Introduction

In the world of manufacturing and quality control, understanding AQL is crucial for ensuring products meet specified standards without compromising efficiency. So, what does AQL mean? At its core, Acceptable Quality Level (AQL) refers to the maximum number of defective items considered acceptable in a sample batch during inspections. This concept not only streamlines production processes but also plays a vital role in maintaining customer satisfaction.

Understanding the Concept of AQL

AQL serves as a benchmark for quality assurance, helping businesses define acceptable limits for defects in their products. By determining what constitutes an acceptable level of quality, organizations can effectively manage risk while minimizing costs associated with over-inspection or product recalls. When we ask, what does AQL mean, we uncover its significance as a tool that balances quality with practicality in manufacturing settings.

Importance of AQL in Quality Control

The importance of AQL cannot be overstated; it directly influences how companies approach their quality control strategies. By establishing clear guidelines on acceptable defect rates, businesses can enhance their operational efficiency and reduce wasteful practices that lead to financial losses. Furthermore, implementing AQL standards fosters trust among consumers who expect high-quality products without excessive price tags.

How AQL Impacts Manufacturing Decisions

When manufacturers integrate AQL into their decision-making processes, they are equipped to make informed choices about production methods and resource allocation. This framework allows them to identify areas for improvement while assuring stakeholders that product integrity remains intact. Ultimately, understanding what does AQL mean empowers organizations to navigate complex manufacturing landscapes with confidence and precision.

What Does AQL Mean?

When diving into the world of quality control, one term that often pops up is AQL, or Acceptable Quality Level. But what does AQL mean? At its core, AQL is a statistical measurement used to determine the maximum number of defective items considered acceptable in a particular sample size. It acts as a threshold that helps manufacturers and quality control professionals decide whether to accept or reject a batch of products.

Definition and Key Terminology

To fully grasp what does AQL mean, it's essential to familiarize yourself with some key terminology. The term “acceptance sampling” refers to the process of inspecting a random sample from a lot to make decisions about the entire batch based on this subset. Additionally, defects per hundred units (DPU) and defective items are crucial concepts; they quantify the level of non-conformance within products. Understanding these terms sets the stage for effectively implementing AQL in various manufacturing processes.

Historical Context of AQL

The concept of acceptable quality levels has roots that trace back to World War II when statistical sampling methods were developed for military supplies. As industries grew post-war, businesses sought efficient ways to ensure product quality without exhaustive inspections—hence, what does AQL mean became increasingly relevant. Over time, organizations like ISO (International Organization for Standardization) have refined these standards, making them applicable across various sectors and ensuring consistent quality assurance practices worldwide.

Common Applications in Various Industries

AQL isn't just confined to one sector; it finds applications across multiple industries including manufacturing, food production, and electronics. In manufacturing settings, companies often use AQL standards during final inspections to evaluate product batches before shipping them out—ensuring customer satisfaction while minimizing waste. Similarly, in the food industry, adherence to specific AQL levels can help maintain safety standards and protect public health by identifying potentially hazardous products before they reach consumers.

AQL Sampling Plans Explained

When it comes to ensuring quality in production, AQL sampling plans are the backbone of effective quality control. These plans provide a structured approach for assessing product quality without inspecting every single item, which can be time-consuming and costly. Understanding what does AQL mean in the context of sampling is crucial for manufacturers aiming to maintain standards while optimizing resources.

Types of Sampling Methods

There are several sampling methods used in AQL practices, each designed to meet specific needs and circumstances. The most common methods include random sampling, systematic sampling, and stratified sampling. Random sampling ensures that every item has an equal chance of being selected, while systematic sampling follows a predetermined interval, and stratified sampling divides the population into subgroups before selection—each method offering its own advantages based on what does AQL mean for your particular situation.

Choosing the right method can make a significant difference in the accuracy of your quality assessments. For instance, random sampling might be best for large batches where variability is expected, while stratified sampling could be more effective when certain characteristics are known to differ within subgroups. Ultimately, understanding these methods helps businesses implement AQL more effectively.

Determining Sample Size

Determining sample size is a critical step in any AQL plan; it directly influences the reliability of your results. Factors such as batch size, desired confidence level, and acceptable risk levels come into play when deciding how many items to inspect. Knowing what does AQL mean in terms of sample size ensures that manufacturers can accurately gauge product quality without overextending their resources.

In practice, larger sample sizes generally yield more reliable results but also require more time and resources—so striking a balance is key. Statistical tables or software tools can assist in calculating the appropriate sample size based on your specific parameters and industry norms. This careful consideration helps businesses avoid unnecessary costs while still maintaining high-quality standards.

Understanding Acceptable Quality Levels

Acceptable Quality Levels (AQL) represent the maximum number of defective items considered acceptable during random sampling inspections within a batch or lot—essentially defining what does AQL mean for product acceptance criteria. By establishing these thresholds upfront, companies can streamline their inspection processes while ensuring that product quality remains intact.

A typical example might set an AQL of 1% for critical defects but allow up to 5% for minor defects; this differentiation helps prioritize which issues need immediate attention versus those that may not significantly impact functionality or safety. Understanding these levels empowers manufacturers to make informed decisions about production processes and resource allocation based on their unique operational goals and customer expectations.

In conclusion, grasping how these components fit together enhances overall manufacturing efficiency while reinforcing commitment to quality assurance through effective use of AQL principles.

Industries That Use AQL Standards

AQL, or Acceptable Quality Level, is a critical aspect of quality control that extends across various industries. Understanding what does AQL mean and its implications can help businesses maintain high standards while optimizing their processes. Let's delve into how different sectors leverage AQL to ensure product quality and consumer satisfaction.

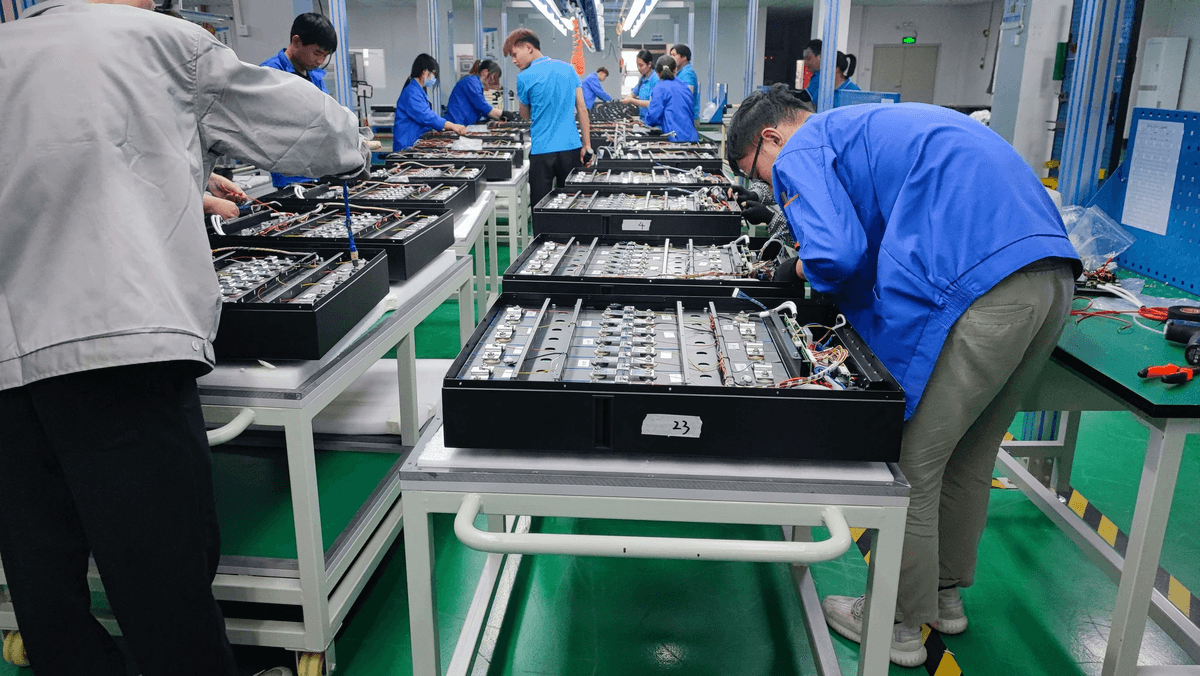

Manufacturing Sector Insights

In the manufacturing sector, understanding what does AQL mean is essential for maintaining product consistency and meeting customer expectations. Manufacturers often implement AQL standards to minimize defects in their production lines, ensuring that only products meeting quality benchmarks reach the market. By employing effective sampling methods and determining appropriate sample sizes, manufacturers can make informed decisions about production adjustments based on inspection results.

Moreover, the use of AQL helps streamline processes by reducing waste and improving efficiency. When manufacturers adhere to established acceptable quality levels, they can avoid costly recalls and enhance their reputation for reliability. Ultimately, implementing AQL standards leads to better resource management and increased profitability in the competitive manufacturing landscape.

Food Industry Quality Control

The food industry is another sector where understanding what does AQL mean plays a vital role in ensuring safety and compliance with health regulations. Food producers utilize AQL standards to monitor product quality throughout production stages, from sourcing raw materials to final packaging. By applying these principles, companies can detect contamination or spoilage early on and take corrective actions before products reach consumers.

Furthermore, adherence to acceptable quality levels helps food businesses build trust with customers who prioritize safety in their dietary choices. Regular inspections based on AQL criteria enable companies to maintain compliance with stringent food safety regulations while also enhancing overall product quality. In an industry where consumer health is paramount, leveraging AQL practices ensures that food products are both safe and enjoyable.

Electronics and AQL Practices

In the fast-paced world of electronics manufacturing, understanding what does AQL mean is crucial for delivering high-quality products that meet market demands. Electronic components require precision engineering; thus, adhering to acceptable quality levels allows manufacturers to identify defects early in the production process efficiently. This proactive approach not only minimizes returns but also enhances customer satisfaction through reliable performance.

Additionally, as technology evolves rapidly, so do consumer expectations regarding electronics' functionality and durability. Implementing robust AQL practices enables companies to remain competitive by consistently delivering superior products that meet or exceed industry standards. By prioritizing quality control through effective sampling methods aligned with acceptable quality levels, electronic manufacturers can foster innovation while safeguarding their brand reputation.

The Role of Inspection Companies

In the world of manufacturing and quality control, inspection companies play a pivotal role in ensuring that products meet the required standards. These third-party entities act as unbiased evaluators, providing an essential layer of assurance for businesses seeking to uphold their reputation and deliver high-quality products. By understanding what does AQL mean, companies can better leverage the expertise of these inspectors to enhance their quality assurance processes.

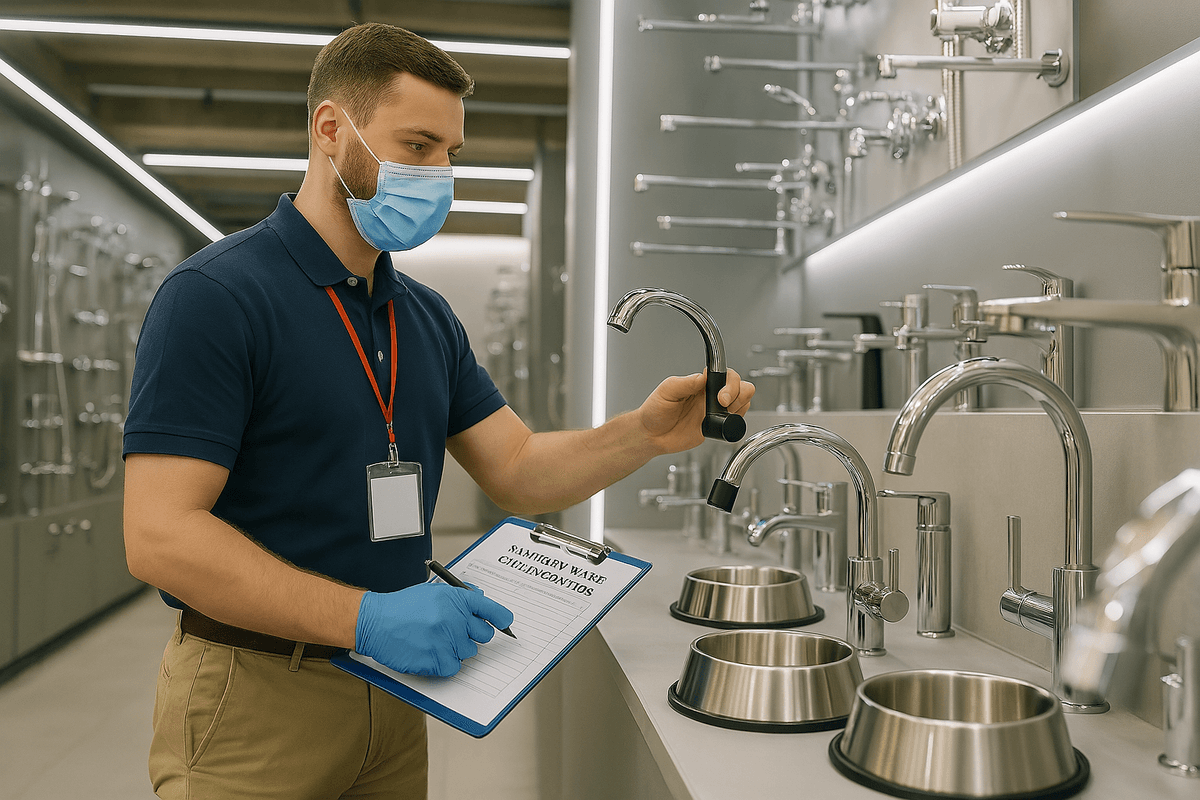

Importance of Third-Party Inspections

Third-party inspections are crucial because they provide an objective assessment of product quality, free from any potential biases that may arise within the organization itself. Understanding what does AQL mean is vital for these inspections since it helps define acceptable quality levels and sampling methods that ensure consistency across batches. Moreover, third-party inspectors bring specialized knowledge and experience to the table, which can help identify issues that internal teams might overlook.

Engaging with a third-party inspection company not only enhances credibility but also builds consumer trust in your brand. When customers know that an independent entity has verified product quality through rigorous AQL standards, they are more likely to feel confident in their purchase decisions. This confidence translates into customer loyalty and can significantly impact a company's bottom line.

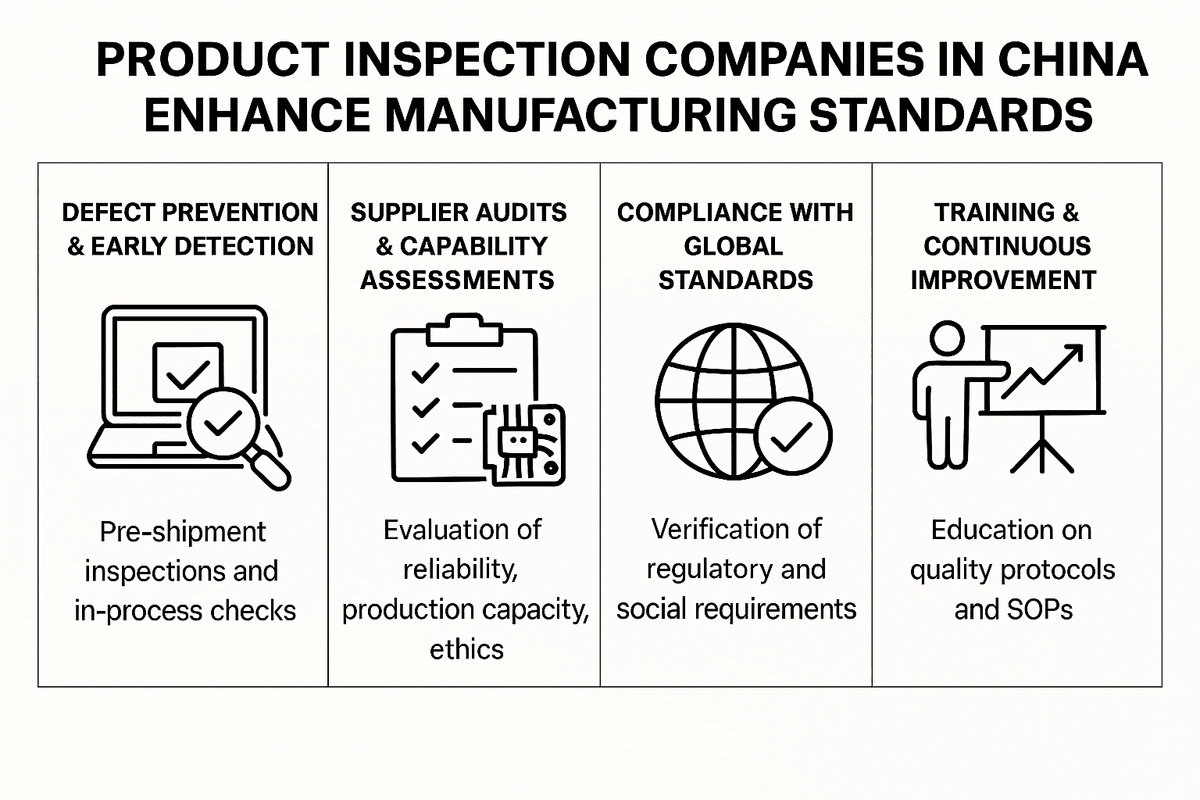

How China Inspection Pro Enhances AQL Processes

China Inspection Pro is a notable player in the realm of inspection services, particularly when it comes to enhancing AQL processes for manufacturers operating in or sourcing from China. They specialize in conducting thorough inspections based on well-defined sampling plans that align with international AQL standards. By utilizing their expertise, businesses can gain insights into what does AQL mean and how it applies specifically to their production lines.

The team at China Inspection Pro employs advanced techniques and tools to ensure accurate assessments while minimizing disruptions to manufacturing operations. Their focus on clear communication means clients receive timely updates about inspection results and recommendations for improvement based on established AQL criteria. This proactive approach helps companies make informed decisions regarding production adjustments or supplier negotiations.

Additionally, by partnering with China Inspection Pro, manufacturers can streamline their supply chain management processes while adhering strictly to quality guidelines set forth by industry standards like AQL. This partnership not only mitigates risks associated with defective products but also fosters long-term relationships with suppliers who prioritize quality assurance alongside cost-effectiveness.

Benefits of Partnering with Inspection Experts

Partnering with inspection experts offers numerous advantages beyond just understanding what does AQL mean; it opens doors to improved operational efficiency and enhanced product reliability. These experts bring invaluable insights into best practices for implementing effective sampling plans tailored to specific industries or product types—ensuring compliance with both local regulations and global standards alike.

Moreover, working closely with experienced inspectors allows companies to identify potential pitfalls early on during the production process rather than after goods have been shipped out—a costly mistake many businesses face otherwise! With continuous monitoring based on established Acceptable Quality Levels (AQL), organizations can proactively address issues before they escalate into larger problems affecting customer satisfaction or brand reputation.

Ultimately, collaborating with seasoned inspection professionals leads not only to higher-quality products but also fosters innovation within manufacturing environments by encouraging adherence to rigorous quality control measures rooted firmly in understanding what does AQL mean for each unique scenario faced by different sectors today.

Challenges in Implementing AQL

Implementing Acceptable Quality Levels (AQL) can be a daunting task for many organizations, primarily due to various misconceptions and resistance to change. While the benefits of AQL are well-documented, these hurdles can hinder its effective adoption. Understanding what does AQL mean and addressing these challenges is crucial for enhancing product quality.

Common Misconceptions About AQL

One prevalent misconception about AQL is that it guarantees perfect quality; however, that’s not the case. Instead, it establishes a threshold for acceptable quality levels, meaning some defects may still pass inspection. Additionally, many believe that adopting AQL is an expensive endeavor, but in reality, it often leads to cost savings by reducing waste and rework.

Another misunderstanding is that AQL only applies during the final inspection phase of production. In truth, understanding what does AQL mean involves recognizing its role throughout the entire manufacturing process—from initial design to final delivery. This holistic approach helps ensure consistent quality rather than treating inspections as a one-off event.

Lastly, some companies think that implementing AQL means they need to overhaul their entire quality control system overnight. However, gradual integration with existing processes often proves more effective and less disruptive in the long run.

Overcoming Resistance to AQL Standards

Resistance to adopting AQL standards often stems from fear of change or lack of understanding among staff members. To combat this reluctance, organizations should invest in training programs that clarify what does AQL mean and how it benefits everyone involved—from management to production teams. By fostering an environment where employees feel empowered and informed about these standards, companies can ease transitions.

Moreover, showcasing success stories from other businesses can help alleviate fears associated with implementing new procedures. When teams see tangible results—like improved product quality or reduced costs—they’re more likely to embrace changes related to AQL standards willingly. Transparency about potential challenges and how they can be overcome will also build trust within the organization.

Finally, involving employees in discussions about integrating AQL into current processes encourages buy-in at all levels of the company hierarchy. By making them part of the solution rather than imposing changes from above, organizations can cultivate a culture of continuous improvement centered around quality assurance.

Future Trends in Quality Assurance

As industries evolve and consumer expectations rise, future trends in quality assurance will likely emphasize even greater reliance on data-driven decision-making regarding what does AQL mean for businesses today. Advanced technologies like artificial intelligence (AI) and machine learning are beginning to play significant roles in predicting defects before they occur—enhancing traditional sampling plans significantly.

Additionally, sustainability will become increasingly important as companies strive not just for acceptable quality levels but also for environmentally responsible practices throughout their supply chains. This shift may lead organizations to adopt more stringent criteria when evaluating suppliers based on their commitment to sustainable practices alongside traditional metrics tied directly back into understanding what does AQL mean within this context.

Finally—and perhaps most importantly—the trend towards increased collaboration between manufacturers and third-party inspection firms will continue growing stronger over time as businesses seek expert insights into navigating complex global markets effectively while maintaining high-quality standards across all products produced under their brand name.

Conclusion

In the world of quality assurance, AQL stands as a beacon of reliability and efficiency. Understanding what does AQL mean is crucial for businesses aiming to maintain high standards while managing costs effectively. By integrating AQL into their processes, companies can not only enhance product quality but also secure a competitive edge in their respective markets.

The Significance of AQL in Business Success

The significance of AQL in business success cannot be overstated; it directly influences customer satisfaction and brand reputation. When companies grasp what does AQL mean, they unlock the potential to deliver consistent quality that meets or exceeds customer expectations. This commitment to quality fosters loyalty, encouraging repeat business and positive word-of-mouth referrals that are invaluable in today’s marketplace.

Navigating AQL for Better Product Quality

Navigating the complexities of AQL can be daunting, but mastering it leads to better product quality across all stages of production. Companies that understand what does AQL mean are better equipped to implement effective sampling plans and inspection processes that minimize defects and enhance overall output. This proactive approach not only elevates product standards but also streamlines operations, reducing waste and operational costs.

Building Trust with AQL and Inspections

Building trust through effective use of AQL and inspections is essential for long-term success in any industry. Transparent practices around what does AQL mean help foster an environment where stakeholders feel confident in the products being delivered. When consumers see a brand committed to rigorous quality control measures, they are more likely to engage with confidence, knowing they receive value for their investment.