Introduction

In today's fast-paced technological landscape, the importance of testing electronic components cannot be overstated. From smartphones to sophisticated medical devices, every piece of equipment relies on the reliability and functionality of its components. Rigorous testing ensures that these components not only meet performance standards but also safeguard consumer safety and satisfaction.

Importance of Testing Electronic Components

Testing electronic components is crucial for several reasons, including quality assurance and compliance with industry standards. Without thorough testing, manufacturers risk releasing faulty products that can lead to malfunctions or even hazardous situations for users. Ensuring that each component is rigorously tested helps build trust in the brand and reduces costly recalls or repairs down the line.

Key Testing Methods Explained

There are various methods employed to test electronic components effectively, each designed to evaluate specific attributes like durability and functionality. Visual and Mechanical Inspection allows for early detection of physical defects, while Electrical Testing assesses how well a component performs under electrical loads. Additionally, Safety Testing ensures compliance with regulatory standards, Environmental Testing evaluates performance in extreme conditions, and Life Testing examines longevity—each method plays a vital role in comprehensive testing strategies.

Ensuring Quality and Reliability

Ensuring quality and reliability through meticulous testing processes is essential for maintaining consumer trust in electronic products. By implementing a combination of Visual and Mechanical Inspection, Electrical Testing, Safety Testing, Environmental Testing, and Life Testing and Reliability assessments, manufacturers can confidently deliver high-quality components to the market. Ultimately, this rigorous approach not only enhances product performance but also reinforces brand reputation in an increasingly competitive marketplace.

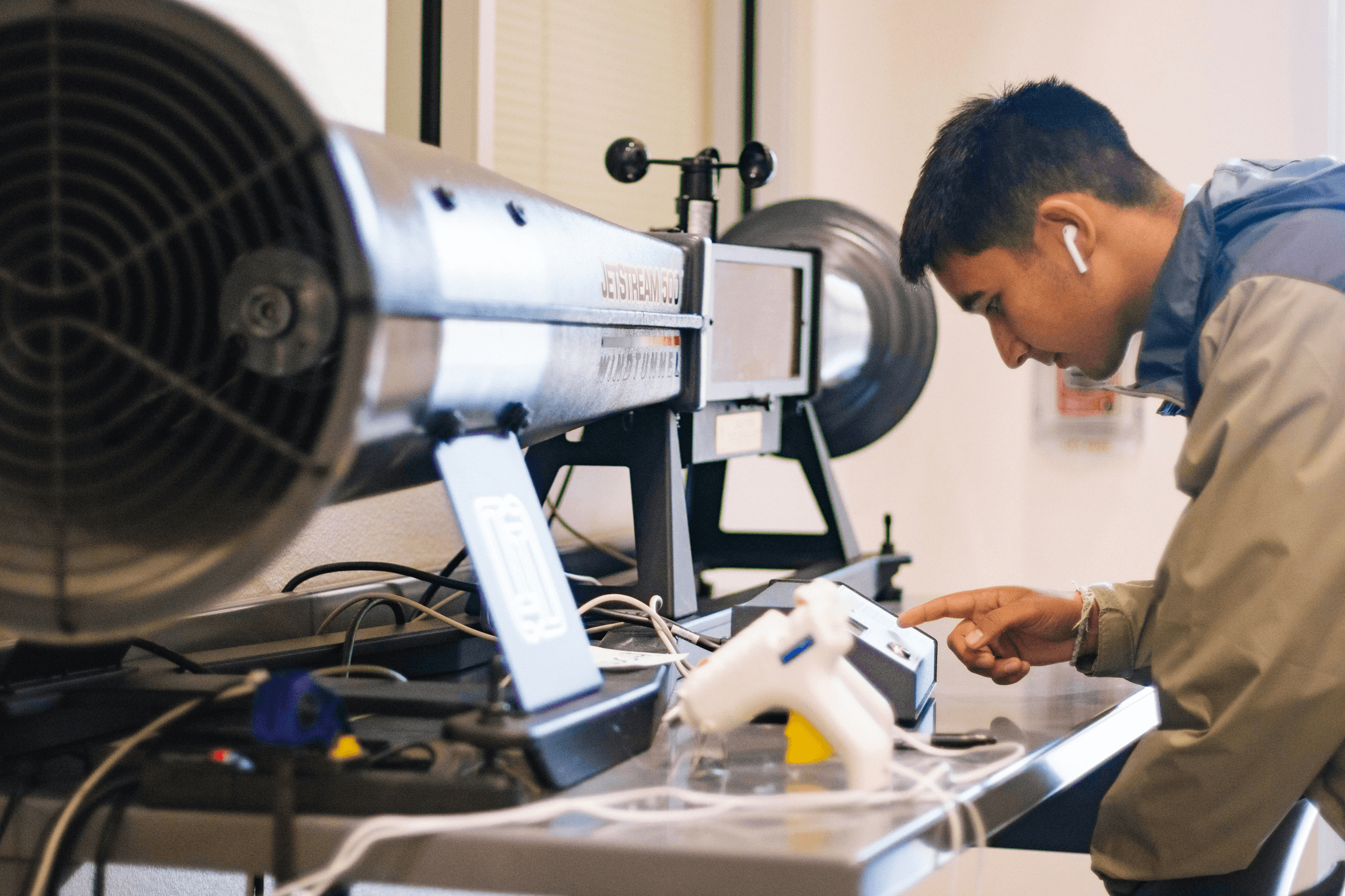

Visual and Mechanical Inspection

This phase is crucial in identifying any surface-level defects that could compromise performance or safety later on. By employing a range of inspection techniques, manufacturers can catch potential issues before they escalate, saving time and costs associated with faulty components.

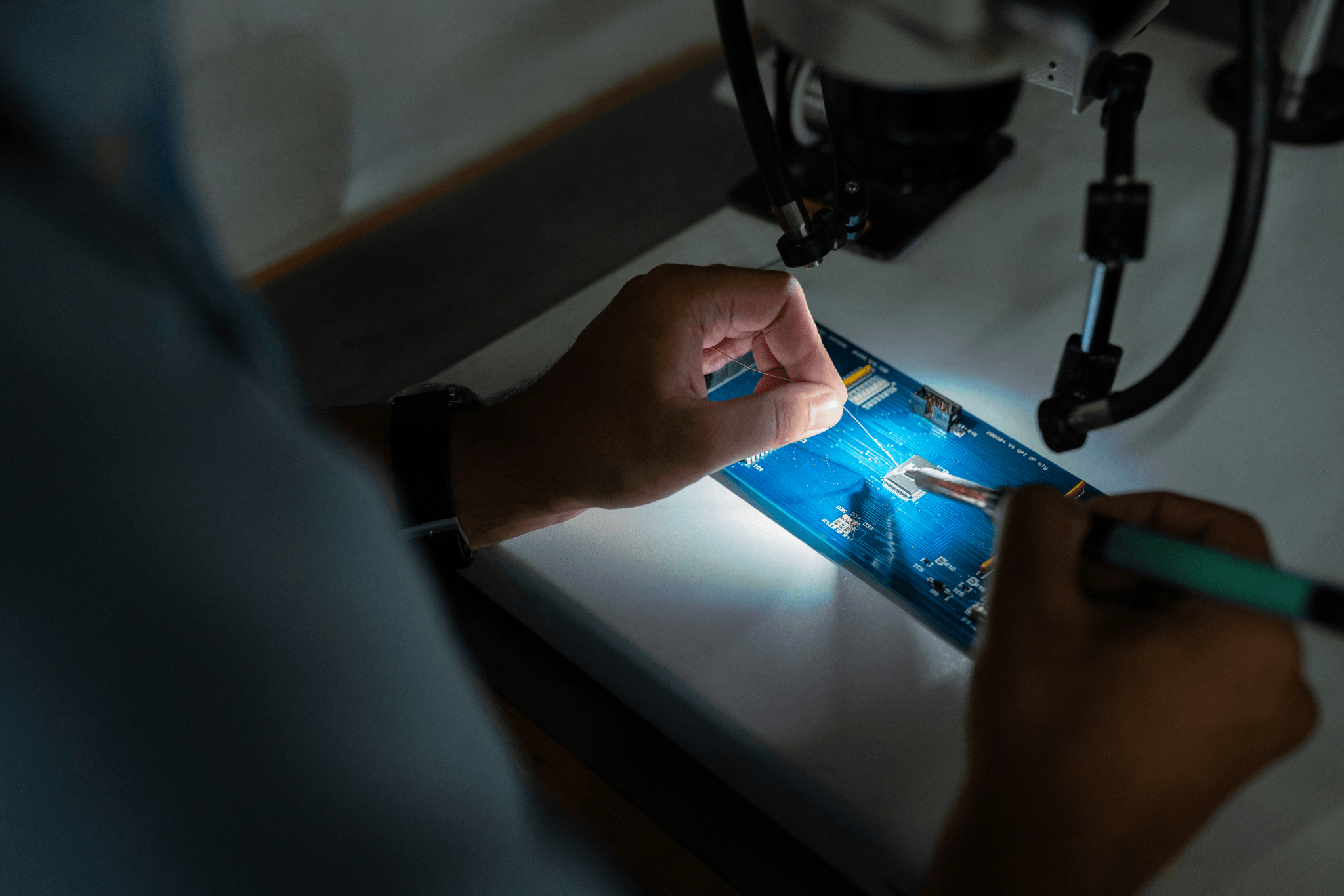

Overview of Visual Inspection Techniques

Visual inspection techniques are all about the art of observation—keeping a keen eye on every detail of electronic components. This may involve using magnifying tools or even sophisticated imaging technology to spot signs of wear, corrosion, or misalignment. Not only does this method help in assessing the physical integrity of parts, but it also plays a vital role in ensuring that components meet industry standards before moving on to Electrical Testing and beyond.

Mechanical Inspection Essentials

Mechanical inspection dives deeper into how well electronic components can withstand physical stressors. This involves testing for mechanical strength, durability, and overall fit within assemblies—think torque tests and vibration assessments. By rigorously evaluating these aspects, manufacturers can ensure that their products will not only function correctly but also endure real-world conditions without failure.

Role in Quality Control

The role of Visual and Mechanical Inspection in quality control cannot be overstated; it's akin to a gatekeeper for component reliability. Effective inspections help detect flaws early, preventing defective products from reaching consumers and ultimately enhancing brand reputation. In an era where safety matters more than ever, ensuring that every component passes through these rigorous checks is essential for maintaining trust in the marketplace.

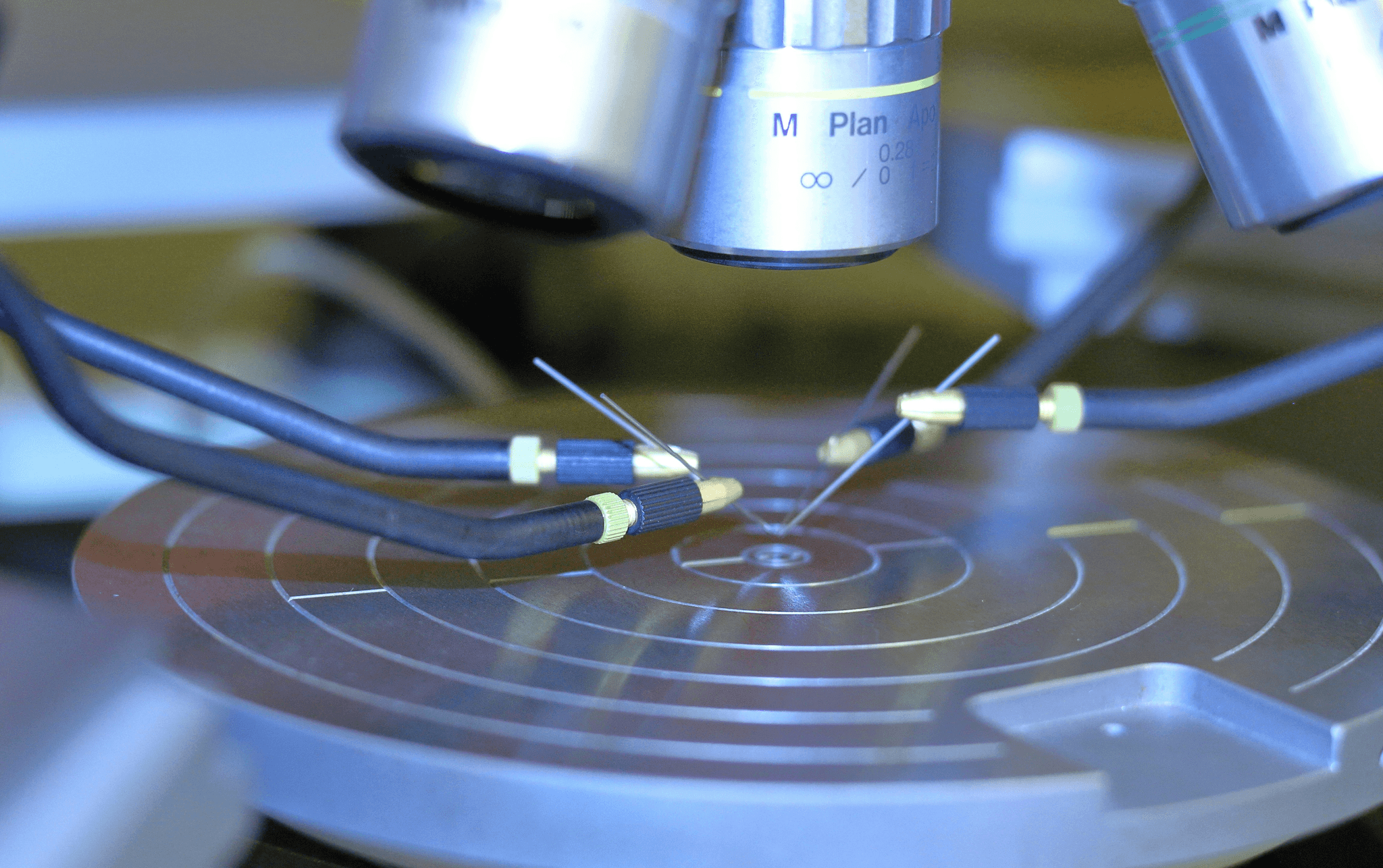

Electrical Testing

This testing phase dives deep into the electrical parameters that define how components behave under different conditions. By rigorously evaluating these parameters, manufacturers can identify potential failures, paving the way for safer and more efficient products.

Understanding Electrical Parameters

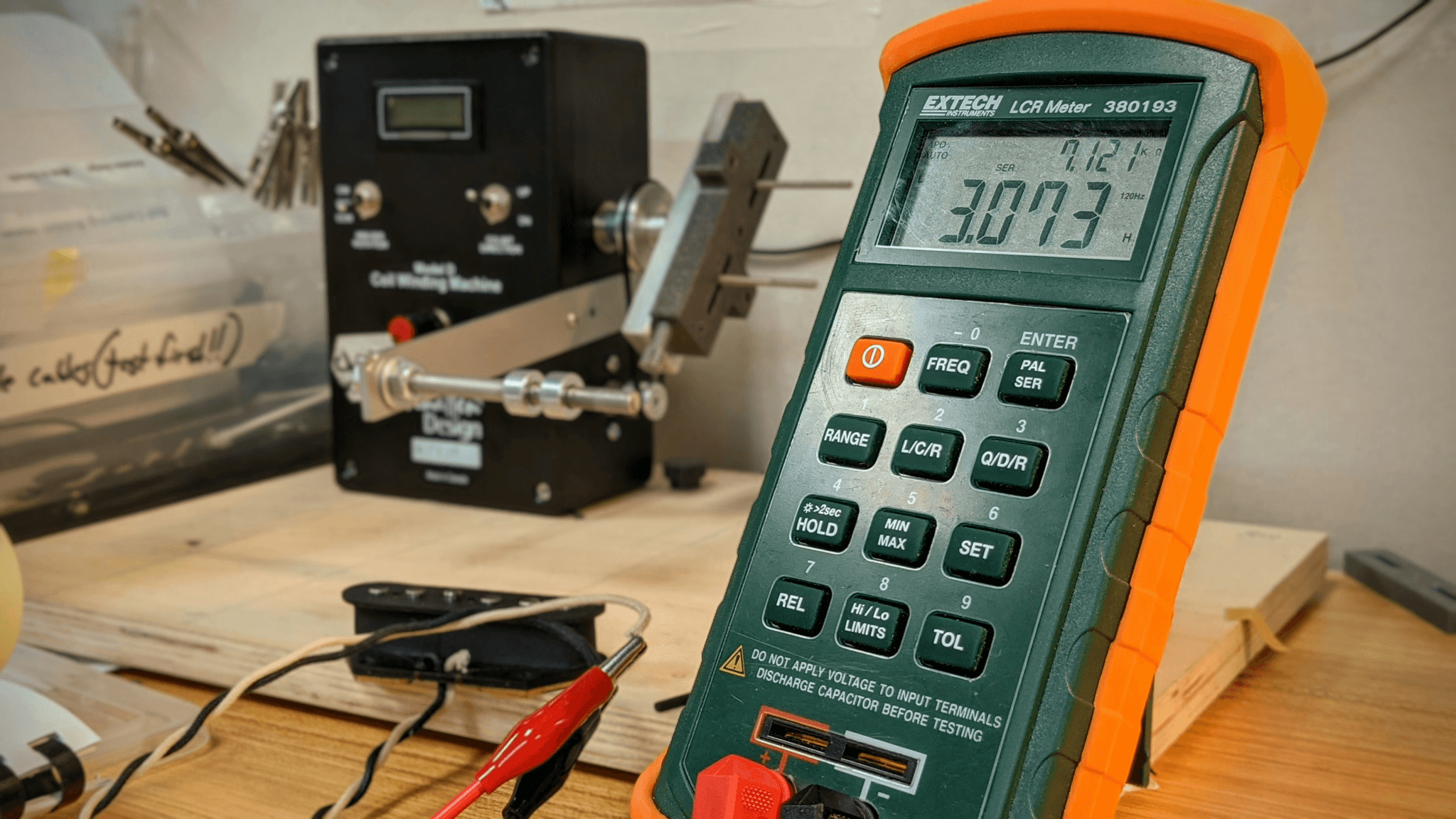

Electrical parameters are the lifeblood of any electronic component; they dictate how well a device will perform in real-world applications. Key parameters include voltage, current, resistance, capacitance, and inductance—each playing a crucial role in the overall functionality of electronic systems. Understanding these parameters allows engineers to design components that not only meet specifications but also excel in performance during Visual and Mechanical Inspection.

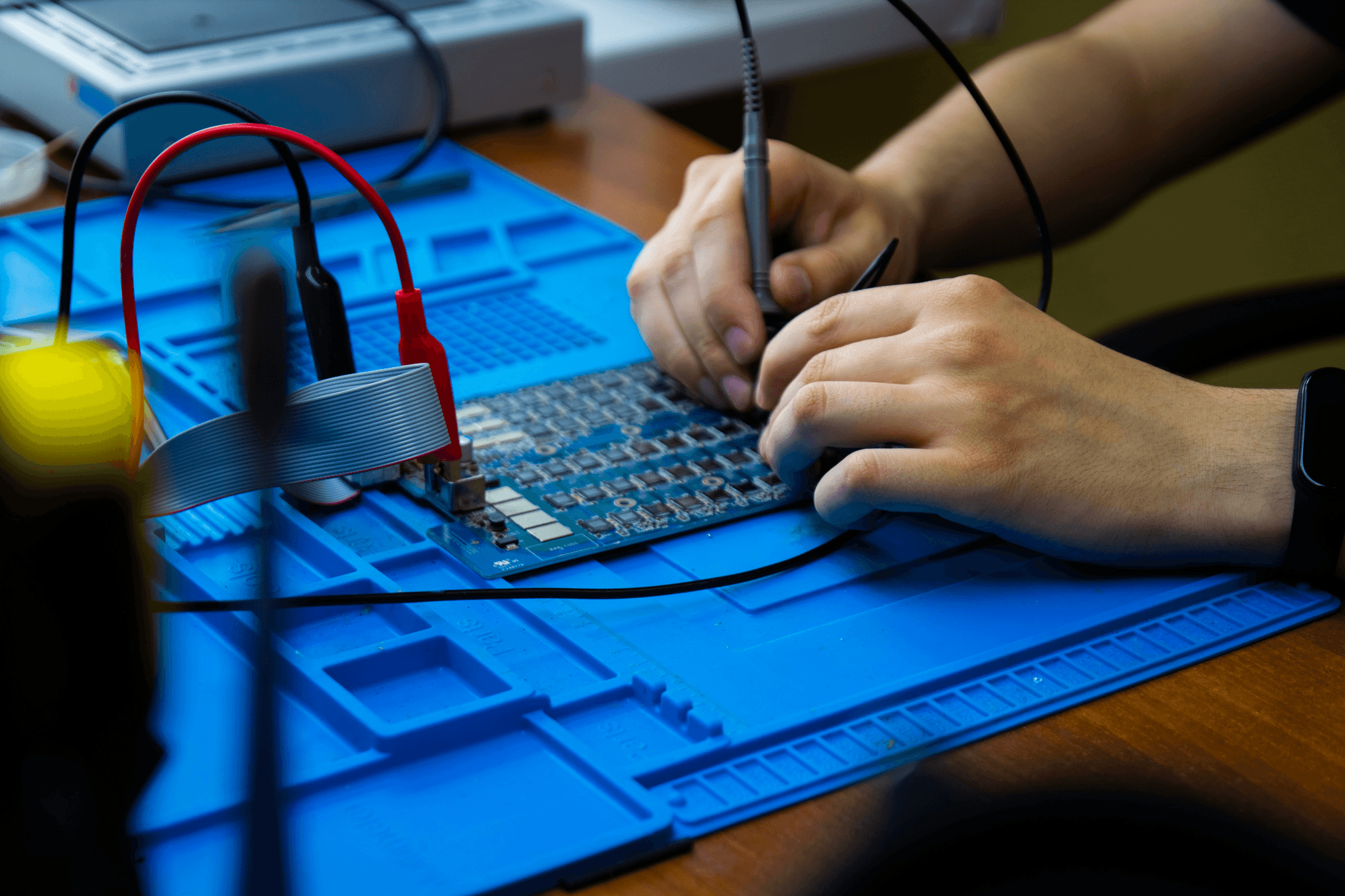

Common Electrical Testing Methods

There is no shortage of methods when it comes to electrical testing; each one tailored for specific needs within the industry. Common techniques include multimeter testing for voltage and resistance checks, oscilloscopes for waveform analysis, and automated test equipment (ATE) for high-volume production environments. These methods are essential not just for quality assurance but also to ensure that all components can withstand rigorous Safety Testing before reaching consumers.

Importance for Component Functionality

The importance of electrical testing cannot be overstated; it directly influences component functionality and longevity in various applications. Without thorough electrical evaluations, manufacturers risk releasing faulty products into the market, which could lead to costly recalls or safety hazards down the road. Ultimately, effective electrical testing ensures that electronic components perform reliably throughout their intended lifespan while maintaining compliance with Environmental Testing standards.

Safety Testing

Safety testing is a crucial step in the lifecycle of electronic components, ensuring that they meet stringent regulatory standards before entering the market. With the increasing complexity of electronics, it’s imperative to test electronic components not just for functionality but also for safety to prevent potential hazards. By adhering to established safety regulations, manufacturers can protect consumers and build trust in their products.

Regulatory Standards for Safety

Regulatory standards for safety serve as a framework within which all electronic components must operate. These standards are set by various organizations, including Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC), which outline specific requirements that ensure safe operation under normal and fault conditions. Compliance with these regulations is essential not only for legal reasons but also for fostering consumer confidence in products that have undergone rigorous safety testing.

In many regions, failure to comply with these standards can result in severe penalties or product recalls, emphasizing the importance of thorough testing processes. Manufacturers are therefore compelled to test electronic components against these benchmarks regularly. This proactive approach helps mitigate risks associated with electrical shocks, fire hazards, and other potential dangers linked to faulty electronics.

Key Safety Testing Procedures

Key safety testing procedures include a variety of assessments designed to evaluate different aspects of component safety. These tests often encompass dielectric strength tests, thermal stability assessments, and short-circuit tests among others—each targeting specific vulnerabilities in electrical systems. By rigorously executing these procedures during the development phase, manufacturers can identify weaknesses early on and rectify them before mass production.

Moreover, many organizations employ third-party laboratories specializing in safety testing to ensure an unbiased evaluation of their products. This adds another layer of reliability and credibility to the results obtained from safety tests. Ultimately, implementing comprehensive safety testing procedures not only fulfills regulatory requirements but also enhances product quality and longevity.

Impact on Consumer Protection

The impact of effective safety testing on consumer protection cannot be overstated; it significantly reduces the risk associated with using electronic devices in everyday life. When manufacturers prioritize rigorous testing protocols for their products—such as visual and mechanical inspection alongside electrical testing—they contribute directly to user safety by minimizing defects that could lead to accidents or malfunctions.

Consumers benefit from this diligence through enhanced confidence in their purchases; knowing that a product has passed stringent safety standards allows them to use it without fear of unexpected failures or hazards. Furthermore, when companies demonstrate commitment towards thorough safety evaluations through reliable practices like environmental testing and life testing and reliability assessments, they position themselves favorably within competitive markets while ensuring consumer welfare remains paramount.

Environmental Testing

Environmental testing is essential for ensuring that electronic components can withstand the rigors of real-world conditions. This type of testing evaluates how components perform under various environmental stresses, such as extreme temperatures, humidity, and vibration. By subjecting components to these conditions, manufacturers can identify potential failures before they reach consumers.

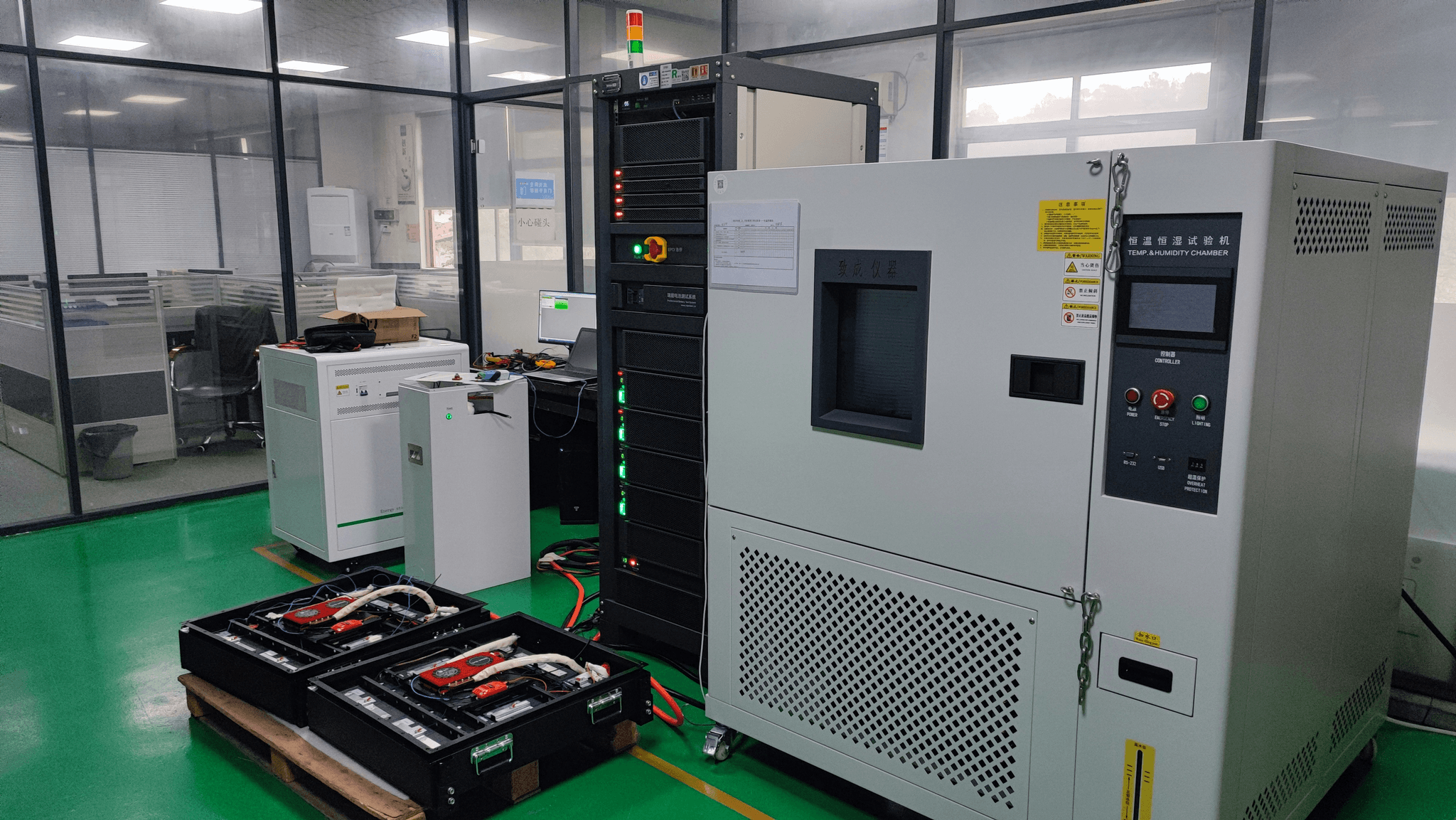

Testing Components Under Extreme Conditions

When we talk about testing components under extreme conditions, we're diving into the deep end of reliability assessment. This includes exposing electronic components to high and low temperatures, humidity extremes, and even corrosive environments to see how well they hold up. Such rigorous tests are crucial because they simulate the harsh realities that products may face in everyday use or in challenging environments.

Importance of Environmental Reliability

Environmental reliability is not just a buzzword; it's a fundamental aspect of product safety and performance. If electronic components fail due to environmental factors, it can lead to catastrophic failures in devices that rely on them, affecting everything from consumer electronics to critical infrastructure systems. Therefore, ensuring that components can withstand these stressors is vital for maintaining quality and customer trust.

Procedures for Environmental Testing

Procedures for environmental testing involve a series of standardized tests designed to evaluate how well electronic components endure adverse conditions. Common methods include thermal cycling tests, humidity exposure tests, and salt spray tests for corrosion resistance. These procedures help manufacturers gather data on component performance over time and provide insights into potential long-term reliability issues.

Life Testing and Reliability

Life testing involves subjecting components to various conditions to simulate their operational lifespan, ultimately determining how long they can function effectively. This process is crucial for manufacturers aiming to guarantee that their products not only meet performance standards but also satisfy customer expectations over extended periods.

What is Life Testing?

Life testing is a systematic approach used to evaluate the longevity and durability of electronic components under controlled conditions. By pushing these components to their limits, engineers can identify potential failure modes before they occur in real-world applications. This proactive strategy helps manufacturers design better products while also providing valuable data for quality assurance processes like Visual and Mechanical Inspection, Electrical Testing, Safety Testing, and Environmental Testing.

Methods to Assess Component Longevity

There are several methods employed in life testing to assess component longevity effectively. Accelerated life testing (ALT) is one such method where components are exposed to heightened stress levels—such as temperature extremes or voltage surges—to expedite aging processes. Other techniques include thermal cycling tests and humidity tests, which help simulate environmental conditions that could affect performance over time; both complement the earlier mentioned methods of Visual and Mechanical Inspection as well as Environmental Testing.

Significance for Long-Term Use

The significance of life testing cannot be overstated when it comes to long-term use of electronic components; it directly influences consumer trust and product reliability. By ensuring that components can withstand various stresses over time, manufacturers not only enhance safety but also reduce warranty claims and recalls—a win-win situation! Ultimately, thorough life testing contributes significantly to overall product quality by ensuring that all facets—from Electrical Testing through Safety Testing—align with industry standards.

Conclusion

In the fast-paced world of electronics, ensuring quality and reliability through comprehensive testing is not just a necessity but a fundamental principle. As we’ve explored, various methods such as Visual and Mechanical Inspection, Electrical Testing, Safety Testing, Environmental Testing, and Life Testing and Reliability play critical roles in assessing electronic components. By implementing these approaches systematically, manufacturers can confidently deliver products that meet stringent standards and satisfy consumer expectations.

Comprehensive Approaches to Testing

The journey to test electronic components effectively begins with a multi-faceted approach that encompasses all aspects of performance and safety. Visual and Mechanical Inspection sets the stage by identifying any physical defects or irregularities before further testing occurs. Following this, Electrical Testing measures key parameters essential for functionality while Safety Testing ensures compliance with regulatory standards—both crucial for maintaining market integrity.

Environmental Testing rounds out the strategy by simulating extreme conditions to assess reliability over time. Life Testing and Reliability then provide insights into how long components will perform under normal usage scenarios. Together, these methods create a robust framework that not only enhances product quality but also builds trust with consumers who rely on these technologies daily.

The Role of China Inspection Pro

China Inspection Pro stands at the forefront of ensuring that manufacturers adhere to rigorous testing protocols when they seek to test electronic components. With their expertise in Visual and Mechanical Inspection as well as advanced Electrical Testing methodologies, they help companies navigate complex regulatory landscapes while maintaining high-quality standards. Their commitment to thorough Safety Testing practices ensures that products are safe for consumers worldwide.

Moreover, their capabilities extend into Environmental Testing procedures designed to challenge components under various conditions—ensuring they can withstand real-world applications without failure. Life Testing and Reliability assessments conducted by China Inspection Pro provide invaluable data on product longevity, empowering businesses to make informed decisions about their offerings. By partnering with such an organization, manufacturers can enhance their credibility in an increasingly competitive market.

Final Thoughts on Component Quality and Safety

In conclusion, the importance of rigorously testing electronic components cannot be overstated; it is vital for both consumer protection and brand reputation alike. From Visual and Mechanical Inspection through to Life Testing and Reliability assessments, each method plays an integral role in delivering dependable products to market while adhering to safety standards set forth by governing bodies worldwide.

As technology continues to evolve rapidly, staying ahead of potential pitfalls through comprehensive testing strategies will remain essential for manufacturers aiming for success in this dynamic landscape. Ultimately, investing in quality assurance through diligent testing practices fosters innovation while ensuring that consumers receive safe and reliable electronic components they can trust.