Introduction

In the world of manufacturing, the importance of glass quality inspection cannot be overstated. High-quality glass products are crucial for safety and functionality across various industries, from construction to automotive. A robust quality control process ensures that every piece of glass meets stringent standards, ultimately safeguarding both consumers and manufacturers.

Importance of Glass Quality Inspection

Glass quality inspection is essential for maintaining product integrity and customer satisfaction. Defects in glass can lead to catastrophic failures, making thorough quality control inspections vital in preventing accidents and ensuring compliance with industry regulations. Moreover, a commitment to quality management fosters trust between manufacturers and their clients, enhancing brand reputation.

Overview of Quality Control Practices

Quality control practices encompass a range of methods designed to monitor and maintain product standards throughout the manufacturing process. From initial raw material assessment to final product evaluation, each step plays a pivotal role in ensuring that glass products meet or exceed expectations. By implementing rigorous quality inspection protocols, companies can identify defects early on, reducing waste and improving overall efficiency.

How Technology Enhances Quality Management

Technology has revolutionized the landscape of quality management in recent years, particularly through innovations like automatic visual inspection systems. These advanced tools allow for real-time monitoring and analysis of glass products during production, significantly increasing accuracy while minimizing human error. As a result, manufacturers can achieve higher levels of quality improvement while streamlining their operations.

Understanding Glass Quality Inspection

In the world of glass manufacturing, quality inspection is paramount. It serves as a critical checkpoint to ensure that products meet the required standards before they reach consumers. By understanding the nuances of glass quality inspection, manufacturers can significantly enhance their quality management practices and ultimately drive quality improvement.

Key Metrics for Quality Inspection

When it comes to glass quality inspection, several key metrics help gauge product integrity. These metrics often include thickness uniformity, optical clarity, and surface finish—each playing a vital role in determining overall product quality. By closely monitoring these metrics during the quality control process, manufacturers can identify deviations early and implement corrective measures swiftly.

Another essential metric is the rate of defects per batch, which provides insight into the effectiveness of current production methods. High defect rates may indicate underlying issues that need addressing through improved processes or technology upgrades like automatic visual inspection systems. Overall, consistent measurement against these key metrics fosters a culture of continuous improvement in quality management.

Common Defects in Glass Products

Despite rigorous efforts in glass manufacturing, common defects still plague many products on the market today. Air bubbles, scratches, and inconsistent thickness are just a few examples that can compromise both functionality and aesthetics. Such defects not only impact customer satisfaction but also pose significant challenges for effective quality control.

Understanding these common defects is crucial for implementing targeted solutions during the quality inspection phase. For instance, employing an automatic visual inspection system can help detect imperfections quickly and accurately before products leave the factory floor. With proactive measures in place to tackle these issues head-on, manufacturers can boost their reputation while ensuring adherence to high-quality standards.

Role of Quality Control in Manufacturing

Quality control plays a pivotal role in ensuring that every piece of glass produced meets stringent safety and performance standards. It involves systematic inspections at various stages of production to catch any potential flaws early on—thereby reducing waste and enhancing overall efficiency. A robust quality management framework not only safeguards product integrity but also builds consumer trust over time.

Moreover, effective quality control practices contribute significantly to cost savings by minimizing rework or recalls due to defective products reaching the market. As technologies evolve within this domain—especially with advancements like automatic visual inspection systems—the ability to maintain high-quality standards has never been more attainable for manufacturers worldwide. Ultimately, investing in comprehensive quality control is synonymous with investing in long-term business success.

Quality Control Techniques for Glass

In the world of glass manufacturing, quality control techniques play a pivotal role in ensuring that products meet stringent standards. Various methods have been developed over the years to enhance glass quality inspection, each with its own strengths and weaknesses. By understanding these techniques, manufacturers can implement effective quality management strategies that lead to significant improvements in product reliability and customer satisfaction.

Traditional Inspection Methods

Traditional inspection methods for glass quality inspection often rely on manual processes conducted by skilled inspectors. These inspectors examine glass products visually or use simple tools to identify defects such as scratches, bubbles, or distortions. While effective in some cases, this approach can be time-consuming and subject to human error, leading to inconsistencies in quality control.

Moreover, traditional methods may not keep pace with the increasing demand for high-quality glass products in today's fast-paced market. As a result, manufacturers are seeking more efficient ways to conduct quality inspections without compromising on quality management practices. The challenge lies in balancing thoroughness with speed while ensuring that all critical metrics are met.

The Impact of Automated Systems

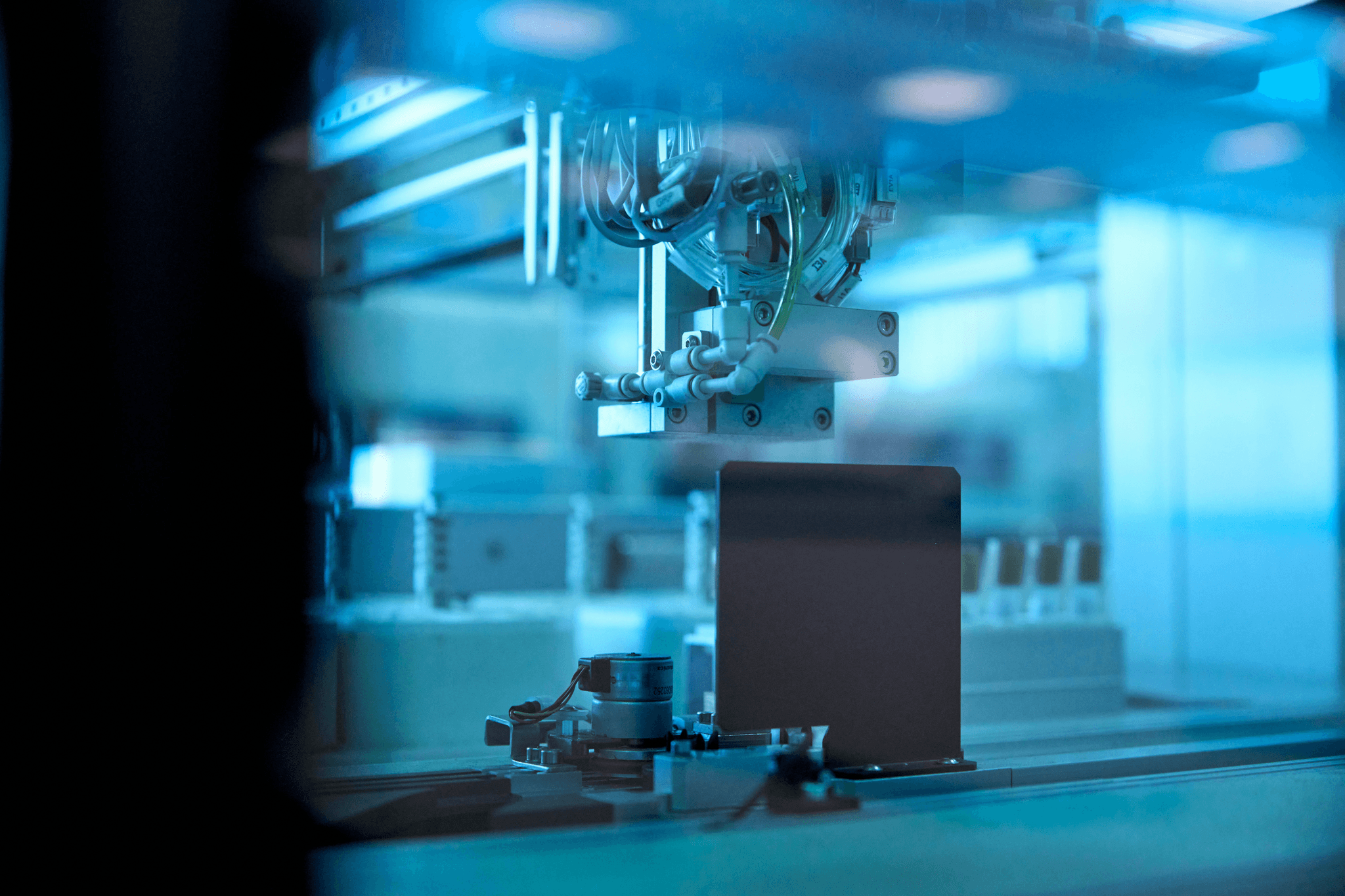

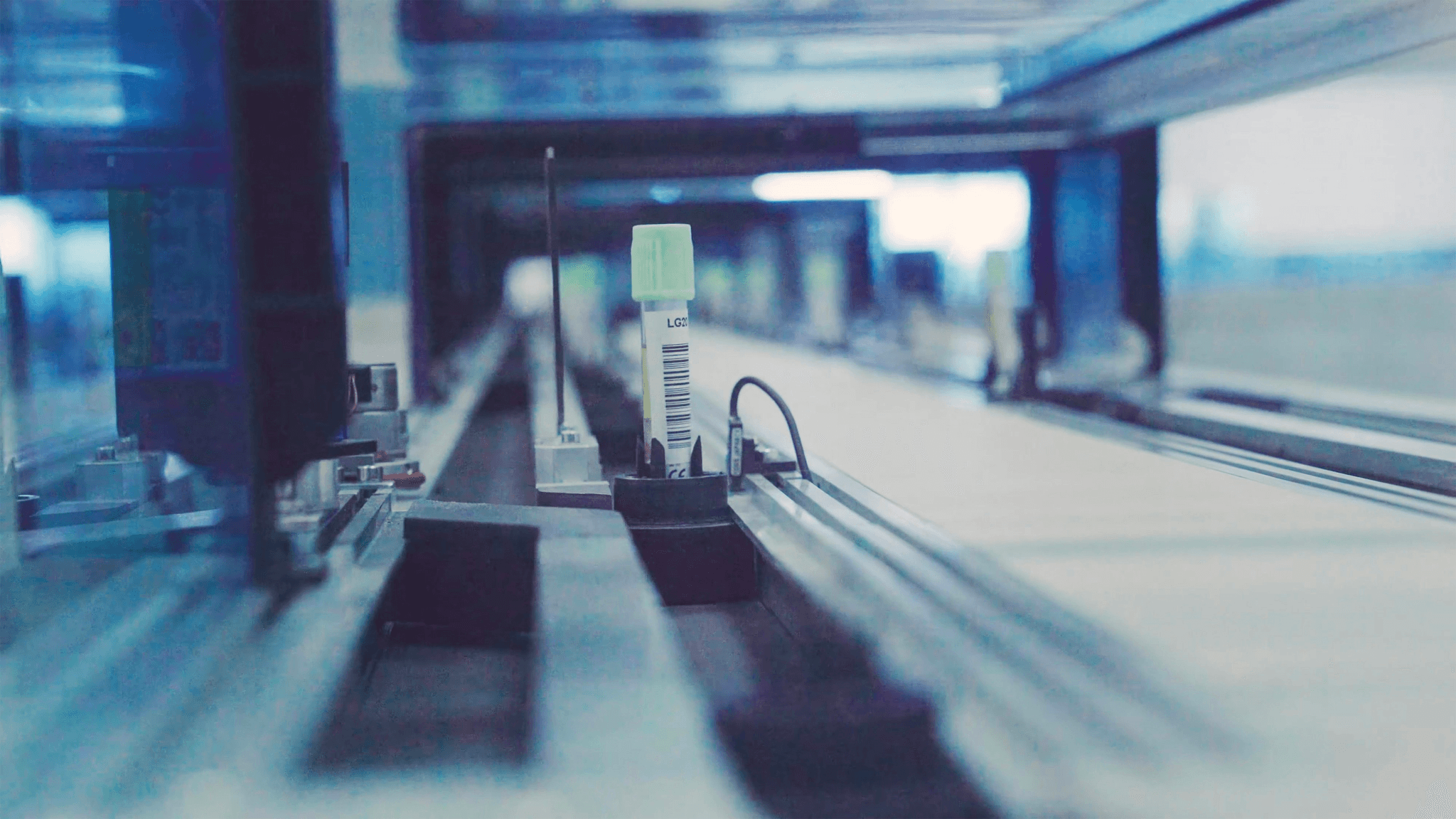

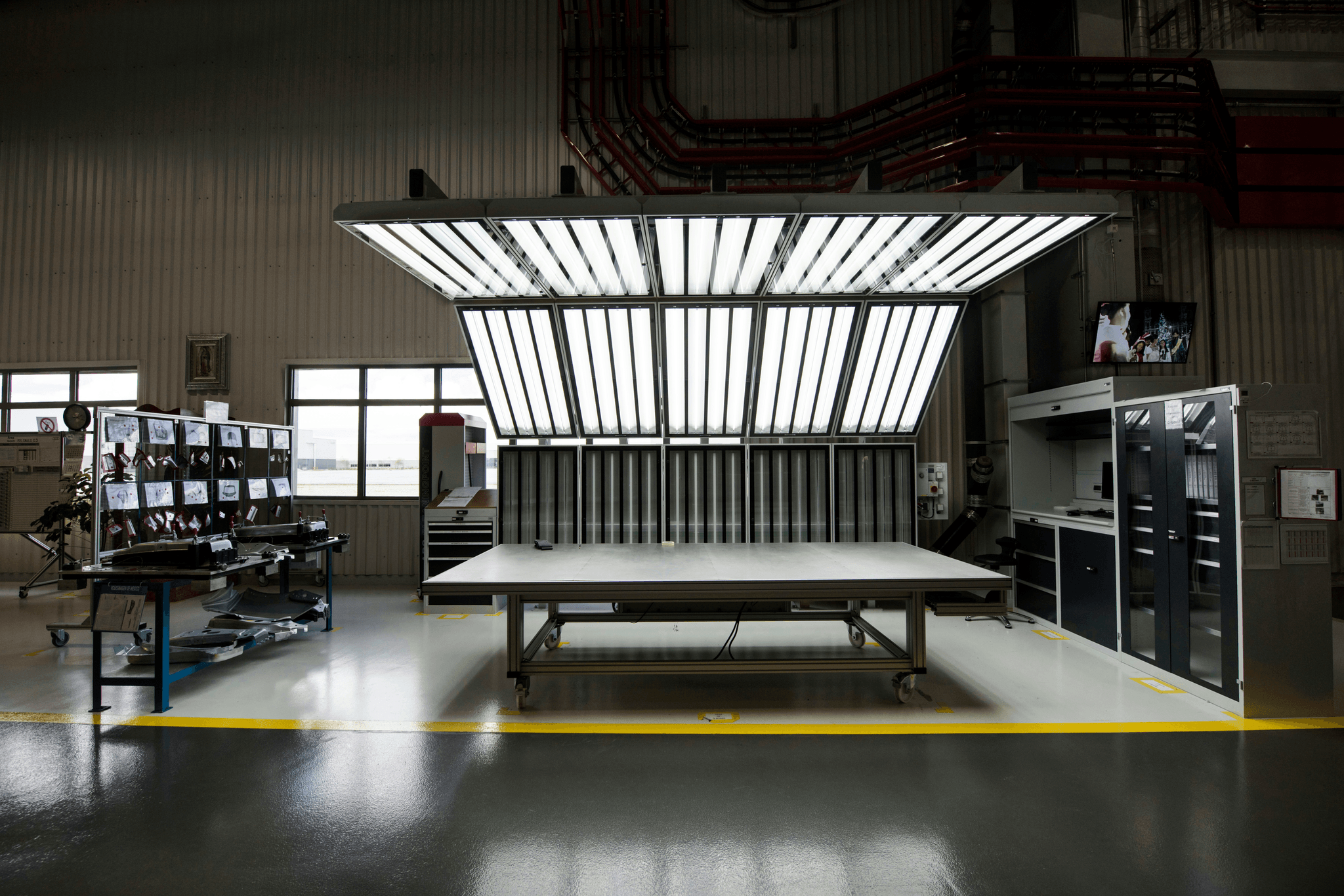

Automated systems have revolutionized the landscape of glass quality inspection by introducing speed and precision into the process. These advanced technologies utilize sensors and cameras to detect defects automatically, significantly reducing the reliance on human intervention. The impact of automated systems on quality control is profound; they not only enhance efficiency but also improve accuracy in identifying flaws that might go unnoticed during manual inspections.

Furthermore, these automated solutions enable continuous monitoring throughout the production process, allowing for real-time adjustments that lead to better overall quality management outcomes. By integrating automatic visual inspection systems into their operations, manufacturers can ensure consistent adherence to industry standards while minimizing waste and rework costs associated with defective products. This shift towards automation marks a significant step forward in achieving lasting improvements in glass quality.

Advantages of Visual Inspection Systems

Visual inspection systems offer several advantages when it comes to enhancing glass quality inspection processes within manufacturing environments. These systems employ advanced imaging technology combined with artificial intelligence algorithms to analyze products at high speeds while maintaining exceptional accuracy levels. One key benefit is their ability to detect subtle defects that traditional methods might overlook—ensuring higher-quality output.

Additionally, visual inspection systems contribute significantly toward streamlining production workflows by reducing bottlenecks caused by manual inspections or delays due to defect identification processes. With improved efficiency comes enhanced productivity—a vital component for any manufacturer aiming for success in today’s competitive market landscape focused on quality improvement initiatives across various sectors including automotive glazing or architectural applications involving large-scale installations.

In conclusion, embracing modern techniques such as automated and visual inspection systems is essential for advancing effective quality control measures within the realm of glass manufacturing—ultimately leading companies toward greater success through improved product reliability and customer satisfaction levels achieved via robust approaches targeting comprehensive assessments during every stage involved throughout production cycles.

The Role of China Inspection Pro

When it comes to maintaining high standards in glass quality inspection, China Inspection Pro stands out as a key player in quality control. Their comprehensive approach ensures that manufacturers meet rigorous quality management criteria, ultimately leading to better products and satisfied customers. With a focus on detail, they provide invaluable services that enhance the overall quality improvement process.

What They Do for Quality Control

China Inspection Pro specializes in various aspects of quality control, offering tailored solutions for glass manufacturers. They conduct thorough quality inspections that encompass everything from raw materials to finished products, ensuring that each stage meets predefined standards. By utilizing advanced technologies like automatic visual inspection systems, they can detect defects early and efficiently, preventing costly mistakes down the line.

Benefits of Third-Party Inspections

Engaging third-party inspections from China Inspection Pro brings numerous benefits to manufacturers seeking robust quality management practices. First and foremost, these independent assessments provide an unbiased evaluation of product quality, which is crucial for building trust with clients and stakeholders alike. Additionally, their expertise in quality control inspection helps identify potential issues before they escalate into larger problems, ultimately saving time and resources while enhancing overall product reliability.

Ensuring Compliance with International Standards

In today's global marketplace, compliance with international standards is non-negotiable for any manufacturer looking to thrive. China Inspection Pro plays an essential role in ensuring that glass products adhere to these stringent guidelines through meticulous quality inspections and ongoing support throughout the manufacturing process. This commitment not only fosters confidence among consumers but also positions manufacturers favorably within competitive markets by showcasing their dedication to maintaining high-quality standards.

Innovations in Quality Management

The landscape of quality management is rapidly evolving, particularly in the realm of glass quality inspection. With technological advancements, manufacturers can now leverage innovative tools and systems to enhance their quality control processes. These innovations not only streamline operations but also ensure that products meet stringent quality standards, ultimately leading to improved customer satisfaction.

Emerging Technologies in Quality Inspection

Emerging technologies are revolutionizing the way glass quality inspection is conducted. Automated systems, such as automatic visual inspection systems, utilize advanced algorithms and machine learning to detect defects that may go unnoticed by human inspectors. This shift towards automation enhances accuracy and efficiency in quality control, reducing the chances of human error and ensuring a higher standard of glass products.

Furthermore, the integration of artificial intelligence (AI) into quality management allows for real-time data analysis and decision-making. By employing AI-driven tools, manufacturers can monitor production processes continuously and identify potential issues before they escalate into significant problems. This proactive approach to quality inspection helps maintain high-quality standards throughout the manufacturing process.

Predictive Analytics for Quality Improvement

Predictive analytics has emerged as a game-changer in the field of quality improvement within glass manufacturing. By analyzing historical data from previous production runs, manufacturers can identify patterns and trends that indicate potential defects or failures in their products. This foresight enables them to implement corrective measures before issues arise, significantly reducing waste and enhancing overall product reliability.

Moreover, predictive analytics can optimize maintenance schedules for machinery involved in glass production, minimizing downtime caused by equipment failure. By ensuring that all components are functioning optimally through timely interventions based on analytical insights, companies can maintain consistent output while adhering to rigorous quality control standards. Ultimately, this leads to a more efficient operation where both cost savings and product integrity are prioritized.

Case Studies of Successful Implementations

Several companies have successfully implemented innovative technologies into their glass quality inspection processes with remarkable results. For instance, a leading manufacturer adopted an automatic visual inspection system that reduced defect rates by over 30% within just six months of implementation. This remarkable improvement not only enhanced their reputation for reliability but also allowed them to expand their market share due to increased customer trust.

Another case study highlights how predictive analytics transformed a struggling glass producer's operations by providing actionable insights into their manufacturing process inefficiencies. By leveraging data-driven strategies tailored from historical performance metrics, they achieved a 25% increase in production efficiency while simultaneously improving product consistency—an impressive feat for any manufacturer striving for excellence in quality management.

These examples underscore the importance of integrating cutting-edge technology into traditional practices like glass quality inspection—showing that innovation is key not just for survival but thriving in today's competitive marketplace.

Challenges in Glass Quality Control

Quality control in the glass manufacturing industry is fraught with challenges that can impact the final product's integrity and performance. From identifying defects to ensuring compliance with international standards, maintaining high levels of quality management is critical. Companies must navigate a complex landscape of risks while striving for continuous quality improvement.

Identifying and Mitigating Risks

The first step in effective glass quality inspection is recognizing the potential risks that could compromise the product's quality. Common issues include defects during production, such as bubbles, scratches, or uneven thickness, which can go unnoticed without robust quality inspection processes. By implementing an automatic visual inspection system, manufacturers can significantly enhance their ability to identify these flaws early in the production cycle, allowing for timely interventions and reducing waste.

Mitigating risks also involves training staff on best practices for quality control inspection and ensuring they understand the importance of adhering to established protocols. Regular audits and reviews of quality management systems can help pinpoint areas needing improvement or adjustment. Ultimately, a proactive approach to risk identification not only enhances product reliability but also builds trust with customers who rely on high-quality glass products.

Balancing Cost and Quality

One of the perennial challenges faced by manufacturers is balancing cost constraints with the need for high-quality products. While investing in advanced technologies like automated visual inspection systems may seem costly upfront, these systems often lead to long-term savings by reducing defects and rework costs associated with poor glass quality inspection practices. Striking this balance requires a strategic approach where businesses evaluate their current processes against potential improvements.

Moreover, companies must consider how cutting corners on quality control might lead to greater expenses down the line due to customer dissatisfaction or regulatory penalties. By prioritizing comprehensive quality management strategies that incorporate both traditional methods and innovative technologies, manufacturers can achieve a sustainable balance between cost efficiency and superior product standards. This dual focus not only enhances profitability but also fosters customer loyalty through consistent delivery of high-quality glass products.

Strategies for Continuous Quality Improvement

To thrive in today’s competitive market, organizations must embrace continuous quality improvement as part of their culture rather than viewing it as a one-time initiative. Implementing regular training sessions focused on best practices for glass quality inspection ensures that all team members are aware of current industry standards and methodologies for effective quality control inspections. Additionally, soliciting feedback from employees involved in production can uncover valuable insights into areas where improvements are needed.

Another effective strategy involves leveraging predictive analytics tools that analyze historical data to forecast potential defects before they occur during manufacturing processes. This proactive approach allows companies to adjust their production techniques accordingly, minimizing waste while enhancing overall product integrity through meticulous attention to detail in every stage of production—from raw materials sourcing to final inspections using advanced technologies like automatic visual inspection systems.

Fostering an environment focused on continuous improvement not only elevates the standard of glass products but also cultivates a culture where every employee feels responsible for upholding excellence throughout their work processes—ultimately leading to superior outcomes across all facets of operations.

Conclusion

In the world of glass manufacturing, quality inspection is not just a box to check; it’s the backbone of product integrity and customer satisfaction. The integration of advanced quality management practices ensures that every piece of glass meets stringent standards, safeguarding against defects that can lead to costly recalls or damage to reputation. As we look ahead, embracing innovations in quality control will be paramount for manufacturers aiming to stay competitive and reliable.

Key Takeaways on Quality Inspection

Quality inspection is essential for maintaining high standards in glass production, where even minor defects can have significant repercussions. Key metrics such as clarity, thickness, and surface finish are critical in assessing glass quality effectively. Moreover, the implementation of automatic visual inspection systems enhances efficiency and accuracy in identifying faults during the quality control process.

Future Trends in Quality Control

The future of quality control is set to be revolutionized by emerging technologies such as AI-driven analytics and machine learning applications. These advancements promise not only improved accuracy in detecting defects but also predictive analytics for proactive quality improvement strategies. Manufacturers must adapt to these trends to ensure their processes remain robust and responsive to evolving market demands.

Building Trust in Glass Manufacturing

Building trust within the glass manufacturing sector hinges on consistent quality management practices that prioritize transparency and accountability. Third-party inspections play a vital role by providing an unbiased assessment of products against international standards, reinforcing confidence among stakeholders. Ultimately, a commitment to rigorous glass quality inspection fosters stronger relationships with customers and partners alike.