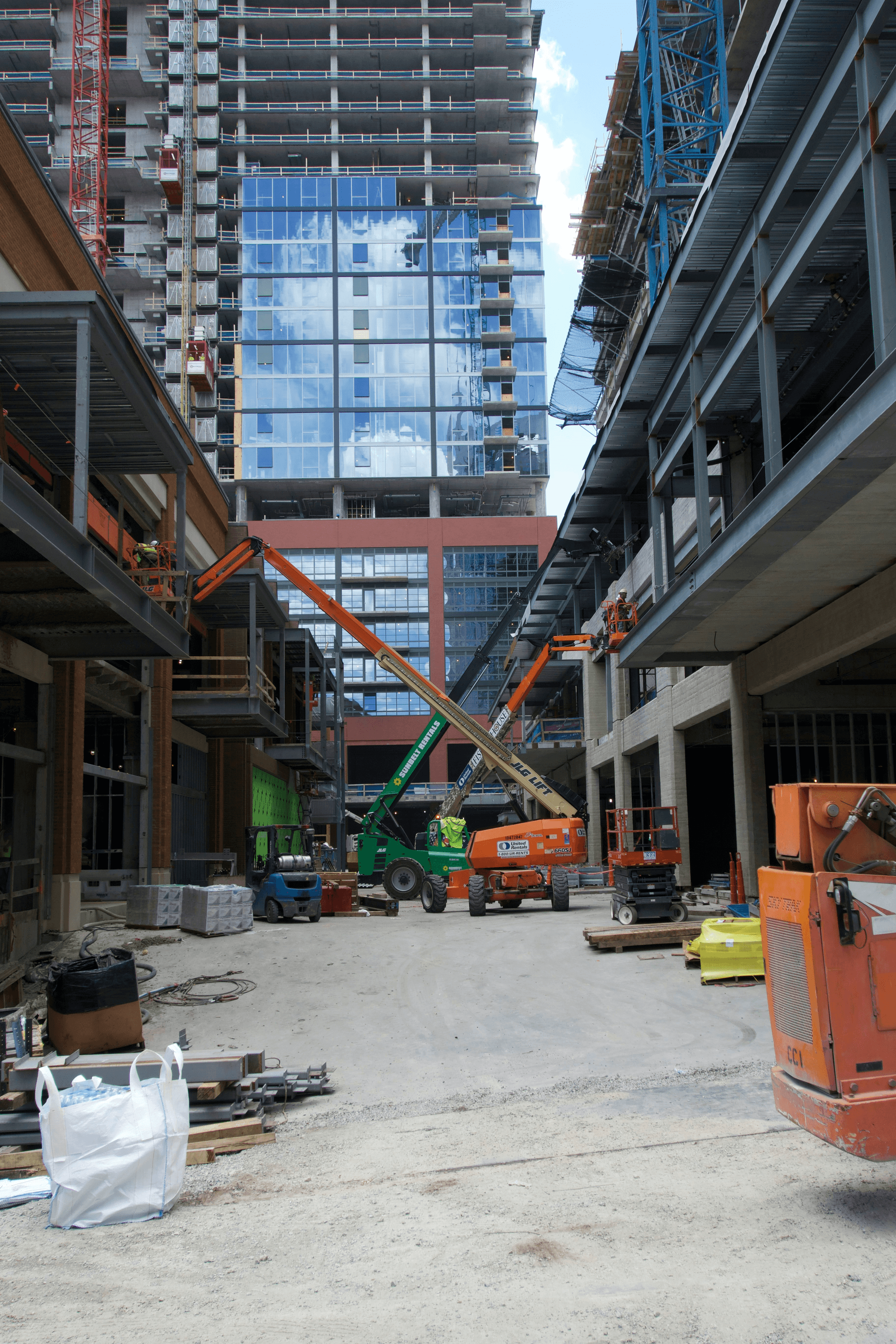

Introduction

In the realm of construction, quality assurance is not just a buzzword; it’s a foundational element that ensures projects are completed to the highest standards. Quality assurance in construction encompasses various processes and practices designed to maintain high-quality outcomes throughout the project lifecycle. By understanding the nuances of quality assurance and its relationship with construction quality control, stakeholders can better navigate the complexities of building projects.

Understanding Quality Assurance in Construction

Quality assurance (QA) in construction refers to systematic processes that prevent defects and ensure that project deliverables meet specified requirements. This proactive approach focuses on establishing standards and procedures that guide teams toward achieving desired quality outcomes. In essence, QA is about creating a framework where quality quality assurance becomes an integral part of every stage in the construction process.

Importance of Quality Control in Building Projects

Quality control (QC) plays a critical role in ensuring safety, compliance, and overall project efficiency within building projects. By implementing effective QC practices, teams can identify potential issues early on, minimizing risks associated with safety violations or structural failures. Ultimately, robust quality control measures lead to reduced long-term costs by preventing costly rework and ensuring client satisfaction.

Overview of Key Quality Assurance Concepts

Key concepts surrounding quality assurance include continuous monitoring, pre-construction planning, and final assessments—all aimed at maintaining high standards throughout the project lifecycle. Understanding these principles empowers construction professionals to integrate QA seamlessly into their workflows while balancing speed with quality control control measures effectively. As we explore these concepts further, it becomes clear that investing time and resources into QA leads to successful outcomes for all stakeholders involved.

What is Quality Assurance?

Quality assurance (QA) is a systematic process designed to ensure that construction projects meet specific standards and requirements. It encompasses a range of activities aimed at preventing defects and ensuring quality throughout the project lifecycle. By implementing effective quality assurance strategies, construction companies can enhance their overall project outcomes and client satisfaction.

Definition and Objectives

Quality assurance in construction refers to the planned and systematic actions required to provide adequate confidence that a product or service will satisfy given requirements for quality. The primary objective of QA is to establish a framework that ensures consistent quality throughout all phases of construction, from planning through execution to completion. By focusing on prevention rather than detection, QA helps reduce errors, improve safety, and ultimately deliver higher-quality structures.

Difference Between Quality Assurance and Quality Control

While both quality assurance (QA) and quality control (QC) aim to ensure high standards in construction projects, they serve distinct purposes within the broader framework of construction quality control. Quality assurance focuses on process-oriented activities designed to prevent defects before they occur, whereas quality control is more about inspecting finished work or components to identify any issues after they arise. In essence, QA lays the groundwork for effective QC by establishing procedures that promote ongoing improvement and compliance with industry standards.

The Role of Quality Assurance in Construction

The role of quality assurance in construction cannot be overstated; it acts as the backbone for successful project delivery by fostering an environment where continuous improvement is prioritized. Through rigorous QA practices, stakeholders can identify potential risks early on, implement corrective measures promptly, and ensure adherence to established building codes and regulations. Ultimately, effective quality assurance not only enhances safety but also contributes significantly to cost savings by minimizing rework and delays associated with poor-quality outcomes.

The Importance of Construction Quality Control

In the realm of construction, quality control is not just a box to check; it's the backbone of successful projects. Effective construction quality control ensures that every aspect of a building meets stringent standards, safeguarding both the structure and its occupants. By prioritizing quality assurance throughout the project lifecycle, stakeholders can prevent costly mistakes and enhance overall satisfaction.

Ensuring Safety and Compliance

Safety is non-negotiable in construction, and effective quality control plays a pivotal role in ensuring compliance with safety regulations. By implementing rigorous qc quality control measures, builders can identify potential hazards before they become serious issues. This proactive approach not only protects workers but also ensures that the final product adheres to local codes and standards.

Moreover, when quality assurance practices are integrated into every phase of construction, it fosters a culture of accountability among all team members. Everyone from project managers to subcontractors becomes invested in maintaining high-quality standards. Ultimately, this commitment to safety leads to fewer accidents on-site and greater peace of mind for everyone involved.

Enhancing Project Efficiency

When it comes to enhancing project efficiency, robust construction quality control strategies are essential. By focusing on qa quality assurance from the outset, teams can streamline processes and minimize delays caused by rework or inspections that fail to meet standards. This efficiency translates into faster project completion times without sacrificing the integrity or safety of the build.

Additionally, effective quality control often uncovers opportunities for innovation in processes and materials used during construction. Teams that embrace continuous improvement through regular assessments tend to operate more smoothly than those who overlook these practices. As a result, enhanced efficiency not only boosts productivity but also elevates overall project outcomes.

Reducing Long-term Costs

Investing in comprehensive construction quality control may seem like an upfront cost; however, it pays dividends over time by reducing long-term expenses associated with poor-quality work. When projects adhere closely to established quality assurance protocols, there’s less likelihood of defects arising after completion—defects that could lead to expensive repairs or even litigation down the road.

Moreover, implementing effective qc quality control measures can help identify inefficiencies early on in a project's life cycle—before they escalate into significant financial burdens or delays. By addressing these issues proactively through thorough monitoring and assessment processes, companies save money while also enhancing their reputation in an increasingly competitive market.

In conclusion, prioritizing construction quality control is essential for ensuring safety compliance while promoting efficiency and minimizing costs over time—a trifecta that benefits everyone involved!

Key Quality Assurance Processes

In the realm of construction quality control, implementing effective quality assurance processes is paramount for project success. These processes not only help in maintaining standards but also ensure that every phase of the project meets the desired quality benchmarks. From planning to execution and final assessment, each step plays a crucial role in achieving overall quality assurance.

Pre-Construction Quality Planning

Pre-construction quality planning is where the foundation of construction quality control is laid. This phase involves setting clear objectives and defining standards that must be adhered to throughout the project lifecycle. By establishing comprehensive QA quality assurance protocols at this stage, teams can anticipate potential issues and devise strategies to mitigate risks before they escalate.

Incorporating stakeholder input during this planning phase ensures that everyone involved understands their roles in maintaining quality. Moreover, detailed documentation outlining procedures and expectations sets a benchmark for accountability within the team. Ultimately, effective pre-construction planning fosters a culture of quality where every member is committed to upholding high standards throughout the project.

Continuous Quality Monitoring

Once construction begins, continuous quality monitoring becomes essential for maintaining construction quality control throughout all phases of work. This ongoing process involves regular inspections and assessments to ensure compliance with established standards and specifications. By employing various tools and techniques for real-time monitoring, teams can quickly identify deviations from expected outcomes and implement corrective actions immediately.

Quality assurance in this context means being proactive rather than reactive; it’s about catching potential problems before they snowball into costly setbacks or safety hazards. Regular training sessions for staff on QC quality control practices also contribute significantly to this process by keeping everyone informed about current standards and best practices. Continuous monitoring not only enhances overall efficiency but also reinforces a commitment to excellence among team members.

Final Quality Assessment

The final quality assessment serves as a critical checkpoint in the construction process, evaluating whether all aspects of the project meet predetermined criteria for success. During this stage, thorough inspections are conducted to confirm compliance with both internal QA protocols and external regulations or building codes. This assessment helps identify any lingering issues that may have been overlooked during previous phases of construction.

Moreover, documenting these findings provides valuable insights for future projects while ensuring transparency with stakeholders regarding project outcomes related to construction quality control efforts. The culmination of these assessments often leads to certifications or approvals necessary for project completion, underscoring their importance in validating overall performance against established benchmarks. In essence, final assessments play a vital role in reinforcing trust between contractors, clients, and regulatory bodies alike.

Industry Standards and Regulations

In the realm of construction quality control, adhering to industry standards and regulations is non-negotiable. These guidelines ensure that every project meets safety, durability, and performance benchmarks. Understanding these standards helps construction professionals implement effective quality assurance practices that lead to successful outcomes.

Overview of Building Codes

Building codes serve as the backbone of construction quality control, outlining minimum requirements for safety and structural integrity. They vary by location but generally encompass aspects such as materials, design specifications, and environmental considerations. Compliance with these codes not only protects occupants but also enhances the overall quality assurance process in building projects.

Building codes are enforced through inspections at various stages of construction; this is where quality control measures come into play. By ensuring that each phase meets regulatory standards, contractors can avoid costly rework or legal issues down the line. Ultimately, a solid grasp of building codes is essential for any professional aiming to uphold high levels of quality in their work.

International Organization for Standardization Standards

The International Organization for Standardization (ISO) provides globally recognized standards that elevate quality assurance across various industries, including construction. ISO 9001 is particularly relevant as it focuses on effective management systems that enhance customer satisfaction through consistent product or service delivery. Integrating ISO standards into construction practices strengthens both quality control and overall project success.

Moreover, ISO standards often serve as benchmarks against which companies can measure their performance in terms of quality assurance. Adopting these international guidelines not only boosts a firm's credibility but also fosters a culture of continuous improvement within organizations. In an increasingly globalized market, aligning with ISO standards becomes vital for maintaining competitive advantage in construction quality control.

The Role of China Inspection Pro in Quality Assurance

China Inspection Pro plays a pivotal role in enhancing construction quality control through its comprehensive inspection services tailored to local regulations and international standards alike. Their expertise ensures adherence to both building codes and ISO requirements, facilitating seamless integration into any project's workflow. By leveraging their services, contractors can significantly bolster their approach to QA quality assurance.

Additionally, China Inspection Pro provides valuable insights into common pitfalls associated with construction projects while offering solutions that align with best practices in the industry. This proactive stance enables teams to identify potential issues early on and implement corrective actions promptly—key elements in maintaining high-quality outcomes throughout the project lifecycle. Thus, engaging with entities like China Inspection Pro serves as an investment toward achieving excellence in QC quality control.

Common Quality Assurance Challenges

In the realm of construction, quality assurance is paramount, yet it comes with its fair share of challenges. Addressing these hurdles effectively can be the difference between a successful project and a costly failure. From identifying potential quality issues to ensuring adequate staffing and training for quality control, construction professionals must navigate this complex landscape.

Identifying Potential Quality Issues

Identifying potential quality issues early in the construction process is crucial for effective quality assurance. Many problems can arise from design flaws, material defects, or inadequate workmanship, which can ultimately lead to significant delays and increased costs. A proactive approach involves regular inspections and audits that focus on construction quality control measures to catch these issues before they escalate.

Moreover, utilizing advanced technology such as Building Information Modeling (BIM) can enhance the identification of potential pitfalls in real-time. By integrating QA quality assurance practices into daily operations, teams can create a culture of vigilance that prioritizes quality over speed. This commitment not only helps in maintaining high standards but also fosters trust among stakeholders involved in the project.

Staffing and Training for Quality Control

The success of any construction project hinges on having skilled personnel dedicated to maintaining high-quality standards through effective staffing and training for quality control. Hiring qualified staff who understand both the technical aspects of construction and the principles of qc quality control is essential for achieving desired outcomes. Continuous training programs ensure that team members are up-to-date with industry best practices, fostering an environment where everyone is committed to excellence.

Moreover, investing in staff development creates a sense of ownership among employees regarding their roles in ensuring construction quality control throughout all phases of a project. This commitment not only improves individual performance but also enhances overall team dynamics when tackling challenges related to quality assurance. Ultimately, well-trained personnel become invaluable assets who contribute significantly to reducing long-term costs associated with poor workmanship or compliance failures.

Balancing Speed and Quality

In today's fast-paced construction environment, balancing speed and quality often presents a daunting challenge for project managers striving for optimal outcomes through effective qa quality assurance measures. While meeting deadlines is critical for client satisfaction and profitability, sacrificing construction quality control can lead to dire consequences down the line—think costly rework or safety violations that could have been avoided with thorough oversight.

To achieve this balance effectively requires strategic planning that incorporates flexible timelines while still emphasizing rigorous inspection protocols throughout every phase of development. Implementing lean management techniques allows teams to streamline processes without compromising on standards; after all, it’s possible to be both efficient and thorough! By fostering open communication among all stakeholders involved—contractors, subcontractors, suppliers—everyone remains aligned towards shared goals focused on delivering top-notch projects without unnecessary delays.

Conclusion

In wrapping up our exploration of quality assurance in construction, it’s clear that a robust framework for construction quality control is essential for successful projects. Quality assurance quality and the methodologies employed not only ensure compliance with industry standards but also enhance overall project efficiency. By understanding the nuances of QA quality assurance, stakeholders can mitigate risks and deliver superior results.

Key Takeaways on Quality Assurance

Quality assurance is fundamentally about building confidence in processes and outcomes; it’s not just about meeting minimum standards but striving for excellence in every aspect of construction. The distinction between quality assurance and quality control is vital—while QA focuses on prevention through planning, QC emphasizes detection through inspection. Ultimately, a well-implemented quality control control strategy leads to safer buildings, satisfied clients, and reduced long-term costs.

The Future of Quality Control Practices

The future of construction quality control lies in embracing technology and innovative practices that enhance efficiency without compromising safety or compliance. With advancements such as AI-driven monitoring systems and real-time data analytics, the landscape of qa quality assurance will evolve significantly. As the industry adapts to these changes, we can expect more proactive approaches to identifying potential issues before they escalate into costly problems.

Tips for Effective Quality Management in Construction

To achieve effective quality management in construction projects, start by establishing a comprehensive pre-construction plan that outlines all QA/QC protocols clearly. Invest in continuous training for staff to ensure they are equipped with the latest knowledge on best practices for both QC and QA processes. Finally, foster a culture of open communication where team members feel empowered to raise concerns about potential quality issues—this will ultimately lead to better outcomes across all phases of construction.