Introduction

In today's competitive market, the significance of quality control inspection services cannot be overstated. Businesses are increasingly recognizing that quality assurance is not just a box to tick but a vital component that drives success and fosters customer loyalty. Quality control inspectors play a crucial role in this process, ensuring that products meet established standards and specifications.

Importance of Quality Control Inspection

Quality control inspection serves as the backbone of any successful manufacturing or service-oriented business. By implementing rigorous quality assurance protocols, organizations can identify defects before they reach consumers, saving both time and money. The importance of these inspections lies in their ability to uphold brand reputation and maintain customer trust, which is invaluable in today’s marketplace.

How Quality Assurance Drives Success

Quality assurance is more than just a set of procedures; it’s a mindset that permeates through every level of an organization. Effective QA practices lead to improved operational efficiency and reduced waste, ultimately enhancing profitability. When businesses prioritize quality control, they not only meet compliance requirements but also create products that resonate with customers, driving long-term success.

The Role of Quality Control Inspectors

Quality control inspectors are the guardians of product integrity within an organization. These dedicated professionals utilize their expertise to conduct thorough quality inspections at various stages of production, ensuring adherence to safety and performance standards. Their work not only helps prevent costly errors but also reinforces the overall commitment to quality and assurance across the company.

Understanding Quality Control Inspection Services

In today's competitive landscape, understanding quality control inspection services is crucial for businesses aiming to thrive. These services are designed to ensure that products meet established standards of quality and performance before they reach the market. By integrating quality assurance into their processes, companies can enhance their reputation and customer satisfaction.

What Are Quality Control Inspection Services?

Quality control inspection services involve systematic evaluations of products at various stages of production to ensure compliance with specific standards and regulations. These inspections can be conducted in-house or by third-party quality assurance specialists who bring an unbiased perspective to the process. The role of a quality control inspector is pivotal; they meticulously assess everything from raw materials to finished goods, ensuring that each item aligns with the company's quality benchmarks.

Key Benefits for Businesses

Investing in quality control inspection services yields numerous benefits for businesses across different sectors. Firstly, these inspections help identify defects early in the production process, reducing waste and minimizing costs associated with rework or returns. Secondly, companies that prioritize quality assurance often see improved customer loyalty; when customers trust that a brand delivers consistent quality, they're more likely to make repeat purchases.

Moreover, implementing robust quality control measures can lead to increased operational efficiency. By streamlining processes based on inspection feedback, businesses can improve productivity while maintaining high standards of excellence. Ultimately, the financial implications are significant—companies that embrace comprehensive QA practices often enjoy better profit margins due to reduced liabilities and enhanced market positioning.

Common Industries Utilizing Quality Control

Quality control inspection services are not confined to one particular industry; they span a wide array of sectors including manufacturing, food production, electronics, textiles, and pharmaceuticals. In manufacturing, for instance, rigorous inspections ensure that machinery operates efficiently while meeting safety regulations. Meanwhile, in the food industry, strict adherence to health standards during production prevents contamination and guarantees consumer safety.

The electronics sector also heavily relies on quality inspections; as technology evolves rapidly, ensuring product reliability becomes paramount for brand reputation. Furthermore, pharmaceuticals must adhere strictly to regulatory guidelines where any lapse could result in severe consequences for public health—hence the critical role of a dedicated QA team cannot be overstated here either! With such diverse applications across industries, it’s clear why quality assurance remains a cornerstone of successful business operations today.

Enhancing Product Quality with Inspections

Quality control inspection services play a pivotal role in elevating product quality across various industries. By implementing rigorous quality assurance processes, businesses can identify defects and inconsistencies before products reach the market. This proactive approach not only enhances the overall quality of products but also fosters a culture of continuous improvement within organizations.

How Quality Control Improves Products

Quality control improves products by ensuring that they meet predefined standards and specifications throughout the production process. With dedicated quality inspectors on the ground, companies can catch potential issues early, reducing the likelihood of costly recalls or customer dissatisfaction later on. Moreover, this meticulous attention to detail reinforces a brand's reputation for reliability and excellence in its offerings.

When quality inspection services are integrated into production lines, they help streamline operations by identifying inefficiencies and areas for improvement. This leads to optimized manufacturing processes that not only enhance product quality but also reduce waste and lower costs over time. Ultimately, organizations that prioritize quality assurance reap significant rewards in terms of customer loyalty and market competitiveness.

Case Studies from Successful Companies

Numerous successful companies have harnessed the power of quality control inspection services to drive their growth and maintain high standards. For instance, a leading electronics manufacturer implemented rigorous QA practices that involved regular inspections at various stages of production. As a result, they reduced defect rates by 40% within just one year, significantly boosting customer satisfaction ratings.

Another example can be found in the automotive industry where a prominent car manufacturer adopted comprehensive quality assurance measures involving third-party inspections. By doing so, they were able to enhance their vehicle safety features while simultaneously improving fuel efficiency metrics across their fleet. Such strategic investments in quality control not only improved their products but also solidified their position as industry leaders.

These case studies illustrate how integrating effective quality control practices can yield tangible results—both in product performance and brand perception—underscoring the critical importance of investing in robust QA systems.

The Impact of Quality Assurance on Customer Satisfaction

The relationship between quality assurance and customer satisfaction is undeniable; consumers expect high-quality products that perform reliably over time. When businesses employ diligent quality control inspectors to ensure adherence to standards, customers are more likely to trust the brand and remain loyal over time. In fact, studies show that companies with strong QA protocols experience higher retention rates compared to those without such measures in place.

Moreover, effective quality inspections lead to fewer complaints and returns from customers since potential issues are addressed before products reach end-users. This not only saves businesses money but also fosters an overall positive experience for consumers who appreciate receiving high-quality goods consistently. Ultimately, investing in robust QA strategies translates into increased customer satisfaction—a key driver for long-term success.

In conclusion, enhancing product quality through meticulous inspections is essential for any business aiming for excellence in today's competitive landscape. By leveraging comprehensive quality control inspection services alongside skilled QA specialists and inspectors, organizations can ensure superior products that meet—and exceed—customer expectations.

Risk Mitigation Through Quality Inspections

In today's fast-paced business environment, risk mitigation is more critical than ever, and quality control inspection services play a vital role in this process. By implementing robust quality assurance measures, companies can identify potential risks early, ensuring smoother operations and reducing the likelihood of costly errors. Quality control inspectors are the frontline defenders against these risks, providing valuable insights that help businesses maintain high standards.

Identifying Potential Risks Early

Identifying potential risks early is like having a crystal ball for your production processes; it allows companies to foresee issues before they escalate into major problems. Quality inspection services provide a systematic approach to evaluating products at various stages of production, highlighting discrepancies that could lead to defects or failures down the line. This proactive stance not only saves time and money but also enhances overall quality assurance efforts.

How Quality Control Prevents Costly Mistakes

Quality control is essentially a safety net that catches mistakes before they fall through the cracks and wreak havoc on your bottom line. By employing dedicated quality assurance specialists who conduct thorough inspections, businesses can prevent costly mistakes related to product recalls or customer dissatisfaction. The financial implications of ignoring quality control can be staggering—think lost revenue, damaged reputation, and even legal repercussions—all easily avoidable with diligent inspections.

Real-World Examples of Risk Mitigation

Take a look at some real-world examples where effective quality control inspection services have made all the difference in risk mitigation. For instance, an electronics manufacturer faced significant challenges with product defects that were identified during routine inspections by their quality control inspectors; corrective actions were taken promptly, resulting in improved product reliability and substantial cost savings over time. Another case involved a food processing company that utilized QA quality practices to ensure compliance with health regulations; their rigorous inspections helped them avoid potentially disastrous health violations and maintain consumer trust.

Building Trust with Third-Party Inspections

In the world of quality control, third-party inspections serve as a beacon of trust and reliability. Businesses often face the challenge of ensuring that their products meet high standards without bias. By choosing third-party services, companies can leverage impartial assessments to enhance their quality assurance efforts.

Why Choose Third-Party Services?

Third-party services bring an objective perspective to the table, which is crucial for maintaining integrity in quality control inspection services. Unlike in-house teams, these external specialists provide unbiased evaluations that can uncover issues that might otherwise go unnoticed. Additionally, utilizing a quality assurance specialist from a reputable third-party ensures that your inspections align with industry standards and best practices.

Choosing third-party inspections also allows businesses to save time and resources while focusing on core operations. With expert quality inspectors handling the nitty-gritty details, companies can streamline their processes and avoid potential pitfalls associated with product defects. Ultimately, this choice fosters a culture of transparency and accountability that resonates well with customers.

The Role of China Inspection Pro in Quality

China Inspection Pro stands out as a leading provider of quality control inspection services tailored for businesses operating in or sourcing from China. Their team of dedicated quality control inspectors specializes in various fields, ensuring comprehensive coverage across industries such as electronics, textiles, and manufacturing. By employing rigorous testing methods and adherence to international standards, they help companies maintain high levels of quality assurance throughout their supply chains.

Moreover, China Inspection Pro offers customized solutions designed to meet specific client needs—whether it's pre-production audits or final random inspections before shipment. This adaptability not only enhances product reliability but also builds confidence among stakeholders who rely on consistent outcomes from their suppliers. As a result, businesses can enjoy peace of mind knowing they've partnered with experts committed to delivering exceptional quality control.

Boosting Supplier Relationships through Inspections

Implementing robust quality inspection processes through third-party services like China Inspection Pro significantly strengthens relationships with suppliers. When both parties are aligned on expectations regarding product standards and compliance measures set forth by independent inspectors, it creates an environment conducive to collaboration and trustworthiness. This synergy encourages suppliers to invest in better practices knowing they are being held accountable by reliable external parties.

Furthermore, regular interactions during the inspection process foster open communication channels between manufacturers and buyers—leading to improved problem-solving capabilities when issues arise. Quality assurance becomes a shared goal rather than just an obligation; this collaborative spirit paves the way for long-lasting partnerships built on mutual respect for high-quality output. In essence, prioritizing thorough inspections not only elevates product standards but also cultivates healthier supplier dynamics essential for business growth.

The Economics of Quality Assurance

In today's competitive landscape, the economics of quality assurance cannot be overstated. Investing in quality control inspection services not only safeguards a company’s reputation but also translates into tangible financial benefits. Understanding the cost-benefit analysis of quality control is essential for businesses aiming to thrive and maintain a competitive edge.

Cost-Benefit Analysis of Quality Control

When evaluating the cost-benefit analysis of quality control, businesses must consider both direct and indirect costs associated with poor quality. Implementing robust quality assurance measures can reduce defects, minimize returns, and enhance customer satisfaction, leading to increased sales and loyalty. By investing in a dedicated quality control inspector or a team of QA specialists, companies often find that initial expenditures are far outweighed by long-term savings and revenue growth.

Moreover, effective quality inspection processes can lead to streamlined operations and reduced waste, further bolstering a company's bottom line. The upfront costs associated with these services are typically recouped through improved efficiency and reduced rework expenses down the line. Ultimately, organizations that prioritize quality assurance enjoy enhanced profitability while fostering a culture of excellence throughout their operations.

Investing in Quality for Long-Term Gains

Investing in quality for long-term gains is not just about immediate returns; it's about building a sustainable business model rooted in excellence. Companies that prioritize QA consistently outperform their competitors by delivering superior products that meet customer expectations time after time. This commitment to high-quality standards creates brand loyalty that translates into repeat business—a crucial factor for sustained growth.

Moreover, businesses that engage in regular quality inspections demonstrate accountability and reliability to their customers, which enhances their market reputation over time. By fostering strong relationships with suppliers through consistent inspections, organizations can ensure smoother operations and improved product delivery timelines as well. In essence, investing in robust quality assurance practices is an investment in future success.

Financial Success Stories from Quality-Focused Companies

Several companies have successfully leveraged their commitment to quality control inspection services as a cornerstone of their financial success stories. For instance, renowned brands like Toyota have built an empire on strict adherence to QA principles—resulting in vehicles known for reliability and longevity while minimizing recalls significantly over the years. Their approach demonstrates how prioritizing quality can lead to substantial market share and profitability.

Another example is Apple Inc., whose rigorous standards for product design and manufacturing ensure high levels of customer satisfaction while maintaining premium pricing strategies across its product lines. The company's focus on continuous improvement through effective QA practices has solidified its position as an industry leader with loyal customers willing to pay more for perceived value. These examples underscore how integrating comprehensive quality assurance into business strategies leads not only to financial success but also reinforces brand strength within competitive markets.

Conclusion

In today's competitive landscape, quality control inspection services have become a hallmark of successful businesses. Companies that prioritize quality assurance not only enhance their product offerings but also gain a significant edge over their competitors. By investing in robust quality control measures, organizations can ensure they meet customer expectations while minimizing risks associated with subpar products.

The Competitive Edge of Quality Control

Quality control is no longer just an afterthought; it's a strategic advantage that businesses can't afford to ignore. With effective quality inspection processes, companies can identify defects before they reach consumers, ensuring that only the best products make it to market. This proactive approach not only saves money in the long run but also solidifies a company's reputation as a leader in quality and assurance.

Strengthening Brand Loyalty through Quality

When customers experience consistent quality in products or services, their trust in the brand deepens significantly. Quality assurance specialists play an essential role in this process by implementing rigorous standards that foster reliability and satisfaction among consumers. As customers become loyal advocates for brands known for their commitment to quality control, businesses can reap the rewards of increased sales and enhanced market presence.

Investing in Quality Assurance for Future Growth

The journey toward excellence begins with an investment in quality assurance practices that yield long-term benefits. Companies that prioritize quality control inspections often see substantial returns on investment through reduced waste and improved operational efficiency. As these organizations continue to grow and evolve, their dedication to maintaining high standards will ensure they remain at the forefront of their industries.

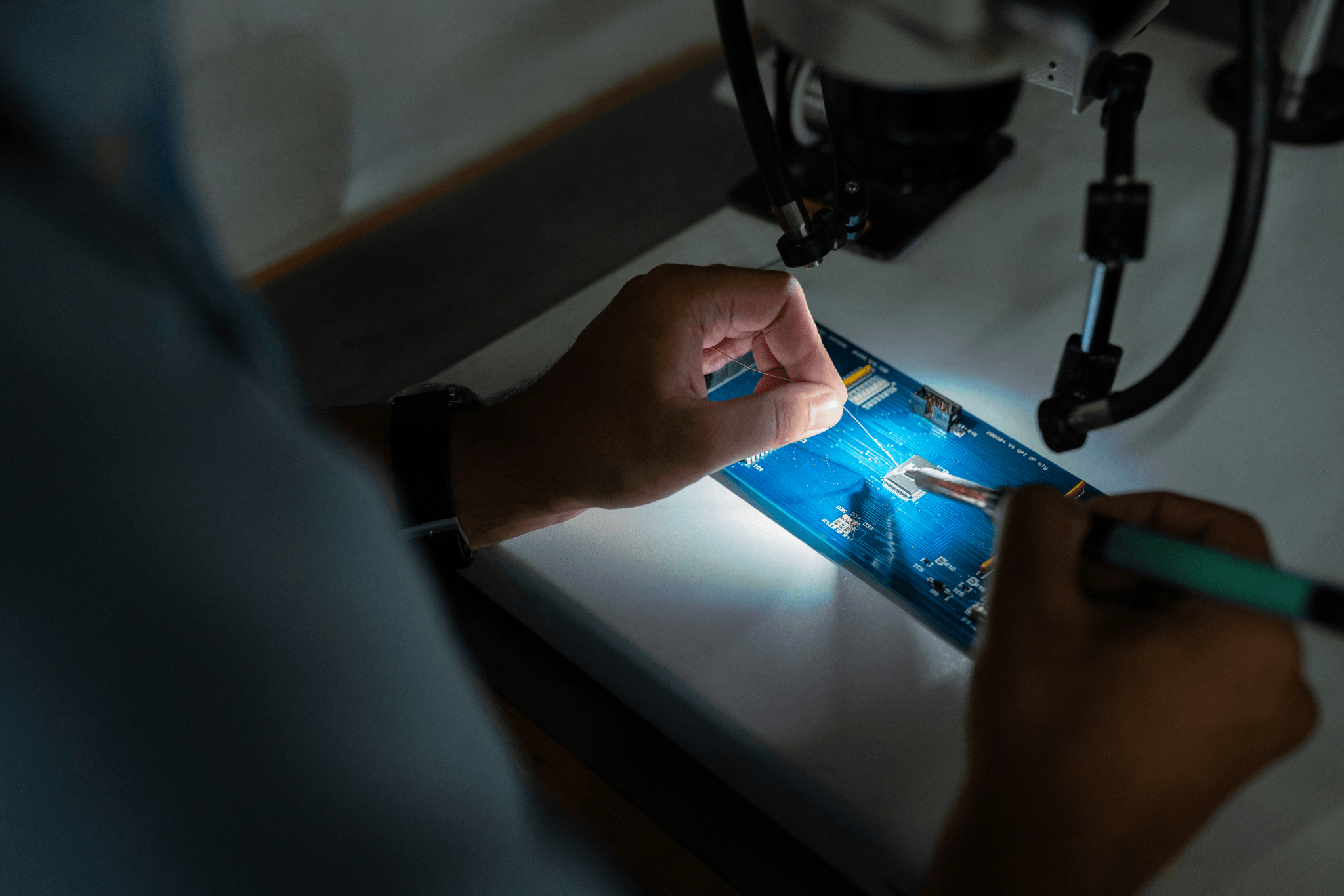

[Image description=team conducting thorough inspections on various products, office setting with charts and graphs displayed, focused professionals examining items closely, bright lighting highlighting attention to detail, teamwork emphasized through collaboration], Image name=quality_control_inspection_team, Alt tag=quality control inspection services enhance product reliability and customer satisfaction