Introduction

In the realm of manufacturing and production, maintaining high quality standards is paramount to success. The AQL sampling table emerges as a crucial tool in this endeavor, providing a systematic approach to quality inspection that helps ensure products meet established criteria. By utilizing the AQL sampling table, companies can streamline their quality control processes and enhance overall quality production.

Overview of AQL and Its Importance

AQL, or Acceptable Quality Level, serves as a benchmark in quality assurance that defines the maximum number of defective items considered acceptable in a sample batch. This standard not only facilitates effective quality inspection but also underscores the importance of consistency in product output. Understanding AQL is essential for any quality assurance inspector aiming to uphold rigorous standards while minimizing waste and costs associated with poor-quality goods.

Role of Quality Assurance in Production

Quality assurance plays an integral role in production by ensuring that every step adheres to predefined standards and specifications. It encompasses a variety of practices aimed at preventing defects before they reach consumers, thus safeguarding a company's reputation and profitability. By implementing robust quality control measures, including the use of the AQL sampling table, businesses can foster trust among customers and enhance their market position.

Benefits of Using the AQL Sampling Table

The AQL sampling table simplifies the complex process of determining acceptable defect rates by providing clear guidelines for sample sizes and acceptance criteria. This not only saves time during inspections but also reduces ambiguity around what constitutes an acceptable level of defects in products. Furthermore, employing this tool leads to more consistent results across different batches, ensuring that each product meets necessary quality standards while optimizing resource allocation during quality checks.

What is the AQL Sampling Table?

The AQL sampling table is a crucial tool in quality control, serving as a guide for quality inspectors to determine the acceptable levels of defects in a production batch. By establishing a systematic approach to quality inspection, it helps maintain high standards in quality assurance and ensures that products meet consumer expectations. Essentially, it is a bridge between production realities and quality standards, allowing manufacturers to achieve optimal quality production efficiently.

Definition and Purpose

At its core, the AQL sampling table defines Acceptable Quality Levels (AQL), which are statistical measures used during quality inspections to determine whether a batch of products meets predetermined quality standards. The purpose of this table is straightforward: it helps inspectors decide how many items from a lot should be sampled and what defect rate is acceptable for that lot to pass inspection. This structured approach not only streamlines the quality check process but also reduces the risk of rejecting entire batches over minor defects.

Historical Background and Development

The concept of AQL has roots dating back to World War II when the military needed efficient methods for inspecting munitions and supplies. Over time, this approach evolved into what we now recognize as the AQL sampling table, which gained prominence in manufacturing sectors post-war as industries aimed for improved efficiency and reduced waste in production processes. Today, this historical context underpins why many organizations rely on AQL sampling: it represents decades of refinement aimed at achieving robust quality assurance practices.

Key Components of the Table

The key components of an AQL sampling table include sample size, acceptance number, rejection number, and the specific AQL level chosen for inspection purposes. Sample size refers to how many items will be inspected from a batch; acceptance numbers indicate how many defects are permissible within that sample before rejecting an entire lot; rejection numbers define when an entire lot must be discarded due to excessive defects; finally, different AQL levels reflect varying degrees of stringency based on product type or industry requirements. Understanding these components enables effective application during quality inspections while ensuring adherence to established quality standards.

How to Use the AQL Sampling Table

Navigating the world of quality inspection can feel like a maze, but the AQL sampling table serves as a trusty map. Understanding how to effectively utilize this table is critical for quality assurance inspectors who aim to uphold quality standards in production. With a clear step-by-step approach, avoiding pitfalls, and learning from real-world examples, you’ll be well-equipped for successful quality checks.

Step-by-Step Guide for Quality Inspectors

Using the AQL sampling table begins with defining your lot size; this is crucial as it determines which section of the table you will reference. Next, select your desired AQL level—this reflects the maximum allowable defects in your sample and sets your quality control expectations. Once you've established these parameters, consult the table to find the corresponding sample size and acceptance number; this tells you how many units to inspect and how many defects are permissible.

After gathering your sample, conduct thorough inspections based on your findings from the AQL sampling table. Document any defects meticulously—this record will guide future decisions and improve overall quality production processes. Finally, decide whether to accept or reject the lot based on whether it meets or exceeds the acceptance criteria outlined in your chosen AQL level.

Common Mistakes to Avoid

Even seasoned quality assurance inspectors can stumble when using an AQL sampling table; one common pitfall is miscalculating lot sizes or selecting incorrect sample sizes. This can lead to inaccurate assessments that compromise product integrity and skew results during quality inspection processes. Another frequent mistake involves misunderstanding or misapplying different AQL levels; remember that each level corresponds to specific tolerances that must be adhered to strictly.

Additionally, failing to document inspections thoroughly can create gaps in data that hinder effective decision-making down the line. Consistency is key—always use standardized procedures when performing inspections based on your selected standard from the AQL sampling table. Lastly, be wary of rushing through inspections; taking time ensures thoroughness and helps maintain high-quality production standards.

Real-World Examples of Application

Consider a toy manufacturing company facing challenges with consistent product quality due to varying supplier materials. By implementing an AQL sampling strategy based on their specific needs using an appropriate sampling table, they were able to identify defective batches early in their production cycle—leading to significant savings in both time and resources while enhancing overall customer satisfaction.

In another case involving electronics manufacturing, a company utilized an advanced software tool integrated with their existing systems for real-time monitoring of quality checks aligned with their chosen AQL levels. This allowed them not only to streamline their inspection process but also provided valuable insights into trends over time regarding defect rates—which directly impacted their ability to maintain high-quality standards across all products.

These examples illustrate that effective use of an AQL sampling table can transform how organizations approach quality control and ensure adherence to rigorous standards throughout production cycles.

AQL Sampling and Quality Control

In the realm of quality control, the AQL sampling table serves as a pivotal tool for ensuring that products meet established quality standards. It allows quality assurance inspectors to determine acceptable levels of defects in a batch, effectively balancing cost with quality. This approach not only enhances customer satisfaction but also minimizes waste and rework, making it indispensable in modern manufacturing.

Importance of AQL in Quality Control

The significance of AQL in quality control cannot be overstated; it provides a structured method for assessing product quality without the need for exhaustive inspection of every item. By using the AQL sampling table, companies can efficiently identify defective goods while maintaining productivity. This method empowers quality assurance inspectors to make informed decisions that align with both business objectives and consumer expectations.

Moreover, implementing AQL sampling fosters a culture of continuous improvement within organizations. It encourages teams to focus on reducing defect rates over time, which ultimately leads to enhanced overall product quality. As businesses strive to meet increasingly stringent market demands, adhering to established quality standards through effective use of AQL becomes crucial.

Differentiating Between AQL and Other Standards

While many may confuse the AQL sampling method with other quality standards like ISO or Six Sigma, it's essential to understand their distinct functions within the broader scope of quality management. The primary difference lies in their focus: while ISO emphasizes comprehensive documentation and process adherence, AQL centers around practical inspection techniques tailored for real-time evaluation during production runs.

Moreover, unlike Six Sigma's rigorous statistical methodologies aimed at reducing variability and defects across processes, the AQL sampling table provides a more straightforward approach specifically designed for batch acceptance criteria. This unique positioning allows businesses to adopt both methodologies harmoniously when striving for excellence in their production processes.

Understanding these differences is vital for organizations aiming to implement effective quality check strategies tailored to their specific needs while avoiding potential pitfalls associated with misapplication or misunderstanding of these standards.

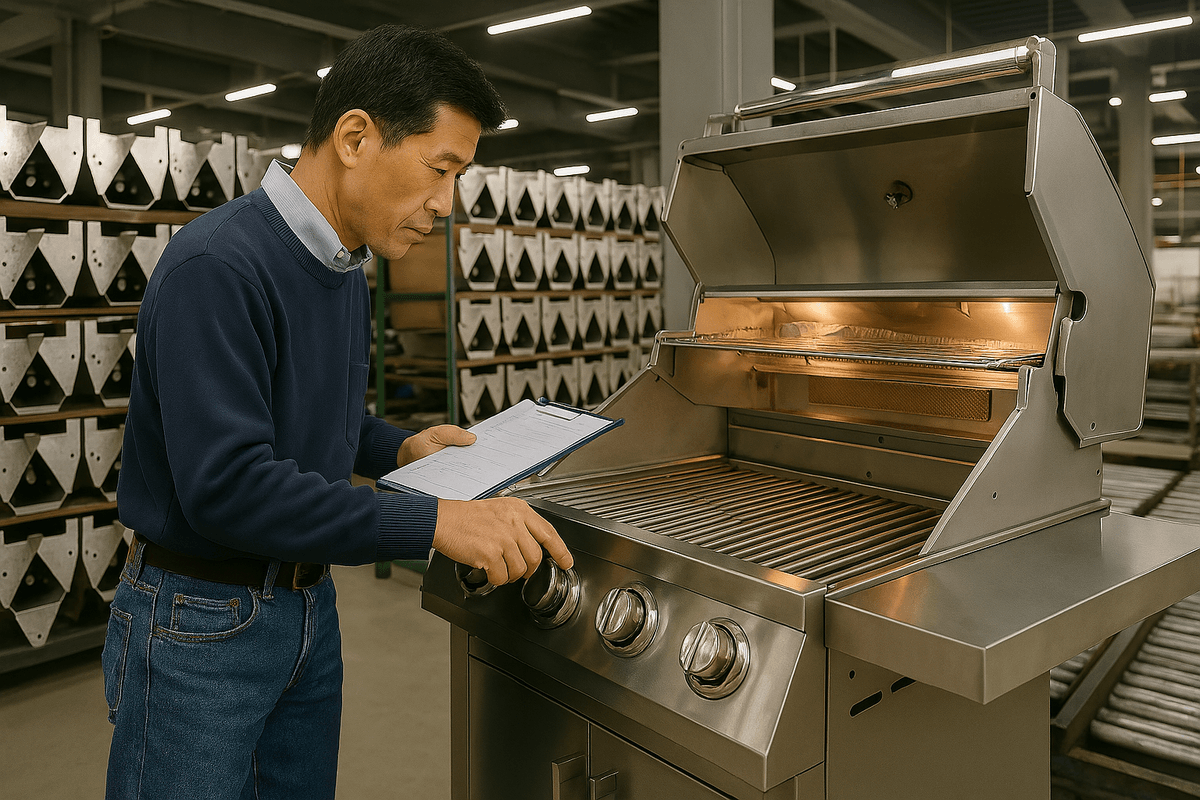

Impact of AQL on Quality Production

The impact of utilizing the AQL sampling table on overall quality production is profound and multifaceted. By providing clear guidelines on acceptable defect levels, it enables manufacturers to streamline their processes while ensuring compliance with industry regulations and customer expectations alike. Consequently, this leads not only to improved product consistency but also enhances brand reputation over time.

Furthermore, adopting an effective AQL strategy can significantly reduce costs associated with returns and rework due to defective items slipping through the cracks during initial inspections. Quality assurance inspectors equipped with robust tools like the AQL sampling table are better positioned to identify issues early in production cycles—saving time and resources that would otherwise be spent addressing problems post-production.

In summary, embracing an effective approach towards using an aql sampling table has far-reaching effects on fostering high-quality production environments where defects are systematically minimized—ultimately leading companies toward sustainable success in an increasingly competitive landscape.

Integrating AQL in Quality Check Processes

Integrating the AQL sampling table into quality check processes is essential for maintaining high-quality production standards. By leveraging effective strategies, tools, and real-world examples, organizations can enhance their quality inspection protocols. This section will explore how to embed AQL sampling into daily operations to ensure robust quality control.

Strategies for Effective Quality Inspections

Effective quality inspections begin with a clear understanding of the AQL sampling table and its application in various production scenarios. One strategy is to train all quality assurance inspectors on the nuances of the table, ensuring they grasp how different AQL levels affect product acceptance or rejection. Regularly reviewing inspection results can also help identify patterns that may indicate areas needing improvement in both processes and products.

Another strategy involves implementing standardized procedures for conducting inspections using the AQL sampling method. This includes setting predetermined criteria for when to escalate issues or conduct further checks based on initial findings from the sampling process. Additionally, fostering a culture of continuous improvement encourages teams to seek feedback and refine their inspection techniques regularly.

Finally, utilizing cross-functional teams during inspections can provide diverse perspectives on potential quality issues and solutions. By involving members from different departments—such as production, engineering, and logistics—organizations can better understand how various factors influence product quality. This collaborative approach not only enhances overall effectiveness but also promotes a shared commitment to upholding high-quality standards.

Tools and Software for AQL Sampling

In today’s digital age, several tools and software applications facilitate effective use of the AQL sampling table in quality control processes. These tools often include features that automate calculations related to sample sizes based on lot sizes and specified AQL levels, saving time for quality assurance inspectors while minimizing human error during assessments. Moreover, many software solutions provide analytical capabilities that help track trends over time regarding defect rates or compliance with established quality standards.

Additionally, mobile applications have emerged that allow inspectors to conduct real-time data entry during site visits or inspections. These apps often come equipped with customizable checklists aligned with specific industry requirements or internal protocols related to aql sampling practices. The integration of such technology enhances communication among team members by providing instant access to inspection results through cloud-based platforms.

Lastly, utilizing visual management tools like dashboards can help stakeholders quickly assess performance metrics related to product quality and compliance with the AQL sampling table guidelines. Such visual aids make it easier for teams to spot deviations from expected outcomes promptly so they can take corrective actions as needed—ultimately supporting continuous improvement efforts within an organization’s production processes.

Case Studies: Success Stories

Several companies have successfully integrated the AQL sampling table into their quality check processes, leading to significant improvements in overall product reliability and customer satisfaction levels. One notable example is a manufacturing firm specializing in electronics that adopted systematic training programs focused on empowering its quality assurance inspectors with knowledge about effective aql sampling techniques tailored specifically for their products’ unique challenges.

As a result of this initiative, defect rates dropped dramatically by 25% within six months due largely imparting skills related not just solely around using an aql sampling table but also enhancing teamwork across departments involved throughout production cycles—from design through delivery stages—all aimed at ensuring adherence toward established quality standards consistently across all operations.

Another success story comes from an automotive parts supplier who implemented advanced software solutions designed explicitly around optimizing their application of the aql sampling methodology during routine inspections conducted throughout various production phases—including raw material intake checks right up until final assembly verification points prior shipping finished goods out customers’ doors! This strategic investment led them achieving remarkable gains productivity while concurrently reducing costs associated non-conformance issues stemming past experiences where insufficient attention had been paid earlier towards aligning efforts closely following best practices outlined within industry-recognized frameworks like those provided by relevant governing bodies overseeing automotive sector regulations globally!

Choosing the Right AQL Level

Selecting the appropriate Acceptable Quality Level (AQL) is crucial for effective quality control in any production process. The AQL sampling table provides a framework that helps quality assurance inspectors determine the maximum number of defective items allowable in a sample size. This decision directly impacts product quality, customer satisfaction, and overall production efficiency.

Understanding Different AQL Levels

AQL levels are typically expressed as percentages, indicating the maximum allowable defects in a batch of products. Common levels include 0.65%, 1%, 2.5%, and 4%, each reflecting varying degrees of tolerance for defects during quality inspection. Understanding these levels is essential since they guide quality assurance inspectors in making informed decisions about product acceptability based on specific industry standards.

For instance, a lower AQL level signifies stricter quality control and is often used in industries where safety is paramount, such as aerospace or medical devices. Conversely, higher AQL levels may be acceptable for less critical products like textiles or consumer goods, where minor flaws may not significantly affect usability or safety. By grasping these distinctions, businesses can align their quality check processes with their operational goals and customer expectations.

Factors to Consider When Selecting AQL

When choosing the right AQL level for your production line, several factors come into play that can significantly influence your decision-making process. Firstly, consider the nature of your product; items requiring high reliability should adopt stricter AQL standards to mitigate risks associated with defects during use. Secondly, evaluate customer expectations—if consumers demand flawless products, it’s wise to lean toward lower AQLs to ensure satisfaction and brand loyalty.

Additionally, production volume plays a role; larger batches may necessitate more lenient standards due to practical limitations on inspection resources and time constraints during quality inspections. Furthermore, regulatory requirements specific to certain industries must also be taken into account when determining acceptable defect rates within your quality assurance practices. Balancing these factors will help you select an appropriate AQL that supports both quality production and operational efficiency.

Insights from China Inspection Pro

China Inspection Pro offers valuable insights into implementing effective AQL sampling practices tailored to various industries' unique needs. Their expertise emphasizes understanding local market conditions while maintaining global quality standards through precise application of the AQL sampling table during inspections. By leveraging their services, companies can enhance their overall approach to quality control while ensuring compliance with international benchmarks.

Moreover, China Inspection Pro highlights case studies showcasing successful implementations of tailored AQL strategies that resulted in improved product reliability and reduced defect rates across different sectors. Their guidance assists organizations in navigating complex supply chains by providing clarity on how best to integrate robust quality check processes using established AQL principles effectively. Ultimately, collaborating with experienced partners like China Inspection Pro can lead businesses toward achieving superior outcomes in their commitment to excellence through diligent quality assurance practices.

Conclusion

In wrapping up our exploration of the AQL sampling table, it’s clear that this tool is indispensable in the realm of quality control. The AQL sampling method not only streamlines the quality inspection process but also ensures that products meet established quality standards before reaching consumers. By implementing effective AQL sampling practices, organizations can significantly enhance their quality production efforts, ultimately leading to higher customer satisfaction and reduced costs.

Summarizing the Importance of AQL Sampling

The significance of AQL sampling lies in its ability to provide a systematic approach to assessing product quality without exhaustive testing. Utilizing the AQL sampling table allows quality assurance inspectors to make informed decisions based on statistical data rather than guesswork. This method not only saves time and resources but also helps maintain consistent adherence to quality standards across production lines.

Future Trends in Quality Assurance

Looking ahead, we can expect advancements in technology to further enhance the effectiveness of quality inspections through automation and AI-driven analytics. These innovations will likely integrate seamlessly with traditional methods like the AQL sampling table, providing real-time insights into production processes and enabling more agile responses to potential issues. As industries continue to evolve, so too will the frameworks for ensuring quality production, making adaptability a key trait for future quality assurance inspectors.

How to Become a Quality Assurance Inspector

Becoming a successful quality assurance inspector involves mastering various practices and methodologies related to quality control, including familiarity with tools like the AQL sampling table. Aspiring inspectors should pursue relevant training or certification programs that cover statistical methods and inspection techniques while gaining hands-on experience through internships or entry-level positions in manufacturing environments. With dedication and continuous learning, anyone can carve out a rewarding career ensuring products meet stringent quality standards.