Introduction

In today's global marketplace, China Factory Audits have become a vital tool for businesses looking to ensure compliance and maintain quality standards in their supply chains. As companies increasingly rely on overseas manufacturing, understanding the importance of these audits is paramount. A comprehensive compliance audit not only safeguards product integrity but also enhances brand reputation and customer trust.

Importance of China Factory Audits

China Factory Audits serve as a critical checkpoint for companies aiming to verify that their suppliers adhere to industry regulations and internal quality standards. These audits help identify potential risks in the supply chain, ensuring that businesses can mitigate issues before they escalate into costly problems. By investing in an audit company with expertise in this area, organizations can gain peace of mind knowing that their products are manufactured under compliant conditions.

Key Benefits of Compliance and Audit

Engaging in a thorough compliance audit provides several key benefits that extend beyond mere regulatory adherence. First and foremost, it fosters a culture of accountability among suppliers, encouraging them to maintain high-quality production practices. Furthermore, consistent audits lead to improved operational efficiencies and reduced costs over time—turning compliance & audit into a strategic advantage rather than just a necessity.

Understanding the Audit Process

The audit process involves several stages designed to evaluate supplier capabilities comprehensively. It begins with preparing for the audit by gathering necessary documentation and aligning expectations between the buyer and supplier. Following this preparation, the on-site inspection takes place where auditors assess various aspects of operations before concluding with post-audit reporting that highlights findings and actionable insights—crucial steps for any organization committed to quality and audit excellence.

What is a China Factory Audit?

China Factory Audits are essential evaluations conducted to ensure that manufacturing facilities meet specific compliance and quality standards. These audits play a crucial role in enhancing supply chain transparency and reliability, allowing businesses to assess potential risks associated with their suppliers. Understanding the audit process not only helps in maintaining product quality but also fosters trust between buyers and manufacturers.

Definition and Purpose

A China Factory Audit serves as a systematic review of a factory's operations, focusing on compliance with industry regulations, safety standards, and operational efficiency. The primary purpose of these audits is to identify potential risks, verify adherence to contractual obligations, and ensure that products meet quality expectations before they reach the market. By conducting a compliance audit, companies can safeguard their reputation while ensuring that their suppliers operate ethically and effectively.

Types of Factory Audits

There are several types of China Factory Audits tailored to different needs and objectives within the audit process. Compliance audits focus on regulatory requirements, while quality audits assess the effectiveness of quality control processes in place at the factory. Other types include social audits that evaluate labor practices and environmental audits aimed at sustainability efforts—each providing unique insights into various aspects of factory operations.

Why Choose an Audit Company

Choosing an audit company is vital for ensuring a thorough evaluation of your supplier's capabilities through professional expertise in the audit process. An experienced audit company brings specialized knowledge about compliance & audit standards relevant to your industry while leveraging established methodologies for accurate assessments. By partnering with an expert firm like China Inspection Pro, businesses can transform complex findings into actionable insights that improve overall product quality and supplier performance.

[Image description=an auditor reviewing documents at a manufacturing facility, workers operating machinery in background, checklist on table showing compliance criteria, bright lighting emphasizing cleanliness], Image name=auditor_factory_review_2023, Alt tag=China Factory Audits ensuring compliance through thorough inspections

The Compliance Audit Journey

Navigating the world of China Factory Audits can seem daunting, but understanding the compliance audit journey simplifies the process significantly. By breaking it down into three main phases—preparation, on-site experience, and post-audit reporting—you can effectively manage your audit and compliance efforts. This structured approach not only enhances your understanding of the audit process but also maximizes the benefits derived from it.

Preparing for the Audit

Preparation is key when it comes to a successful compliance audit. Before you even think about auditing a company, ensure that all necessary documentation is in order; this includes quality control records, financial statements, and previous audit reports. Engaging with an experienced audit company like China Inspection Pro can streamline this phase; they provide guidance on what to expect during the audit and help identify areas that may need special attention.

Furthermore, communicate openly with your suppliers about what will be required during the China Factory Audits. This transparency fosters a culture of compliance & audit readiness and sets clear expectations for everyone involved. Remember, a well-prepared supplier can significantly enhance the overall quality and audit experience.

The On-Site Audit Experience

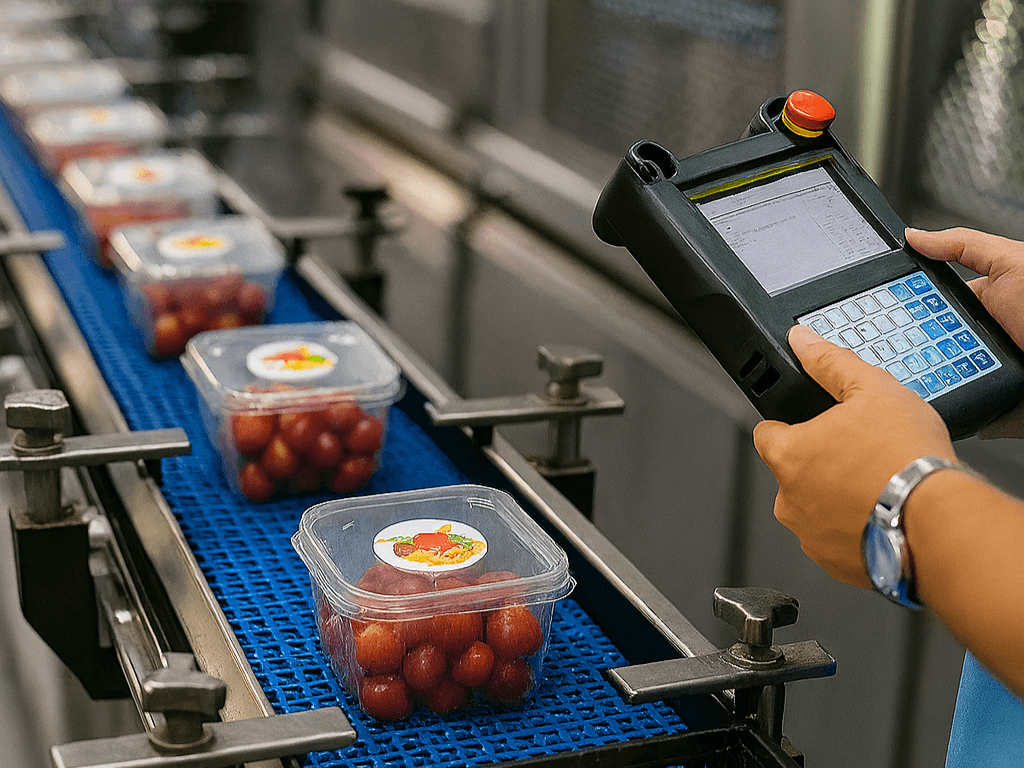

The on-site audit is where all your preparation pays off—it’s where theory meets practice in real-time! During this phase of the compliance audit, auditors will assess various aspects of factory operations including quality control processes and infrastructure capabilities. An effective audit company will not only evaluate these factors but also engage with staff at different levels to gauge their understanding of quality standards.

While conducting China Factory Audits on-site, auditors utilize checklists based on established criteria to ensure thorough evaluations are made across all relevant areas. This hands-on approach allows for immediate feedback and interaction between auditors and factory personnel which enriches both sides’ understanding of compliance requirements. It’s essential that any findings are documented meticulously as they will serve as a foundation for post-audit reporting.

Post-Audit Reporting

Once the dust settles after an intense day (or days) of auditing, it’s time for post-audit reporting—a crucial step in the compliance & audit process that should never be overlooked! Here is where China Inspection Pro shines by turning findings into actionable insights tailored specifically for your business needs. A comprehensive report should outline strengths and weaknesses identified during the factory audits while providing recommendations for improvement.

These reports are not just paperwork; they serve as blueprints guiding future actions towards enhancing supplier capabilities and ensuring ongoing compliance with industry standards. It's critical to follow up on these recommendations promptly—neglecting them could lead to recurring issues in future audits or worse yet, regulatory challenges down the line! Ultimately, effective post-audit reporting transforms findings into strategic opportunities that elevate overall quality management practices.

Key Factors to Evaluate Supplier Capabilities

When it comes to China Factory Audits, evaluating a supplier's capabilities is essential for ensuring compliance and audit effectiveness. Suppliers are the backbone of your supply chain, and understanding their strengths and weaknesses can significantly impact product quality and business success. Thorough assessments help you make informed decisions that align with your audit process goals.

Assessing Quality Control Processes

Quality control processes are the heart of any manufacturing operation, especially in China Factory Audits. A robust quality management system ensures that products meet specified standards consistently, which is crucial during compliance audits. By closely examining these processes, an audit company can identify potential risks and areas for improvement that may affect overall product quality.

During the assessment phase, it's vital to look at how suppliers monitor their production lines, conduct inspections, and handle non-conformance issues. Effective quality control not only enhances product reliability but also contributes to a smoother audit process by minimizing surprises during on-site evaluations. Ultimately, strong quality control processes lead to better compliance & audit outcomes.

Supplier Financial Health

Evaluating a supplier's financial health is another critical factor in assessing their capabilities during China Factory Audits. A financially stable supplier is more likely to invest in necessary improvements and maintain high-quality standards throughout the production process. Understanding their financial position helps mitigate risks associated with working with companies that may struggle to fulfill orders or maintain compliance.

Financial assessments should include reviewing balance sheets, profit margins, and cash flow statements to gauge long-term viability. This information provides insight into whether the supplier can sustain operations under various market conditions while adhering to compliance and audit requirements. An unstable financial situation could compromise the integrity of your supply chain and impact overall product quality.

Infrastructure and Technology Assessment

Infrastructure and technology play pivotal roles in a supplier’s ability to deliver high-quality products consistently during China Factory Audits. Evaluating these elements allows you to understand if the supplier has adequate facilities, equipment, and technological capabilities aligned with industry standards. An effective infrastructure supports efficient production processes while advanced technology can enhance precision in manufacturing.

During an infrastructure assessment, consider factors such as facility layout, machinery condition, maintenance practices, and capacity for scaling operations as needed for compliance audits. Additionally, technology integration—like automation or data analytics—can streamline operations significantly while improving adherence to quality benchmarks set forth in your audit process guidelines. By ensuring that suppliers have robust infrastructure backed by modern technology solutions, you pave the way for successful audits that yield actionable insights.

The Role of Quality Inspection

Quality inspection plays a pivotal role in the landscape of China Factory Audits, ensuring that products not only meet compliance standards but also align with the expectations of buyers. By integrating quality control measures throughout the audit process, companies can significantly enhance their operational efficiency and product reliability. This proactive approach helps to mitigate risks associated with non-compliance and poor-quality goods, ultimately safeguarding brand reputation.

Overview of China Inspection Pro

China Inspection Pro is a leading audit company specializing in quality inspection services tailored for businesses engaging with Chinese manufacturers. Our specialists rigorously examine every detail to ensure your goods meet or exceed industry standards, providing you with peace of mind during the compliance audit journey. With deep experience and advanced methodologies, we guide you through complex challenges so your products satisfy both market expectations and regulatory requirements.

Importance of Quality and Audit Integration

Integrating quality assurance within the audit and compliance framework is crucial for effective China Factory Audits. When quality inspections are embedded into the audit process, organizations can identify potential issues early on, allowing for timely interventions that enhance overall product quality. This synergy not only streamlines operations but also fosters a culture of continuous improvement within supplier relationships.

Turning Findings into Actionable Insights

The true value of a compliance audit lies in its findings; however, these insights must be transformed into actionable recommendations to drive meaningful change. At China Inspection Pro, we focus on turning findings from our audits into clear steps that businesses can implement to improve their manufacturing processes and product offerings. By leveraging these insights effectively, companies can boost their competitive edge while ensuring they remain compliant with industry standards.

Common Pitfalls in Factory Audits

Navigating the landscape of China Factory Audits can be tricky, and several common pitfalls can lead to ineffective compliance audits. Recognizing these missteps is crucial for ensuring that the audit and compliance process yields valuable insights rather than mere checkboxes on a form. By understanding these pitfalls, companies can enhance their audit processes and ultimately improve supplier relationships.

Misunderstanding Audit Criteria

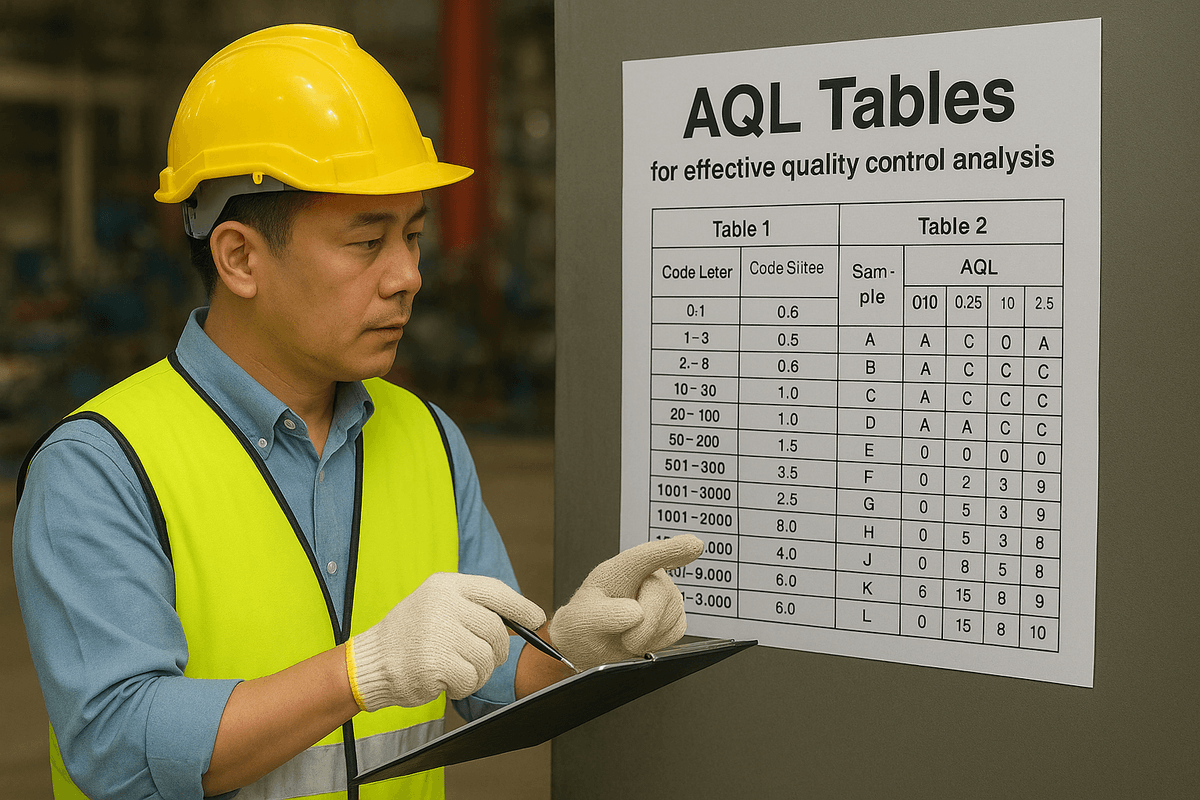

One of the most significant hurdles in China Factory Audits is misunderstanding the specific criteria against which suppliers are evaluated. Different audit companies may employ varying standards, leading to confusion about what constitutes a successful audit outcome. This misalignment can result in inadequate preparations or unrealistic expectations, ultimately compromising the quality and audit process.

To avoid this pitfall, it’s essential for businesses to clarify the criteria with their chosen audit company before commencing an audit. Establishing clear communication about expectations ensures that both parties are aligned on goals and standards for compliance & audit evaluations. By doing so, companies can significantly enhance their chances of receiving a comprehensive assessment that accurately reflects supplier capabilities.

Neglecting Follow-Up Actions

Another common mistake during factory audits is neglecting follow-up actions after the initial compliance audit has been completed. Many organizations may feel a sense of relief once they have received their report but fail to implement necessary changes based on findings from the quality inspection process. Without proper follow-up, any identified issues remain unaddressed, potentially leading to recurring problems down the line.

To maximize benefits from China Factory Audits, businesses should develop a structured plan for addressing any shortcomings highlighted during the post-audit reporting phase. This includes setting deadlines for corrective actions and assigning responsibilities to relevant team members or departments within the organization. By taking proactive steps post-audit, companies not only improve supplier performance but also strengthen their overall quality control processes.

Relying Solely on Documentation

While documentation plays an essential role in audits, relying solely on paperwork can lead to an incomplete understanding of a factory's true capabilities during compliance audits. Many suppliers might present polished documents that do not accurately reflect actual practices or conditions within their facilities—this is where onsite inspections by an experienced audit company become invaluable. Quality inspections deliver insights that paperwork simply cannot provide.

It’s crucial for businesses conducting China Factory Audits to balance documentation review with thorough onsite evaluations as part of their overall strategy in assessing supplier capabilities effectively. This dual approach ensures that organizations gain a well-rounded perspective on both documented policies and real-world operations within factories they engage with. Ultimately, integrating quality inspection practices into your compliance & audit strategy leads to more informed decisions and better long-term partnerships.

Conclusion

In the ever-evolving landscape of global manufacturing, China Factory Audits stand as a crucial pillar for businesses striving for excellence. The audit process not only ensures compliance with industry standards but also enhances supplier relationships through transparency and accountability. By leveraging the insights gained from these audits, companies can maximize their operational efficiency and mitigate risks associated with non-compliance.

Maximizing Benefits of Supplier Audits

To truly capitalize on the advantages offered by compliance audits, organizations must integrate audit findings into their strategic planning. This involves actively engaging with the audit company to understand areas of improvement and implementing actionable recommendations that arise from quality and audit assessments. By fostering a culture of continuous improvement, businesses can enhance product quality, streamline operations, and ultimately drive profitability.

Continuous Improvement Through Compliance

The journey doesn't end once the compliance audit is completed; rather, it's an ongoing process that requires commitment to excellence. Regular audits not only help in identifying potential pitfalls but also encourage suppliers to maintain high standards consistently. As companies prioritize quality and audit integration in their operations, they cultivate an environment where continuous improvement becomes part of their DNA, leading to sustained success in international markets.

Future of China Factory Audits

Looking ahead, the future of China Factory Audits will likely be shaped by advancements in technology and data analytics. As more businesses recognize the importance of real-time monitoring and proactive compliance strategies, we can expect a shift towards more dynamic auditing processes that leverage digital tools for enhanced accuracy and efficiency. With firms like China Inspection Pro leading the charge in quality inspection services, organizations will be better equipped than ever to navigate complexities while ensuring their products meet both market expectations and regulatory requirements.