit in China. Start by examining records related to quality control procedures such as inspection reports, testing results, and compliance documentation against industry regulations. This helps verify that what you observed aligns with documented practices.

Moreover, assessing records related to training programs for staff on quality management is crucial; well-trained employees are more likely to adhere strictly to established guidelines during production runs. Don’t forget about maintenance logs—these documents provide insight into equipment reliability which directly impacts product integrity during manufacturing processes.

In conclusion, conducting a factory audit requires meticulous preparation followed by effective onsite evaluation techniques combined with thorough document review and analysis—all aimed at ensuring robust quality inspection practices are upheld throughout the supply chain process.

Evaluating Quality Control Systems

In the realm of manufacturing, evaluating quality control systems is paramount to ensuring that products meet both regulatory standards and customer expectations. A robust quality management framework not only enhances product reliability but also fosters trust between suppliers and buyers. This section delves into the significance of quality management, the assessment of quality inspection procedures, and how to identify areas for improvement.

Importance of Quality Management

Quality management is the backbone of any successful factory audit in China. It encompasses a systematic approach to managing organizational processes, ensuring that products are consistently produced at high standards. By prioritizing quality control, companies can mitigate risks associated with defects and non-compliance, ultimately leading to enhanced customer satisfaction and loyalty.

Furthermore, effective quality management creates a culture of continuous improvement within organizations. This proactive mindset encourages teams to regularly evaluate their practices and strive for excellence in every aspect of production. In a competitive landscape where consumer expectations are ever-increasing, investing in quality management is not just beneficial; it’s essential for long-term success.

Assessing Quality Inspection Procedures

Quality inspection procedures are critical components in maintaining high-quality standards during production processes. During a factory audit in China, it’s vital to scrutinize these procedures thoroughly to ensure they align with international best practices. An effective assessment will involve examining how inspections are conducted at various stages—raw materials, in-process checks, and final product evaluations.

Moreover, understanding the tools and techniques used for quality inspection can reveal much about a supplier's commitment to quality control. Are they employing advanced technologies or relying on outdated methods? The answers can significantly impact the overall effectiveness of their quality management system and highlight areas needing attention or enhancement.

Identifying Areas for Improvement

Identifying areas for improvement is crucial after evaluating existing quality control systems during a factory audit in China. Regular audits should not merely be about compliance; they should also focus on discovering gaps that could lead to inefficiencies or product failures down the line. By pinpointing weaknesses—be it inadequate training programs or insufficiently documented processes—companies can take actionable steps toward elevating their overall performance.

Additionally, fostering an environment where feedback is welcomed can significantly enhance audit outcomes related to audit quality control. Engaging employees in discussions about potential improvements often yields valuable insights that might otherwise go unnoticed during formal evaluations. Ultimately, addressing these areas not only strengthens supplier relationships but also drives continuous improvement across all levels of production.

Common Pitfalls in Factory Audits

Navigating the landscape of factory audits can be tricky, especially when conducting a factory audit in China. Despite the best intentions, several common pitfalls can undermine the effectiveness of quality control efforts. By understanding these pitfalls, businesses can bolster their quality inspection processes and enhance overall quality management.

Miscommunication with Suppliers

One of the most significant hurdles in a factory audit is miscommunication with suppliers. If expectations are not clearly articulated before the audit, misunderstandings can arise that compromise the entire process. This lack of clarity may lead to discrepancies in quality control measures or even result in missed quality inspection opportunities that could have identified critical issues.

Moreover, cultural differences and language barriers can exacerbate these miscommunications during a factory audit in China. It's essential to establish open lines of communication and ensure that both parties are on the same page regarding objectives and expectations for quality management. Regular check-ins before and after audits can help bridge any gaps and foster a more collaborative relationship.

Overlooking Audit Quality Control

Another common pitfall is overlooking audit quality control itself during the factory audit process. It's easy to get caught up in checking boxes or focusing solely on compliance without considering whether the audit's methodology is sound. Quality inspection should never be an afterthought; instead, it should be integrated into every step of the auditing process.

Without proper oversight, vital components of quality management might be ignored or inadequately assessed, leading to misleading conclusions about supplier capabilities. Implementing a robust framework for audit quality control ensures that every aspect of the factory audit is thoroughly evaluated and contributes meaningfully to improving overall performance. Remember, an effective audit isn't just about finding faults—it's about driving continuous improvement.

Failing to Follow-Up on Findings

The final pitfall worth noting is failing to follow up on findings from previous audits effectively. After conducting a thorough factory audit in China, it's crucial to take actionable steps based on identified issues rather than letting them gather dust in a report file. This lack of follow-up not only undermines previous efforts but also signals to suppliers that concerns raised during audits are not taken seriously.

Establishing a systematic approach for addressing findings helps reinforce accountability within both your organization and your suppliers’ operations regarding quality control practices. Regular follow-ups create opportunities for dialogue about improvements made since previous audits while also allowing you to reassess areas needing further enhancement within their operations or your own quality inspection processes. Ultimately, consistent follow-up cultivates trust and fosters stronger relationships within global supply chains.

Leveraging Third-Party Inspection Services

In the realm of manufacturing, particularly when dealing with international suppliers, leveraging third-party inspection services can be a game changer. These services provide an independent perspective that enhances the integrity of factory audits in China, ensuring that quality control measures are not just a box-ticking exercise. By engaging experts who specialize in quality inspection, businesses can make informed decisions based on accurate and unbiased data.

Benefits of Using China Inspection Pro

China Inspection Pro stands out as a premier choice for companies seeking to elevate their factory audit processes. One significant benefit is their deep understanding of local manufacturing practices and regulations, which allows them to conduct thorough quality inspections tailored to specific industry needs. Moreover, utilizing such specialized services helps mitigate risks associated with supply chain disruptions by ensuring that products meet established quality standards before they reach the market.

Additionally, partnering with China Inspection Pro streamlines communication between buyers and suppliers during the audit process. Their expertise in quality management translates into actionable insights that help identify potential issues early on, allowing for timely resolutions. Ultimately, this partnership fosters stronger supplier relationships and drives continuous improvement in overall product quality.

How Third-Party Auditors Enhance Credibility

The role of third-party auditors cannot be overstated when it comes to enhancing credibility in factory audits. These independent assessors bring objectivity to the evaluation process, which is crucial for establishing trust among stakeholders involved in the supply chain. When suppliers know that an impartial party is conducting the audit, they are more likely to adhere strictly to quality control protocols and practices.

Furthermore, third-party auditors often have established reputations within the industry for delivering reliable results based on rigorous standards of audit quality control. This reputation not only benefits suppliers but also instills confidence in buyers who rely on these evaluations to gauge supplier capabilities accurately. In essence, third-party inspections serve as a badge of credibility that reinforces accountability across global supply chains.

Maximizing the Value of Inspection Reports

To truly maximize the value derived from inspection reports generated by third-party auditors, companies must engage actively with these findings post-audit. Quality inspection reports should not merely sit on a shelf collecting dust; instead, businesses should analyze them thoroughly to identify trends or recurring issues related to quality management practices at their factories in China. By doing so, organizations can implement targeted strategies aimed at addressing weaknesses and enhancing overall operational efficiency.

Moreover, regular follow-ups with suppliers based on insights from these reports create opportunities for dialogue regarding improvements needed within their processes or products. This ongoing communication helps establish a culture of continuous improvement where both parties work collaboratively toward shared goals related to product excellence and reliability. Ultimately, leveraging high-quality inspection reports leads not only to better products but also fosters long-term partnerships built on transparency and mutual respect.

Conclusion

In the ever-evolving landscape of global manufacturing, conducting a factory audit in China is not just a checkbox exercise; it’s an essential strategy for fostering robust supplier relationships and ensuring quality control. By prioritizing thorough inspections and quality management practices, companies can not only enhance their operational efficiency but also create a more resilient supply chain. Ultimately, the insights gained from these audits pave the way for continuous improvement, benefiting both suppliers and businesses alike.

Enhancing Supplier Relationships

Factory audits serve as a bridge between manufacturers and suppliers, fostering open communication and mutual understanding. When companies invest time in quality inspection processes, they signal to their suppliers that they value transparency and accountability in quality management. This proactive approach not only strengthens partnerships but also encourages suppliers to adopt better practices, resulting in improved product quality.

Moreover, regular factory audits can help identify potential issues before they escalate into major problems, allowing for timely interventions that benefit both parties. By engaging in constructive dialogue during these audits, businesses can work collaboratively with suppliers to address concerns related to audit quality control and operational inefficiencies. This collaborative spirit ultimately cultivates trust and loyalty within the supplier network.

Driving Continuous Improvement in Quality

Quality control is an ongoing journey rather than a destination; it requires constant vigilance and adaptation to changing market demands. Conducting comprehensive factory audits provides valuable insights into existing processes while identifying areas ripe for improvement in quality inspection procedures. With each audit cycle, organizations can refine their practices, ensuring that they remain competitive while consistently delivering high-quality products.

Additionally, leveraging findings from factory audits allows companies to set benchmarks for future performance metrics within their supply chains. By actively monitoring progress over time through regular evaluations of quality management systems, businesses can foster a culture of continuous improvement that resonates throughout their operations. This commitment to excellence not only enhances product offerings but also solidifies brand reputation among consumers.

Building Trust in Global Supply Chains

Trust is the cornerstone of any successful business relationship—especially when navigating the complexities of global supply chains involving multiple stakeholders across different regions like China. A well-executed factory audit instills confidence among partners by demonstrating due diligence regarding compliance with industry standards and regulations surrounding quality control measures. When suppliers know they're being held accountable through systematic audits, they're more likely to uphold high standards themselves.

Furthermore, transparent reporting from third-party inspection services enhances credibility by providing unbiased assessments of supplier capabilities during factory audits in China or elsewhere around the globe. These objective evaluations ensure all parties are aligned on expectations regarding product quality while minimizing risks associated with miscommunication or oversight during production runs. Ultimately, building trust through rigorous auditing processes lays the groundwork for long-lasting partnerships that thrive on shared goals.