Introduction

In the bustling world of international trade, Container Loading Inspection serves as a critical checkpoint to ensure that goods are safe and sound before they embark on their journey. It’s not just about tossing items into a container; it involves meticulous attention to detail, from assessing the condition of export cartons to verifying shipping marks and inspecting containers for any signs of damage. A thorough inspection process can save companies from costly delays and damaged merchandise, making it an essential aspect of logistics.

Importance of Container Loading Inspection

The importance of Container Loading Inspection cannot be overstated in today’s global marketplace. Ensuring the condition of export cartons and pallets is paramount for maintaining product integrity during transit. By identifying potential issues early on, businesses can mitigate risks associated with loss or damage, ultimately safeguarding their reputation and bottom line.

Overview of Key Steps in Inspections

A successful Container Loading Inspection involves several key steps that work in harmony to achieve optimal results. First, inspectors assess the condition of export cartons while verifying shipping marks against documentation to ensure accuracy. Following this, they evaluate the condition of containers themselves and implement the ISO Container Inspection Checklist to maintain industry standards throughout the loading process.

Role of China Inspection Pro in Inspections

When it comes to reliable inspections, China Inspection Pro stands out as a trusted partner in ensuring quality assurance during container loading processes. With expertise in assessing packaging integrity and supervising loading techniques, they play a vital role in maintaining compliance with ISO Container Checklist Guidelines. Leveraging their knowledge helps businesses navigate the complexities involved in international shipping while ensuring that every detail is meticulously checked off before departure.

Assess the Condition of Export Cartons

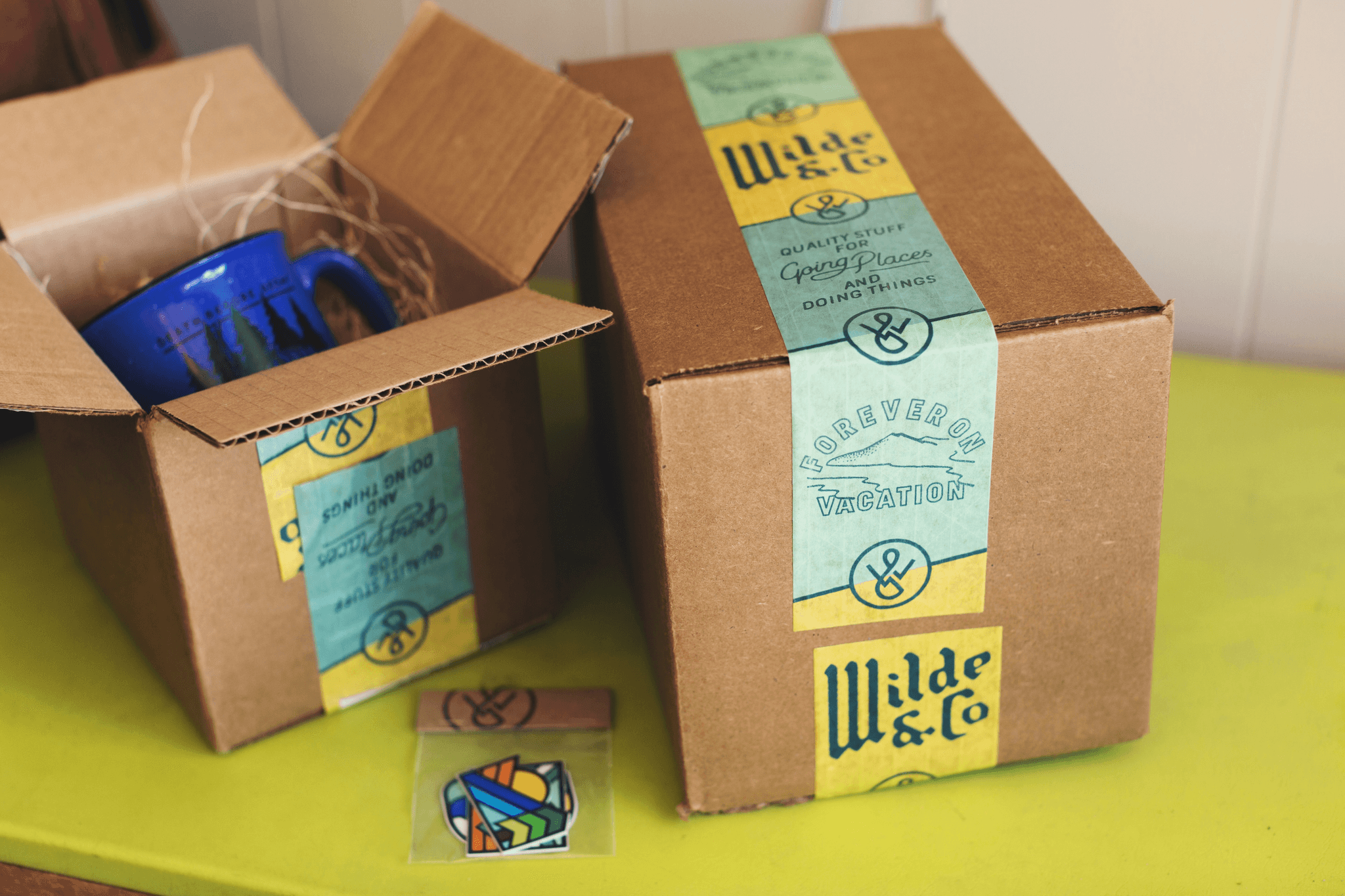

These cartons serve as the first line of defense for your products, ensuring they arrive at their destination in pristine condition. A thorough evaluation not only safeguards your goods but also enhances overall supply chain efficiency.

Examine Packaging Integrity

The integrity of packaging is paramount in Container Loading Inspection; it’s essential to ensure that export cartons are robust enough to withstand transit challenges. Inspectors should look for signs of wear and tear, ensuring that each carton is sealed properly and free from any defects. A well-packaged product can prevent significant losses during shipping and protect against contamination or damage.

Check for Damage or Compromise

Next on the agenda is checking for damage or compromise in the export cartons. This involves examining each carton for dents, tears, or any signs that may indicate a breach in protection. Identifying these issues early on allows companies to take corrective measures before loading, ultimately preserving product quality and compliance with shipping standards.

Ensure Compliance with Specifications

Lastly, ensuring compliance with specifications is vital in this phase of Container Loading Inspection. Each shipment must adhere to specific guidelines regarding dimensions, weight limits, and material types outlined by both manufacturers and regulatory bodies. By confirming that all export cartons meet these requirements, businesses can avoid costly delays and penalties while maintaining a high standard of quality assurance throughout the logistics process.

Verify Shipping Marks

Shipping marks serve as the primary identifiers for packages and containers, ensuring that everything is in order before they leave the facility. A thorough verification process can prevent costly mistakes and delays down the line, making it essential for maintaining smooth logistics operations.

Confirm Labels and Identifiers

The first step in shipping marks verification involves confirming that all labels and identifiers are present and accurate on the export cartons and pallets. Each label should clearly indicate the destination, contents, and handling instructions to facilitate efficient transit. It's vital to ensure that these labels are not only legible but also securely affixed to avoid any mishaps during transportation.

Cross-check Against Shipping Documents

Next up is cross-checking these labels against shipping documents to ensure consistency across all records involved in the Container Loading Inspection process. This means looking at invoices, packing lists, and bills of lading to confirm that what’s physically present matches what’s documented. Any discrepancies found during this cross-check could signal potential issues with compliance or miscommunication between parties involved.

Importance of Accurate Documentation

Accurate documentation is paramount in logistics; it serves as a legal record of what was shipped, where it’s going, and who is responsible for it at various stages of transit. Inaccurate or missing documentation can lead to delays in customs clearance or even penalties from authorities—definitely not something you want when managing container loads! Therefore, ensuring that shipping marks are verified against these documents is an integral part of maintaining efficiency throughout the loading process supervision.

Evaluate the Condition of Containers

Evaluating the condition of containers is a critical step in ensuring that goods are shipped safely and securely. A thorough inspection can prevent potential losses and damages during transportation, making it an essential part of the Container Loading Inspection process. This evaluation includes checking for structural integrity, signs of contamination, and ensuring that seals and locks are secure.

Inspect for Structural Integrity

The first step in evaluating containers is to inspect their structural integrity. Look for any visible dents, rust, or deformities that could compromise the container's ability to protect its contents during transit. A well-maintained container not only safeguards the condition of export cartons but also ensures adherence to ISO Container Checklist Guidelines, which emphasize safety and reliability.

During this inspection, pay attention to the corners and edges where stress fractures are more likely to occur. Any signs of weakness should be documented, as they could lead to larger issues down the line if not addressed immediately. Remember, a strong container is your first line of defense against external elements that may threaten your shipment.

Look for Signs of Contamination

Next up on our checklist: contamination! It's crucial to look for any signs that might indicate contamination inside the container. This includes checking for mold growth, foreign odors, or residues from previous shipments that could affect the condition of export cartons or even spoil perishable goods.

Contamination can lead to serious repercussions not just for your shipment but also for your brand reputation. If you spot any suspicious substances or smells during your inspection, it’s essential to take immediate action—whether that's cleaning out the container or reporting it as unfit for use according to ISO Container Inspection Checklist standards. After all, a clean environment is key in maintaining product integrity throughout shipping.

Check Seals and Locks for Security

Finally, don’t overlook those seals and locks! Checking these components is critical in ensuring that your cargo remains secure throughout its journey. Any tampering with seals can indicate potential theft or damage risks; thus verifying their condition should be a top priority during your Container Loading Inspection.

Make sure all seals are intact and functioning properly before loading begins; this helps maintain accountability throughout transportation processes related to shipping marks verification as well as compliance with international shipping regulations. If you find any broken locks or missing seals during your evaluation, take immediate steps towards replacing them before proceeding with loading—after all, peace of mind comes from knowing your goods are safe!

Implement the ISO Container Inspection Checklist

When it comes to ensuring a smooth and safe shipping process, implementing the ISO Container Inspection Checklist is paramount. This checklist serves as a structured guide that helps inspectors methodically evaluate the condition of export cartons, pallets, and containers during the loading process. By adhering to these guidelines, businesses can enhance their container loading inspection procedures and mitigate potential risks.

Overview of ISO Container Checklist Guidelines

The ISO Container Checklist Guidelines outline specific criteria that must be met during inspections to ensure compliance with international standards. These guidelines encompass various aspects such as the condition of containers, packaging integrity, and shipping marks verification. By following these established protocols, inspectors can systematically assess whether all components meet safety and quality benchmarks.

Steps for Effective Implementation

To effectively implement the ISO Container Inspection Checklist, organizations should start by training their personnel on its contents and significance. Next, they should establish a routine for conducting inspections at key stages of the loading process—before loading begins, during loading operations, and after completion. Finally, maintaining accurate records of each inspection will facilitate ongoing improvements in container loading inspection practices while ensuring adherence to ISO standards.

Importance of Adhering to ISO Standards

Adhering to ISO standards in container loading inspections is crucial for several reasons. Firstly, it ensures that all parties involved are following best practices designed to prevent damage or contamination during transit—protecting both products and profits alike. Secondly, compliance with these standards enhances credibility with clients and partners who prioritize quality assurance in their supply chains; this trust can lead to better business relationships over time.

Supervise the Loading Process

Supervising the loading process is a critical aspect of Container Loading Inspection, ensuring that everything is executed smoothly and safely. Proper supervision not only safeguards the condition of export cartons but also mitigates risks associated with improper handling. By overseeing this phase, inspectors can confirm adherence to best practices and compliance with ISO Container Checklist Guidelines.

Monitor Loading Techniques

Monitoring loading techniques is essential for maintaining the integrity of goods during transportation. Inspectors should observe how pallets are handled, ensuring that workers follow established procedures to prevent damage to the condition of containers and export cartons. Employing correct techniques reduces the risk of shifting loads, which can lead to costly damages or safety hazards.

Ensure Proper Weight Distribution

Ensuring proper weight distribution within containers is crucial for safe transport and compliance with shipping regulations. Inspectors must check that heavy items are placed at the bottom, evenly distributing weight across pallets to maintain balance during transit. This practice not only protects the condition of export cartons but also enhances overall safety during loading.

Address Safety Concerns During Loading

Addressing safety concerns during loading is vital for protecting both personnel and cargo integrity. Inspectors should be vigilant about potential hazards such as unsecured loads or improper lifting techniques that could compromise safety or damage containers. By fostering a culture of safety awareness throughout the loading process, inspectors contribute significantly to successful Container Loading Inspection outcomes.

Conduct Final Inspection and Reporting

After all the meticulous steps of Container Loading Inspection have been completed, it’s time to wrap things up with a final inspection and reporting phase. This stage is crucial as it consolidates all findings into a detailed report that serves as a record of the inspection process. A well-structured report not only highlights the condition of export cartons and pallets but also documents any discrepancies found during shipping marks verification and the overall condition of containers.

Compile Findings in a Detailed Report

Compiling findings in a detailed report is an essential step in ensuring that every aspect of the Container Loading Inspection is documented accurately. This report should include observations related to the condition of export cartons, pallets, and any issues identified during shipping marks verification or container assessments. By following ISO Container Checklist Guidelines, inspectors can present their findings in an organized manner that enhances clarity and facilitates understanding for all stakeholders involved.

Importance of Timely Reporting

Delays in sharing the results can lead to missed opportunities for corrective actions, potentially jeopardizing shipment schedules or compliance standards. By promptly delivering reports on the condition of containers and any concerns regarding loading process supervision, businesses can ensure swift resolutions and maintain smooth operations.

Communicate Issues to Relevant Parties

Effective communication is key when addressing issues uncovered during inspections; it ensures that everyone involved is aware of potential problems related to container loading processes. Relevant parties must be informed about discrepancies noted during shipping marks verification or concerns regarding pallet conditions so they can take appropriate action swiftly. By fostering open lines of communication post-inspection, organizations can enhance their operational efficiency while upholding high standards for quality assurance.

Conclusion

In wrapping up our discussion on Container Loading Inspection, it’s clear that a meticulous approach is essential for ensuring the safe and efficient transport of goods. From assessing the condition of export cartons to verifying shipping marks and supervising the loading process, each step plays a crucial role in safeguarding your cargo. By following the ISO Container Inspection Checklist guidelines, businesses can significantly reduce risks associated with damaged or lost shipments.

Recap of Container Loading Inspection Steps

To summarize, effective Container Loading Inspection begins with a thorough assessment of export cartons to ensure they meet quality standards. Next, shipping marks verification is critical for confirming that all labels and identifiers are accurate and match shipping documents. Subsequently, evaluating the condition of containers themselves ensures structural integrity while adhering to ISO Container Checklist guidelines throughout the loading process.

Significance of Professional Inspections

The significance of professional inspections cannot be overstated; they serve as a safeguard against potential mishaps during transportation. With experts overseeing every detail—from checking pallets to ensuring compliance with regulations—businesses can avoid costly errors and delays. Ultimately, investing in professional inspections not only enhances safety but also boosts customer confidence in your supply chain operations.

Trust China Inspection Pro for Quality Assurance

When it comes to quality assurance in Container Loading Inspection, China Inspection Pro stands out as a reliable partner you can trust. Their expertise ensures that every aspect—from inspecting export cartons to supervising loading processes—is executed with precision and care. By choosing China Inspection Pro, you’re not just getting an inspection; you’re securing peace of mind knowing your cargo is in capable hands.