Introduction

In an era where efficiency and safety are paramount, the rise of remote visual inspection has revolutionized how industries approach quality control. Traditional methods often relied on destructive testing, which not only posed risks but also incurred significant costs and downtime. Enter non-destructive inspection (NDI) techniques, which offer a game-changing alternative that preserves the integrity of materials while providing crucial insights.

The Rise of Remote Visual Inspection

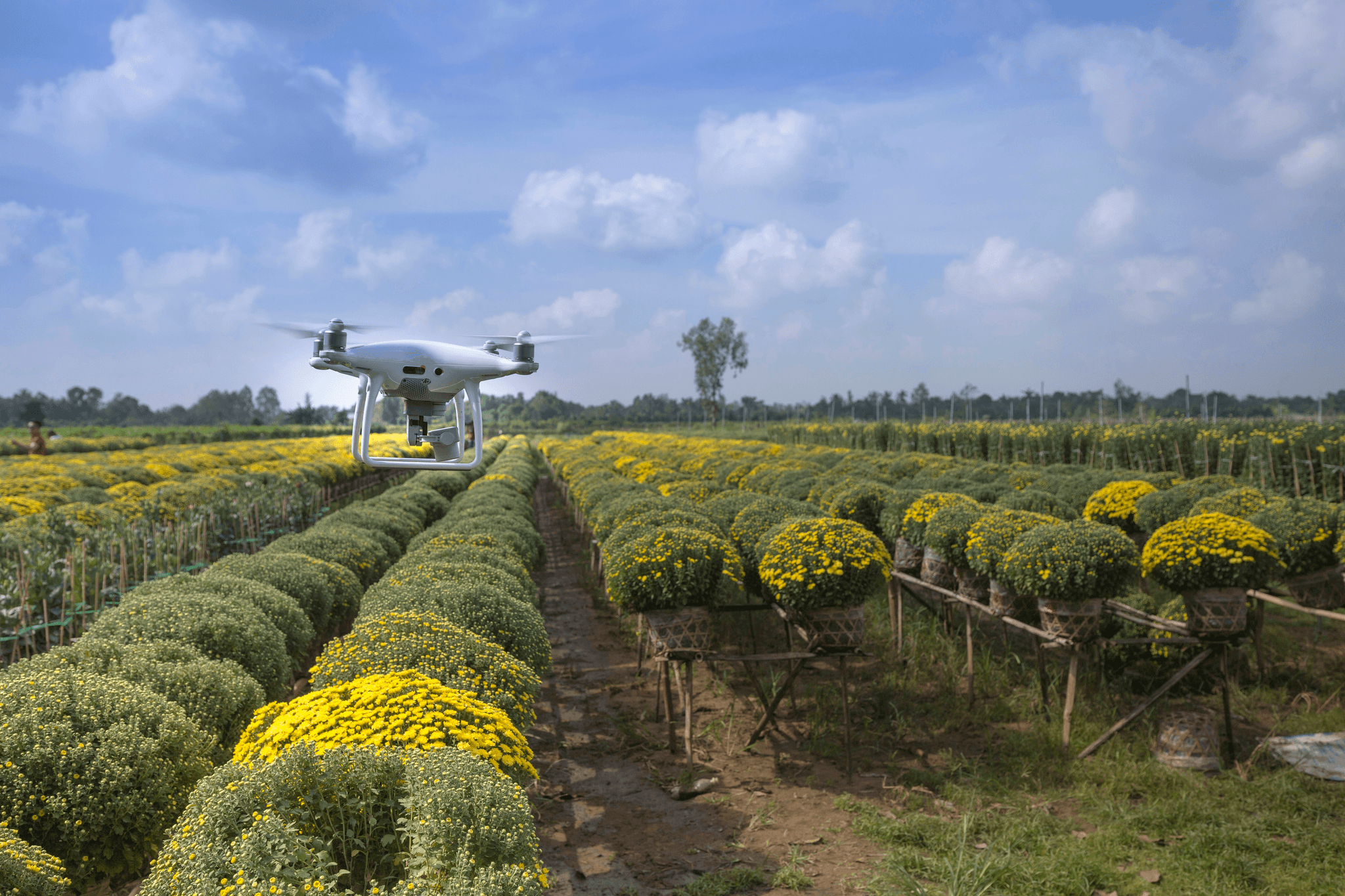

Visual inspection services have seen a meteoric rise in popularity, driven by advancements in technology and a growing need for efficient quality assurance processes. With tools like drones and high-resolution cameras, remote visual inspections can cover vast areas quickly and accurately, reducing the need for personnel to be physically present in potentially hazardous environments. This shift not only enhances safety but also allows companies to respond swiftly to issues as they arise.

Benefits of Non-Destructive Testing

The benefits of NDT non-destructive testing are manifold; foremost among them is the ability to assess the condition of materials without causing any damage. Unlike destructive testing methods that compromise structural integrity, NDT allows for ongoing monitoring and maintenance without sacrificing performance or reliability. This cost-effective approach ensures that resources are utilized efficiently while maintaining compliance with industry standards.

Streamlining Your Processes with NDT

Integrating NDT non-destructive testing into your operations can significantly streamline processes across various sectors, from manufacturing to construction. By leveraging real-time data collection through visual inspection services, businesses can make informed decisions quickly, ultimately leading to enhanced productivity and reduced operational costs. Embracing these modern techniques positions organizations at the forefront of innovation while safeguarding their assets against unforeseen failures.

Understanding Visual Inspection Services

Visual inspection services are essential components of quality assurance across various industries, providing a means to assess the condition of materials and structures without causing damage. These services utilize trained professionals and advanced technologies to detect flaws, ensuring compliance with safety regulations. By employing non-destructive inspection methods, organizations can maintain operational integrity while minimizing downtime and costs associated with destructive testing.

What Are Visual Inspection Services?

At their core, visual inspection services involve examining objects or systems using the naked eye or optical devices to identify defects or irregularities. Unlike destructive non-destructive testing methods that compromise the integrity of a sample, visual inspections allow for thorough evaluations without altering the tested materials. This makes them an invaluable tool in industries such as manufacturing, construction, and maintenance where safety and reliability are paramount.

Key Technologies in Remote Inspection

The landscape of remote inspection is rapidly evolving thanks to innovative technologies that enhance visual inspection services. Drones equipped with high-resolution cameras can access hard-to-reach areas while providing real-time imagery for immediate analysis. Additionally, augmented reality (AR) tools enable inspectors to overlay digital information onto physical environments, streamlining the process of identifying potential issues during non-destructive testing.

The Role of NDT Non-Destructive Testing

NDT non-destructive testing plays a crucial role in modern quality control processes by allowing inspectors to evaluate materials without causing harm or destruction. This approach not only saves time and resources but also enhances safety by identifying potential failures before they escalate into serious problems. By integrating NDT testing within visual inspection services, organizations can ensure comprehensive assessments that uphold industry standards while promoting efficient operations.

Advantages of NDT Non-Destructive Testing

Non-destructive testing (NDT) offers a myriad of advantages that make it an essential tool in various industries. By utilizing visual inspection services, organizations can ensure the integrity of their materials and structures without compromising them. This approach not only enhances safety but also fosters compliance with industry regulations, proving that NDT non-destructive testing is a wise investment for any business looking to thrive.

Enhancing Safety and Compliance

One of the most significant benefits of NDT non-destructive testing is its ability to enhance safety across various sectors. Visual inspection services allow for thorough evaluations without risking damage to critical components, thereby reducing the likelihood of catastrophic failures. Furthermore, adhering to strict compliance standards becomes more manageable when using non-destructive inspection methods, ensuring that businesses meet regulatory requirements while maintaining high safety levels.

Cost-Effectiveness Over Destructive Methods

When comparing destructive and non-destructive testing methods, cost-effectiveness often tips the scale in favor of NDT non-destructive testing. Destructive non-destructive testing can lead to costly downtime and repairs, not to mention the expense involved in replacing damaged materials. In contrast, visual inspection services provide a thorough assessment without incurring additional costs associated with material loss or extensive repairs—making it an economical choice for long-term sustainability.

Real-Time Data Collection and Analysis

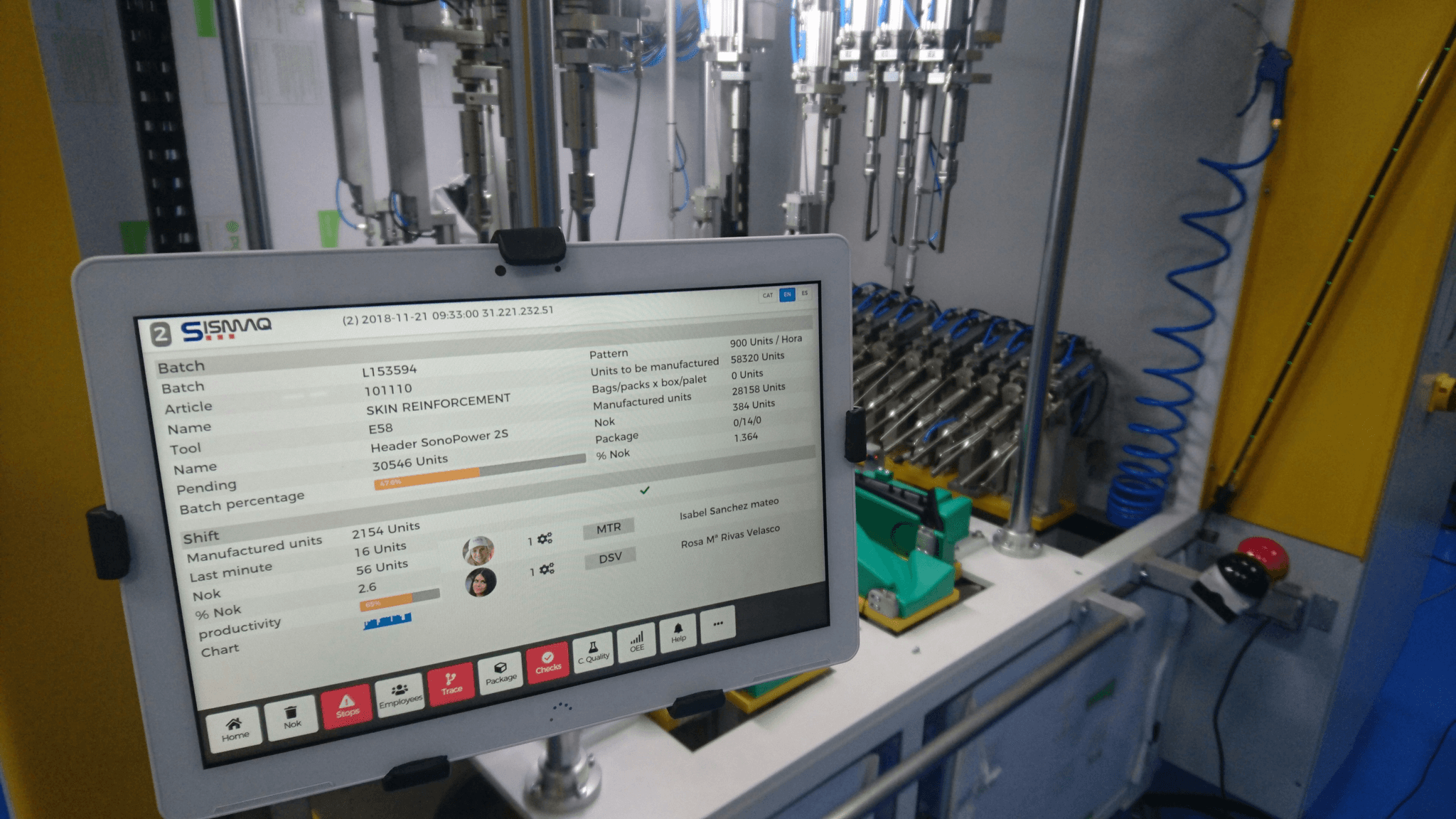

Another game-changing advantage of NDT non-destructive testing is its capability for real-time data collection and analysis. With advanced technologies integrated into visual inspection services, inspectors can gather crucial information on material conditions instantly and assess potential issues before they escalate into major problems. This proactive approach not only streamlines maintenance schedules but also empowers companies to make informed decisions quickly—ultimately enhancing operational efficiency.

Integration of Remote Visual Inspection

Integrating remote visual inspection services into existing workflows can significantly enhance operational efficiency and safety. The process involves adopting advanced technologies, training personnel, and ensuring compliance with industry standards. This section delves into the steps necessary for a seamless integration, the challenges faced during implementation, and real-world examples of successful adaptation.

Steps to Integrate Remote Inspection

To effectively integrate remote inspection services, organizations should first assess their current inspection processes and identify areas where non-destructive testing (NDT) can be beneficial. Next, it is essential to select appropriate technologies that align with specific needs—such as drones or robotic systems equipped for NDT non-destructive testing. Training staff on these new tools is crucial; they must understand both the technical aspects of NDT testing and how to interpret the data collected from these inspections.

Additionally, establishing clear protocols for reporting and analyzing findings will streamline communication across teams. Regular evaluations should be conducted to refine processes continuously; this ensures that destructive and non-destructive testing methods are utilized effectively without compromising quality or safety. Ultimately, a phased approach allows organizations to adapt gradually while minimizing disruption.

Challenges and Solutions During Integration

While integrating remote visual inspection services offers numerous advantages, several challenges may arise during the transition phase. One common issue is resistance from employees who may be accustomed to traditional methods of destructive non-destructive testing; overcoming this requires effective change management strategies that emphasize training and support. Another challenge involves ensuring data security when using cloud-based platforms for storing inspection results—organizations must implement robust cybersecurity measures to protect sensitive information.

Moreover, technical issues can occur with new equipment or software solutions; having a dedicated support team in place can help troubleshoot problems quickly as they arise. By addressing these potential hurdles proactively through comprehensive planning and employee engagement initiatives, companies can foster a smoother integration process for their NDT non-destructive testing efforts.

Case Studies of Successful Integration

Numerous industries have successfully integrated remote visual inspection services into their operations with impressive results. For instance, an aerospace manufacturer adopted drone technology for routine inspections of aircraft components; this shift not only reduced downtime but also enhanced safety by minimizing human exposure in hazardous environments during NDT testing procedures. The company reported significant cost savings due to decreased reliance on traditional destructive methods while maintaining high-quality standards.

Another example comes from the oil and gas sector where a leading firm implemented robotic systems equipped with advanced sensors for pipeline inspections—a move that improved accuracy in detecting leaks or corrosion while reducing manual labor costs associated with traditional methods of destructive non-destructive testing. These case studies illustrate how embracing innovative technologies in visual inspection services leads not only to improved efficiency but also better compliance with safety regulations across various industries.

The Impact of Visual Inspection on Quality Control

In today's fast-paced industrial landscape, the integration of remote visual inspection services has revolutionized quality control processes. By leveraging non-destructive inspection techniques, companies can ensure that their products meet stringent safety and quality standards without compromising their integrity. This shift from traditional methods to advanced NDT non-destructive testing is not just a trend; it's a necessity for maintaining competitiveness in the market.

How Remote Inspection Improves Quality Assurance

Remote visual inspection services enhance quality assurance by allowing real-time monitoring and evaluation of materials and components. With NDT non-destructive testing, inspectors can identify potential defects without damaging the item being inspected, ensuring that products maintain their intended functionality and safety standards. This proactive approach not only minimizes the risk of costly recalls but also fosters a culture of continuous improvement within organizations.

Moreover, the ability to perform inspections remotely means that teams can access critical data from anywhere in the world, leading to faster decision-making processes. By utilizing advanced technologies like drones and high-resolution cameras in visual inspection services, companies can capture detailed images and videos that facilitate thorough analysis and reporting. Ultimately, this innovative method streamlines operations while significantly boosting overall product quality.

Comparative Analysis with Traditional Methods

When comparing remote visual inspection services to traditional destructive non-destructive testing methods, several key differences emerge that highlight the advantages of modern approaches. Traditional methods often involve physically cutting into materials or dismantling components to assess their integrity—an approach that carries inherent risks and costs associated with material loss. In contrast, NDT non-destructive techniques allow for comprehensive evaluations without compromising the structural integrity of assets.

Furthermore, while traditional methods may require extensive downtime for repairs or replacements after inspections are completed, remote visual inspections enable continuous operation with minimal disruption. This efficiency translates into significant cost savings over time as businesses avoid unnecessary delays in production schedules due to lengthy assessments or repairs related to destructive testing practices.

Additionally, remote visual inspections provide more accurate data collection through advanced imaging technologies compared to conventional methods reliant on subjective human interpretation—leading to more reliable outcomes in quality control processes.

Insights from China Inspection Pro

China Inspection Pro serves as a compelling case study illustrating how effective visual inspection services can enhance quality control across various industries. By implementing NDT non-destructive testing strategies tailored specifically for local manufacturing challenges, they have successfully improved compliance rates while reducing operational costs significantly.

Their experience highlights how integrating advanced technologies such as AI-driven analytics with traditional inspection frameworks leads not only to better detection rates but also fosters collaboration among teams spread across different locations globally—an essential feature for modern enterprises aiming for excellence in production standards.

In conclusion, China Inspection Pro's commitment to embracing innovative solutions demonstrates how organizations can leverage remote visual inspection services effectively within their operations—ultimately resulting in superior product quality assurance through enhanced efficiency and reduced reliance on destructive testing methodologies.

Future Trends in Remote Visual Inspection

The landscape of remote visual inspection is evolving rapidly, driven by technological advancements and a growing emphasis on efficiency and safety. As industries increasingly recognize the value of non-destructive testing (NDT), innovations are emerging that redefine how visual inspection services are conducted. From enhanced imaging technologies to artificial intelligence, the future promises significant improvements in NDT non-destructive testing methodologies.

Innovations Shaping NDT Non-Destructive Testing

One of the most exciting innovations in NDT non-destructive testing is the integration of drones equipped with high-resolution cameras for visual inspection services. These aerial devices can access hard-to-reach areas, providing a comprehensive view without compromising structural integrity. Additionally, advancements in thermal imaging and ultrasonic testing technology are enabling inspectors to detect flaws that traditional methods might miss, ensuring that destructive and non-destructive testing remains effective.

Moreover, machine learning algorithms are beginning to play a pivotal role in analyzing data collected during NDT inspections. By processing vast amounts of information quickly, these algorithms can identify patterns and anomalies that human inspectors may overlook. This not only enhances the accuracy of visual inspection services but also streamlines the overall process, making it more efficient than ever before.

Predictions for Industry Adoption

As industries continue to embrace remote technologies, predictions suggest a significant uptick in the adoption of NDT non-destructive testing across various sectors over the next decade. Industries such as aerospace, automotive, and construction are expected to lead this charge due to their stringent safety regulations and quality assurance needs. With ongoing investments in training personnel on advanced visual inspection services techniques and tools, organizations will likely see improved compliance rates alongside reduced downtime.

Furthermore, as more companies realize the cost-effectiveness associated with remote inspections compared to traditional destructive methods, we can expect a shift away from destructive non-destructive testing practices altogether. This transition will not only enhance operational efficiency but also contribute positively to environmental sustainability by minimizing waste generated from destructive tests.

The Growing Importance of Remote Technologies

The growing importance of remote technologies cannot be overstated; they represent a fundamental shift towards smarter operations within industries reliant on thorough inspections for quality control. As companies seek ways to optimize their processes while maintaining rigorous standards for safety and compliance, remote visual inspection services will become indispensable tools in their arsenals.

Additionally, with global supply chains becoming increasingly complex due to factors like globalization and digital transformation, having reliable NDT non-destructive methods at one's disposal ensures that potential issues can be identified promptly—before they escalate into costly problems or safety hazards. Ultimately, embracing these innovations will pave the way for safer workplaces while enhancing product quality across diverse sectors.

Conclusion

As industries evolve, the transition to remote inspection technologies marks a significant shift in how we approach quality control and safety. Remote visual inspection services have emerged as a game changer, allowing organizations to conduct non-destructive testing (NDT) with unparalleled efficiency and accuracy. By leveraging these advanced methods, businesses can ensure compliance while minimizing disruptions to operations, making destructive and non-destructive testing a thing of the past.

Why Remote Inspection is a Game Changer

Remote inspection fundamentally alters the landscape of quality assurance by integrating cutting-edge technology into traditional practices. It enhances the capabilities of NDT non-destructive testing by providing real-time data analysis, which allows for immediate decision-making and corrective actions when needed. As a result, companies can maintain high standards of safety and reliability without resorting to destructive methods that compromise valuable assets.

Key Takeaways on Quality and Efficiency

The benefits of visual inspection services extend beyond mere compliance; they also drive efficiency across various sectors. With NDT non-destructive testing techniques, organizations can save time and resources while maintaining rigorous quality standards. Additionally, the cost-effectiveness of these methods compared to destructive non-destructive testing approaches ensures that businesses get more bang for their buck without sacrificing safety or integrity.

Steps to Get Started with Visual Inspection Services

To embark on your journey into remote visual inspection, start by assessing your current processes and identifying areas where NDT testing could enhance performance. Next, invest in training your team on the latest technologies in visual inspection services so that they are equipped to leverage these tools effectively. Finally, partner with experienced providers who specialize in non-destructive inspection to ensure successful implementation and ongoing support.