Introduction

In the fast-paced world of manufacturing, quality inspection is not just a checkbox on a list; it's the backbone of effective quality management. Understanding the importance of quality inspection means recognizing how it safeguards products, enhances customer satisfaction, and ultimately drives business success. With various methods available, manufacturers can implement tailored quality checks in manufacturing to ensure their products meet required standards.

Understand the Importance of Quality Inspection

Quality inspection serves as a critical filter that prevents defective products from reaching consumers. By identifying issues early in the production process, businesses can save time and resources while maintaining their reputation for delivering high-quality goods. Thus, understanding the importance of quality inspection is essential for any manufacturer committed to excellence.

The Role of Quality Control in Manufacturing

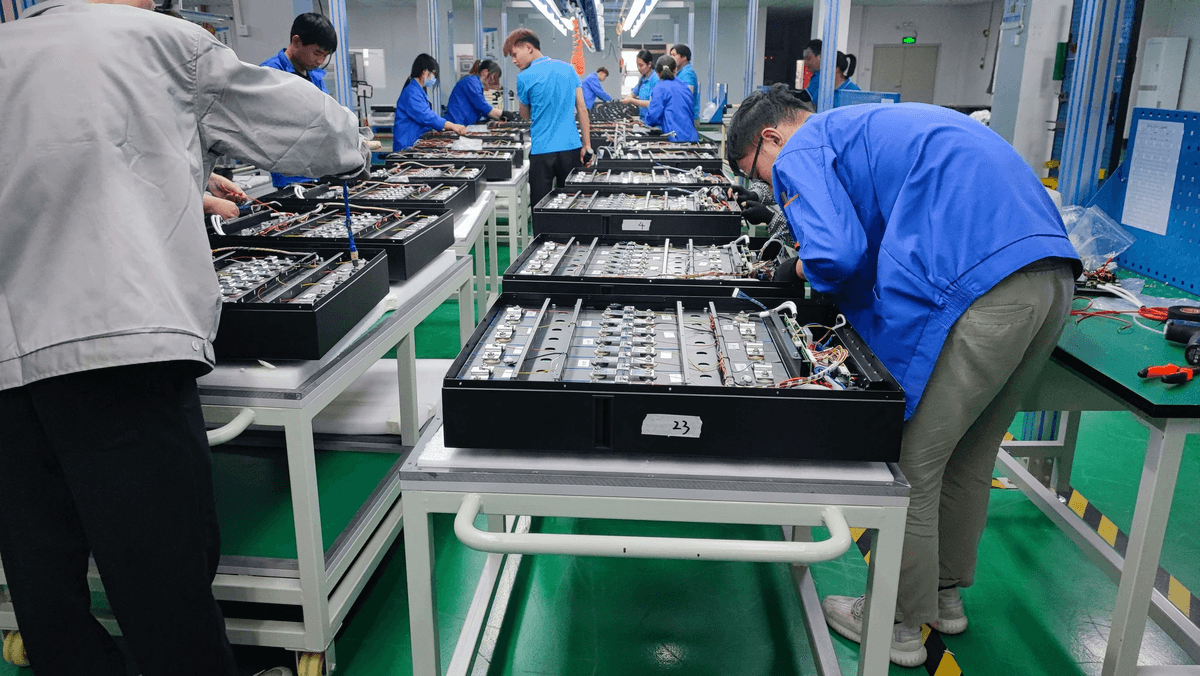

Quality control plays an integral role in manufacturing by establishing systematic processes that monitor and maintain product standards throughout production. This proactive approach helps to minimize errors and ensures compliance with industry regulations, leading to fewer recalls and increased customer trust. In essence, effective quality control in manufacturing is vital for sustaining operational efficiency and enhancing overall product reliability.

What are the 4 Types of Quality Inspection

When it comes to ensuring product integrity, manufacturers typically rely on four types of quality inspection: visual inspection, dimensional inspection, functional testing, and destructive testing. Each type offers unique benefits tailored to specific aspects of product evaluation—ranging from basic visual checks to rigorous assessments that may involve breaking samples apart for analysis. Understanding these 4 types of quality inspection allows businesses to choose appropriate methods that align with their quality management goals.

Visual Inspection

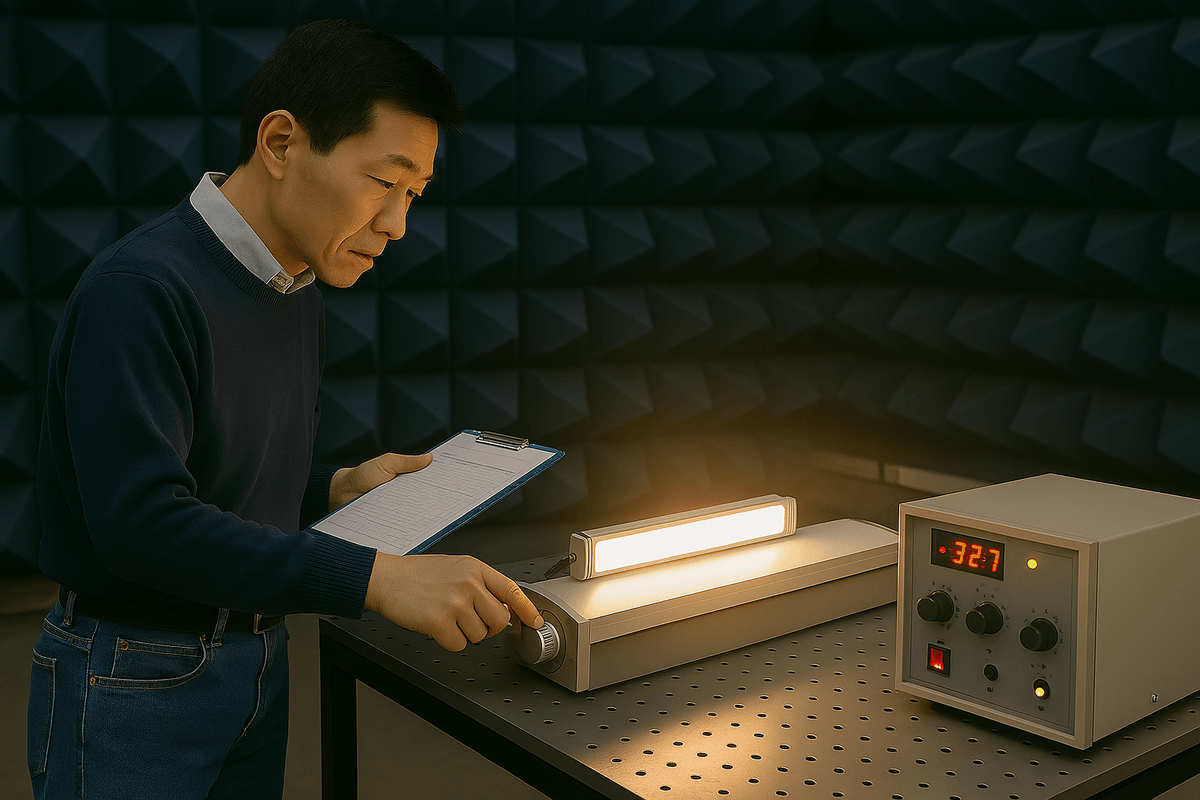

Visual inspection stands as a fundamental component of the 4 types of quality inspection, playing a pivotal role in quality control and manufacturing. It involves the careful examination of products to identify defects, inconsistencies, or deviations from specifications. This type of quality check is often the first line of defense in ensuring that products meet established standards before they reach customers.

Basics of Visual Quality Inspection

At its core, visual quality inspection relies on the keen eyes of trained inspectors who assess products for visible defects. This process encompasses everything from checking for scratches and dents to evaluating color consistency and overall appearance. In quality control within manufacturing, visual inspections are often performed at various stages—during production, assembly, and pre-shipment—to catch issues early and maintain high-quality standards.

Techniques Used in Visual Checks

Several techniques enhance the effectiveness of visual checks in quality management processes. Inspectors may use tools like magnifying glasses or specialized lighting to better illuminate product surfaces and reveal hidden flaws. Additionally, standardized checklists can help ensure that all critical aspects are evaluated consistently across different batches during quality checks in manufacturing.

Benefits and Limitations

The benefits of visual inspection are numerous; it is cost-effective, quick, and can be conducted without sophisticated equipment. However, this method does have its limitations—human error can lead to missed defects, especially with complex items requiring detailed scrutiny. Thus, while visual inspections are invaluable for initial assessments in quality control and manufacturing, they should ideally be complemented by other types of inspections for comprehensive quality assurance.

Dimensional Inspection

Dimensional inspection is a crucial aspect of quality control in manufacturing, focusing on the precise measurements of components and products. It ensures that every item meets the specified dimensions, which is vital for functionality and interoperability. Without accurate measurements, even the best-designed products can fail to perform as intended, leading to costly reworks or replacements.

Importance of Accurate Measurements

Accurate measurements are fundamental in maintaining quality and quality management throughout the manufacturing process. They directly impact product performance, safety, and customer satisfaction; if a component is even slightly off-spec, it could lead to significant issues down the line. In fact, understanding the importance of dimensional inspection can save manufacturers from potential failures that arise from poor quality checks in manufacturing.

Tools for Dimensional Quality Checks

A variety of tools are employed for dimensional quality checks to ensure precision and reliability in measurements. Common instruments include calipers, micrometers, and coordinate measuring machines (CMM), each designed for specific types of measurements. By utilizing these tools effectively within a robust framework of quality control and manufacturing practices, businesses can achieve high standards that meet or exceed customer expectations.

Ensuring Compliance with Specifications

Ensuring compliance with specifications is essential not only for meeting regulatory requirements but also for fostering trust with clients who rely on consistent product quality. Regular dimensional inspections help identify deviations from design specifications early in the production process—ideally before pre-shipment—thereby minimizing risks associated with faulty products reaching customers. By integrating rigorous dimensional checks into their quality management systems, manufacturers enhance their reputation while reducing costs associated with returns or recalls.

Functional Testing

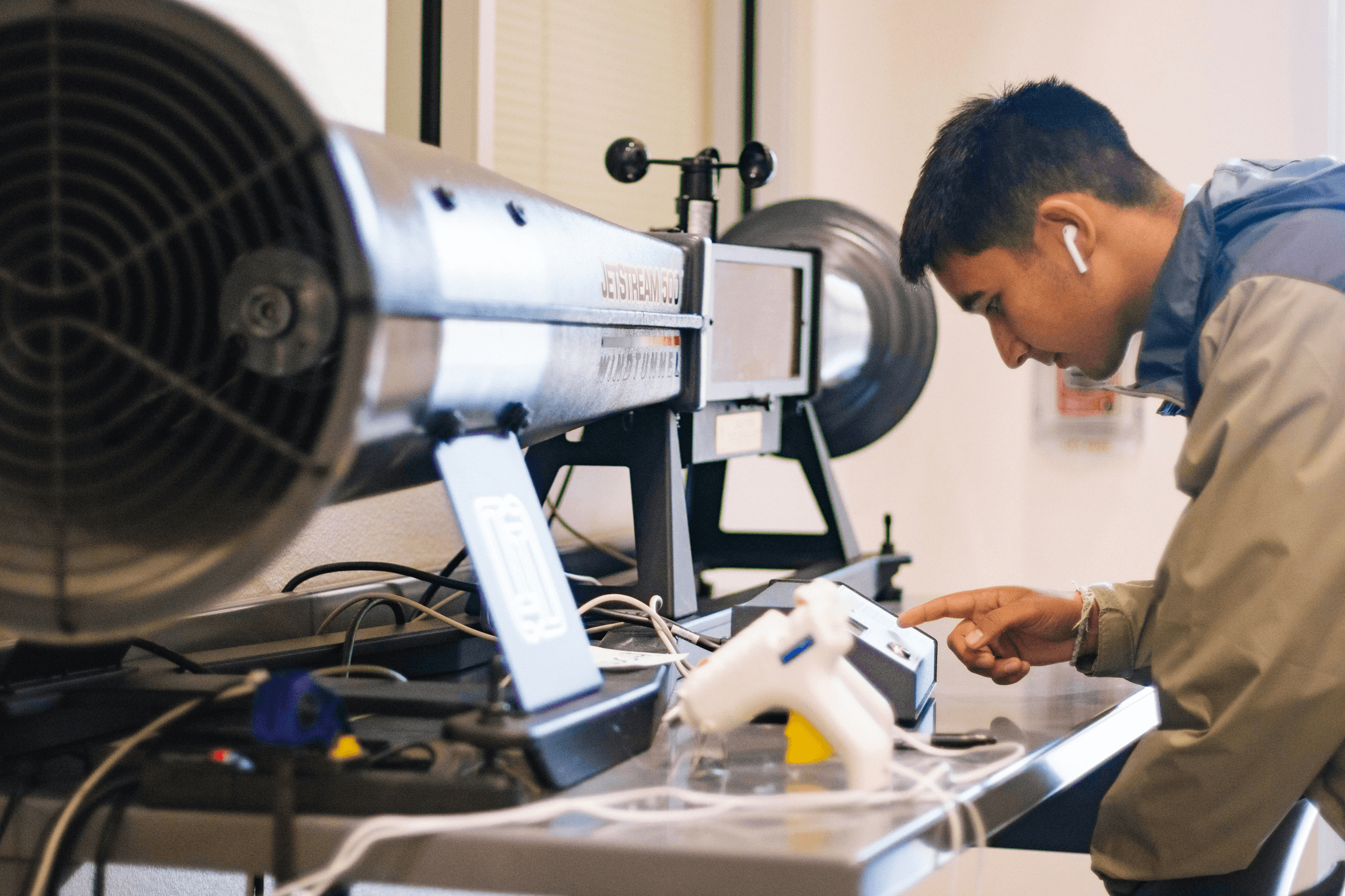

Functional testing is a crucial aspect of quality inspection, focusing on ensuring that products perform their intended functions correctly. This type of quality control in manufacturing assesses whether a product meets the required specifications and standards before it reaches the customer. By implementing functional quality inspection, manufacturers can significantly reduce the risk of defects and enhance overall quality management.

What is Functional Quality Inspection?

Functional quality inspection involves evaluating a product's performance against predetermined criteria to verify its operational capabilities. It plays a vital role in the broader context of quality checks in manufacturing, ensuring that each item not only looks good but also works as intended. This type of inspection is essential for maintaining high standards of quality control and manufacturing, safeguarding both brand reputation and customer satisfaction.

Common Tests in Manufacturing

There are several common tests conducted during functional testing, tailored to different industries and products. For instance, electronics may undergo electrical safety tests, while mechanical components might be subjected to stress or load tests to assess durability under pressure. These various tests are integral to the 4 types of quality inspection, providing valuable data that informs improvements in design and production processes.

Identifying Issues Before Shipment

Identifying issues before shipment is one of the primary goals of functional testing within the framework of quality management. By catching defects early through rigorous testing protocols, manufacturers can avoid costly returns and maintain customer trust—something every business strives for! Pre-shipment inspections that include functional testing ensure that products not only meet aesthetic standards but also deliver on performance promises.

Destructive Testing

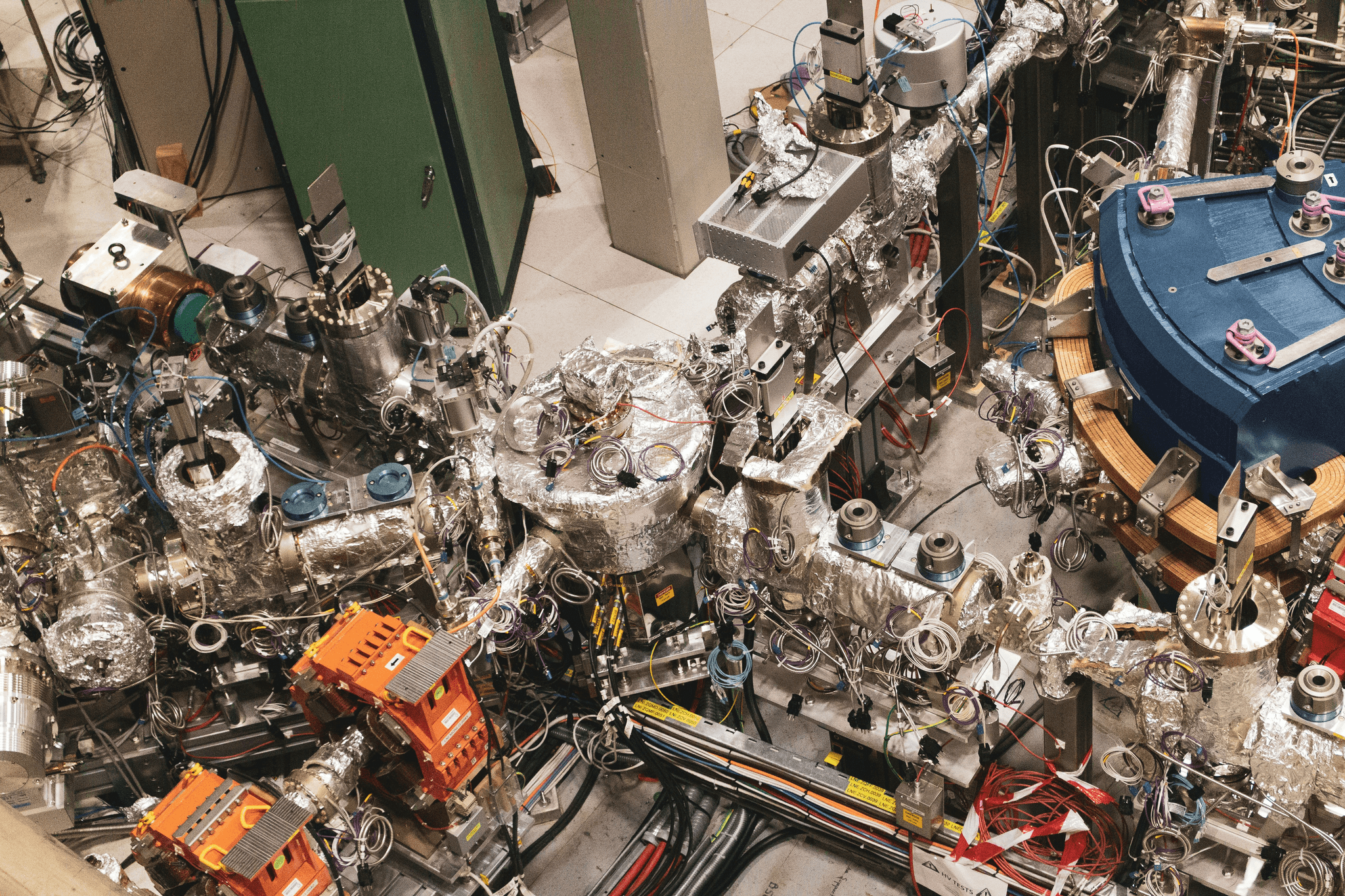

Destructive testing is a critical aspect of the 4 types of quality inspection, particularly in industries where safety and reliability are paramount. Unlike other methods that assess quality without damaging the product, destructive testing involves subjecting items to extreme conditions until they fail. This approach provides invaluable data on material properties and performance, making it essential for quality control in manufacturing.

Understanding Destructive Quality Checks

Destructive quality checks are designed to evaluate a product's durability and integrity by applying stress or force until failure occurs. This method can reveal weaknesses in materials that might not be detectable through non-destructive means, ensuring that only the highest quality products reach consumers. By understanding how products behave under stress, manufacturers can implement better designs and enhance overall quality management processes.

When is Destructive Testing Necessary?

Destructive testing is necessary in scenarios where safety is non-negotiable, such as aerospace components or medical devices. In these cases, a failure could lead to catastrophic consequences; thus, rigorous quality checks in manufacturing are crucial. Additionally, when developing new materials or products, destructive tests help determine whether they meet specifications before pre-shipment inspections take place.

Balancing Quality and Cost in Manufacturing

Balancing quality and cost in manufacturing often poses a challenge for businesses seeking to maintain high standards while controlling expenses. Implementing destructive testing can be costly due to the need for specialized equipment and potential waste of materials; however, it ultimately saves money by preventing defective products from reaching customers. By investing wisely in the 4 types of quality inspection—including destructive testing—companies can enhance their reputation for reliability while optimizing their overall production costs.

Conclusion

In the realm of manufacturing, understanding the 4 types of quality inspection is essential for maintaining high standards. Quality control plays a pivotal role in ensuring that products meet specifications and consumer expectations. By employing effective quality checks in manufacturing processes, businesses can mitigate risks and enhance overall product reliability.

Key Takeaways from the 4 Types

The four types of quality inspection—visual, dimensional, functional testing, and destructive testing—each serve unique purposes in quality management. Visual inspection offers a quick way to identify obvious defects, while dimensional inspection ensures precise measurements are met. Functional testing evaluates how well a product performs its intended function, and destructive testing helps assess material properties under stress; together, they form a comprehensive approach to quality control in manufacturing.

Implementing Quality Checks in Your Process

To effectively implement quality checks in manufacturing, it's crucial to integrate all four types of inspections into your production workflow. Begin by establishing clear criteria for each type of inspection based on your product specifications and industry standards. Regular training for staff on these methods will enhance their ability to identify issues early on, thereby reducing pre-shipment problems and ensuring that only top-quality products reach customers.

Choosing China Inspection Pro for Quality Management

When it comes to quality management solutions, selecting a partner like China Inspection Pro can elevate your quality control efforts significantly. They offer expertise across all 4 types of quality inspection tailored to your specific needs, ensuring compliance with both local and international standards. By leveraging their services, you can streamline your processes while maintaining rigorous quality checks in manufacturing that ultimately lead to customer satisfaction.