Introduction

In the dynamic landscape of global manufacturing, quality control in China has emerged as a critical factor for success. As businesses increasingly rely on Chinese manufacturers, understanding the intricacies of quality control processes becomes essential. This introduction will delve into the significance of inspections and audits, as well as the pivotal role that lab testing plays in maintaining high standards in quality control.

Understanding Quality Control in China

Quality control in China encompasses a broad range of practices designed to ensure that products meet established standards before they reach consumers. With an ever-growing demand for high-quality goods, manufacturers must implement robust QC quality control measures throughout their production processes. By prioritizing quality checks in manufacturing, companies can mitigate risks associated with defective products and enhance their reputation in competitive markets.

Importance of Inspections and Audits

Inspections and audits are vital components of an effective quality control system in manufacturing environments. Regular inspections help identify potential issues early on, allowing for timely intervention and corrections before products leave the factory floor. Moreover, audits serve as a comprehensive evaluation tool to assess compliance with industry standards and internal policies, ensuring that manufacturers uphold their commitment to excellence.

The Role of Lab Testing in Quality Control

Lab testing is another crucial element within the framework of quality control and manufacturing practices. By utilizing third-party labs for product testing, companies can gain unbiased insights into their product's safety and performance characteristics. This not only enhances consumer trust but also helps businesses comply with international regulations—ultimately solidifying their position within the competitive landscape of global trade.

Overview of Quality Control in Manufacturing

Quality control in manufacturing is not just a buzzword; it's the backbone of producing reliable products. In China, where manufacturing is a cornerstone of the economy, quality control is paramount. It involves systematic processes to ensure that products meet specified standards and customer expectations, encompassing everything from raw materials to final inspections.

Definition and Key Components

At its core, quality control (QC) refers to the procedures and activities aimed at ensuring that manufactured goods are consistent in quality and performance. Key components of QC include quality checks in manufacturing, inspections at various stages of production, and feedback loops for continuous improvement. In a landscape as vast as China's manufacturing sector, these components work together to create a robust framework that minimizes defects while maximizing efficiency.

Importance of Quality Control in China

Quality control in China is critical for several reasons. Firstly, it helps maintain product integrity and safety, which is essential for both domestic consumption and international trade. Secondly, with increasing globalization, consumers are more discerning than ever; effective QC measures can enhance brand reputation and foster customer loyalty by ensuring high standards are met consistently.

Common Challenges in Quality Control

Despite its importance, implementing effective quality control poses several challenges within the manufacturing sector in China. One significant hurdle is the variation in standards across different regions and industries; this inconsistency can lead to discrepancies in product quality. Additionally, limited access to advanced technology or training can hinder effective QC practices, making it essential for manufacturers to invest adequately in their quality inspection processes to overcome these obstacles.

The Inspection Process Explained

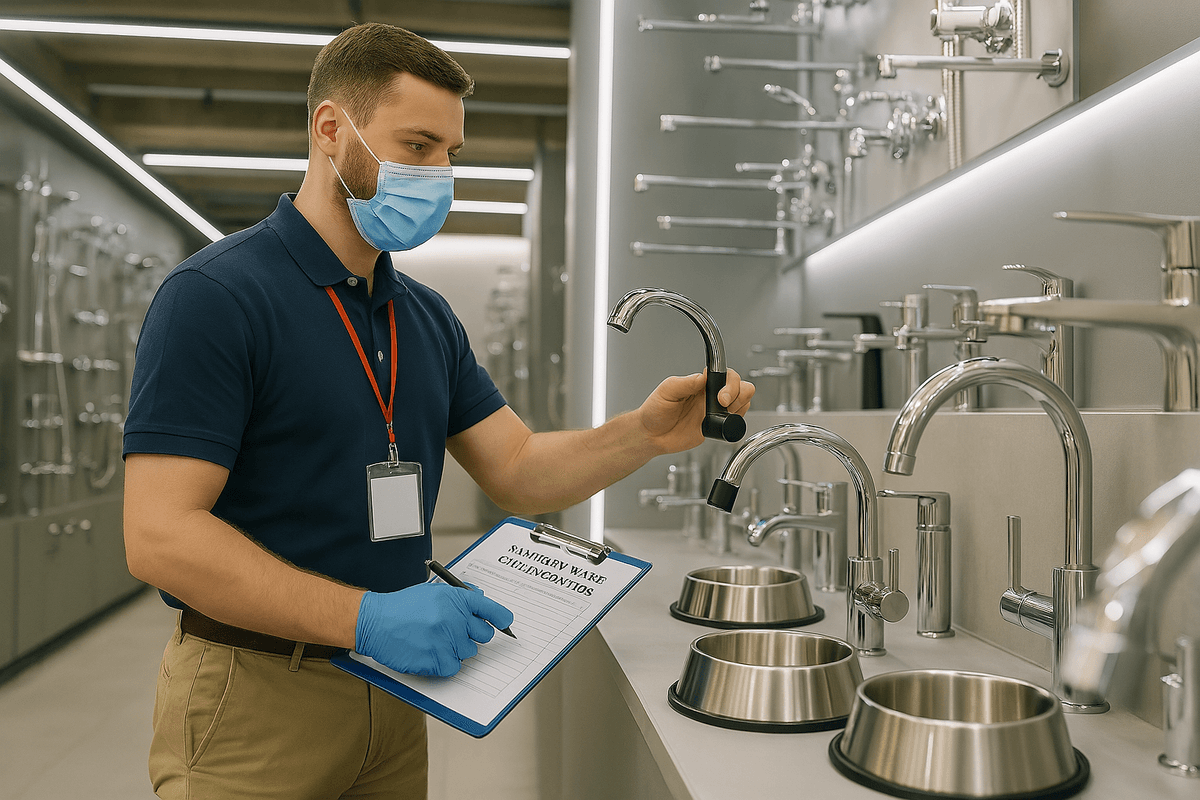

In the world of quality control in manufacturing, inspections play a pivotal role in ensuring that products meet established standards before they reach consumers. Quality inspections are not just a formality; they are critical checkpoints that can save businesses from costly recalls and reputation damage. Understanding the different types of inspections and how to effectively implement them is essential for maintaining high-quality standards.

Types of Quality Inspections

Quality inspections come in various forms, each tailored to address specific needs within the manufacturing process. Pre-production inspections help identify potential issues before production begins, while during-production inspections ensure that quality checks in manufacturing are performed at crucial stages. Finally, post-production inspections focus on finished goods, verifying that they meet all specifications and regulatory requirements.

These types of quality inspection not only enhance product reliability but also foster trust between manufacturers and their clients. In a landscape where quality control china is increasingly scrutinized by global markets, understanding these inspection types becomes even more vital for businesses looking to thrive. By implementing a comprehensive inspection strategy, companies can mitigate risks associated with subpar products.

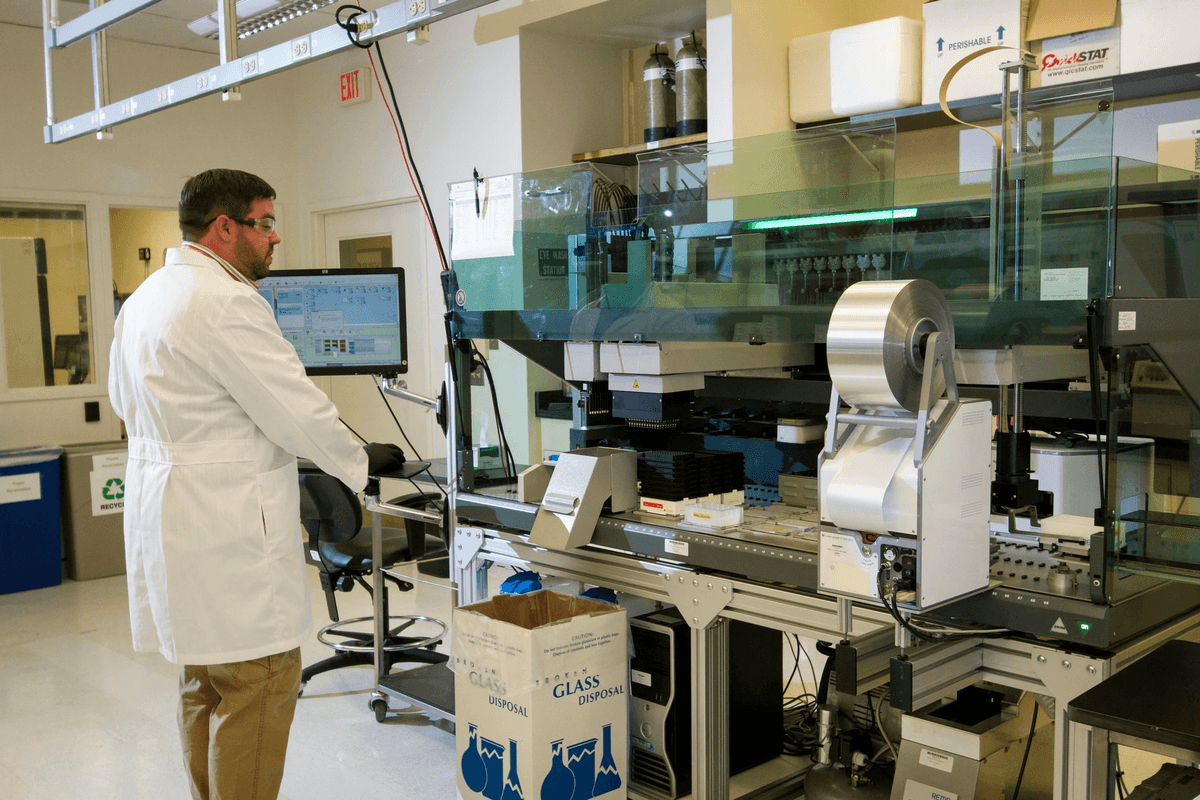

How China Inspection Pro Ensures Quality

China Inspection Pro takes a proactive approach to quality control by employing highly trained inspectors who specialize in various industries and product categories. Their rigorous processes ensure that every aspect of production aligns with international standards and client expectations. By leveraging advanced technology and methodologies, they provide real-time insights into the manufacturing process, allowing for immediate corrective actions when necessary.

The emphasis on transparency sets China Inspection Pro apart; clients receive detailed reports outlining findings from each inspection stage, ensuring accountability throughout the supply chain. This commitment to excellence reinforces confidence among partners seeking reliable quality control china solutions for their operations. Ultimately, this level of diligence contributes significantly to overall product integrity.

Best Practices for Effective Inspections

To optimize quality control and manufacturing processes through effective inspections, several best practices should be adopted by organizations striving for excellence. First and foremost is establishing clear criteria for what constitutes acceptable quality; without defined benchmarks, evaluations can become subjective and inconsistent. Regular training sessions for inspectors also help maintain high standards while adapting to evolving industry regulations.

Additionally, integrating technology such as automated data collection tools can enhance efficiency during quality checks in manufacturing by minimizing human error and expediting reporting processes. Lastly, fostering open communication between teams involved in production allows for quicker identification of problems as they arise—because no one wants surprises when it comes to product quality!

By following these best practices consistently, companies can create a robust framework around their inspection processes that supports ongoing improvements in both product quality and customer satisfaction.

Audits: The Backbone of Quality Assurance

In the realm of quality control in manufacturing, audits serve as a crucial pillar that ensures products meet the required standards. Regular audits not only help in identifying potential issues but also foster a culture of continuous improvement within organizations. By embedding audit practices into the quality control framework, businesses can enhance their overall operational efficiency and product reliability.

Importance of Regular Audits

Regular audits are essential for maintaining high standards of quality control in China, where manufacturing processes can vary significantly from one supplier to another. These audits provide an objective assessment of compliance with industry regulations and company policies, helping to mitigate risks associated with poor quality products. Moreover, they reinforce accountability among employees and suppliers, ensuring that everyone is aligned with the company's quality objectives.

Types of Audits in Manufacturing

Manufacturing audits come in various flavors—each tailored for specific needs within the quality control landscape. Common types include internal audits, which focus on assessing a company's own processes; external audits conducted by third parties for unbiased evaluations; and supplier audits that ensure vendors adhere to agreed-upon standards. Each type plays a vital role in the broader strategy of quality checks in manufacturing, enabling organizations to pinpoint areas for improvement.

How Audits Enhance Quality Control

Audits enhance quality control by providing actionable insights that drive improvements across all levels of production. Through systematic evaluations, companies can identify weaknesses and implement corrective actions before they escalate into significant issues affecting product integrity. Additionally, regular auditing fosters greater transparency between manufacturers and stakeholders, ultimately leading to stronger relationships built on trust—an invaluable asset within the competitive landscape of quality control china.

Lab Testing: Ensuring Product Safety

In the realm of quality control in China, lab testing stands as a critical pillar for ensuring product safety and compliance with international standards. With an ever-growing demand for high-quality products, manufacturers must prioritize rigorous quality checks in manufacturing processes. Lab testing not only verifies that products meet safety regulations but also enhances consumer trust and brand reputation.

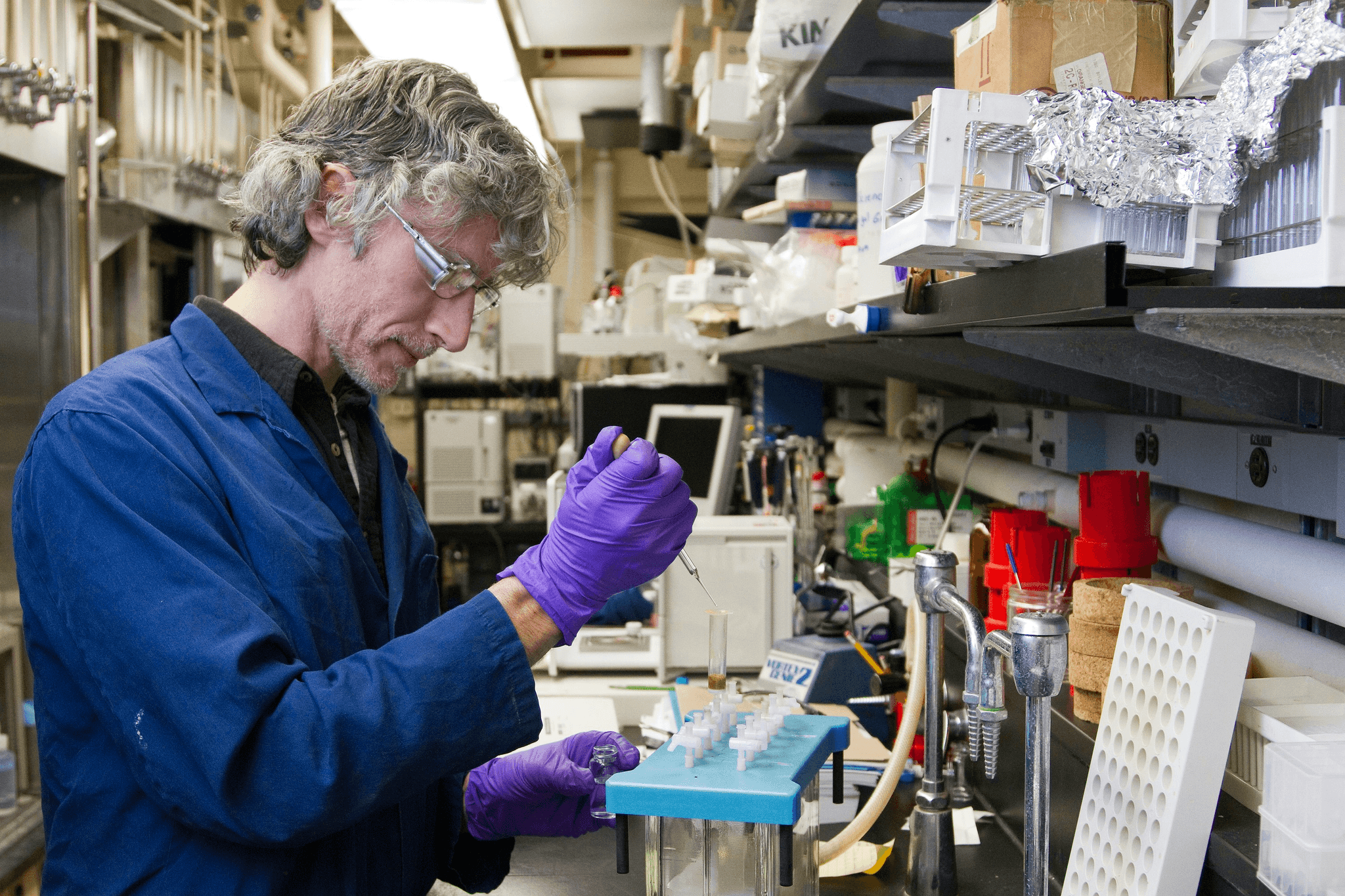

Types of Lab Testing Available

There is a diverse array of lab testing options available to manufacturers seeking to uphold quality control standards. Common types include mechanical testing, chemical analysis, and environmental testing, each tailored to assess specific product attributes and compliance requirements. By utilizing these various testing methods, companies can ensure their products are safe and reliable before reaching the market.

Role of Third-party Labs

Third-party labs play an essential role in the landscape of quality control and manufacturing by providing unbiased assessments of product quality. These independent labs offer expertise that may not be available in-house, allowing manufacturers to benefit from specialized knowledge and advanced testing technologies. Furthermore, third-party validation helps build credibility with clients and regulatory bodies alike, reinforcing confidence in the manufacturer’s commitment to quality.

Benefits of Lab Testing for Quality Checks

The advantages of incorporating lab testing into quality checks in manufacturing are manifold. Firstly, it helps identify potential issues early in the production process, mitigating risks associated with defective products reaching consumers. Secondly, lab testing can lead to cost savings by preventing recalls or legal issues down the line; after all, a stitch in time saves nine! Ultimately, consistent lab testing fosters continuous improvement within organizations striving for excellence in quality control china.

Real-world Examples of Quality Control Best Practices

In the realm of quality control in manufacturing, real-world examples provide invaluable insights into effective practices and pitfalls to avoid. By examining successful inspections and learning from failures, companies can refine their quality checks in manufacturing processes. These case studies not only highlight the importance of quality control but also offer practical strategies for improvement.

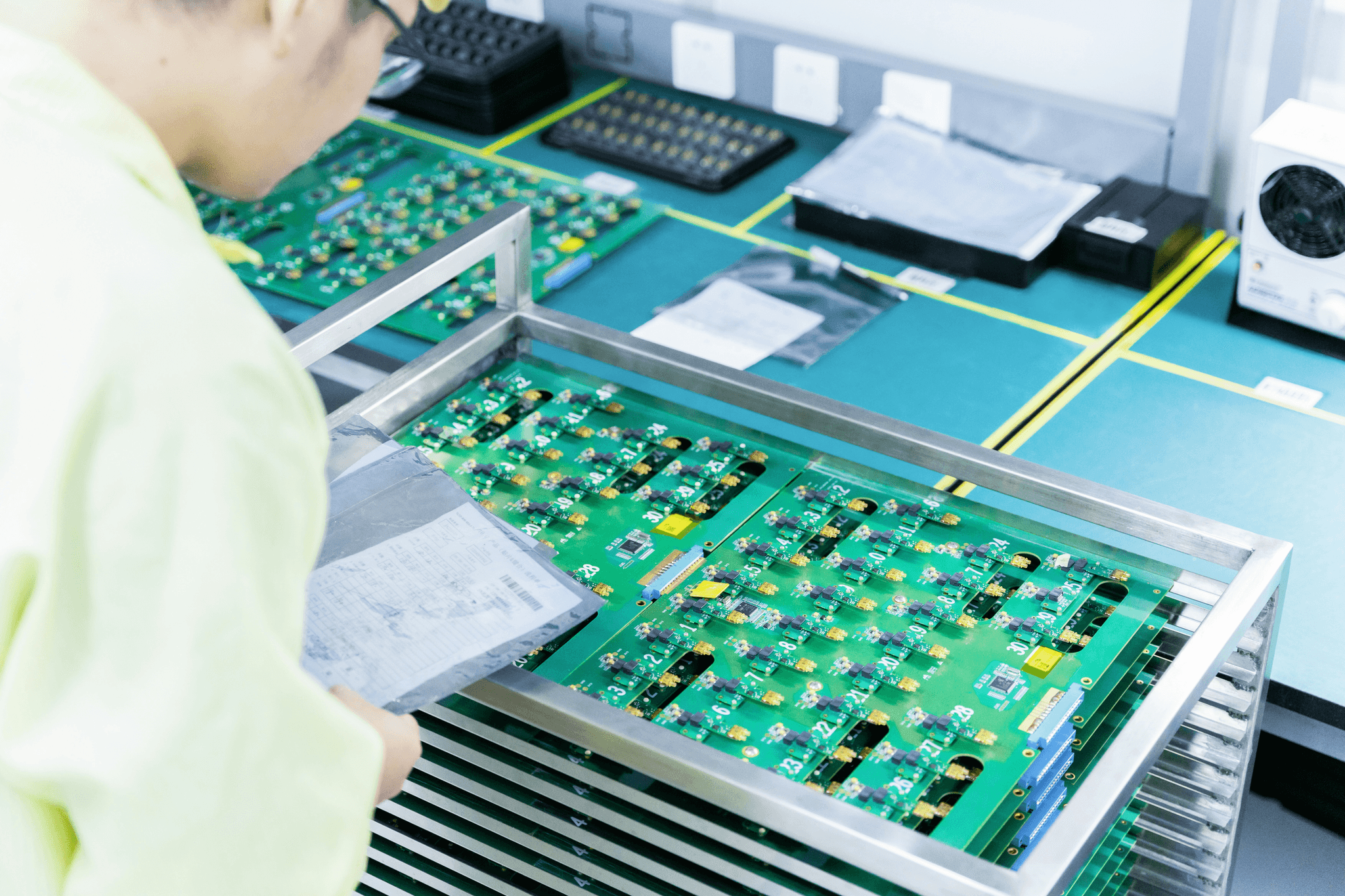

Case Studies of Successful Inspections

One standout example of effective quality inspection comes from a leading electronics manufacturer in China. This company implemented a rigorous QC quality control system that included multiple layers of inspections throughout the production process. As a result, they reduced defects by 30% within a year, showcasing how proactive quality checks can significantly enhance product reliability and customer satisfaction.

Another notable case involves a textile producer that faced challenges with inconsistent fabric quality. By adopting comprehensive quality control measures, including regular audits and third-party lab testing, they improved their final product's consistency and durability. This shift not only boosted their reputation but also led to increased orders from international clients who valued reliable quality control in China.

These examples illustrate that successful inspections aren't just about checking boxes; they're about creating a culture of continuous improvement within organizations focused on maintaining high standards in manufacturing.

Lessons Learned from Quality Failures

Quality failures can be costly, both financially and reputationally. A well-known incident involved a toy manufacturer whose products were recalled due to safety violations stemming from inadequate QC processes. This failure highlighted the critical need for robust quality inspections at every stage—something that many companies underestimate until it's too late.

Another cautionary tale comes from an automotive parts supplier that faced significant backlash after delivering faulty components due to poor quality checks in manufacturing. They learned the hard way that neglecting thorough audits could lead to disaster—not only affecting their bottom line but also endangering consumer safety. These lessons emphasize the necessity for ongoing vigilance and investment in comprehensive QC practices.

By analyzing these failures, businesses can better understand the potential pitfalls associated with lax attitudes toward quality control and take proactive steps to prevent similar issues.

Implementing Lessons in Your Manufacturing Process

To effectively implement lessons learned from both successes and failures, manufacturers should prioritize establishing clear protocols for quality control china-wide initiatives. Creating standardized procedures for inspections can help ensure consistency across all production lines while empowering employees to take ownership of their roles in maintaining high-quality standards.

Additionally, integrating technology into your QC processes can streamline operations and enhance accuracy during inspections. Utilizing software solutions for tracking defects or automating certain aspects of lab testing allows manufacturers to focus on critical areas needing attention without compromising overall efficiency.

Ultimately, fostering an organizational culture centered around continuous improvement will lead to stronger supply chains through enhanced collaboration among stakeholders focused on achieving top-notch quality control in manufacturing practices.

Conclusion

In the fast-paced world of manufacturing, especially in a powerhouse like China, understanding quality control is not just a luxury—it's a necessity. Quality checks in manufacturing ensure that products meet stringent standards, which is crucial for maintaining consumer trust and brand reputation. As we wrap up this discussion on quality control, let’s highlight some key takeaways and consider what the future holds.

Key Takeaways for Quality Control

Quality control in manufacturing encompasses a range of practices designed to ensure that products are safe, reliable, and meet customer expectations. Regular quality inspections not only help identify defects early but also foster continuous improvement within production processes. Remember, effective QC quality control isn't merely about checking boxes; it's about cultivating a culture of excellence from the ground up.

Future Trends in Quality Control in China

As technology continues to evolve, so too will the landscape of quality control china. Automation and AI-driven analytics are set to revolutionize how manufacturers approach quality inspections and audits, making them more efficient than ever before. Additionally, with increasing global scrutiny on sustainability practices, expect to see an emphasis on eco-friendly materials and processes as part of comprehensive quality checks in manufacturing.

Building Stronger Supply Chains through Quality Control

A robust approach to quality control can significantly strengthen supply chains across industries. By prioritizing consistent quality checks and thorough audits, manufacturers can mitigate risks associated with defects or recalls while enhancing overall operational efficiency. Ultimately, investing in effective QC practices fosters stronger partnerships with suppliers and customers alike—because when you prioritize quality control china style, everyone wins!