Introduction

In the world of global commerce, ensuring product quality is paramount, and that’s where a Third Party Inspector steps in. Imagine a day filled with meticulous checks, engaging conversations with manufacturers, and the thrill of traveling to factories around the globe. Each inspection is not just a job; it’s a commitment to excellence and reliability in every product that reaches consumers.

A Day in the Life of a Third Party Inspector

A typical day for a Third Party Inspector begins with contacting the manufacturer to set up inspections tailored to specific needs and quality standards. From the early morning coffee to late-night flights, traveling to factory locations becomes second nature as inspectors navigate time zones and cultures. The excitement of arriving at the factory brings its own challenges—assessing environments, meeting factory representatives, and understanding production processes are all part of this dynamic role.

Why Product Inspection Matters

Product inspection is crucial for maintaining high standards in manufacturing, ultimately protecting brand reputation and customer satisfaction. Without thorough inspections, potential defects may slip through unnoticed, leading to costly recalls or dissatisfied customers down the line. By having a dedicated Third Party Inspector on site, manufacturers can ensure compliance with regulations while fostering trust among stakeholders.

The Role of China Inspection Pro

China Inspection Pro serves as an invaluable partner for businesses looking to enhance their quality assurance processes through expert inspections. Specializing in various services from contacting the manufacturer to writing and submitting draft inspection reports, they streamline every step of product verification. Their commitment extends beyond just identifying issues; by having factory staff sign appropriate forms after inspections, they help build lasting relationships that pave the way for future collaborations.

Contacting the Manufacturer

Contacting the manufacturer is a crucial step for any Third Party Inspector gearing up for an inspection. This initial communication sets the tone for collaboration and ensures that both parties are aligned on expectations. A well-structured approach to contacting the manufacturer can significantly streamline the entire inspection process.

Setting Up the Inspection

Setting up the inspection involves coordinating schedules and logistics with the manufacturer, which can be quite a juggling act. A Third Party Inspector must clearly communicate their availability and preferred dates, while also accommodating the manufacturer's production schedule. This proactive engagement not only establishes rapport but also lays a foundation for effective collaboration during subsequent stages, such as Traveling to Factory.

Discussing Quality Standards

Discussing quality standards with manufacturers is where things get particularly interesting and often a bit complex. It's essential for a Third Party Inspector to understand both international quality norms and specific client requirements, ensuring everyone is on the same page before any actual inspection takes place.

Establishing Inspection Criteria

Establishing clear inspection criteria is like drawing up a game plan before heading onto the field; it’s all about knowing what to look for! A Third Party Inspector should work closely with manufacturers to define measurable benchmarks that products must meet during inspections. These criteria will guide every step of the process, from Arriving at The Factory to Writing and Submitting Draft Inspection Reports, ensuring consistency and accuracy throughout.

Traveling to the Factory

Traveling to the factory is an essential step for a Third Party Inspector, as it sets the stage for effective product inspection and quality assurance. This journey involves careful planning and consideration of various logistical factors, cultural nuances, and regulatory compliance. Each aspect plays a critical role in ensuring that the inspection process goes smoothly and yields reliable results.

Logistics of Traveling Internationally

Booking flights well in advance can save costs and ensure availability, while choosing hotels close to the manufacturing site can minimize travel time on inspection day. Additionally, coordinating with the manufacturer about local transport options can help streamline your journey from arrival at the airport to arriving at the factory.

Preparing for Cultural Differences

Cultural differences can significantly impact communication and interactions during your visit as a Third Party Inspector. Understanding local customs, greetings, and business etiquette will help establish rapport with factory staff right from your first meeting. It’s also important to be aware of language barriers; having key phrases translated or using translation apps can facilitate smoother discussions about quality standards when contacting the manufacturer or carrying out product inspections.

Ensuring Compliance with Regulations

Compliance with international regulations is paramount for any Third Party Inspector traveling abroad. This includes understanding import/export laws relevant to your inspection activities as well as any specific regulations that pertain to product safety in that country. Before you start writing and submitting draft inspection reports or having factory staff sign appropriate forms, ensuring you have all necessary permits or documentation will keep you on solid ground legally while conducting your inspections.

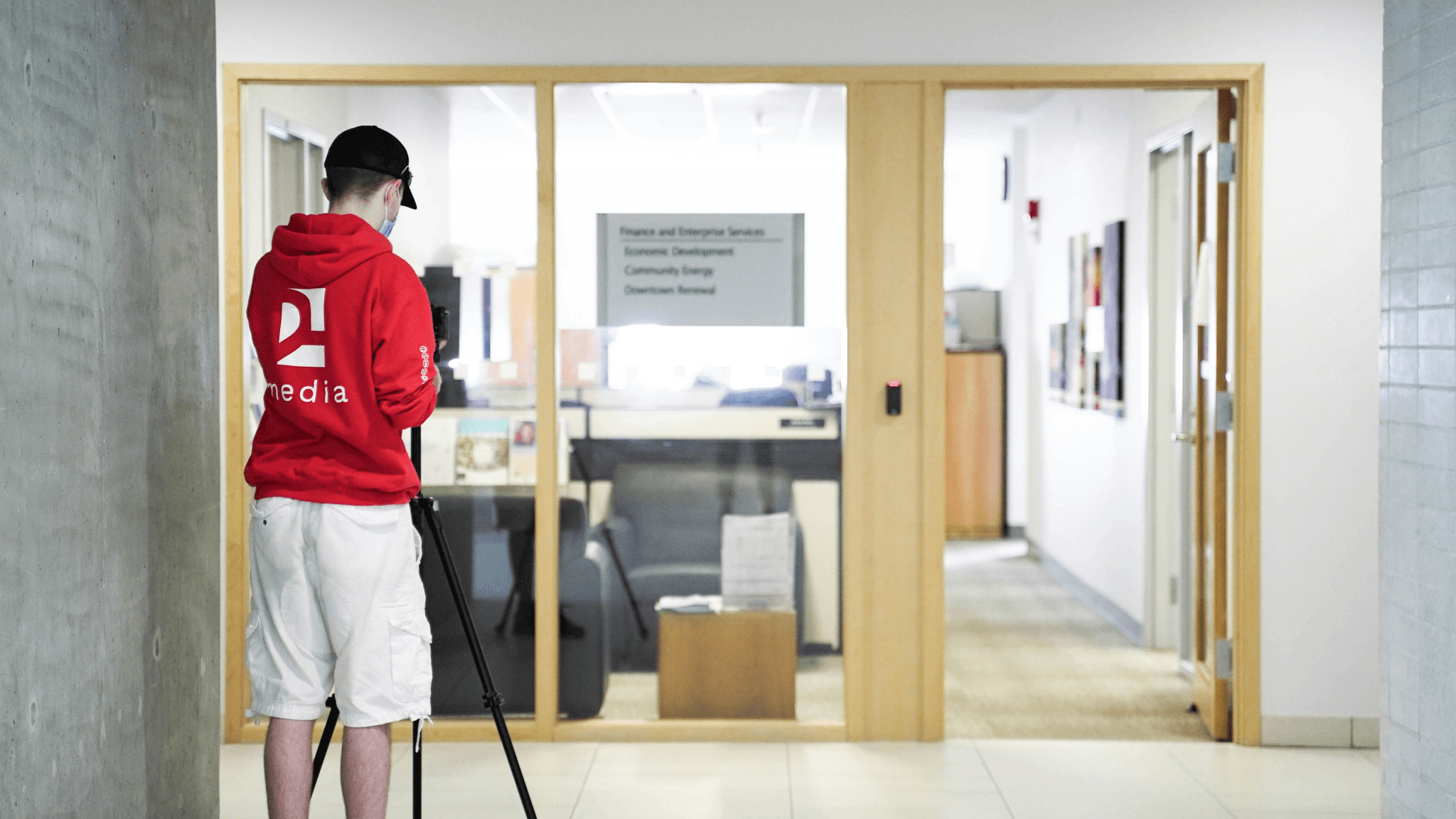

Arriving at the Factory

Upon arriving at the factory, a third party inspector is often greeted by a mix of anticipation and curiosity. The environment can tell you a lot about the company’s commitment to quality before you even step through the door. Observing the cleanliness of the premises, organization of materials, and overall atmosphere sets the tone for what’s to come.

First Impressions: Assessing the Environment

The initial assessment begins as soon as you step foot on factory grounds. Is it bustling with activity or eerily quiet? A well-organized facility usually indicates that the manufacturer takes pride in their operations, which bodes well for your upcoming product inspection.

As a third party inspector, your keen eye will notice both minor details and larger systemic issues that could impact quality control. You’ll want to pay attention to safety protocols in place; this not only reflects on compliance but also on how much they value their workers and products alike. These first impressions are crucial in shaping your expectations for carrying out product inspection tasks later on.

Meeting Factory Representatives

Once you've assessed the environment, it’s time to meet with factory representatives who will guide you through their processes. This initial interaction is vital; establishing rapport can make all subsequent discussions smoother and more productive. Discussing quality standards right away helps set a clear agenda for what you're looking for during inspections.

During this meeting, be sure to communicate your role clearly as a third party inspector focused on ensuring product integrity and compliance with established criteria. This opens up avenues for collaboration, making it easier to discuss any potential concerns later in your visit. Remember, building relationships now could mean smoother sailing when writing and submitting draft inspection reports down the line.

Navigating the Facility

With introductions made and expectations set, it's time to navigate through various sections of the facility—an essential part of preparing for carrying out product inspections effectively. Familiarizing yourself with production lines gives insight into workflow efficiency and potential bottlenecks that might affect product quality later on.

As you walk through different areas of production, keep an eye out for signs of organized chaos or inefficiencies that could lead to issues during inspections or even after products leave the factory floor. It’s important not just to observe but also engage with staff along your route; they can provide invaluable insights into operational challenges or successes that may influence your findings when writing and submitting draft inspection reports.

Taking careful notes during this phase ensures that when it comes time for having factory staff sign appropriate forms at the end of your visit, you'll have all necessary information documented accurately—making everyone's life easier in future interactions!

Carrying Out Product Inspection

Once the groundwork has been laid through contacting the manufacturer and traveling to the factory, it's time for the real action: carrying out product inspection. This phase is where a third party inspector steps into their role, ensuring that quality standards are met and potential issues are identified before products hit the market. The inspection process is a critical component of maintaining product integrity and fostering trust between manufacturers and consumers.

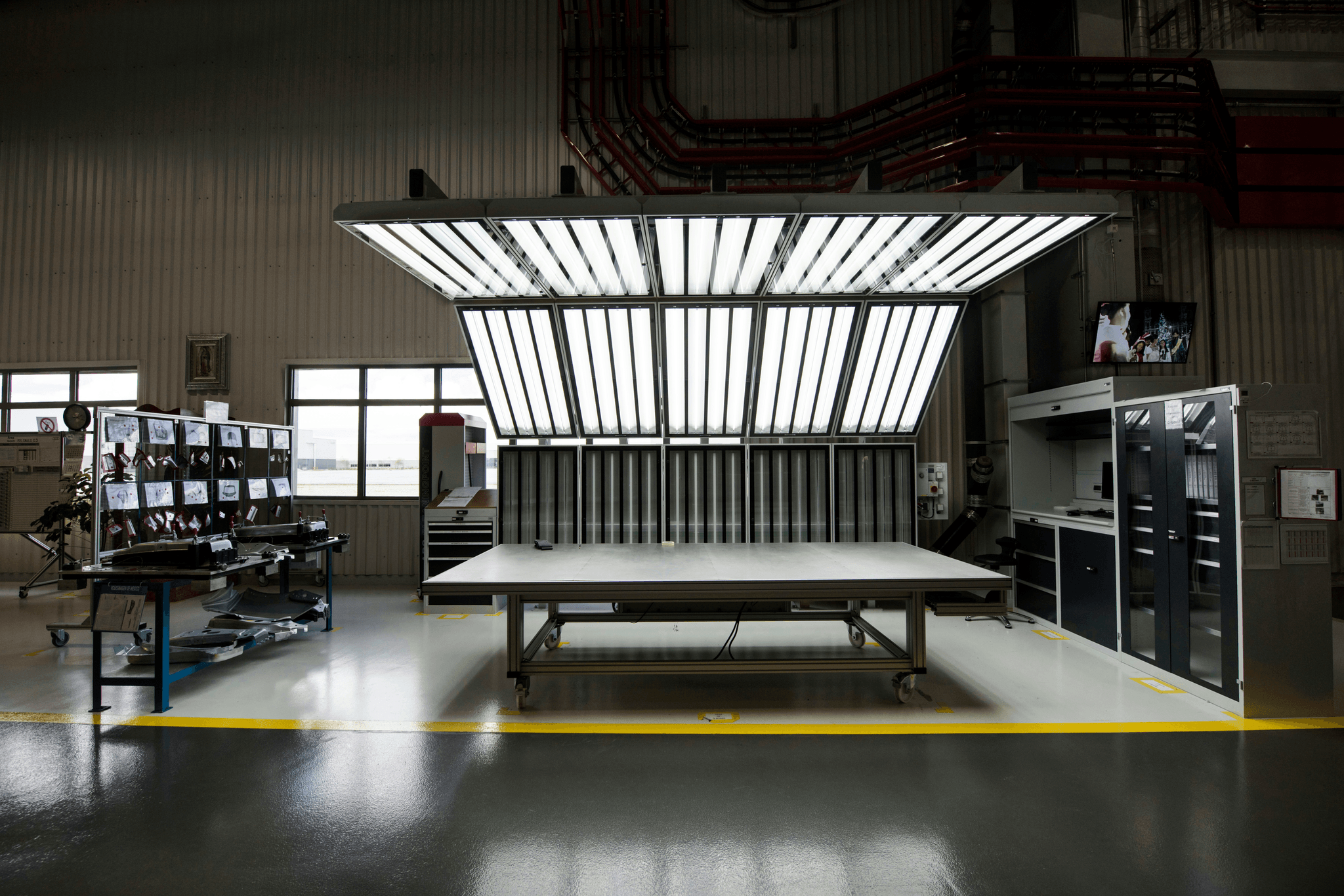

Examining Samples and Production Lines

The first step in carrying out product inspection involves examining samples and production lines with meticulous attention to detail. A third party inspector will assess not only the physical samples but also observe how they are produced on the assembly line. By closely inspecting these elements, inspectors can ensure that everything aligns with the agreed-upon quality standards discussed during initial communications with the manufacturer.

During this examination, it’s vital for inspectors to be thorough; even minor discrepancies can lead to significant issues later on. Inspectors often use tools like calipers or gauges to measure dimensions, while also checking for color consistency, labeling accuracy, and packaging integrity. This hands-on approach ensures that any variations from expected outcomes are caught early in the production process.

Performing Quality Checks

Once samples have been examined, performing quality checks becomes paramount in confirming that products meet specified criteria. A third party inspector will systematically evaluate various aspects such as functionality, durability, and safety compliance during these checks. These evaluations often include stress tests or operational assessments tailored to each specific product type.

This phase not only helps identify defects but also provides an opportunity for immediate feedback to factory staff about any necessary adjustments needed in production techniques or materials used. By actively participating in quality checks, inspectors foster an environment of continuous improvement within manufacturing processes—an invaluable asset when aiming for long-term success in product quality.

Identifying Potential Issues

Identifying potential issues is perhaps one of the most crucial responsibilities of a third party inspector during this stage of carrying out product inspection. Whether it’s spotting subpar materials or detecting inconsistencies between batches, vigilance is key to ensuring high-quality outcomes. Inspectors must maintain a keen eye throughout their evaluations; after all, an undetected flaw could lead to costly recalls or damage a brand’s reputation.

In addition to physical inspections, inspectors will also analyze documentation related to production processes—this includes checking compliance with industry regulations established during discussions when contacting the manufacturer earlier on. By connecting dots between what they see on-site and what’s documented officially, inspectors create a comprehensive picture of overall quality assurance efforts at play within the factory environment.

Ultimately, identifying potential issues not only safeguards consumer interests but also strengthens relationships between manufacturers and their clients by demonstrating commitment towards excellence—a win-win scenario all around!

Writing and Submitting Draft Inspection Report

After a thorough inspection, the next crucial step for a Third Party Inspector is to compile and submit a draft inspection report. This document serves as the backbone of communication between the inspector and the manufacturer, encapsulating all findings in a clear and concise manner. The goal here is not just to relay information but to do so with precision, ensuring that every detail is accounted for.

Documenting Findings with Precision

Documenting findings with precision is paramount for any Third Party Inspector, as it lays the groundwork for future actions. Each observation made during the inspection must be recorded meticulously, highlighting both positive aspects and areas needing improvement. By employing structured templates and checklists during the Carrying Out Product Inspection phase, inspectors can ensure that no stone is left unturned when it comes to quality assessment.

Moreover, clarity in documentation helps prevent miscommunication later on; this is especially important when Contacting the Manufacturer about specific issues identified during inspections. The draft report should include photographs or samples whenever possible to visually support findings—after all, a picture speaks a thousand words!

Creating Actionable Recommendations

Once findings are documented, it's time for the Third Party Inspector to pivot towards creating actionable recommendations based on those observations. These recommendations should be straightforward yet comprehensive enough to guide manufacturers in addressing any identified issues effectively. For instance, if certain production processes were found lacking during Traveling to Factory visits, suggesting specific improvements can help streamline operations.

An effective recommendation will not only address current problems but also provide insights into preventing future discrepancies—essentially turning past mistakes into learning opportunities. This proactive approach ensures that manufacturers understand how vital their role is in maintaining quality standards established during discussions about quality criteria earlier on.

Collaborating with the Manufacturer

Collaboration with the manufacturer post-inspection is critical for an effective resolution of any issues raised in the draft report. A successful Third Party Inspector knows that fostering open lines of communication can lead to better understanding and quicker implementation of recommended changes. After all, this relationship doesn't end once you leave Arriving at The Factory; rather it’s just beginning!

During this collaboration phase, inspectors may need to revisit some points discussed while Having Factory Staff Sign Appropriate Forms after inspections have concluded—this helps reinforce accountability on both sides. It’s also beneficial for inspectors to remain available for follow-up questions or clarifications regarding their reports; doing so builds trust and strengthens partnerships over time.

In summary, crafting a thorough draft inspection report involves documenting findings precisely, creating actionable recommendations based on those observations, and collaborating closely with manufacturers moving forward—a trifecta that enhances product quality across industries.

Having Factory Staff Sign Appropriate Forms

Once the product inspection is complete, it's time for a crucial step: having factory staff sign appropriate forms. This finalization of the inspection process is not just a formality; it serves as a record that both parties agree on the findings and any necessary actions that need to be taken. As a Third Party Inspector, ensuring this step is executed correctly helps build credibility and trust with the manufacturer.

Finalizing the Inspection Process

Finalizing the inspection process involves more than just collecting signatures; it’s about confirming that all aspects of the inspection have been thoroughly discussed and documented. The factory staff must acknowledge any issues identified during your visit, which can range from minor discrepancies to major quality concerns. This agreement not only reinforces accountability but also sets the stage for improvements in future production runs.

Ensuring All Documentation is Accurate

Accuracy in documentation cannot be overstated when you're dealing with multiple stakeholders in international trade. As a Third Party Inspector, you need to meticulously review each form and report before they are signed off by factory staff. Any discrepancies could lead to misunderstandings down the road, so double-checking every detail ensures everyone is on the same page regarding what was inspected and what needs addressing.

Building Relationships for Future Inspections

Having factory staff sign appropriate forms also plays an essential role in relationship-building for future inspections. When manufacturers see that you are diligent about documentation and follow-through, they’re more likely to view you as a valuable partner rather than just another inspector passing through their facility. Establishing this rapport can lead to smoother interactions down the line, making subsequent visits easier and more effective.

Conclusion

In the world of manufacturing, the role of a Third Party Inspector is invaluable. These professionals bridge the gap between manufacturers and clients, ensuring that quality standards are met and maintained throughout the production process. Their expertise not only safeguards products but also fosters trust and transparency in international trade.

The Impact of a Third Party Inspector

A Third Party Inspector plays a crucial role in Contacting the Manufacturer to set up inspections that align with quality expectations. By traveling to factories around the globe, they provide an unbiased assessment of production processes and product integrity. This independent oversight helps mitigate risks associated with overseas manufacturing, ultimately benefiting all stakeholders involved.

How Inspections Enhance Product Quality

Inspections conducted by a Third Party Inspector significantly enhance product quality by identifying potential flaws before they reach consumers. By meticulously carrying out product inspections at various stages—whether examining samples or observing production lines—inspectors ensure compliance with established standards. This proactive approach not only reduces costly recalls but also boosts consumer confidence in products.

Why Choose China Inspection Pro for Your Needs

When it comes to selecting a partner for your inspection needs, China Inspection Pro stands out as a leader in the industry. With their expertise in Traveling to Factories across diverse sectors, they offer tailored solutions that address specific client requirements while ensuring thorough inspections are carried out effectively. From writing and submitting draft inspection reports to having factory staff sign appropriate forms, China Inspection Pro provides comprehensive services designed to elevate your product quality assurance process.