Introduction

In the fast-evolving world of lighting technology, LED Light Inspection has become a critical component in ensuring product quality and reliability. With the increasing prevalence of LED lighting solutions across various applications, rigorous inspection processes are essential to maintain high standards. This not only enhances performance but also fosters consumer trust in the products they use daily.

The Importance of LED Light Inspection

LED Light Inspection is crucial for confirming that products meet industry standards and customer expectations. By conducting thorough inspections, manufacturers can identify potential issues early on, preventing costly recalls and enhancing overall safety. Moreover, regular inspections contribute to the longevity and efficiency of LED lights, ensuring that they operate effectively throughout their lifespan.

Ensuring Safety and Compliance

Ensuring safety and compliance is a top priority in any manufacturing process, especially with LED lights that may be used in sensitive environments. Rigorous testing protocols—including Electrical Performance Inspection and Safety Testing—help mitigate risks associated with electrical failures or environmental factors. Compliance with regulations not only safeguards users but also protects manufacturers from legal liabilities.

The Role of Third-Party Inspection

Third-party inspection plays a pivotal role in maintaining objectivity and credibility within the LED light industry. By engaging independent inspectors for assessments like Electromagnetic Compatibility (EMC) Testing or Life Testing, manufacturers can ensure their products are evaluated without bias. This transparency builds confidence among consumers while reinforcing the manufacturer's commitment to quality assurance.

Overview of LED Light Inspection

LED Light Inspection is a crucial process that ensures the quality and reliability of LED products before they hit the market. This inspection encompasses various testing components designed to evaluate different aspects of LED lights, including their appearance, electrical performance, and even their safety features. With the rapid advancement in LED technology, thorough inspections have become essential to meet industry standards and consumer expectations.

What is LED Light Inspection?

LED Light Inspection refers to a systematic evaluation process aimed at assessing the quality and performance of LED lighting products. This includes examining how well these lights perform under various conditions and ensuring they comply with safety regulations. By conducting comprehensive inspections, manufacturers can identify potential defects early on, leading to safer and more efficient lighting solutions for consumers.

Key Testing Components

The key testing components of LED Light Inspection include Appearance and Dimensional Inspection, Electrical Performance Inspection, Optical Performance Inspection, Electromagnetic Compatibility (EMC) Testing, Safety Testing, Environmental Adaptability Testing, and Life Testing. Each component plays a vital role in determining the overall functionality and reliability of an LED product. For instance, Appearance and Dimensional Inspection focuses on visual defects while Electrical Performance Inspection measures energy efficiency—both critical for customer satisfaction.

Benefits of Comprehensive Inspections

Comprehensive inspections offer numerous benefits that extend beyond mere compliance with regulations; they enhance product quality significantly. By implementing rigorous testing protocols like Electrical Performance Inspection or Optical Performance Assessment, manufacturers can ensure their products deliver optimal performance in real-world applications. Additionally, thorough Life Testing helps predict long-term durability while Environmental Adaptability Testing assesses resilience against harsh conditions—both essential for increasing consumer trust in LED products.

Appearance and Dimensional Inspection

Visual appeal can significantly influence consumer choice, while precise dimensions are essential for compatibility with fixtures and installations. Therefore, a thorough inspection of these attributes is a fundamental part of the overall quality assurance process.

Importance of Visual and Size Accuracy

Visual accuracy in LED lighting is paramount; after all, who wants an unsightly light fixture ruining their home decor? A well-designed product should not only illuminate spaces efficiently but also blend seamlessly into its environment. Furthermore, size accuracy ensures that the LED lights fit perfectly within designated spaces, avoiding installation headaches that could lead to costly adjustments or replacements.

Common Defects in LED Lighting

Despite advances in technology, common defects still plague the world of LED lighting. Issues such as inconsistent color temperatures, uneven brightness distribution, and physical imperfections like scratches or dents can undermine both functionality and aesthetic appeal. Identifying these defects during the Appearance and Dimensional Inspection phase helps manufacturers address problems before they reach consumers, maintaining a high standard for quality.

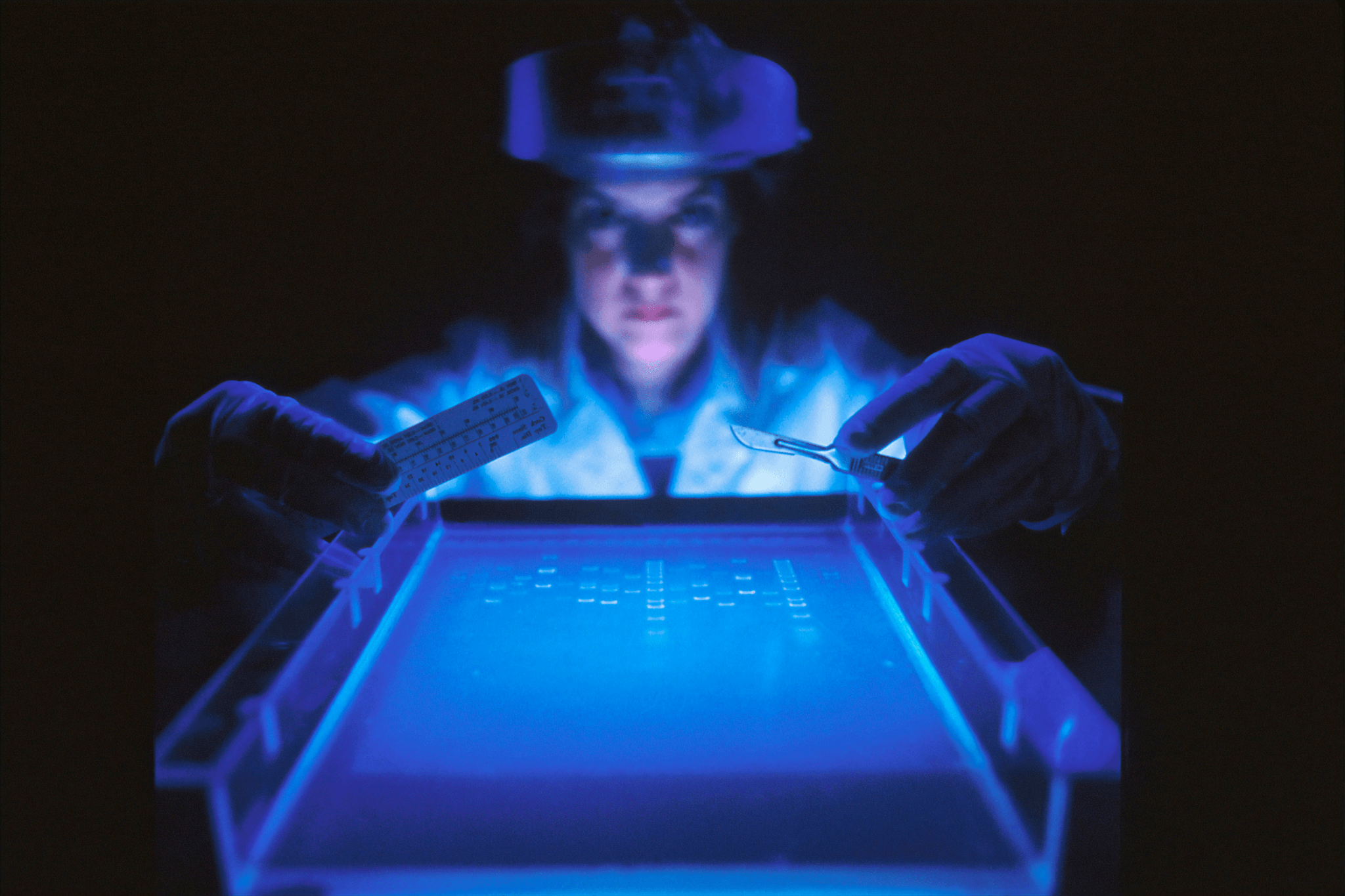

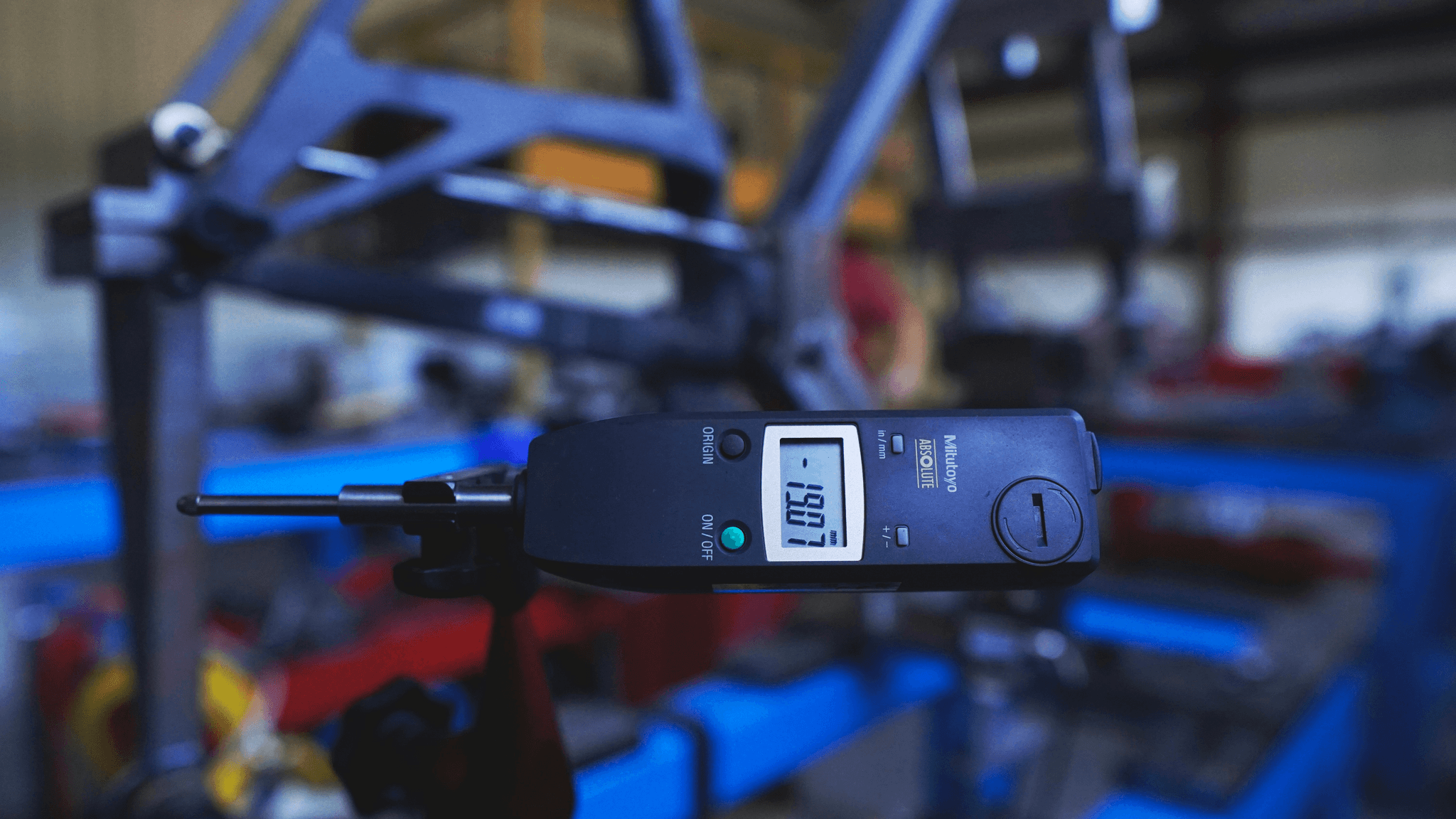

Techniques for Effective Appearance Evaluation

To conduct effective appearance evaluations during LED Light Inspection, various techniques can be employed to ensure thoroughness. Visual inspections should include close examinations under different lighting conditions to assess color consistency and surface integrity accurately. Additionally, using measurement tools like calipers can help verify dimensional accuracy against specifications—after all, precision is key when it comes to Electrical Performance Inspection and Optical Performance Inspection as well!

Electrical Performance Inspection

This process ensures that the LED lights not only meet performance standards but also operate efficiently, thereby maximizing their lifespan and effectiveness. By focusing on electrical efficiency, power consumption, and common electrical issues, manufacturers can guarantee that their products are safe and reliable.

Measuring Electrical Efficiency

Measuring electrical efficiency is a cornerstone of Electrical Performance Inspection in LED Light Inspection. It involves assessing how well an LED light converts electrical energy into visible light without excessive waste in heat or other forms of energy loss. High-efficiency LEDs not only save on electricity costs for consumers but also contribute to a more sustainable environment by reducing overall energy demand.

Assessing Power Consumption

Assessing power consumption is another vital component of Electrical Performance Inspection during the LED Light Inspection process. This evaluation helps determine how much energy each lighting unit consumes under various operating conditions, ensuring compliance with regulatory standards and consumer expectations. By understanding power consumption patterns, manufacturers can optimize designs for better performance while minimizing environmental impact.

Addressing Common Electrical Issues

Addressing common electrical issues is essential for maintaining the integrity of LED lights throughout their lifecycle as part of a comprehensive LED Light Inspection strategy. Problems such as flickering, overheating, or inconsistent brightness can significantly affect user experience and safety. Regular inspections help identify these issues early on so that they can be resolved before they escalate into more significant problems requiring extensive repairs or replacements.

Optical Performance Inspection

This section delves into the evaluation of luminance and color quality, the significance of beam pattern integrity, and the tools utilized for optical assessment. By ensuring these parameters meet industry standards, manufacturers can guarantee that their products deliver optimal performance and meet customer expectations.

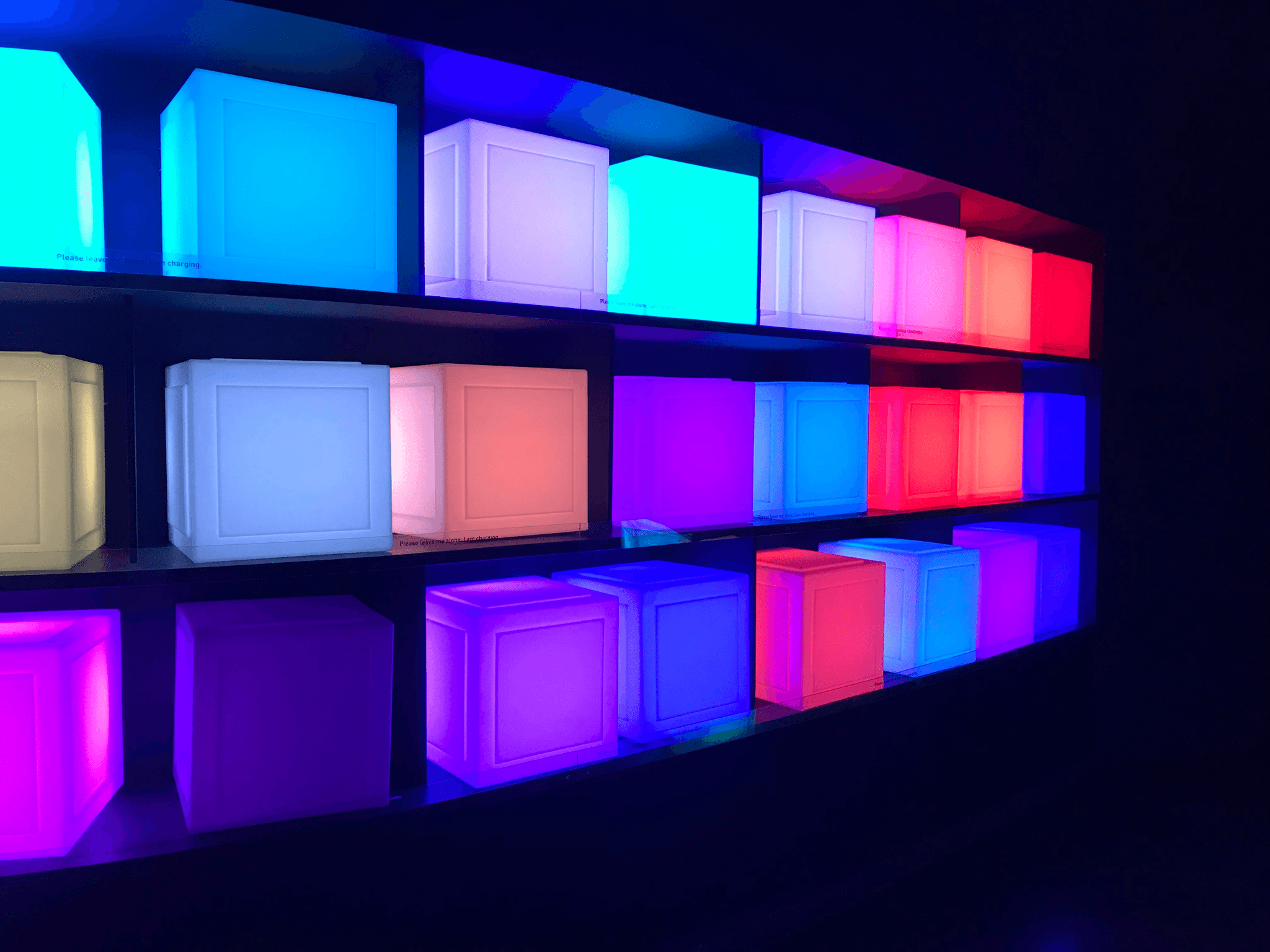

Evaluating Luminance and Color Quality

Luminance refers to the brightness emitted by an LED light source, while color quality encompasses how accurately colors are rendered under that light. In LED Light Inspection, evaluating both luminance and color quality is essential for determining a product's suitability for various applications, from residential lighting to commercial displays. A well-executed inspection will involve measuring luminous flux and color temperature to ensure compliance with specifications.

Furthermore, poor luminance can lead to inadequate visibility in workspaces or public areas, while subpar color rendering can distort colors in retail environments or art galleries. This highlights why thorough Electrical Performance Inspection is crucial; it ensures that the product not only shines bright but also casts colors faithfully. Manufacturers must prioritize these evaluations during their inspection processes to maintain high-quality standards.

Importance of Beam Pattern Integrity

Beam pattern integrity refers to how well an LED light maintains its intended distribution of light across a surface area. During LED Light Inspection, assessing this feature is vital because improper beam patterns can result in uneven lighting or glare—issues that are particularly problematic in settings like offices or theaters where ambiance matters significantly. An effective beam pattern ensures that light is directed where it's needed most without causing discomfort or distraction.

Moreover, inconsistencies in beam patterns can lead to energy inefficiencies as users may need additional lights to compensate for poorly distributed illumination. This ties back into Electrical Performance Inspection; if a product's design leads to wasted energy due to bad beam patterns, it defeats the purpose of using efficient LEDs in the first place. Therefore, maintaining beam pattern integrity should be prioritized during inspections.

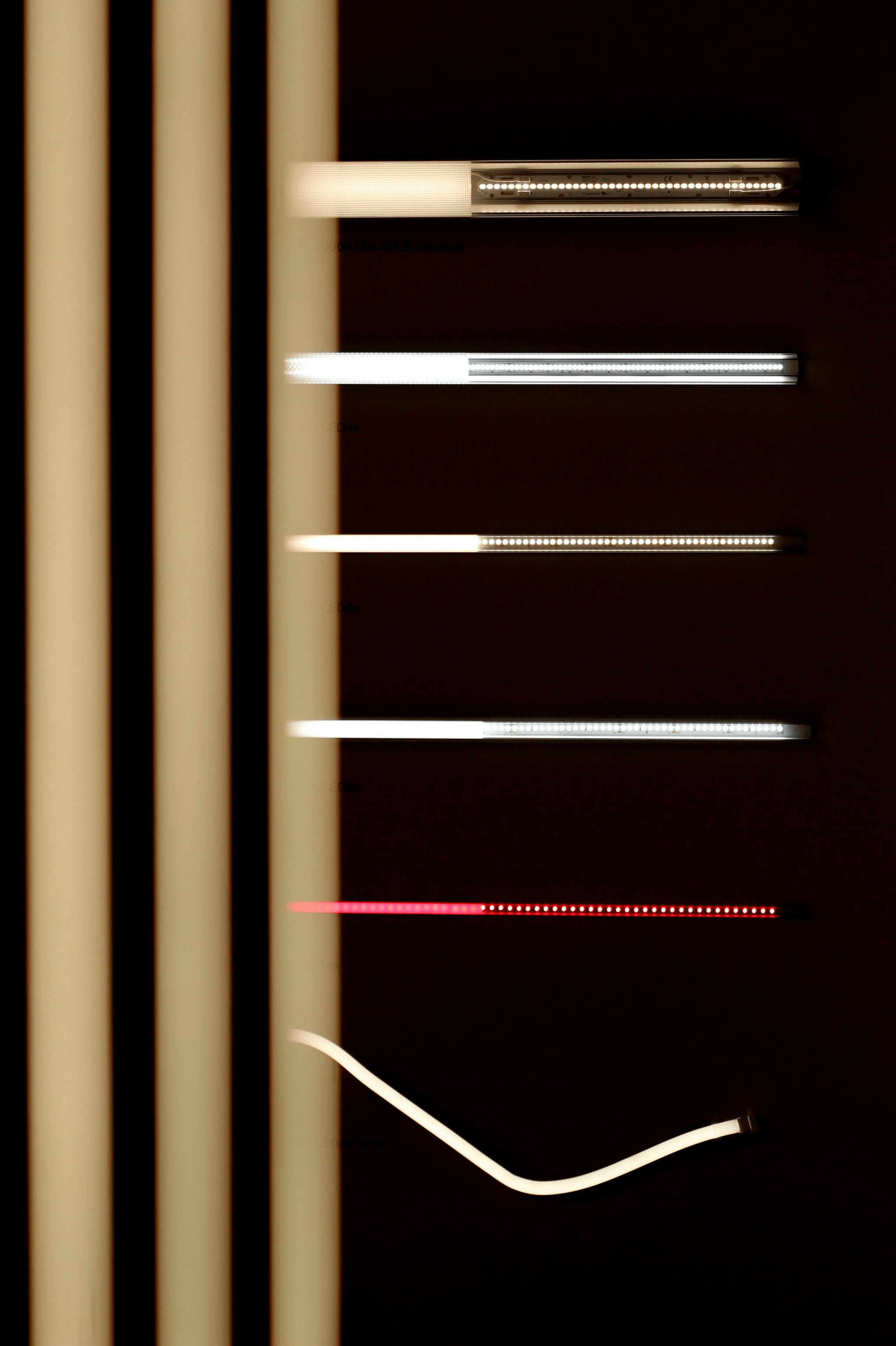

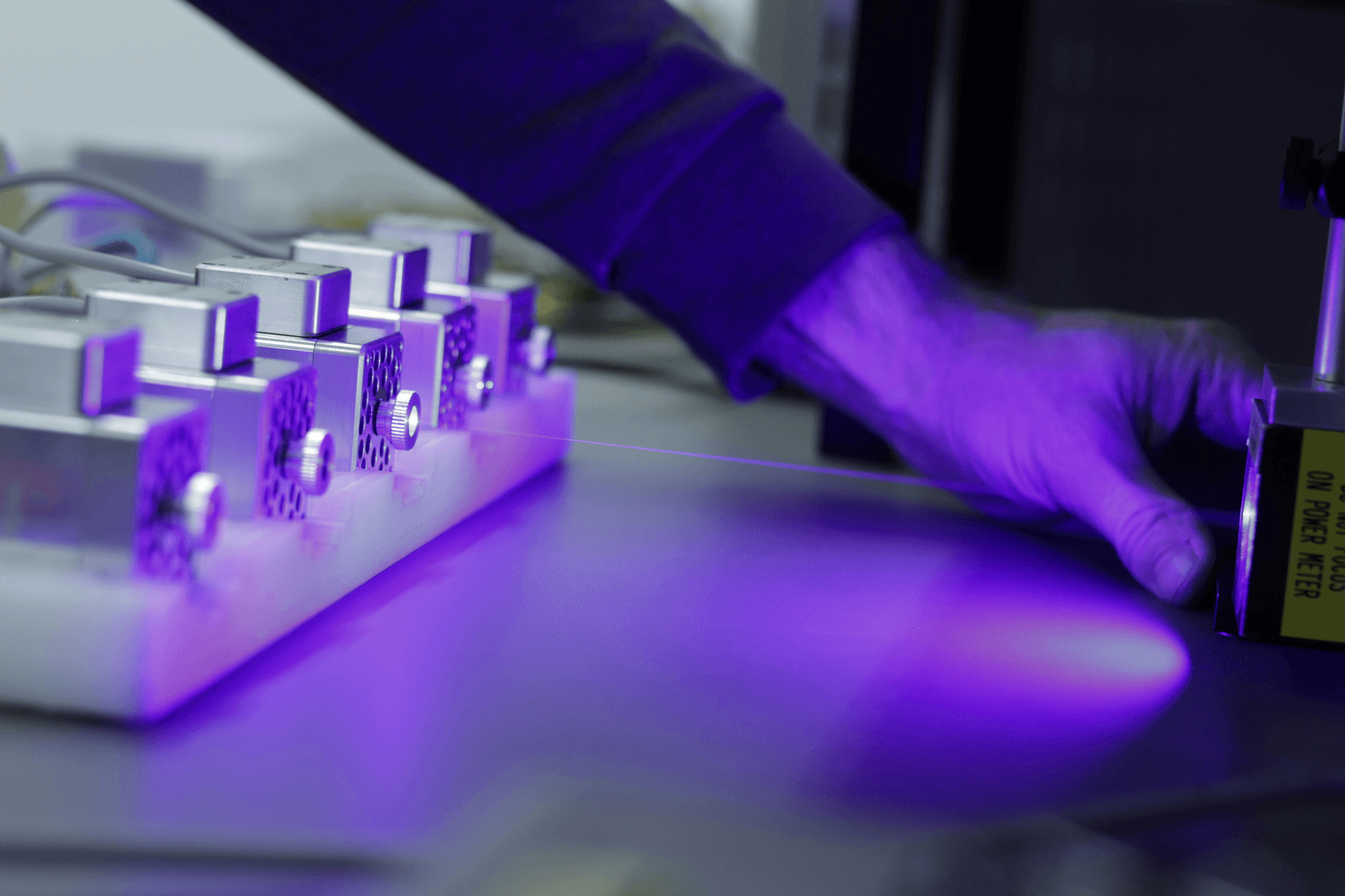

Tools for Optical Assessment

A variety of specialized tools are employed during optical assessments within LED Light Inspection processes. These include goniophotometers for measuring luminous intensity distribution and spectroradiometers for evaluating color quality metrics such as CRI (Color Rendering Index) and CCT (Correlated Color Temperature). Utilizing advanced technology allows inspectors to gather precise data on how well an LED performs optically.

In addition to these sophisticated instruments, software solutions play an integral role in analyzing results from optical tests efficiently and accurately. The combination of hardware and software ensures comprehensive assessments that feed into broader safety testing protocols like Environmental Adaptability Testing and Life Testing—factors critical for long-term reliability in real-world conditions. As manufacturers strive for excellence through rigorous Optical Performance Inspections, they pave the way toward delivering superior lighting solutions.

Electromagnetic Compatibility (EMC) Testing

When it comes to LED Light Inspection, one of the often-overlooked aspects is Electromagnetic Compatibility (EMC) Testing. This testing ensures that LED lights operate effectively without causing or being affected by electromagnetic interference. Understanding EMC is crucial for manufacturers aiming to produce compliant and reliable lighting solutions.

Understanding EMC in LED Lights

Electromagnetic Compatibility (EMC) refers to the ability of electronic devices, like LED lights, to function properly in their electromagnetic environment without causing or suffering from interference. In the context of LED Light Inspection, this means ensuring that the emitted electromagnetic fields do not disrupt nearby electronic devices while also confirming that the LEDs are immune to external disturbances. A solid grasp of EMC principles helps manufacturers design products that meet regulatory standards and perform reliably in various environments.

Potential Issues with Electromagnetic Interference

Electromagnetic interference (EMI) can lead to a host of problems for LED lighting systems, including flickering lights, reduced performance, and even complete failure under certain conditions. Common sources of EMI include radio frequency signals from communication devices and fluctuations from power lines or other electrical equipment. During Electrical Performance Inspection, it’s essential to identify these potential issues early on; otherwise, they could compromise not just the functionality of the LEDs but also user safety.

Strategies for Achieving Compliance

To achieve compliance with EMC requirements during LED Light Inspection, manufacturers can implement several strategies aimed at mitigating interference risks. First off, proper circuit design—such as using shielded cables and filtering components—can significantly reduce susceptibility to EMI. Additionally, conducting thorough Safety Testing alongside Environmental Adaptability Testing ensures that products can withstand various conditions while maintaining performance integrity over time.

Safety Testing and Environmental Adaptability

In the world of LED lighting, safety testing and environmental adaptability are paramount. These factors not only ensure compliance with regulations but also protect consumers from potential hazards associated with faulty products. A comprehensive LED Light Inspection that includes safety assessments can significantly mitigate risks and enhance product reliability.

Importance of Safety Testing in LED Products

Safety testing is crucial in the development of LED products, as it identifies potential hazards before they reach consumers. This process involves rigorous evaluations to ensure that products meet established safety standards, which can prevent electrical shocks, overheating, or fire risks. By incorporating safety testing into the overall LED Light Inspection framework, manufacturers can foster consumer trust and promote a safer lighting environment.

Moreover, various components undergo scrutiny during safety testing to assess their durability and performance under different conditions. This includes evaluating materials for flammability and ensuring that electrical components are adequately insulated. Ultimately, thorough safety testing serves as a safeguard for both manufacturers and users alike.

Evaluating Resistance to Environmental Factors

Environmental adaptability testing assesses how well LED products withstand diverse conditions such as humidity, temperature fluctuations, and exposure to dust or corrosive elements. This evaluation is vital because LEDs are often used in outdoor settings where they encounter harsh climates that could compromise their performance over time. A robust LED Light Inspection should include these tests to confirm that products maintain functionality despite environmental stresses.

For instance, an effective Environmental Adaptability Testing regimen will reveal if an LED fixture can operate efficiently in extreme temperatures without sacrificing brightness or color quality—critical aspects also evaluated during Optical Performance Inspection. Furthermore, understanding how well LEDs resist moisture intrusion can prevent failures in outdoor applications where water damage may occur.

Life Testing and Long-Term Performance

Life testing is essential for determining the longevity of LED lights under normal operating conditions; this involves simulating years of use within a controlled environment to gauge performance degradation over time. By integrating life testing into their inspection process, manufacturers gain insights into when an LED product may begin to falter—information invaluable for warranty considerations and customer satisfaction guarantees.

Additionally, long-term performance assessments help identify any latent defects that could surface after months or years of use—issues often overlooked during initial inspections like Appearance and Dimensional Inspection or Electrical Performance Inspection. Ultimately, life testing contributes significantly to product reliability by ensuring LEDs continue performing effectively throughout their intended lifespan while adhering to safety standards established during earlier evaluations.

Conclusion

In wrapping up our exploration of LED Light Inspection, it’s clear that this process is not just a checkbox on a compliance list; it’s an essential element for ensuring quality and safety in lighting products. From Appearance and Dimensional Inspection to Electrical Performance Inspection, each aspect plays a critical role in determining the overall effectiveness and reliability of LED lights. As technology advances, the importance of thorough inspections only grows, paving the way for safer and more efficient lighting solutions.

Key Takeaways on LED Light Inspection

LED Light Inspection encompasses various testing methodologies that ensure products meet stringent standards for performance and safety. Key areas such as Optical Performance Inspection and Electromagnetic Compatibility (EMC) Testing are vital to prevent issues like flickering or interference that could compromise user experience. Moreover, incorporating Life Testing and Environmental Adaptability Testing provides insights into how well these lights will perform under real-world conditions, extending their lifespan and reliability.

Role of China Inspection Pro in Quality Assurance

China Inspection Pro stands at the forefront of quality assurance in the realm of LED Light Inspection. Their expertise ensures that manufacturers adhere to rigorous standards across all inspection categories, including Safety Testing and Electrical Performance Inspection. By leveraging their services, companies can confidently navigate compliance requirements while enhancing customer trust through proven product quality.

Future Trends in LED Testing and Compliance

Looking ahead, we can expect significant advancements in LED testing methodologies to keep pace with rapid technological developments. Innovations may include more sophisticated Optical Performance Inspections utilizing AI-driven analytics for precise evaluations or enhanced Life Testing protocols that simulate extreme environmental conditions more accurately than ever before. Overall, as the demand for reliable lighting solutions grows, so will the emphasis on comprehensive inspections encompassing every facet from Appearance and Dimensional Inspections to Environmental Adaptability Testing.