Introduction

In today's competitive market, the significance of effective QC Product Inspections cannot be overstated. These inspections serve as the backbone of quality assurance, ensuring that products meet established standards before reaching consumers. When executed properly, they not only enhance product reliability but also build customer trust and satisfaction.

Importance of Effective QC Product Inspections

Effective QC Product Inspections are crucial for identifying defects early in the production process, which can save companies both time and money. By implementing a robust Quality control inspection checklist, businesses can systematically assess their products against industry standards and customer expectations. This proactive approach minimizes the risk of recalls and enhances overall brand reputation.

Strategies for Consistent Quality Control

To achieve consistent quality control, organizations should develop a comprehensive strategy that includes regular training and adherence to established protocols. Utilizing tools such as a detailed Quality control inspection checklist helps maintain uniformity across inspections and ensures every aspect of the product is evaluated thoroughly. Additionally, defining a clear Line quality control job description for team members fosters accountability and encourages a culture of quality within the organization.

Common Pitfalls in Quality Control Processes

Despite best efforts, many companies fall prey to common pitfalls in their quality control processes that can undermine their inspection efforts. A lack of alignment with industry standards can lead to inconsistent results during QC Product Inspections, resulting in costly errors down the line. Moreover, neglecting to update inspection checklists regularly may cause teams to overlook critical evaluation criteria, ultimately compromising product integrity.

Defining Quality Control Inspection Goals

Establishing clear goals is essential for effective QC Product Inspections, ensuring that every inspection aligns with overarching quality standards. By defining specific objectives, organizations can streamline their processes and enhance product reliability. This section will delve into the importance of setting quality objectives, aligning with industry standards, and assessing customer expectations.

Setting Specific Quality Objectives

When it comes to QC Product Inspections, specificity is key. Setting concrete quality objectives helps teams focus their efforts on measurable outcomes, making it easier to track progress over time. For instance, a well-crafted Quality Control inspection checklist might include targets like reducing defect rates by a certain percentage or achieving compliance with specific safety regulations.

These objectives should be realistic yet challenging enough to inspire continuous improvement within the team. By establishing benchmarks that are both quantifiable and attainable, organizations can ensure their inspections yield meaningful results. Remember: vague goals lead to vague outcomes; clarity is the name of the game in any Line quality control job description.

Aligning with Industry Standards

Aligning your QC Product Inspections with industry standards is not just good practice; it’s often a regulatory requirement. Each sector—from manufacturing to food safety—has established guidelines that dictate acceptable quality levels and inspection procedures. By adhering to these standards, companies can not only ensure compliance but also boost consumer confidence in their products.

Incorporating these benchmarks into your Quality Control inspection checklist ensures that inspections are comprehensive and relevant. Regularly reviewing industry standards allows organizations to stay ahead of changes and adapt their processes accordingly. Ultimately, alignment with recognized standards enhances credibility and positions a company as a leader in its field.

Assessing Customer Expectations

Understanding customer expectations is crucial when defining goals for QC Product Inspections. After all, what good are high-quality products if they don’t meet the needs of your customers? Engaging directly with clients through surveys or feedback sessions can provide invaluable insights into what they truly value.

Incorporating these insights into your Quality Control inspection checklist allows teams to prioritize aspects that matter most to customers—whether it's durability, design features, or environmental sustainability. Moreover, aligning your inspection goals with customer expectations fosters loyalty and encourages repeat business; happy customers often become brand advocates! In crafting effective Line quality control job descriptions, it’s vital for team members to understand how their roles impact overall customer satisfaction.

Crafting a Quality Control Inspection Checklist

Creating a robust quality control inspection checklist is essential for ensuring that QC product inspections are thorough and effective. A well-structured checklist serves as a roadmap, guiding inspectors through the critical elements that need assessment, thus minimizing the risk of oversight. With the right checklist in hand, teams can consistently meet quality standards and enhance overall product reliability.

Essential Items for Effective Inspections

When developing a quality control inspection checklist, it’s crucial to include essential items that address all aspects of product quality. This includes specifications such as dimensions, materials used, functionality, and aesthetic considerations—all vital components in QC product inspections. Additionally, incorporating checks for compliance with relevant regulations and standards ensures that products not only meet internal benchmarks but also align with industry requirements.

Moreover, it's important to tailor the checklist to specific products or projects; for example, a quality control inspection checklist used by the Housing Authority might focus on different criteria than one used in manufacturing electronics. Including categories for potential defects or issues can guide inspectors in identifying common problems quickly and efficiently. Remember, an effective checklist should be comprehensive yet concise to maintain focus during inspections.

Utilizing Technology in Checklists

In today’s digital age, leveraging technology can significantly enhance the effectiveness of your quality control inspection checklist. Mobile applications and software solutions allow inspectors to access checklists on-the-go while providing real-time data collection capabilities during QC product inspections. This not only streamlines the process but also facilitates immediate reporting and analysis of findings.

Integrating barcode scanning or RFID technology into your checklists can further improve accuracy by automating data entry processes and reducing human error during inspections. Additionally, cloud-based platforms enable teams to collaborate seamlessly across different locations—ideal for organizations managing multiple line quality control job descriptions across various sites. By adopting these technological tools, organizations can ensure their checklists remain relevant and efficient.

Importance of Regular Updates

Regularly updating your quality control inspection checklist is vital to maintaining its effectiveness over time. As industry standards evolve or new technologies emerge, it’s essential to revise checklists accordingly so they remain aligned with current best practices in QC product inspections. Failure to update could result in outdated criteria being applied during inspections—leading to potential oversights or non-compliance issues.

Furthermore, incorporating feedback from inspectors who use these checklists daily can provide valuable insights into areas needing improvement or clarification within the list itself. Establishing a routine review process ensures that your inspection protocols stay sharp and relevant while adapting to changing market demands or customer expectations effectively. In this way, regular updates not only bolster compliance but also foster continuous improvement within your organization’s quality assurance efforts.

Implementing Line Quality Control Job Descriptions

In the realm of QC Product Inspections, clarity is key. Establishing well-defined line quality control job descriptions ensures that every team member knows their role in maintaining product integrity. This not only streamlines the inspection process but also fosters a culture of accountability and excellence within the organization.

Defining Roles and Responsibilities

To kick things off, it’s essential to outline specific roles and responsibilities for each position involved in quality control inspections. Whether it’s a quality assurance inspector or a team leader, everyone should understand their part in executing the quality control inspection checklist effectively. When roles are clearly defined, it minimizes overlaps and gaps in responsibilities, leading to smoother operations and enhanced outcomes.

Moreover, including responsibilities that align with industry standards can elevate your QC Product Inspections to new heights. For instance, inspectors should be tasked with not just identifying defects but also documenting findings accurately for future reference. This level of detail is crucial when assessing compliance with regulations set forth by entities such as the Quality Control Inspection Housing Authority.

Training for Quality Assurance Teams

Training is where the magic happens! An effective training program equips your quality assurance teams with the skills necessary to execute inspections proficiently using the established line quality control job description. Regular workshops and hands-on training sessions can help reinforce best practices outlined in your quality control inspection checklist while keeping everyone updated on new technologies or methodologies.

Additionally, fostering an environment of continuous learning encourages team members to share insights gained from real-world experiences during QC Product Inspections. This collaboration can lead to innovative solutions and improved processes that benefit everyone involved in production and inspection alike. Remember, a well-trained team is not just an asset; they are your frontline defenders against defects!

Continuous Improvement Practices

Continuous improvement isn’t just a buzzword; it's a vital practice for enhancing your QC Product Inspections over time. Implementing feedback loops where inspectors can share observations about common issues or challenges leads to actionable insights that refine both processes and checklists used during inspections. By regularly revisiting these practices, you ensure that your approach remains relevant amidst evolving industry standards.

Moreover, incorporating metrics into your line quality control job descriptions allows you to track performance over time effectively. By analyzing this data regularly, teams can identify trends or areas needing improvement—transforming potential pitfalls into opportunities for growth! Continuous improvement practices don’t just enhance product quality; they cultivate an organizational mindset geared toward excellence.

Utilizing Third-Party Inspection Services

In the realm of quality control, leveraging third-party inspection services can significantly bolster your QC Product Inspections. These independent entities bring a fresh perspective, ensuring that your products meet stringent quality standards without bias. By outsourcing inspections, companies can focus on their core competencies while maintaining high-quality outputs.

Benefits of Choosing China Inspection Pro

Choosing China Inspection Pro offers a multitude of benefits for businesses seeking reliable QC Product Inspections. Their expertise in navigating the complexities of international manufacturing ensures that products are inspected thoroughly and efficiently. Moreover, partnering with such reputable services provides peace of mind, knowing that inspections adhere to established quality control inspection checklists tailored to industry standards.

With a dedicated team familiar with various sectors, China Inspection Pro enhances the accuracy and reliability of inspections. Their inspectors are not only well-trained but also equipped with advanced technology to identify potential issues early in the production process. This proactive approach minimizes costly reworks or returns, ultimately saving time and money for manufacturers.

How Third-Party Inspections Enhance Quality

Third-party inspections enhance quality by providing an objective assessment that internal teams might overlook due to familiarity or bias. With their specialized knowledge and experience, these inspectors utilize comprehensive quality control inspection checklists designed for specific industries or products. This meticulous approach helps ensure compliance with regulatory requirements and customer expectations.

Moreover, employing third-party services fosters transparency in the production process, as they provide unbiased reports detailing product performance against established benchmarks. This not only builds trust between manufacturers and clients but also encourages adherence to best practices outlined in line quality control job descriptions across various roles within an organization.

Additionally, third-party inspectors often identify areas for improvement that internal teams may miss due to routine processes becoming stale over time. By incorporating their insights into continuous improvement strategies, organizations can elevate their overall product quality and operational efficiency.

Case Studies of Successful Inspections

Examining case studies reveals how effective QC Product Inspections through third-party services have transformed companies' operations across different sectors. For instance, a leading electronics manufacturer faced challenges meeting safety regulations due to inconsistent internal inspections; however, after engaging China Inspection Pro for regular assessments based on a robust quality control inspection checklist, they achieved compliance swiftly.

Another example involves a textile company struggling with defects in fabric production that led to high return rates from retailers. By implementing third-party inspections focused on identifying flaws early in the manufacturing process—using detailed line quality control job descriptions—they significantly reduced defects by 30%, resulting in improved customer satisfaction and reduced costs associated with returns.

These success stories underscore the value of integrating third-party inspection services into your QC strategy as part of an ongoing commitment to excellence in product delivery.

Analyzing Inspection Data for Continuous Improvement

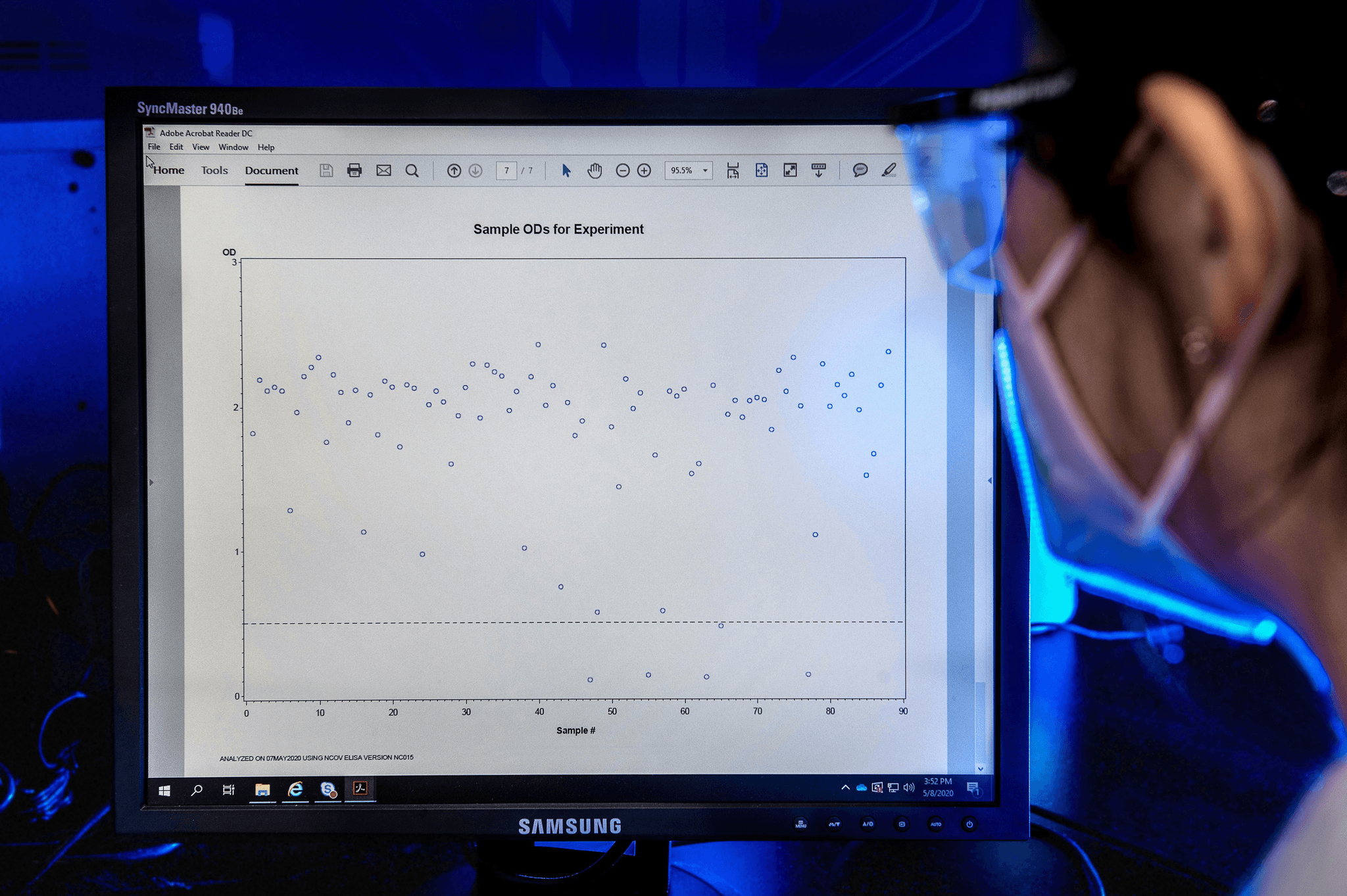

In the realm of QC Product Inspections, data analysis is the cornerstone of continuous improvement. By meticulously collecting and interpreting inspection results, organizations can identify trends, spot defects, and ultimately enhance their quality control processes. This not only leads to better products but also fosters a culture of accountability and excellence within teams.

Collecting and Interpreting Inspection Results

To kick off the analysis process, it’s crucial to establish a robust framework for collecting inspection results. This involves utilizing a comprehensive Quality Control inspection checklist that captures all relevant data points during inspections. Once gathered, interpreting these results requires keen analytical skills; trends should be identified and anomalies investigated to ensure that any underlying issues are addressed promptly.

Moreover, integrating technology can streamline this collection process, making it easier to compile vast amounts of data efficiently. For instance, digital tools can automate data entry from QC Product Inspections, reducing human error and improving accuracy in interpretation. The ultimate goal is to transform raw data into actionable insights that drive quality enhancements across production lines.

Leveraging Data for Quality Enhancements

Once you have a treasure trove of analyzed inspection data at your fingertips, leveraging this information becomes paramount for quality enhancements. Organizations can use statistical methods to pinpoint recurring issues or areas needing improvement in their processes—think of it as finding the weak links in your production chain. By addressing these weaknesses through targeted interventions or adjustments in the line quality control job description, businesses can significantly elevate their product standards.

Additionally, fostering a feedback loop where insights from inspections inform future practices ensures that improvements are not just one-off fixes but part of an ongoing commitment to quality control excellence. Engaging with team members during this phase encourages ownership and accountability—after all, who better understands potential pitfalls than those on the front lines? Ultimately, leveraging data effectively transforms QC Product Inspections from mere checkboxes into powerful tools for continuous growth.

Communicating Findings to Stakeholders

Effective communication is key when it comes to sharing findings from your analysis with stakeholders—whether they are internal teams or external partners like the Quality Control inspection Housing Authority. Crafting clear reports that outline key insights from QC Product Inspections ensures everyone involved understands what’s working well and what needs attention moving forward. Visual aids such as charts or graphs can help distill complex information into easily digestible formats.

Furthermore, regular updates on inspection results foster transparency and build trust among stakeholders; they appreciate being kept in the loop about how products measure up against established standards or customer expectations. When stakeholders see actionable insights being implemented based on real data from inspections—such as adjustments made in line quality control job descriptions—they’re more likely to support ongoing initiatives aimed at enhancing product quality over time.

In conclusion, analyzing inspection data isn't just about crunching numbers; it's about creating a narrative around continuous improvement that resonates with everyone involved in your production journey.

Conclusion

Quality control is not just a checkbox on a to-do list; it’s the backbone of any successful production process. Effective QC Product Inspections ensure that products meet the required standards and customer expectations, ultimately leading to enhanced satisfaction and loyalty. By implementing best practices, organizations can significantly reduce defects and improve their overall quality management systems.

Best Practices for Effective QC Inspections

To achieve the highest standards in QC Product Inspections, creating a thorough Quality Control inspection checklist is essential. This checklist should encompass all critical aspects of the product, from materials used to final packaging, ensuring nothing slips through the cracks. Regularly updating this checklist based on industry trends and feedback will keep your inspections relevant and effective.

Another best practice involves defining clear roles within your team through a well-structured line quality control job description. Each member should understand their responsibilities in maintaining quality throughout the production process, which fosters accountability and enhances performance. Training programs tailored to these roles can further equip teams with the necessary skills to conduct effective inspections.

Lastly, embracing technology can streamline QC processes dramatically. Utilizing software tools for data collection during inspections allows for real-time analysis and quicker decision-making. These innovations not only boost efficiency but also enhance the accuracy of your QC Product Inspections.

Long-Term Benefits of Quality Control

Investing in robust quality control measures yields long-term benefits that extend beyond immediate cost savings. Consistent QC Product Inspections build a reputation for reliability among customers, translating into increased brand loyalty and market share over time. Additionally, by adhering to a comprehensive Quality Control inspection checklist, businesses can minimize recalls and warranty claims that often erode profit margins.

Moreover, aligning with industry standards during inspections ensures compliance with regulations that protect consumers while enhancing product credibility in competitive markets. Companies that prioritize quality find themselves better positioned against competitors who may overlook these crucial processes. Ultimately, this commitment results in stronger financial performance and sustainable growth.

Lastly, fostering continuous improvement within your organization cultivates an environment where innovation thrives alongside quality assurance efforts. By regularly analyzing inspection data collected from both internal reviews and external audits like those offered by third-party services such as China Inspection Pro, companies can identify areas for enhancement efficiently.

Preparing for Future Quality Challenges

As industries evolve rapidly due to technological advancements and shifting consumer expectations, preparing for future challenges becomes paramount in maintaining high-quality standards across all operations. Regular updates to your Quality Control inspection checklist are vital as they help adapt to new regulations or emerging issues relevant to your market segment—ensuring ongoing compliance without compromising product integrity.

Furthermore, staying ahead means investing in training programs focused on emerging technologies related to line quality control job descriptions within your organization’s framework; this equips employees with skills necessary for navigating future complexities effectively. Continuous professional development fosters resilience against potential disruptions while enhancing overall team performance.

Finally, proactive communication with stakeholders about inspection findings creates transparency that builds trust over time—an invaluable asset when facing unforeseen challenges down the road! In conclusion, by prioritizing effective QC Product Inspections today—alongside embracing innovation—you’re setting up not just products but also your business for enduring success tomorrow!