Introduction

In the rapidly evolving landscape of global trade, the significance of quality control in Asia cannot be overstated. As manufacturers strive to meet international standards, effective quality management becomes paramount in ensuring that products not only meet consumer expectations but also comply with regulatory requirements. This is where production monitoring and inspection services play a crucial role, acting as a bridge between manufacturers and buyers to guarantee product integrity.

Importance of Quality Control in Asia

Asia has emerged as a manufacturing powerhouse, producing a vast array of goods for markets worldwide. However, with this growth comes the challenge of maintaining high standards in quality control. Quality assurance inspectors are essential in this context, as they help identify potential issues during the manufacturing process, thereby fostering continuous quality improvement and enhancing overall production efficiency.

Overview of Production Monitoring Services

Production monitoring services encompass various activities aimed at overseeing and assessing manufacturing processes to ensure compliance with established quality standards. These services include pre-production inspections, during production monitoring techniques, and final random inspections that collectively contribute to robust quality management practices. By implementing these inspection services, businesses can minimize risks associated with defective products and strengthen their supply chains.

The Role of China Inspection Pro

China Inspection Pro stands out as a leading player in the realm of third-party inspection companies dedicated to maintaining consistent product quality throughout manufacturing and shipping processes. With a mission centered on delivering accurate and real-time inspection services, China Inspection Pro helps businesses navigate the complexities of global trade while building trust among stakeholders. Their expertise not only reduces risks but also enhances overall confidence in product delivery through effective quality control measures.

Understanding Quality Control in Manufacturing

In the realm of manufacturing, quality control is not just a buzzword; it's the backbone of successful production. Effective quality management ensures that products meet specified requirements and satisfy customer expectations, which is crucial for maintaining competitive advantage. As businesses increasingly rely on production monitoring & inspection services, understanding the key principles of quality control becomes essential for achieving operational excellence.

Key Principles of Quality Management

Quality management is built on several foundational principles that guide organizations toward delivering superior products consistently. First and foremost, customer focus is vital; understanding customer needs helps shape processes that enhance satisfaction and loyalty. Additionally, a commitment to continuous improvement fosters an environment where quality improvement initiatives can thrive, ensuring that all team members are engaged in enhancing product quality.

Another critical principle is evidence-based decision-making, which relies on data to inform strategies related to quality control in manufacturing. This approach minimizes guesswork and allows organizations to identify areas needing improvement more effectively. By integrating these principles into their operations, companies can leverage production monitoring & inspection services not just as a safety net but as a proactive strategy for maintaining high standards.

The Importance of Quality Assurance Inspectors

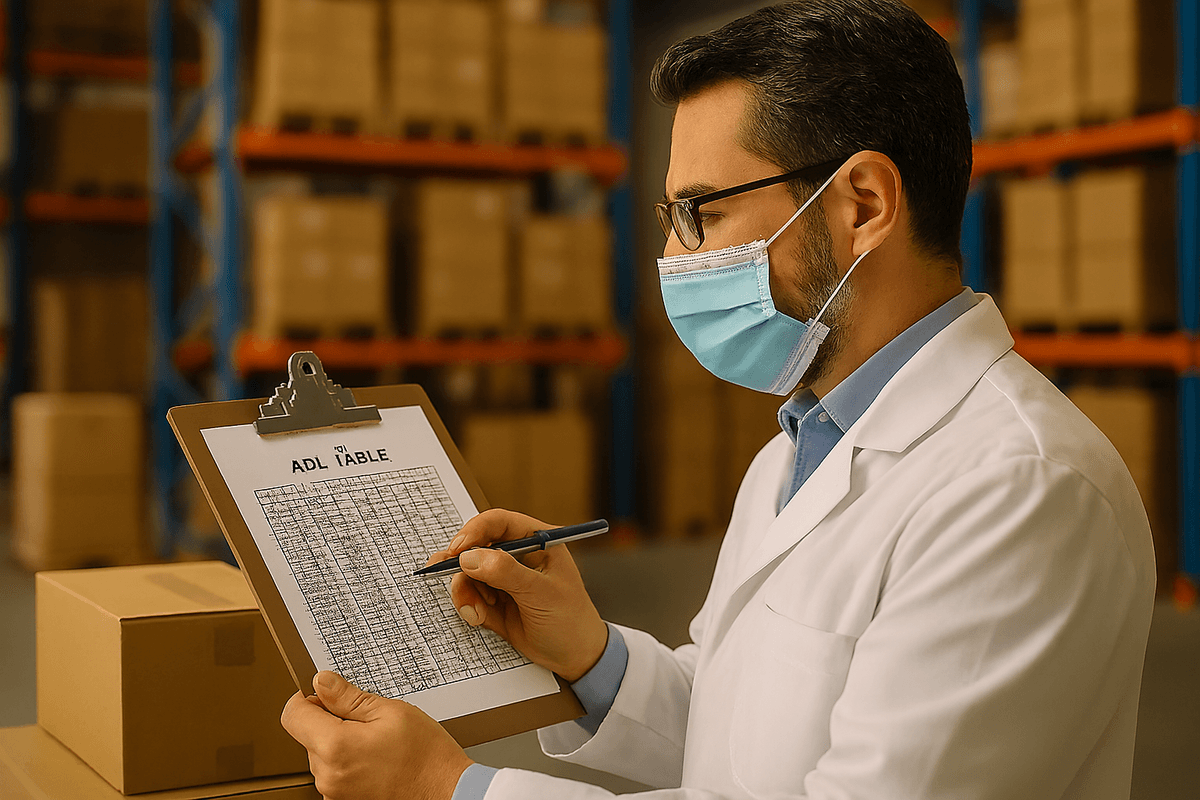

Quality assurance inspectors play a pivotal role in the manufacturing process by serving as the gatekeepers of product integrity. Their expertise ensures that every aspect of production aligns with predefined standards and regulations, reducing defects before they reach consumers. Without these dedicated professionals overseeing quality inspection processes, businesses risk costly recalls and damage to their reputation.

Moreover, quality assurance inspectors provide invaluable insights into potential areas for improvement within manufacturing operations. By analyzing trends and identifying recurring issues during inspections, they help companies implement effective solutions tailored to their unique challenges. Ultimately, investing in skilled inspectors translates into enhanced product reliability and customer trust—key components for long-term success in any industry.

Quality Improvement Techniques

To stay ahead in today’s competitive market landscape, manufacturers must adopt effective quality improvement techniques tailored to their specific needs. One popular method involves utilizing Six Sigma practices aimed at reducing variability and improving overall process efficiency through rigorous data analysis. This technique not only enhances product quality but also streamlines operations by minimizing waste.

Another approach involves implementing Total Quality Management (TQM), which fosters a culture of continuous improvement across all levels of an organization—from top management down to frontline workers involved in daily operations. TQM emphasizes teamwork and collaboration among employees while promoting accountability for maintaining high-quality standards throughout the production cycle.

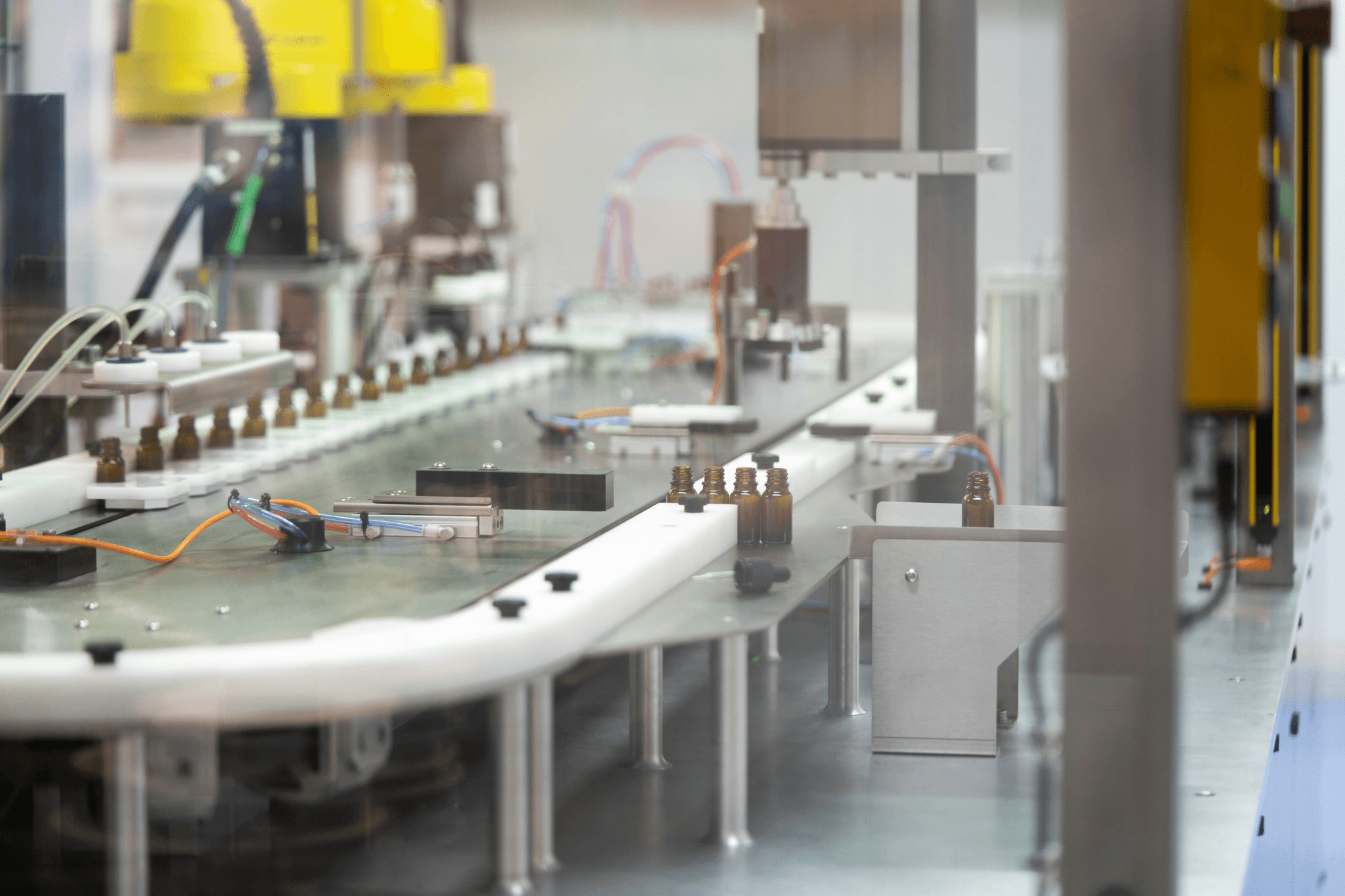

Finally, embracing technology innovations such as automated inspection tools can significantly elevate the effectiveness of production monitoring & inspection services within manufacturing environments. These advancements enable real-time tracking of product performance while providing actionable insights that drive ongoing improvements—ensuring manufacturers remain agile amid evolving market demands.

Types of Inspection Services Offered

In the realm of quality control in manufacturing, the right inspection services can make all the difference between success and costly setbacks. Companies like China Inspection Pro provide a comprehensive suite of production monitoring & inspection services tailored to meet diverse needs. Understanding the various types of inspections available is crucial for businesses aiming to enhance their quality management processes.

Pre-Production Inspection Benefits

Pre-production inspections are a proactive approach that can significantly mitigate risks associated with manufacturing defects. By identifying potential issues before production begins, companies can implement necessary adjustments, ensuring that quality standards are met from the outset. These early interventions not only save time and money but also enhance overall quality improvement efforts throughout the manufacturing process.

Quality assurance inspectors play a vital role during this phase by assessing raw materials, components, and initial samples against established specifications. Their expertise ensures that potential problems are addressed before they escalate into larger issues down the line. With robust pre-production inspections in place, businesses can foster stronger relationships with suppliers and build trust in their production monitoring & inspection services.

During Production Monitoring Techniques

During production monitoring techniques focus on maintaining consistent quality throughout the manufacturing process itself. This ongoing oversight allows quality assurance inspectors to identify deviations from standards as they occur, enabling immediate corrective actions to be taken before products leave the factory floor. Such vigilance is essential for maintaining high-quality output and ensuring compliance with regulatory requirements.

These techniques often involve real-time reporting systems that provide transparency into production workflows and highlight any areas needing attention. Additionally, regular audits during this phase help reinforce accountability among manufacturers while promoting a culture of continuous improvement within their operations. By leveraging effective during-production monitoring strategies, companies can optimize their overall quality management practices.

Final Random Inspection Procedures

Final random inspection procedures serve as a critical checkpoint before products are shipped out to customers or retailers. This stage involves selecting random samples from finished goods and conducting thorough examinations to ensure they meet predefined quality criteria and specifications set forth during earlier phases of production monitoring & inspection services. These checks help catch any remaining defects or inconsistencies that may have slipped through previous inspections.

The importance of final random inspections cannot be overstated; they act as a safety net for businesses by validating product integrity just before it reaches consumers' hands. Moreover, these procedures contribute significantly to building consumer trust in brands by assuring them that only high-quality products make it to market. Ultimately, implementing effective final random inspection processes is essential for achieving excellence in quality control in manufacturing.

The Impact of Cultural Differences

Cultural differences play a significant role in quality control and inspection services, particularly in diverse regions like Asia. Understanding these cultural nuances can greatly enhance the effectiveness of quality management processes. When companies engage with local manufacturers, being culturally sensitive can lead to smoother operations and better outcomes in production monitoring.

Cultural Sensitivity in Quality Inspection

Cultural sensitivity is essential for effective quality inspection, particularly when dealing with various manufacturing practices across Asia. Different cultures may have unique approaches to quality control and varying expectations regarding product standards. By respecting local customs and practices, companies can foster better relationships with their partners while ensuring that quality improvement initiatives resonate more deeply within the manufacturing environment.

Moreover, cultural sensitivity helps avoid misunderstandings that could jeopardize the integrity of quality management systems. Quality assurance inspectors who are aware of these differences are more likely to gain cooperation from local teams, leading to enhanced communication and collaboration during inspections. Ultimately, this understanding contributes to a more robust approach to maintaining high standards in production monitoring & inspection services.

Navigating Language Barriers

Language barriers can pose significant challenges in the realm of quality control in manufacturing, especially when working with international partners. Miscommunication due to language differences can lead to errors during inspections or misinterpretations of quality requirements. Therefore, investing time into finding bilingual staff or professional translation services is vital for effective communication throughout the inspection process.

In addition to improving communication, addressing language barriers fosters a sense of inclusivity among all stakeholders involved in production monitoring efforts. Quality assurance inspectors who take the time to learn key phrases or terminology relevant to their counterparts’ languages demonstrate respect and commitment toward collaborative success. This approach not only aids clarity but also builds rapport between teams focused on achieving shared goals related to product quality.

Building Trust with Local Manufacturers

Building trust with local manufacturers is crucial for successful partnerships in the field of quality management and inspection services. Trust serves as a foundation for open dialogue about expectations regarding product quality and operational standards during inspections. By demonstrating reliability through consistent performance—like those offered by China Inspection Pro—companies can establish long-term relationships that enhance overall supply chain efficiency.

Moreover, fostering trust encourages transparency among all parties involved in production monitoring processes; this transparency ultimately leads to improved collaboration on addressing potential issues related to product defects or delays. As trust grows over time through effective communication and cultural sensitivity, manufacturers become more willing participants in implementing necessary changes for continuous improvement efforts within their operations.

By recognizing the impact of cultural differences on these dynamics, businesses can navigate complexities effectively while ensuring adherence to rigorous standards for quality control across diverse markets.

Choosing the Right Inspection Partner

Selecting an appropriate inspection partner is crucial for businesses aiming to uphold quality control in manufacturing. The right partner not only enhances product quality but also ensures compliance with international standards, ultimately fostering trust in your supply chain. With numerous options available, it's vital to identify a service provider that aligns with your specific needs and values.

What to Look for in Quality Control Services

When searching for quality control services, consider the company’s experience and expertise in production monitoring & inspection services. A seasoned provider should have a proven track record of successful quality management practices and familiarity with various industries. Additionally, look for a comprehensive range of services including pre-production inspections, during production monitoring techniques, and final random inspections to ensure every stage of your manufacturing process is covered.

Another critical factor is the presence of qualified quality assurance inspectors who can effectively identify issues before they escalate into costly problems. These professionals should be well-versed in quality improvement techniques and possess strong communication skills to relay findings clearly. Ultimately, selecting a partner that prioritizes transparency and collaboration will lead to better outcomes for your business.

China Inspection Pro's Unique Offerings

China Inspection Pro stands out among inspection service providers due to its commitment to delivering accurate and real-time production monitoring & inspection services tailored to client needs. With a team of highly skilled quality assurance inspectors, the company excels at identifying potential risks while ensuring that products meet stringent quality standards throughout the manufacturing process. Their unique offerings include customized inspection plans that cater specifically to clients' requirements while utilizing advanced technology innovations.

Moreover, China Inspection Pro emphasizes building strong relationships with local manufacturers by navigating cultural differences effectively. This approach not only fosters trust but also enhances communication between all parties involved in the supply chain process—an essential aspect of successful quality management practices. By choosing China Inspection Pro as your inspection partner, you are investing in a service that prioritizes both product excellence and customer satisfaction.

Case Studies of Successful Partnerships

Numerous case studies illustrate how effective partnerships with China Inspection Pro have transformed businesses through enhanced quality control measures. For instance, one prominent electronics manufacturer faced significant challenges related to product defects during shipping due to inadequate oversight during production phases. By engaging China Inspection Pro’s comprehensive inspection services—including pre-production assessments and ongoing monitoring—they significantly reduced defect rates by 30% within six months.

Another case study involves a clothing brand struggling with inconsistent fabric quality from various suppliers across Asia; they turned to China Inspection Pro for expert guidance on establishing rigorous quality management protocols tailored specifically for their needs. As a result, they experienced improved supplier compliance rates while decreasing returns related to poor-quality items dramatically—demonstrating how effective partnerships can lead directly toward achieving desired business outcomes through reliable production monitoring & inspection services.

Trends in Quality Control and Inspection

In the fast-paced world of manufacturing, the landscape of quality control is continuously evolving. Companies are increasingly recognizing the importance of integrating advanced technology into their production monitoring and inspection services to enhance quality management. As organizations strive to meet consumer expectations for high-quality products, staying informed about these trends becomes essential for maintaining a competitive edge.

Technology Innovations in Quality Management

The integration of technology into quality management processes has transformed traditional methods of quality inspection. Tools such as artificial intelligence (AI), machine learning, and data analytics are now being utilized to predict potential quality issues before they occur, allowing for proactive measures to be taken. Companies like China Inspection Pro leverage these innovations to provide real-time insights during production monitoring, ensuring that quality control standards are met consistently.

Moreover, mobile applications and cloud-based platforms have made it easier for businesses to track their production processes remotely. This level of accessibility allows companies to collaborate more effectively with quality assurance inspectors, making adjustments on-the-fly based on instant feedback from inspections. As technology continues to advance, we can expect even more sophisticated solutions that further streamline the quality improvement process.

The Move Towards Automation

Automation is rapidly becoming a cornerstone of modern manufacturing practices, particularly in the realm of quality control in manufacturing. Automated inspection systems can conduct thorough evaluations at speeds far surpassing human capabilities while maintaining a high level of accuracy. This shift not only reduces labor costs but also minimizes the risk of human error during critical stages of production monitoring and inspection services.

Furthermore, automation facilitates continuous monitoring throughout the production cycle, allowing for immediate intervention if any deviations from established quality standards are detected. By employing automated solutions alongside skilled quality assurance inspectors, companies can ensure a comprehensive approach to maintaining product integrity and consistency across all manufacturing stages. The future indeed looks bright as more manufacturers embrace automation as part of their overall strategy for achieving exceptional product quality.

Sustainable Practices in Quality Control

As environmental concerns take center stage globally, sustainable practices in quality control have gained significant momentum within the industry. Manufacturers are increasingly adopting eco-friendly materials and processes while implementing rigorous standards for waste reduction during production monitoring activities. This commitment not only enhances product integrity but also aligns with consumer preferences for environmentally responsible brands.

Moreover, sustainable practices extend beyond just materials; they encompass energy-efficient machinery and optimized workflows that minimize resource consumption while maximizing output efficiency in quality management systems. Companies like China Inspection Pro advocate for sustainable approaches by incorporating eco-conscious criteria into their inspection services—ensuring that manufacturers uphold both ethical standards and high-quality benchmarks simultaneously.

By embracing these trends—technology innovations, automation advancements, and sustainability—manufacturers position themselves not just as producers but as responsible partners committed to delivering superior products while protecting our planet's future.

Conclusion

In conclusion, the significance of quality control in Asia cannot be overstated. With the rapid growth of manufacturing and global trade, businesses must prioritize quality management to ensure their products meet international standards. By leveraging production monitoring & inspection services, companies can enhance product quality and build trust with their customers.

Enhancing Product Quality and Trust

Quality inspection plays a pivotal role in enhancing product quality and fostering trust between manufacturers and consumers. When businesses partner with experienced quality assurance inspectors, they gain insights into potential issues before they escalate into costly problems. China Inspection Pro exemplifies this commitment by providing real-time inspection services that not only improve quality but also instill confidence in global trade relationships.

Building Stronger Supply Chains

A robust supply chain is built on the foundation of effective quality control in manufacturing. By implementing rigorous production monitoring & inspection services, companies can identify inefficiencies and ensure that each link in the supply chain adheres to high-quality standards. This proactive approach to quality management not only strengthens partnerships with local manufacturers but also positions businesses for long-term success.

The Future of Quality Control in Asia

Looking ahead, the future of quality control in Asia will be shaped by technological innovations and a growing emphasis on sustainable practices. As automation becomes more prevalent, organizations will need to adapt their strategies for quality improvement while maintaining rigorous standards through effective inspection services. Companies like China Inspection Pro are at the forefront of this evolution, ensuring that as industries change, so too does their commitment to excellence in production monitoring & inspection services.