Introduction

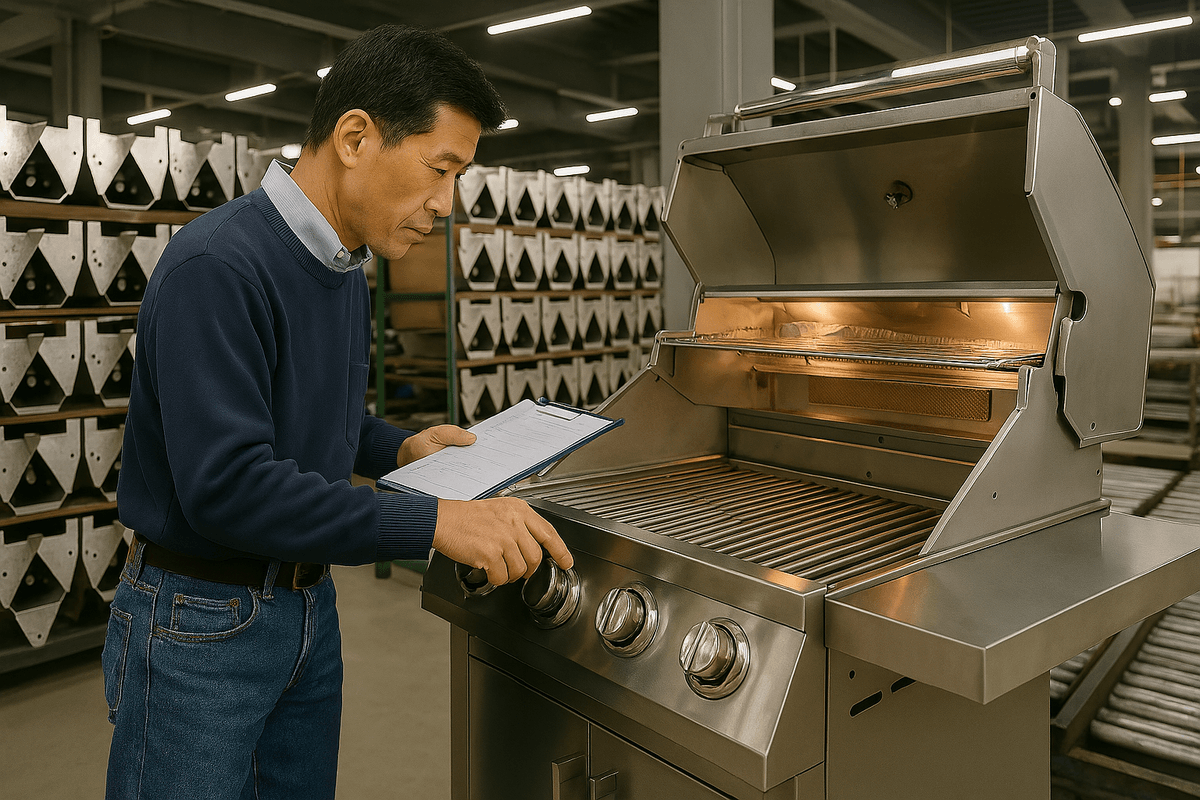

In the world of outdoor cooking, BBQ Grill Quality Inspection plays a crucial role in ensuring that every grill produced meets the highest standards of safety and performance. Whether it's gas BBQ grills, electric BBQ grills, or charcoal BBQ grills, quality inspections are essential to guarantee that consumers receive reliable products that can withstand the test of time and heat. With an increasing number of grilling enthusiasts seeking top-notch equipment, manufacturers must prioritize quality control services in China to maintain their reputation and customer satisfaction.

Importance of BBQ Grill Quality Inspection

The importance of BBQ Grill Quality Inspection cannot be overstated; it serves as a safeguard against potential hazards and performance issues that could arise from subpar manufacturing practices. A professional BBQ grill inspection ensures that each grill is thoroughly evaluated for safety compliance, durability, and functionality before it reaches the market. This not only protects consumers but also helps manufacturers avoid costly recalls and legal liabilities associated with faulty products.

Understanding Third-Party Inspections

Third-party inspections provide an unbiased assessment of product quality by independent entities like China Inspection Company Limited. These inspections offer manufacturers peace of mind by confirming that their gas BBQ grills, electric BBQ grills, or charcoal BBQ grills adhere to industry standards and regulations. By engaging third-party quality control services in China, businesses can enhance their credibility while ensuring their products meet consumer expectations.

Benefits of Quality Control for Grills

Implementing robust quality control measures for grills yields numerous benefits for both manufacturers and consumers alike. For manufacturers, consistent quality leads to increased customer trust and loyalty—essential ingredients for long-term success in a competitive market. Consumers benefit from knowing they are purchasing safe and reliable products backed by thorough inspections like those provided by professional BBQ grill inspection services.

What is Third-Party BBQ Grill Quality Inspection?

These inspections are conducted by independent organizations that evaluate products against established criteria, providing an unbiased assessment of quality. This process is essential for manufacturers and consumers alike, as it fosters trust and guarantees that products will perform as expected.

Definition and Purpose

Third-party BBQ grill quality inspection refers to the evaluation of grills—be they gas, electric, or charcoal—by an external organization specializing in quality control services in China. The primary purpose of these inspections is to identify any defects or compliance issues before the products reach the market. By utilizing professional BBQ grill inspection services, manufacturers can ensure their products not only meet regulatory standards but also exceed consumer expectations.

Role of Companies like China Inspection Pro

Companies like China Inspection Pro play an integral role in the third-party inspection landscape for BBQ grills. They provide comprehensive china factory inspection services that cover every aspect of product quality—from materials used to final assembly checks. By partnering with a reputable china inspection company limited, manufacturers gain access to expert insights and actionable recommendations that enhance their production processes and product offerings.

How Inspections Fit into Manufacturing

Inspections fit seamlessly into the manufacturing process by acting as checkpoints at various stages of production. Before production begins, pre-production inspections help verify that materials are up to par; during manufacturing, in-process quality control ensures adherence to specifications; finally, final product evaluations confirm that each unit meets safety and performance standards before shipping out. This structured approach not only minimizes risks associated with defective BBQ grills but also reinforces a culture of continuous improvement within manufacturing operations.

Key Standards and Regulations for BBQ Grills

These guidelines help manufacturers produce safe, high-quality products that meet consumer expectations. Understanding these standards can significantly enhance the effectiveness of BBQ Grill Quality Inspection, making it a vital part of the manufacturing process.

ANSI and UL Standards

The American National Standards Institute (ANSI) and Underwriters Laboratories (UL) set forth essential benchmarks for BBQ grill safety and performance. ANSI provides guidelines that cover various types of grills—whether they be gas, electric, or charcoal—ensuring that they operate safely under normal conditions. Meanwhile, UL certification signifies that a product has undergone rigorous testing for electrical safety, flammability, and overall quality control services in China.

Compliance with ANSI and UL standards is not just about following rules; it's about instilling confidence in consumers who want to enjoy their grilling experience without worry. As a result, manufacturers who prioritize these certifications often find themselves at an advantage in the competitive market for BBQ grills. When conducting a Professional BBQ Grill Inspection, these standards serve as critical checkpoints to ensure all products are safe for consumer use.

Understanding Safety and Quality Compliance

Safety compliance goes hand-in-hand with quality assurance in the world of BBQ grills. Manufacturers must navigate a maze of regulations that dictate everything from materials used to construction methods employed in their grills. By integrating thorough inspections into their processes—especially through reliable China inspection company limited services—manufacturers can effectively identify potential hazards before products reach consumers.

Quality compliance isn't just about ticking boxes; it’s about creating a culture where safety is prioritized at every level of production—from design to assembly line inspections. A well-structured inspection process helps manufacturers spot issues like material defects or faulty gas connections early on, preventing costly recalls down the line. This proactive approach not only safeguards consumer health but also enhances brand reputation.

Importance of Certification in BBQ Grills

A certified grill assures buyers that it has met stringent quality control measures set by recognized authorities like ANSI and UL. This certification process often involves comprehensive inspections conducted by specialized firms offering quality control services in China.

For consumers shopping for gas, electric, or charcoal BBQ grills, seeing certification marks can make all the difference between choosing one product over another. It signals reliability and commitment to safety—a crucial factor when you’re dealing with appliances designed to handle fire! In essence, investing time in obtaining proper certifications through professional inspections boosts marketability while ensuring peace of mind for end-users.

The Inspection Process Explained

Pre-Production Inspections

Pre-production inspections are essential for laying the foundation of quality control services in China. During this phase, inspectors evaluate materials and components before they enter the manufacturing process. This proactive approach helps identify any discrepancies or defects in raw materials that could compromise the integrity of gas BBQ grills, electric BBQ grills, or charcoal BBQ grills.

By assessing suppliers and their practices early on, companies can ensure compliance with industry standards such as ANSI and UL. Furthermore, these inspections help establish a baseline for quality expectations that manufacturers must meet throughout production. Ultimately, pre-production inspections set the tone for successful BBQ Grill Quality Inspection efforts down the line.

In-Process Quality Control

In-process quality control is where the rubber meets the road—or rather, where the grill meets the flame! At this stage, inspectors monitor production processes to ensure adherence to established safety protocols and design specifications for various types of BBQ grills. This ongoing oversight helps catch any issues that may arise during manufacturing before they escalate into larger problems.

For instance, if an inspector identifies a construction flaw while examining gas BBQ grills or electric BBQ grills during assembly, immediate corrective actions can be taken to rectify it. Moreover, this stage allows manufacturers to maintain consistency across batches by confirming that each unit aligns with quality standards set forth during pre-production inspections. Effective in-process quality control is crucial for delivering reliable products that consumers can trust.

Final Product Evaluation

The final product evaluation serves as a comprehensive check-up on completed BBQ grills before they hit store shelves or backyards across America! Inspectors conduct thorough assessments to ensure each unit meets all safety regulations and performance benchmarks established earlier in the inspection process. This step includes testing functionality—such as ignition systems on gas BBQ grills—and verifying material durability against wear-and-tear over time.

During this phase of professional BBQ grill inspection, any identified flaws can lead to necessary adjustments or even rejections of subpar products from entering circulation altogether. By prioritizing rigorous final evaluations through reputable china factory inspection services like those offered by China Inspection Company Limited, manufacturers reinforce their commitment to consumer safety and satisfaction with every grill sold.

Common Issues Identified During Inspections

A professional BBQ grill inspection can uncover various flaws that might compromise the grill's performance or safety. Understanding these issues helps manufacturers address problems early in the production process, ultimately leading to higher quality products.

Material and Construction Flaws

Material and construction flaws are among the most frequently identified issues during BBQ Grill Quality Inspections. These flaws can range from subpar materials that don't withstand high temperatures to improper welding or assembly techniques that jeopardize structural integrity. For gas BBQ grills, using low-quality components can lead to dangerous leaks, while electric BBQ grills may suffer from inadequate insulation or electrical faults, making thorough inspections essential.

In the realm of charcoal BBQ grills, construction flaws like poor ventilation design can hinder performance and efficiency. By engaging quality control services in China, manufacturers can ensure that their products are built with appropriate materials and craftsmanship. This proactive approach not only enhances safety but also boosts consumer confidence in the brand.

Safety Hazards and Compliance Failures

Safety hazards pose a significant risk in the world of grilling, making them a critical focus during professional BBQ grill inspections. Common compliance failures include missing safety features like flame guards or faulty ignition systems that could result in accidents or injuries during use. Regulatory standards such as ANSI and UL set specific requirements for gas, electric, and charcoal BBQ grills; failing to meet these standards can lead to serious legal repercussions.

A thorough inspection process helps identify any potential hazards before they reach consumers' hands. Companies like China Inspection Company Limited specialize in ensuring compliance with these regulations through rigorous testing protocols tailored for different types of grills. By addressing safety hazards upfront, manufacturers not only protect their customers but also enhance their brand reputation.

Design Flaws That Affect Performance

Design flaws can significantly impact the overall performance of BBQ grills, making them an important aspect of quality control inspections. For instance, poorly designed airflow systems may lead to uneven cooking temperatures or excessive smoke production in charcoal BBQ grills. Similarly, ineffective heat distribution mechanisms in gas or electric models could result in inconsistent cooking results, frustrating users seeking perfectly grilled meals.

During a comprehensive inspection process offered by china factory inspection services, inspectors evaluate design elements alongside material quality and construction methods. They provide valuable feedback on how design modifications could improve functionality and user satisfaction across all types of grills—gas, electric, or charcoal alike. Investing time into addressing design flaws before mass production ensures that consumers receive high-performing products they love.

Choosing the Right Inspection Partner

When it comes to BBQ Grill Quality Inspection, selecting the right inspection partner is crucial for ensuring that your products meet safety and quality standards. A professional BBQ grill inspection can save you from costly recalls and enhance your brand's reputation in the market. With numerous companies offering quality control services in China, understanding what to look for is essential.

Factors to Consider When Selecting an Inspector

First and foremost, experience matters. Look for an inspector who specializes in BBQ grills—whether they are gas BBQ grills, electric BBQ grills, or charcoal BBQ grills—and has a proven track record of thorough inspections. Additionally, consider the inspector's familiarity with relevant standards such as ANSI and UL; knowledge of these regulations can significantly impact the quality control process.

Next, evaluate the inspector’s methodology and tools used during inspections. A reliable inspection partner should employ comprehensive techniques that include pre-production inspections, in-process quality control, and final product evaluations tailored specifically for different types of BBQ grills. Lastly, check for certifications or accreditations that validate their expertise; this adds an extra layer of assurance that you’re working with a reputable china inspection company limited.

Benefits of Working with China Inspection Pro

Choosing China Inspection Pro as your inspection partner comes with numerous benefits tailored to meet your specific needs in BBQ Grill Quality Inspection. They offer extensive experience across various grill types—gas, electric, and charcoal—ensuring that every aspect of your product is scrutinized according to industry standards. Their commitment to quality control services in China means you’ll receive timely reports and actionable insights that help improve your manufacturing processes.

Moreover, China Inspection Pro employs advanced technology during their inspections which enhances accuracy while minimizing human error. They also provide customized solutions based on your unique requirements; whether you're looking for routine checks or specialized evaluations, they have got you covered! By working with them, you gain peace of mind knowing that seasoned professionals are overseeing the safety and compliance aspects of your products.

Questions to Ask During the Selection Process

When considering potential inspectors for your BBQ grill quality inspection needs, asking the right questions can make all the difference. Start by inquiring about their experience specifically related to BBQ grills; ask how many inspections they have conducted on gas BBQ grills versus electric or charcoal ones. This will help gauge their familiarity with various models and designs.

Additionally, ask about their approach regarding compliance with ANSI and UL standards; understanding how they ensure adherence will give you confidence in their capabilities. Finally, don’t hesitate to inquire about turnaround times for reports and follow-up actions after an inspection; timely communication is key when addressing any issues identified during inspections.

Conclusion

In wrapping up our discussion on BBQ Grill Quality Inspection, it’s clear that ensuring safety and quality is paramount for manufacturers and consumers alike. The process of professional BBQ grill inspection not only safeguards users from potential hazards but also elevates the overall standard of products available in the market. With proper quality control services in China, manufacturers can rest assured that their gas, electric, and charcoal BBQ grills meet stringent safety regulations.

Ensuring Safety through Quality Control

Safety is non-negotiable when it comes to BBQ grills; after all, nobody wants a barbecue gone wrong! Implementing a robust BBQ Grill Quality Inspection process minimizes risks associated with faulty designs or materials that could lead to accidents. By prioritizing quality control services in China, manufacturers can identify and rectify issues early on, ensuring their products are safe for consumer use.

How Inspections Improve Consumer Trust

When consumers see certifications from reputable inspection bodies like China Inspection Company Limited, their confidence in the product skyrockets. A thorough professional BBQ grill inspection not only demonstrates a manufacturer’s commitment to quality but also fosters trust among buyers who want reliable gas, electric, or charcoal BBQ grills for their outdoor cooking adventures. Ultimately, this trust translates into brand loyalty and repeat purchases—both essential for long-term success.

Next Steps for Implementing Quality Inspections

To kickstart your journey toward enhanced product safety and consumer satisfaction, consider partnering with an established china factory inspection service that specializes in BBQ grill quality inspections. Start by evaluating potential partners based on their experience and expertise in handling various types of grills. Once you’ve selected the right inspection partner, work together to develop a comprehensive plan that incorporates pre-production inspections, in-process quality control checks, and final product evaluations—ensuring every grill meets high standards before hitting the market.