Introduction

In the realm of quality control, AQL (Acceptable Quality Level) serves as a cornerstone for ensuring products meet specified standards. Understanding AQL and its importance is crucial for manufacturers looking to maintain high-quality outputs while minimizing costs. By effectively utilizing AQL tables, companies can determine appropriate sample sizes for inspections, which directly influences the success of their quality inspection processes.

Understanding AQL and Its Importance

AQL represents the maximum number of defective items considered acceptable in a given sample size during quality control inspections. This metric is pivotal because it helps organizations balance the need for thorough checks with operational efficiency, ensuring that resources are not wasted on excessive sampling. For manufacturing quality inspection software users, understanding AQL provides a framework to streamline sample checking and enhance overall product quality.

The Role of AQL Tables in Sample Size

AQL tables are essential tools that guide companies in determining the appropriate sample size based on their specific inspection requirements and desired confidence levels. These tables simplify complex calculations by providing clear benchmarks that align with industry standards, making it easier for quality control companies to implement effective inspection strategies. By leveraging these tables, businesses can optimize their QA inspections while minimizing risks associated with poor-quality products.

How AQL Impacts Quality Inspection

The impact of AQL on quality inspection cannot be overstated; it shapes how organizations approach both sampling and defect acceptance criteria within their production processes. Properly applied, AQL ensures that even when dealing with large production runs, only a representative portion is inspected—saving time and resources while still maintaining product integrity. Consequently, understanding how to interpret and apply an aql table sample size effectively becomes indispensable for any company committed to excellence in manufacturing and product delivery.

What is AQL?

AQL, or Acceptable Quality Level, is a critical concept in quality control that defines the maximum number of defective items considered acceptable in a sample batch. It serves as a guideline for manufacturers to ensure that their products meet specific quality standards before reaching consumers. Understanding AQL is essential for effective quality inspection and maintaining customer satisfaction.

Definition and Purpose

At its core, AQL quantifies the level of defects permissible in a given sample size during quality inspections. This statistical measure helps organizations determine whether to accept or reject a batch based on the number of non-conformities found during sample checking. The primary purpose of AQL is to balance the cost of inspection with the risk of accepting defective products, ultimately enhancing overall product reliability.

Relationship to Quality Control

AQL plays a pivotal role in quality control by providing measurable criteria for evaluating product conformity during inspections. It allows quality control companies to implement systematic procedures that ensure consistent product quality while minimizing waste and unnecessary rework. By integrating AQL into their processes, organizations can enhance their manufacturing quality inspection software capabilities, leading to more efficient QA inspections.

Importance in Manufacturing

In the manufacturing sector, adhering to established AQL standards significantly impacts operational efficiency and customer satisfaction. By defining acceptable defect levels, manufacturers can streamline their production processes while ensuring that products meet market expectations. Moreover, using an appropriate aql table sample size helps businesses identify issues early on, preventing costly recalls and reinforcing brand reputation through reliable quality control practices.

AQL Table Sample Size Explained

Understanding the intricacies of AQL table sample size is crucial for effective quality control and quality inspection. These tables serve as a guide, helping quality control companies determine how many items to inspect based on the total lot size and acceptable quality levels. By mastering AQL tables, organizations can enhance their sampling strategies and ensure a robust quality assurance process.

Breakdown of AQL Tables

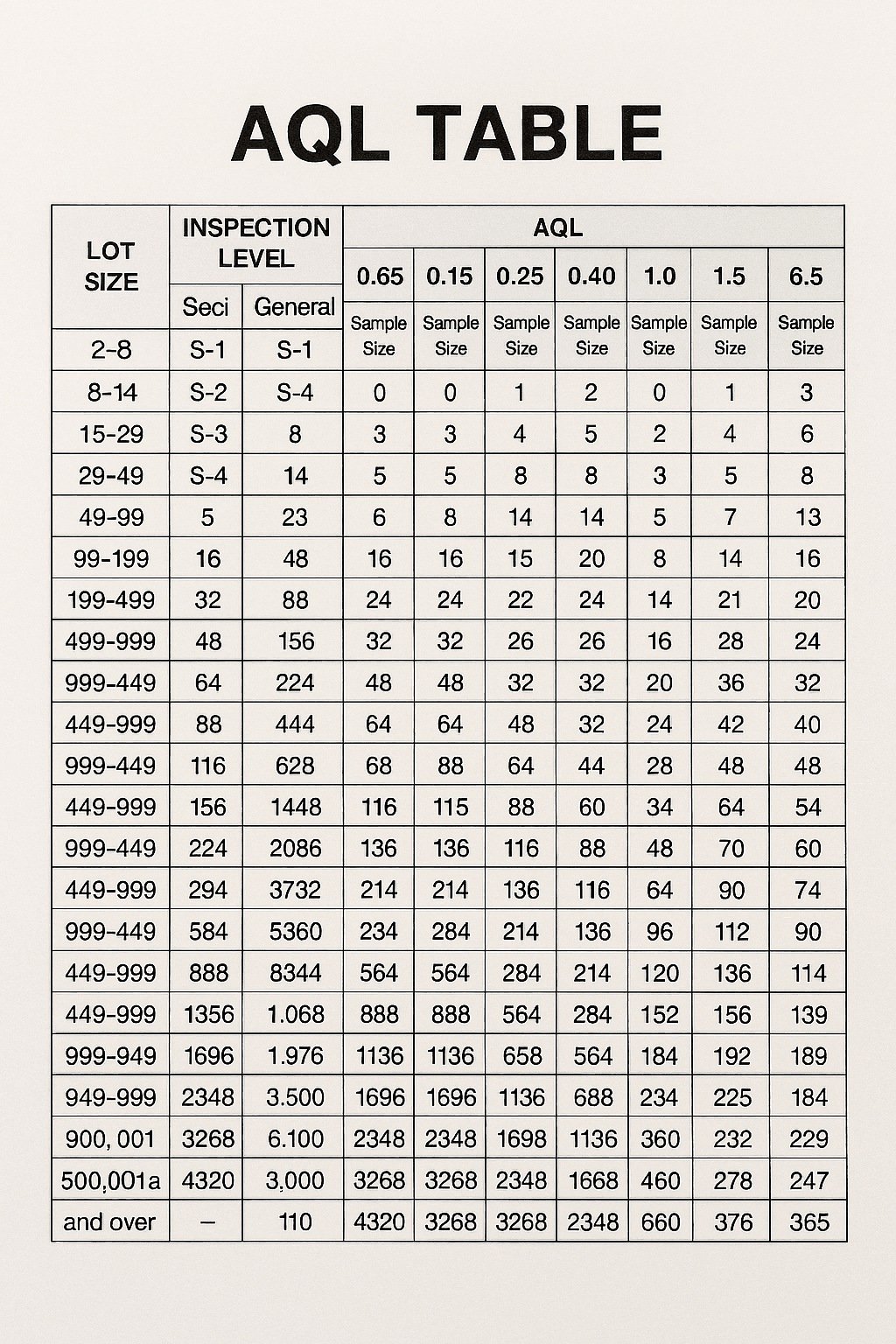

AQL tables are structured to provide a clear framework for sample checking during quality control inspections. Each table typically includes various lot sizes alongside corresponding sample sizes and acceptance numbers based on predefined AQL levels. This breakdown allows manufacturers to quickly identify the necessary sample size they should use in their quality control processes, streamlining the inspection workflow.

The first step in using an AQL table involves determining the lot size, which refers to the total number of items produced in a batch. Following this, one can select the appropriate row in the table that corresponds to that lot size, leading directly to the recommended sample size for inspection. Understanding this structure is essential for effective manufacturing quality inspection software implementation, ensuring that inspections are both efficient and thorough.

Selecting the Right Sample Size

Selecting the right sample size from an AQL table is pivotal in maintaining product integrity while minimizing costs associated with excessive inspections. The decision hinges on several factors such as product complexity, risk associated with defects, and industry standards—each influencing how stringent or lenient your sampling needs to be. Quality control companies must balance these elements carefully; too small a sample may overlook critical defects while too large could waste resources unnecessarily.

It's also important to consider your specific context when choosing an AQL level—higher levels indicate stricter standards which may be necessary for high-risk products or industries like aerospace or medical devices. Conversely, lower levels might suffice for less critical applications where minor defects won't significantly impact performance or safety. By aligning your selection with both product requirements and business goals, you can optimize your approach toward quality control.

How to Read AQL Tables

Reading AQL tables effectively requires familiarity with their layout and terminology used within them—a skill that's invaluable during QA inspections. Typically organized into columns representing different acceptance criteria (like Major Defects or Minor Defects), these tables guide inspectors through understanding what constitutes acceptable versus unacceptable quantities of defects within their sampled items.

To navigate an AQL table successfully, start by identifying your lot size range on one axis before moving across horizontally to find your designated acceptance number based on chosen sampling plans—this will reveal how many units need inspecting in relation to acceptable defect limits set by industry standards. Mastering this skill not only enhances efficiency but also fortifies overall confidence during quality inspections.

Factors Influencing Sample Checking

Understanding these factors can help quality control companies optimize their inspection strategies and ensure that they meet industry standards. This section dives into the nuances of product type, inspection levels, and specific industry considerations that impact AQL table sample size decisions.

Product Type and Complexity

The type of product being inspected significantly influences the AQL table sample size selected for quality inspections. For instance, simple products with fewer components may require a smaller sample size, while complex assemblies with multiple parts often necessitate larger samples to ensure thorough quality control. Additionally, the nature of defects varies by product; hence, understanding these complexities is essential for effective sample checking.

Manufacturers dealing with intricate products must be particularly vigilant during QA inspections since a single defect can lead to significant operational challenges down the line. The complexity not only affects how many units should be sampled but also how those samples are analyzed during quality control inspection processes. Therefore, it's crucial for companies to tailor their approach based on product type to maintain high standards in manufacturing.

Inspection Level and AQL Standards

Inspection levels directly correlate with AQL standards and greatly determine the required sample size for effective quality assurance. Different levels indicate varying degrees of scrutiny; for instance, a higher inspection level might necessitate larger samples from an AQL table to ensure that any potential defects are caught early in production. Quality control companies must choose an appropriate inspection level based on risk assessment and customer requirements.

Moreover, understanding how these levels interact with established AQL standards is vital for maintaining compliance and achieving desired outcomes in manufacturing processes. Quality inspections guided by well-defined AQL tables help streamline decision-making regarding which products pass or fail based on their sampled performance metrics. Consequently, aligning inspection levels with appropriate AQL standards ensures that each batch meets both internal benchmarks and external regulatory requirements.

Industry-Specific Considerations

Each industry has unique characteristics that influence its approach to sample checking and overall quality control practices. For example, industries such as pharmaceuticals or aerospace have stringent regulations requiring more rigorous QA inspections than typical consumer goods manufacturing might demand. These specific considerations dictate not only the frequency of inspections but also how manufacturers interpret their AQL tables when determining sample sizes.

Furthermore, technological advancements like manufacturing quality inspection software have revolutionized how industries analyze data from sampled units—enabling quicker decision-making while adhering to strict compliance guidelines tailored to each sector's demands. Quality control companies must remain agile and adapt their sampling methods according to evolving industry standards while ensuring they leverage all available tools at their disposal effectively. By doing so, they can enhance their overall efficiency in managing quality assurance protocols across various sectors.

The Process of Determining Sample Size

Determining the appropriate sample size for quality inspections is a critical step in ensuring product reliability and compliance with industry standards. This process hinges on understanding AQL (Acceptable Quality Level) tables, which guide quality control companies in selecting the right sample size based on various factors. By following a systematic approach, organizations can enhance their quality inspection processes and minimize risks associated with non-conformances.

Steps to Calculate AQL Sample Size

Calculating AQL sample size begins with identifying the lot size, which is the total number of units produced. Once you have this figure, consult the AQL table to find the corresponding sample size based on your desired level of inspection and acceptable quality levels. After determining the sample size, it’s crucial to conduct thorough sample checking to ensure that every selected unit reflects the overall quality of the lot.

Next, consider any specific requirements related to your industry or product type that might influence your chosen AQL level. For instance, high-risk products may necessitate a stricter AQL standard than lower-risk items. Finally, document your calculations and decisions for future reference and continuous improvement in your quality control processes.

Using Manufacturing Quality Inspection Software

In today's fast-paced manufacturing environment, leveraging technology like manufacturing quality inspection software can streamline the process of determining AQL sample sizes significantly. These tools often come equipped with built-in calculators that simplify the task by automating calculations based on input data such as lot size and desired AQL levels. By using such software, quality control companies can reduce human error while enhancing efficiency in their quality inspection workflows.

Moreover, many software solutions provide real-time analytics and reporting features that allow teams to monitor compliance trends over time. This not only aids in making informed decisions regarding future inspections but also helps identify recurring issues that may require corrective actions or adjustments in sampling strategies. Ultimately, integrating technology into your QA inspections will bolster overall operational effectiveness.

Best Practices for Quality Control Companies

Quality control companies should adopt best practices when it comes to determining their AQL table sample sizes for effective quality inspections. First and foremost, regular training sessions should be conducted for staff members involved in sampling processes to ensure they are well-versed in reading and interpreting AQL tables accurately. This knowledge is vital for avoiding common pitfalls related to misinterpretation or improper application of sampling standards.

Additionally, maintaining open lines of communication among team members during sample checking can lead to more thorough inspections and quicker resolutions when issues arise. Implementing a feedback loop where inspectors share insights from their experiences can help refine processes over time as well—after all, learning from past challenges is key to continuous improvement in any organization’s quality control efforts.

Lastly, staying updated with industry standards and regulations ensures that your practices remain compliant while meeting customer expectations effectively—after all, good enough isn't good enough when it comes to delivering top-notch products!

Common Challenges in AQL Sampling

Quality control in manufacturing is a critical process, but it comes with its fair share of challenges, particularly when it involves AQL sampling. Understanding these hurdles can help quality control companies refine their processes and improve overall inspection results. Let's dive into some common issues faced during AQL sampling and how they can be resolved.

Misinterpretation of AQL Tables

One of the most prevalent challenges in quality inspection is the misinterpretation of AQL tables. Many professionals may not fully understand how to read these tables, leading to incorrect sample sizes being selected for inspection. This misstep can result in either excessive scrutiny or insufficient checks, ultimately affecting product quality and compliance with industry standards.

Moreover, a lack of training on how to utilize the aql table sample size effectively can contribute to errors during sample checking. Quality control teams must ensure that all members are well-versed in interpreting these tables accurately to prevent costly mistakes. Investing time in training and utilizing manufacturing quality inspection software can greatly enhance understanding and application.

Dealing with Non-Conformances

Non-conformances are another significant challenge that arises during the QA inspections process. When products do not meet predefined quality standards, it creates confusion about next steps—should the entire batch be rejected or just the defective items? This uncertainty can lead to delays in production schedules and increased costs for quality control companies.

To tackle non-conformances effectively, it's crucial to establish clear protocols for handling defects once they are identified through sample checking. Implementing robust corrective actions based on data from previous inspections will also help minimize future occurrences of non-conformances. Additionally, integrating advanced manufacturing quality inspection software can streamline reporting and tracking issues more efficiently.

Solutions to Overcome Quality Inspection Issues

Overcoming challenges in AQL sampling requires a proactive approach from quality control teams. One effective solution is adopting best practices such as regular training sessions focused on understanding aql table sample size selections and their implications for overall product quality. This ensures that all team members are equipped with the knowledge needed for effective quality control.

Another solution lies in leveraging technology; using modern manufacturing quality inspection software enables better data collection and analysis during QA inspections, making it easier to identify trends or recurring issues promptly. Furthermore, collaborating with experienced professionals within your organization or external consultants can provide valuable insights into optimizing your sampling strategies.

In summary, while common challenges exist within AQL sampling processes, they are not insurmountable barriers; rather, they present opportunities for improvement through education and technology adoption.

Conclusion

In the fast-paced world of manufacturing, quality control is not just a checkbox on a to-do list; it's the lifeblood of every successful operation. Understanding AQL and its implications on sample size can significantly enhance your quality inspection processes, ensuring that products meet required standards before they reach consumers. By mastering the art of sample checking, companies can minimize defects and maximize customer satisfaction.

Maximizing Quality Control Efficiency

To truly maximize quality control efficiency, businesses must leverage AQL table sample size effectively. This means understanding how to select the right sample size based on product type and complexity while also considering industry-specific regulations. Quality control companies that adopt a systematic approach to QA inspections will find themselves ahead of the competition, delivering consistent results without compromising on standards.

Leveraging Technology for Better Inspections

In today’s digital age, utilizing manufacturing quality inspection software can dramatically improve inspection outcomes and streamline processes. These tools allow for real-time data analysis and reporting, making it easier to interpret AQL tables and adjust sampling strategies accordingly. By integrating technology into their quality control inspection practices, organizations can reduce human error and enhance overall productivity in their operations.

The Importance of Expert Guidance from China Inspection Pro

Navigating the complexities of AQL sampling can be daunting; that's where expert guidance comes into play. China Inspection Pro offers invaluable insights into effective sample checking methods tailored to specific industries, ensuring compliance with global standards while optimizing quality control processes. With their expertise in handling AQL table sample sizes, businesses can confidently tackle challenges head-on and achieve superior results in their quality inspections.