Introduction

In the ever-evolving world of textiles, ensuring quality is paramount. Textile inspection serves as a critical checkpoint, safeguarding both manufacturers and consumers from the pitfalls of poor quality. With the rise of global trade, understanding the nuances of textile inspection has never been more vital.

Importance of Textile Inspection

Textile inspection is essential for maintaining high standards in production and consumer satisfaction. It helps identify common quality defects identified in textile inspection before they reach the market, protecting brand reputation and consumer trust. By implementing rigorous inspections, manufacturers can minimize returns and enhance overall product quality.

Overview of Quality Control in Textiles

Quality control in textiles encompasses a series of processes designed to maintain product integrity throughout production. This includes adhering to established standards used in textile inspections that ensure compliance with industry expectations. By integrating effective quality control measures, businesses can improve their operational efficiency while delivering superior products to consumers.

Key Elements for Effective Inspections

Effective textile inspections hinge on several key elements that streamline the process and ensure accuracy. Understanding what constitutes a thorough inspection involves familiarity with sampling plans and AQL for textile pre-shipment inspections, which help determine acceptable defect levels. Additionally, training inspectors to recognize various defects enhances their ability to deliver reliable results consistently.

Understanding Common Quality Defects Identified in Textile Inspection

When it comes to textile inspection, understanding common quality defects is crucial for maintaining high standards. Defects can stem from various stages of production, affecting everything from fabric integrity to color consistency. By identifying these issues early, manufacturers can ensure that their products meet the expectations set forth by both international standards and consumer demands.

Types of Defects in Textiles

Textile inspection often reveals a range of defects that can compromise the quality of the final product. Common types include fabric flaws such as holes, snags, and uneven dyeing, which can detract from the overall appearance and functionality of textiles. Additionally, issues like incorrect stitching or loose threads may arise during manufacturing processes, making it essential for inspectors to be vigilant in identifying these common quality defects identified in textile inspection.

Impact on Consumer Perception

The impact of quality defects on consumer perception cannot be overstated; a single flaw can tarnish an entire brand's reputation. Consumers expect textiles to be flawless and any deviation from this expectation can lead to dissatisfaction or even product returns. In today's competitive market, where consumers have endless options at their fingertips, maintaining impeccable standards through thorough textile inspection is key to fostering brand loyalty and trust.

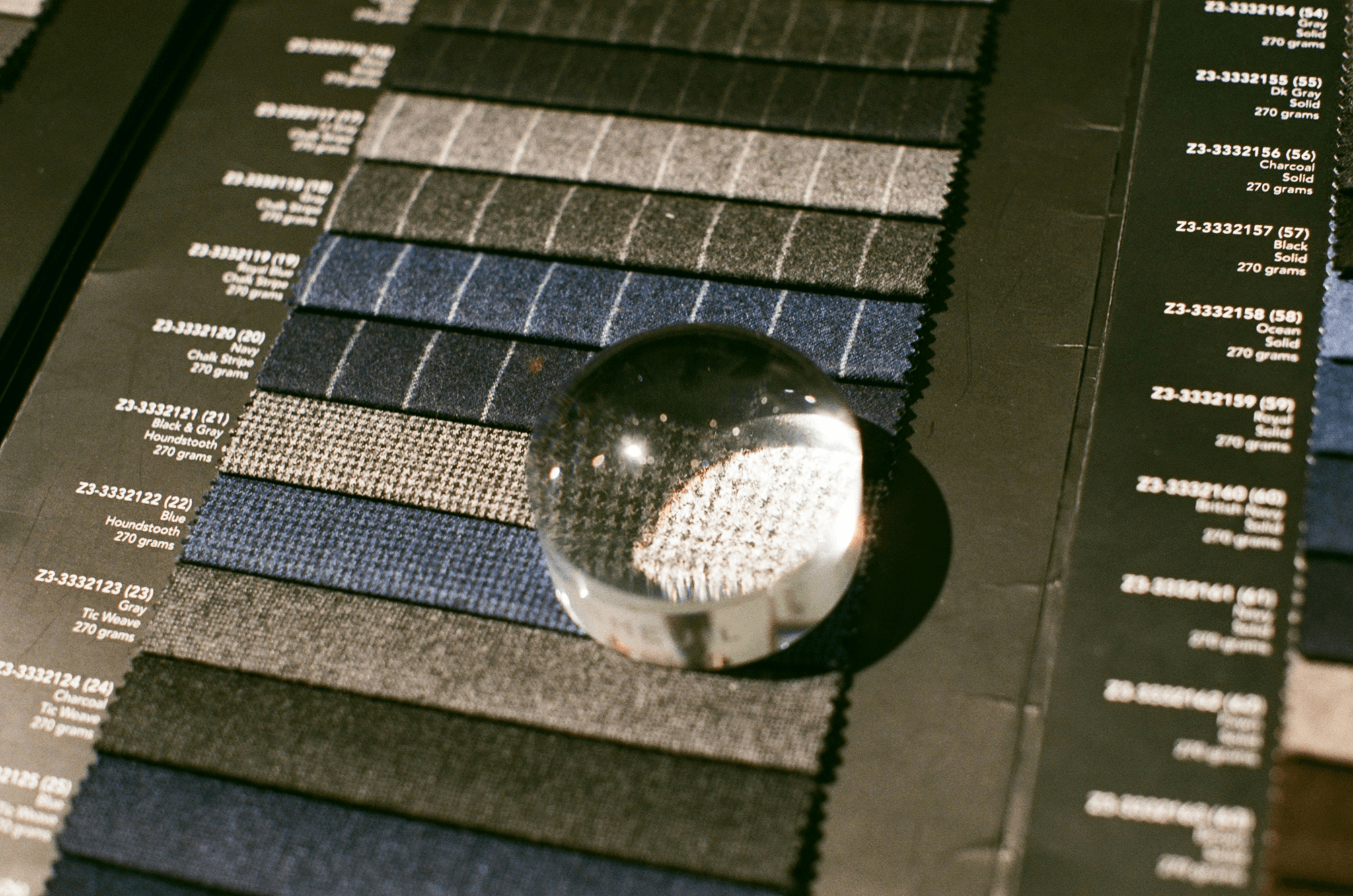

How to Spot Defects Early

Spotting defects early in the production process is vital for effective textile inspection and overall quality control. Inspectors should employ systematic approaches like visual checks under good lighting conditions and utilizing magnifying tools when necessary to identify subtle flaws that might otherwise go unnoticed. Implementing a robust sampling plan and AQL for textile pre-shipment inspections allows teams to catch these common quality defects before they reach consumers, ultimately safeguarding the brand’s reputation.

Standards Used in Textile Inspections

In the world of textile inspection, adhering to established standards is crucial for ensuring quality and consistency. These standards serve as benchmarks that help manufacturers and inspectors identify common quality defects identified in textile inspection processes. By following these guidelines, stakeholders can maintain high-quality products that meet consumer expectations.

International Standards Overview

International standards provide a framework for textile inspection, guiding how products should be evaluated for quality and safety. Organizations like the International Organization for Standardization (ISO) develop these standards to ensure uniformity across borders, allowing manufacturers and consumers alike to trust the integrity of textiles. Understanding these international standards is essential not only for compliance but also for enhancing product reputation in global markets.

Role of ISO and AATCC

ISO plays a pivotal role in setting benchmarks that govern various aspects of textile inspections, from material performance to environmental impact assessments. The American Association of Textile Chemists and Colorists (AATCC) complements this by focusing specifically on testing methods related to colorfastness, fabric care, and other critical attributes. Together, ISO and AATCC establish a comprehensive framework that helps identify common quality defects identified in textile inspection while promoting best practices among manufacturers.

Compliance and Certifications

Compliance with international standards is not just a box-ticking exercise; it’s essential for gaining certifications that enhance marketability. Certifications such as OEKO-TEX® or GOTS signify adherence to stringent quality controls during the textile inspection process, reassuring consumers about product safety and sustainability. By obtaining these certifications, businesses can demonstrate their commitment to excellence while navigating the complexities of sampling plan and AQL for textile pre-shipment inspections effectively.

What is a Textile Pre-Shipment Inspection?

Textile Pre-Shipment Inspection (PSI) is a critical process in the textile industry aimed at ensuring product quality before goods are shipped to clients. It acts as a safety net for importers and exporters, helping them avoid costly mistakes that can arise from poor-quality textiles. By identifying common quality defects identified in textile inspection early on, businesses can maintain their reputation and customer satisfaction.

Definition and Purpose

A Textile Pre-Shipment Inspection is a systematic examination of textiles before they leave the manufacturing facility, designed to verify compliance with established standards used in textile inspections. The primary purpose of this inspection is to ensure that the products meet both the buyer’s specifications and international quality standards, thus minimizing risks associated with defective goods. This proactive approach not only protects buyers but also enhances supplier credibility in a competitive market.

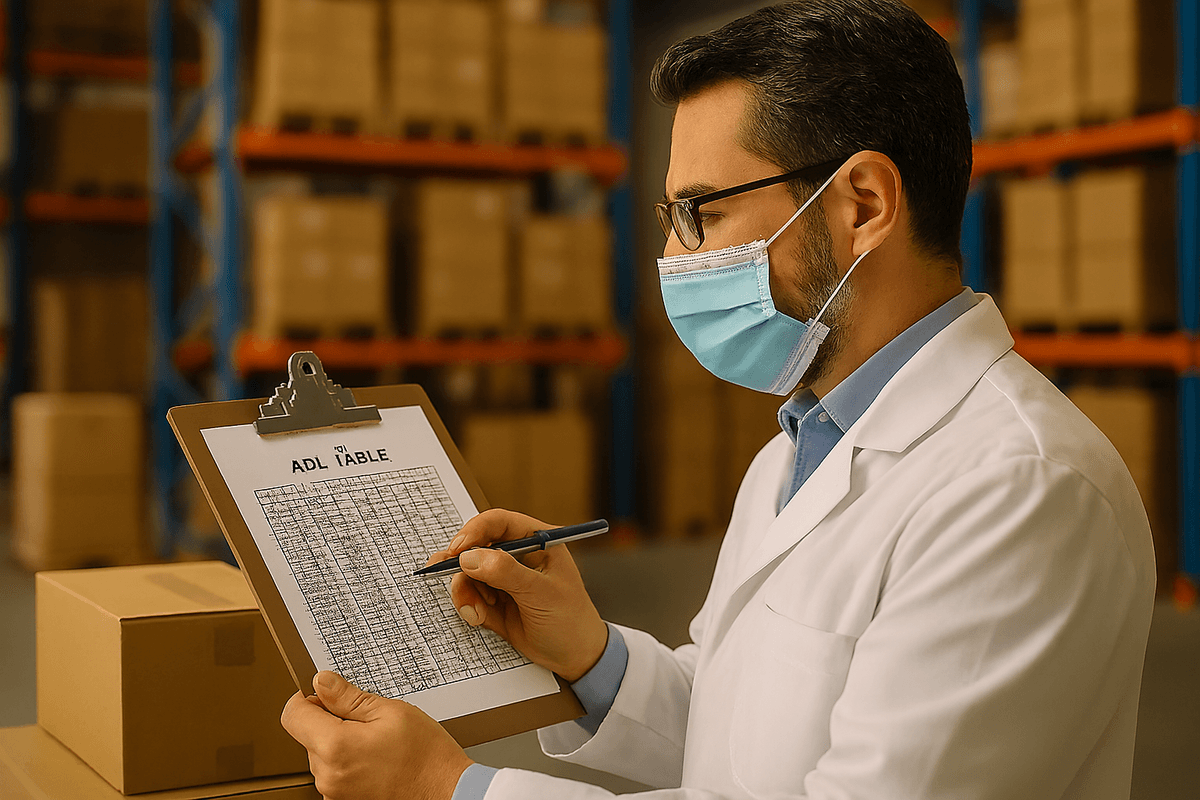

Key Steps in the Process

The Textile Pre-Shipment Inspection process typically involves several key steps to ensure thorough evaluation. First, inspectors assess samples based on a predetermined sampling plan and AQL (Acceptable Quality Level) to determine if production meets quality benchmarks. Following this, they conduct detailed examinations for common quality defects identified in textile inspection such as color discrepancies, fabric flaws, and stitching errors before compiling their findings into an actionable report.

Benefits for Importers and Exporters

For importers and exporters alike, conducting a Textile Pre-Shipment Inspection offers numerous benefits that extend beyond mere compliance with standards used in textile inspections. It significantly reduces the risk of receiving subpar products that could lead to financial losses or damage reputations among consumers. Furthermore, by investing time and resources into effective inspections, businesses can foster long-term partnerships built on trust while ensuring consistent product excellence through rigorous quality control measures.

Sampling Plan and AQL for Textile Pre-Shipment Inspections

In the realm of textile inspection, having a well-structured sampling plan is crucial for identifying common quality defects identified in textile inspection. The Acceptable Quality Level (AQL) serves as a benchmark that helps determine the maximum number of defective items permissible in a batch. Understanding AQL not only streamlines the inspection process but also enhances compliance with standards used in textile inspections, ensuring that products meet consumer expectations.

What is AQL and Why It Matters

AQL, or Acceptable Quality Level, is a statistical measure used during textile inspections to gauge the quality of goods being shipped. It defines the threshold for acceptable defects within a sample size taken from a larger batch, thus allowing importers and exporters to maintain control over product quality without inspecting every single item. By understanding AQL and its implications, businesses can effectively minimize risks associated with common quality defects identified in textile inspection while optimizing their overall quality control processes.

A robust grasp of AQL can significantly impact consumer perception by ensuring that only products meeting specified standards are delivered to market. This becomes particularly important when considering international standards used in textile inspections, which often necessitate strict adherence to predefined quality metrics. Consequently, integrating AQL into your sampling strategy is not just smart; it’s essential for maintaining brand integrity and customer satisfaction.

Developing an Effective Sampling Plan

Creating an effective sampling plan involves several key steps that align with both your goals and industry standards used in textile inspections. Start by determining the size of your production lot; this will help you decide how many samples you need to take based on your chosen AQL level. Once you have established sample sizes, utilize random sampling methods to ensure an unbiased representation of your entire batch.

Incorporating various factors such as production history and previous defect rates can enhance your sampling plan’s effectiveness by tailoring it to specific challenges faced during textile inspections. Moreover, documenting each step of your process will provide transparency should any disputes arise regarding product quality after shipment. Remember that an effective sampling plan not only identifies defects but also fosters continuous improvement within your production processes.

Tips for Ensuring Accurate Sampling

To ensure accurate sampling during pre-shipment inspections, consider these practical tips: First, always use random selection methods when choosing samples; this prevents bias and helps capture a true representation of the entire lot being inspected. Second, maintain proper documentation throughout the process—recording details such as sample sizes and defect types will provide valuable insights into recurring issues related to common quality defects identified in textile inspection.

Additionally, training personnel involved in the inspection process on best practices can significantly improve accuracy levels during pre-shipment checks. Emphasizing adherence to international standards used in textile inspections will further enhance reliability across all stages from production through delivery. By focusing on these strategies, businesses can confidently navigate potential pitfalls associated with their textiles while ensuring compliance with industry regulations.

Role of China Inspection Pro in Textile Quality Control

In the ever-evolving world of textiles, maintaining quality is paramount, and that's where China Inspection Pro steps in. This organization specializes in ensuring that textiles meet rigorous standards through comprehensive inspections. By focusing on common quality defects identified in textile inspection, they help businesses uphold their reputation and deliver excellence.

Introduction to China Inspection Pro

China Inspection Pro is a leading authority in textile inspection services, known for its commitment to quality control. With a team of experienced professionals, they navigate the complexities of textile inspections with ease and precision. Their expertise ensures that manufacturers and importers can trust that their products adhere to international standards used in textile inspections.

Services Offered for Textile Inspection

The range of services offered by China Inspection Pro encompasses various facets of textile inspection, including pre-shipment inspections that are crucial for ensuring product quality before it reaches consumers. They conduct thorough evaluations to identify common quality defects identified in textile inspection, such as fabric flaws or color inconsistencies. Additionally, they assist clients with developing effective sampling plans and AQL for textile pre-shipment inspections to ensure accurate assessments.

Benefits of Partnering with Professionals

Partnering with professionals like China Inspection Pro brings numerous benefits to businesses involved in the textile industry. Not only do they provide peace of mind by ensuring compliance with international standards used in textile inspections, but they also help companies avoid costly mistakes related to defective products. By leveraging their expertise in spotting potential issues early on through systematic inspections, businesses can confidently move forward while enhancing their overall quality control processes.

Conclusion

In the ever-evolving world of textiles, ensuring product excellence through inspections is not just a best practice; it's a necessity. Textile inspection serves as the frontline defense against common quality defects identified in textile inspection processes, safeguarding both manufacturers and consumers. By adhering to established standards used in textile inspections, companies can maintain high-quality output that meets market demands.

Ensuring Product Excellence Through Inspections

At the heart of maintaining product excellence is a robust textile inspection process that identifies defects before they reach consumers. Common quality defects identified in textile inspection can range from color mismatches to fabric flaws, all of which can tarnish brand reputation if overlooked. By implementing thorough inspections at every stage—from production to pre-shipment—businesses can ensure that their products are not only functional but also visually appealing and reliable.

Continuous Improvement in Quality Control

Quality control is an ongoing journey rather than a destination; it requires continuous improvement and adaptation to new challenges. Standards used in textile inspections evolve as technology advances and consumer expectations rise, necessitating regular updates to quality assurance practices. This commitment to improvement extends to understanding what is a textile pre-shipment inspection, which plays a crucial role in verifying quality before products hit the shelves.

Moving Forward with Confidence in Textiles

With an effective sampling plan and AQL for textile pre-shipment inspections, businesses can move forward with confidence knowing their products meet stringent quality standards. The insights gained from identifying common quality defects identified during inspections empower companies to make informed decisions about their production processes. Ultimately, by embracing rigorous inspection protocols and fostering continuous improvement, stakeholders in the textile industry can thrive while delivering exceptional products.