Introduction

In the fast-paced world of microwave manufacturing, ensuring product quality is not just a goal but a necessity. Microwave Inspection plays a pivotal role in maintaining high standards and meeting consumer expectations. As we delve into the various aspects of inspection, it becomes clear that addressing Appearance Issues, Assembly Weaknesses, Component Quality Problems, Functional Failures, and Packaging and Labeling Errors is crucial for delivering reliable appliances.

Understanding the Importance of Microwave Inspection

Microwave Inspection serves as the first line of defense against potential product failures that can arise during manufacturing. By implementing thorough inspection processes, manufacturers can identify critical flaws early on—before they reach consumers. This proactive approach not only enhances product safety but also builds trust with customers who rely on these appliances for their daily needs.

Key Quality Control Challenges in Microwave Products

Despite advancements in technology and manufacturing techniques, several challenges persist in microwave production that can compromise quality control. Common issues include Appearance Issues such as surface defects or inconsistent finishes, which can deter consumers from making a purchase. Additionally, Assembly Weaknesses may lead to structural integrity problems while overlooking Component Quality Problems can result in functional failures that jeopardize user safety.

Essential Elements of a Comprehensive PSI Checklist

To effectively tackle these challenges, a comprehensive Pre-Shipment Inspection (PSI) checklist must be established to cover all critical areas of quality control. This checklist should include Standards and Testing Methods for Microwave Quality Control to ensure compliance with industry regulations while addressing Electrical Safety Testing to validate the functionality of each unit before it leaves the factory floor. By incorporating detailed assessments for each potential issue—from appearance flaws to packaging errors—manufacturers can significantly mitigate risks associated with microwave products.

The Role of Microwave Inspection in Quality Control

Microwave inspection plays a pivotal role in ensuring that products meet the stringent quality standards required in today’s manufacturing landscape. With the increasing complexity of microwave devices, having a robust inspection process helps identify potential issues such as appearance issues, assembly weaknesses, and functional failures before they reach consumers. This proactive approach not only enhances product reliability but also fortifies brand reputation.

Importance of Inspection in Manufacturing

In the world of manufacturing, inspection is not just a checkbox on a to-do list; it’s an essential component that safeguards product integrity. By implementing rigorous microwave inspection protocols, manufacturers can effectively mitigate risks associated with component quality problems and packaging and labeling errors. This is especially crucial given that even minor defects can lead to significant safety concerns or customer dissatisfaction.

Moreover, inspections help to ensure compliance with industry standards and testing methods for microwave quality control, which are vital for maintaining market competitiveness. Without thorough inspections, manufacturers may overlook critical aspects like electrical safety testing, which could result in costly recalls or legal ramifications down the line. Therefore, prioritizing inspection processes translates into long-term savings and enhanced consumer trust.

Common Microwave Inspection Techniques

When it comes to microwave inspection techniques, variety is key to addressing different aspects of product quality. Visual inspections remain one of the most straightforward yet effective methods for identifying appearance issues such as surface blemishes or improper finishes. Additionally, more advanced techniques like X-ray imaging can uncover hidden assembly weaknesses that might compromise the structural integrity of the device.

Functional testing is another cornerstone technique used during microwave inspections; it assesses whether products perform as intended under real-world conditions while also revealing any functional failures early on in production. Furthermore, employing electrical safety testing ensures that all components comply with safety regulations—an absolute must-have for any manufacturer looking to maintain credibility in their field. By utilizing these diverse techniques, manufacturers can create a comprehensive framework for identifying and addressing potential issues before they escalate.

Benefits of Regular Inspections

Regular inspections offer numerous benefits beyond mere compliance; they serve as a foundation for continuous improvement within manufacturing operations. By routinely engaging in microwave inspection activities, companies can identify trends related to component quality problems or recurring assembly weaknesses over time—insights that are invaluable for refining production processes and enhancing product design.

Another significant advantage is the boost in consumer confidence that results from consistent quality assurance practices; customers are more likely to trust brands known for their rigorous adherence to standards and testing methods for microwave quality control. Additionally, regular inspections reduce the likelihood of costly recalls due to packaging and labeling errors or functional failures by catching these issues early on before products hit store shelves.

In conclusion, embracing regular microwave inspections not only elevates product quality but also fosters a culture of excellence within manufacturing organizations—a win-win situation indeed!

Identifying Appearance Issues in Microwave Products

When it comes to microwave products, appearance matters more than you might think. Consumers often judge a product's quality based on its visual appeal, making thorough microwave inspection essential to catch any appearance issues early on. A well-executed visual inspection can help manufacturers avoid costly returns and maintain a positive brand reputation.

Importance of Visual Inspections

Visual inspections are the first line of defense against potential appearance issues in microwave products. They allow quality control teams to spot defects such as scratches, dents, or discoloration that could indicate deeper assembly weaknesses or component quality problems. By prioritizing these inspections, manufacturers can ensure that their microwaves not only function well but also look appealing on the shelf.

Techniques for Detecting Appearance Flaws

Detecting appearance flaws requires a blend of keen observation and appropriate techniques. Common methods include using magnification tools for close-up inspections and employing lighting variations to highlight imperfections that might otherwise go unnoticed. Additionally, standardized checklists based on established standards and testing methods for microwave quality control can streamline the process and ensure consistency across all units.

Impact of Appearance Issues on Consumer Perception

Appearance issues can significantly affect consumer perception, often leading to assumptions about overall product quality and reliability. If a microwave looks poorly made or has visible flaws, consumers may question its functionality, leading them to consider alternatives from competitors with better aesthetics. Therefore, addressing these appearance issues through rigorous microwave inspection is not just about looks; it's crucial for maintaining consumer trust and loyalty.

Assembly Weaknesses: Potential Risks

In the world of microwave production, assembly weaknesses can lead to a cascade of problems that affect product quality and safety. These issues often arise from improper alignment, insufficient fastening, or inadequate soldering techniques. Such challenges not only threaten the structural integrity of the microwave but can also result in functional failures that compromise user safety.

Common Assembly Challenges in Microwave Production

Microwave production is fraught with assembly challenges that can easily derail quality control efforts. One significant issue is misalignment during the assembly process, which can lead to gaps or uneven surfaces that may affect performance. Additionally, component quality problems like poor solder joints or inadequate adhesive applications can create vulnerabilities in the product, making it susceptible to future malfunctions.

Strategies for Identifying Assembly Weaknesses

To combat assembly weaknesses effectively, manufacturers must implement robust inspection strategies throughout the production process. Regular visual inspections are crucial for identifying appearance issues such as misaligned components or improper fittings before they escalate into more significant defects. Utilizing advanced testing methods for microwave quality control—such as X-ray inspection and ultrasonic testing—can also help pinpoint hidden flaws that might not be visible to the naked eye.

Ensuring Structural Integrity through Inspections

Ensuring structural integrity is paramount in microwave manufacturing; hence rigorous inspections play a vital role in this process. By integrating electrical safety testing alongside routine assembly checks, manufacturers can identify potential risks before products reach consumers. Ultimately, a comprehensive approach to microwave inspection helps safeguard against packaging and labeling errors while reinforcing overall product reliability.

Tackling Component Quality Problems

When it comes to microwave inspection, component quality problems can be a significant hurdle in ensuring product performance and safety. These issues not only affect the functionality of the microwave but also pose risks to user safety. Therefore, implementing stringent standards and testing methods for microwave quality control is essential in mitigating these risks and enhancing overall product integrity.

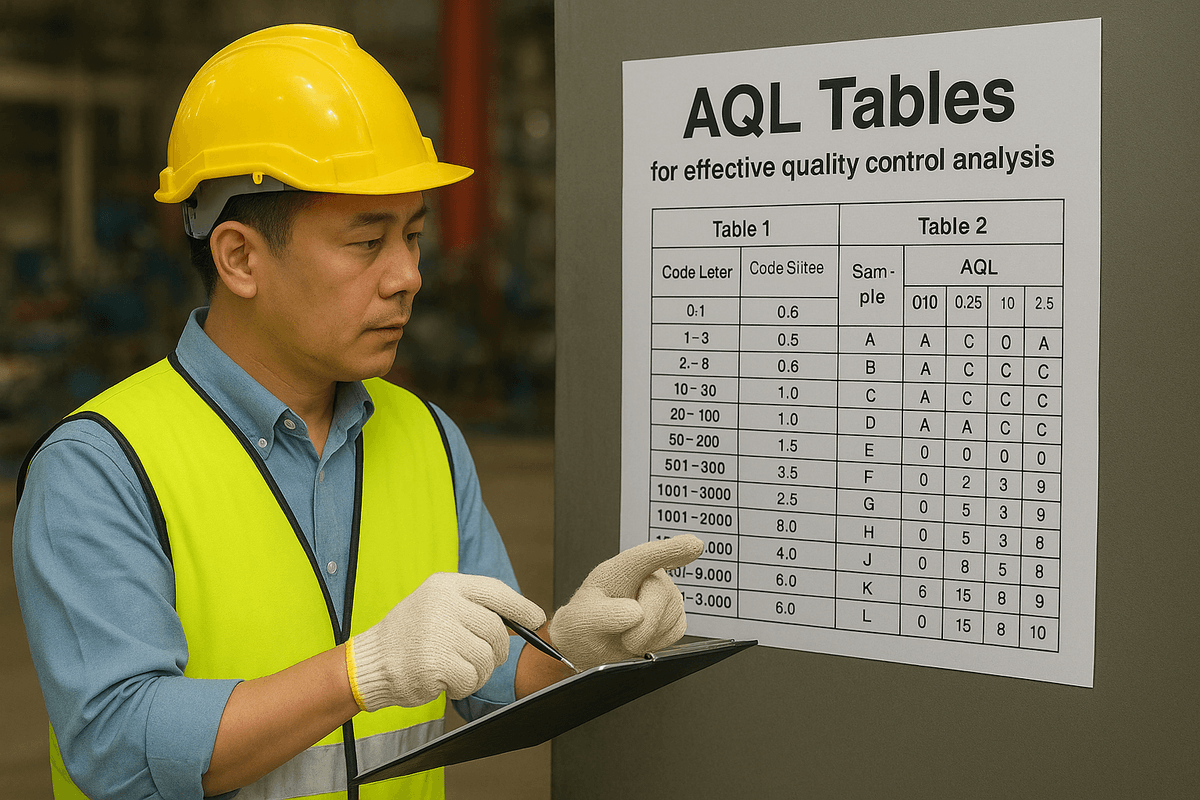

Standards and Testing Methods for Microwave Quality Control

To tackle component quality problems effectively, manufacturers must adhere to established standards that govern microwave inspection processes. These standards include ISO certifications, IEC guidelines, and various industry-specific benchmarks that dictate acceptable quality levels for components used in microwaves. Testing methods such as thermal cycling tests, vibration tests, and electrical safety testing are crucial in identifying potential weaknesses before they turn into functional failures.

Regular adherence to these standards not only helps detect appearance issues early on but also reinforces consumer confidence in the product's reliability. Additionally, employing advanced testing techniques ensures that all components meet rigorous quality requirements throughout the entire manufacturing process. By doing so, manufacturers can significantly reduce assembly weaknesses that could arise from subpar components.

How to Evaluate Component Quality

Evaluating component quality requires a multi-faceted approach that encompasses both visual inspections and performance assessments during microwave inspection procedures. First off, visual inspections help identify any apparent defects or appearance issues that may compromise the aesthetic appeal of the final product. Following this initial evaluation, functional testing is essential to ensure each component operates within specified parameters under various conditions.

Moreover, employing methods such as failure mode analysis allows manufacturers to pinpoint specific vulnerabilities within their components before they lead to assembly weaknesses or functional failures down the line. It’s vital to maintain detailed records of these evaluations so trends can be analyzed over time; this data-driven approach fosters continuous improvement in component selection and supplier partnerships alike.

Importance of Supplier Quality Assurance

Supplier quality assurance plays a pivotal role in addressing component quality problems effectively during microwave inspection processes. Establishing strong relationships with suppliers who prioritize rigorous testing methods enhances overall product integrity right from the source material stage. By conducting thorough audits and evaluations of supplier capabilities—such as their adherence to industry standards—manufacturers can mitigate risks associated with poor-quality components entering their production lines.

Furthermore, ongoing communication with suppliers regarding expectations for electrical safety testing ensures that everyone involved understands their responsibilities concerning component integrity and compliance with regulations related to packaging and labeling errors as well. This collaborative approach not only minimizes potential assembly weaknesses but also cultivates a culture of accountability throughout the supply chain—ultimately benefiting end consumers through higher-quality products.

In conclusion, tackling component quality problems through effective standards enforcement, comprehensive evaluation practices, and robust supplier partnerships is crucial for maintaining excellence in microwave inspection processes.

Functional Failures: Diagnosing the Issues

Functional failures in microwave devices can be a significant concern, impacting both performance and safety. These failures often arise from various factors during the manufacturing process, making thorough Microwave Inspection essential for quality control. Identifying and addressing these issues early on can prevent costly recalls and protect consumer trust.

Overview of Functional Testing Procedures

Functional testing procedures are critical in assessing whether microwave products operate as intended. These tests involve simulating real-world usage scenarios to evaluate performance metrics such as heating efficiency, timer accuracy, and user interface functionality. By implementing rigorous standards and testing methods for microwave quality control, manufacturers can ensure that their products meet safety regulations and customer expectations.

Incorporating functional testing into the production line allows for immediate feedback on any potential functional failures that may arise due to assembly weaknesses or component quality problems. Regularly scheduled inspections not only help catch issues but also provide valuable data for continuous improvement efforts within the manufacturing process. Ultimately, this proactive approach contributes to higher product reliability and customer satisfaction.

Common Causes of Functional Failures

Understanding common causes of functional failures is vital for effective troubleshooting during the inspection process. One prevalent issue stems from faulty components that do not meet established quality standards; these component quality problems can lead to erratic device behavior or complete failure during operation. Additionally, improper assembly practices may introduce mechanical obstacles that hinder performance, illustrating how assembly weaknesses can compromise overall functionality.

Another significant contributor to functional failures is inadequate testing before product release; without thorough evaluations, defects may go unnoticed until they reach consumers' kitchens. Environmental factors such as humidity or temperature fluctuations during storage can also affect microwave performance over time if packaging and labeling errors occur in terms of protective measures taken by manufacturers. Addressing these root causes through diligent inspections helps mitigate risks associated with functional failures.

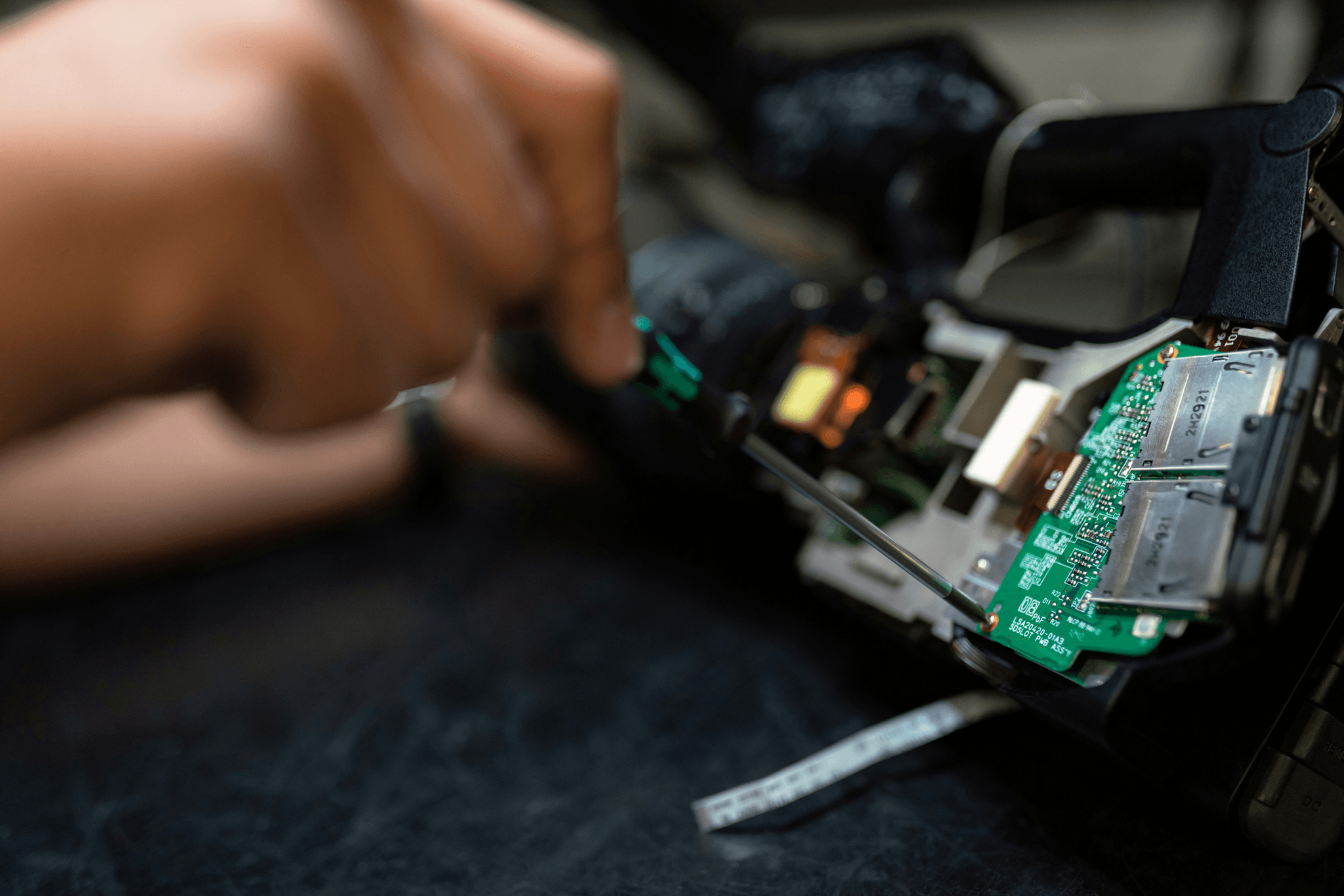

Electrical Safety Testing for Microwave Devices

Electrical safety testing is a non-negotiable aspect of ensuring that microwaves operate safely under various conditions while minimizing risks to users. This type of testing evaluates critical parameters like insulation resistance, dielectric strength, and grounding integrity—factors crucial for preventing electrical hazards that could lead to fires or shocks during operation. Regular Microwave Inspection processes must incorporate these assessments alongside other evaluations focused on appearance issues or structural integrity.

Moreover, adhering to stringent electrical safety standards not only fulfills regulatory requirements but also reinforces consumer confidence in the brand's commitment to safety and quality assurance programs regarding component quality problems within their supply chains. Manufacturers who prioritize electrical safety testing are better positioned to address potential faults proactively before they escalate into serious concerns affecting end-users’ experiences with their products.

In conclusion, diagnosing functional failures through comprehensive inspection processes—including rigorous testing procedures—ensures high-quality microwave devices ready for market entry while safeguarding consumer interests against unforeseen risks associated with poor assembly practices or defective components.

Addressing Packaging and Labeling Errors

Poorly designed packaging can lead to damage during transportation or storage, posing risks to both the product's integrity and consumer safety. Additionally, misleading labels can create confusion or even hazards for users, making effective packaging and labeling essential components of quality control.

The Role of Packaging in Product Safety

Packaging serves as the first line of defense for microwave products against external elements that could compromise their functionality. It protects against physical damage while also safeguarding sensitive components from moisture or contaminants, thereby preventing potential functional failures down the line. Moreover, proper packaging ensures that assembly weaknesses are minimized by providing adequate support during transit, ultimately enhancing overall product reliability.

Techniques for Effective Labeling

Effective labeling is more than just slapping a sticker on a box; it involves clear communication of essential information regarding the product's use, safety precautions, and warranty details. Utilizing standardized symbols and legible fonts can significantly reduce the risk of consumer misinterpretation while complying with industry standards for microwave inspection. Additionally, incorporating QR codes or links to online resources can enhance user experience by providing instant access to manuals or troubleshooting guides.

Importance of Compliance in Packaging Inspections

Regular checks ensure that all labels meet legal requirements regarding safety information and ingredient disclosures while minimizing risks associated with component quality problems or appearance issues that could arise from improper labeling practices. By adhering to stringent compliance measures during packaging inspections, manufacturers not only protect consumers but also build trust in their brand.

Conclusion

In the fast-paced world of microwave manufacturing, comprehensive Microwave Inspection emerges as a critical pillar of quality control. By addressing key areas such as Appearance Issues, Assembly Weaknesses, and Component Quality Problems, manufacturers can significantly enhance product reliability and consumer trust. The proactive approach to inspections not only mitigates risks but also ensures that each microwave meets the high standards expected by users.

The Significance of Comprehensive Microwave Inspection

Comprehensive Microwave Inspection plays a vital role in identifying potential pitfalls in production processes. From catching Appearance Issues early on to uncovering hidden Assembly Weaknesses, thorough inspections help maintain a consistent level of quality throughout the manufacturing cycle. Moreover, these inspections serve as a safety net against Component Quality Problems that could lead to functional failures down the line.

Building Quality Standards through Rigorous Testing

Establishing robust quality standards is not just about adhering to regulations; it’s about fostering a culture of excellence within the organization. Rigorous testing methods for Microwave Quality Control ensure that every aspect—from performance to safety—is scrutinized under various conditions. This commitment to quality helps minimize Functional Failures and enhances customer satisfaction by guaranteeing that products are safe and effective for everyday use.

Partnering with Experts like China Inspection Pro

When it comes to ensuring top-notch quality in microwave production, partnering with experts like China Inspection Pro can make all the difference. Their extensive knowledge in tackling Packaging and Labeling Errors and conducting Electrical Safety Testing streamlines processes and elevates product integrity. Collaborating with seasoned professionals not only saves time but also provides peace of mind knowing that your products meet stringent industry standards.