Introduction

In the fast-paced world of global commerce, the significance of trusted suppliers cannot be overstated. Partnering with reliable suppliers is a cornerstone for businesses aiming to minimize product defects and ensure customer satisfaction. As companies increasingly turn to platforms like Alibaba, understanding how to navigate this vast supplier ecosystem becomes essential for success.

Importance of Trusted Suppliers

Trusted suppliers are not just vendors; they are integral partners in your business journey. When you engage with dependable suppliers, you significantly reduce the risk of product defects that can tarnish your brand's reputation. The process of supplier selection is thus critical, as it lays the groundwork for quality assurance and fosters long-term relationships that can drive growth.

Understanding Product Defects

Product defects can arise from various sources, including poor manufacturing processes or subpar materials. Understanding these potential pitfalls is crucial in devising strategies for minimizing product defects before they reach consumers. By being proactive and engaging in thorough supplier selection practices, businesses can mitigate risks associated with defective products.

Overview of Alibaba's Supplier Ecosystem

Alibaba offers a diverse array of suppliers across multiple industries, making it a go-to platform for sourcing products globally. However, navigating this ecosystem requires knowledge about its dynamics and an understanding of effective sampling processes to evaluate potential partners properly. Arranging a visit to suppliers can also enhance your insights into their operations and capabilities, ensuring that you make informed decisions tailored to your business needs.

The Art of Supplier Selection

Choosing the right supplier is akin to selecting a partner in crime—one that can help you achieve your business goals while minimizing product defects along the way. With countless options available, understanding how to navigate this landscape is crucial for any business looking to thrive. From evaluating credentials to leveraging reviews, each step in the supplier selection process plays a vital role in ensuring quality and reliability.

Key Factors in Choosing Suppliers

First and foremost, consider their experience and specialization; suppliers with a proven track record in your specific industry are more likely to understand your unique needs and challenges. Additionally, assess their production capacity and lead times—finding a supplier that can scale with your demand while consistently delivering quality products is essential for minimizing product defects.

Another important factor is the location of the supplier; proximity can impact shipping times and costs significantly. A local supplier may offer faster turnaround times, while an overseas option could provide cost savings but may require more careful planning regarding logistics. Ultimately, weighing these factors will help you make informed decisions during your supplier selection journey.

Evaluating Supplier Credentials

Evaluating supplier credentials is an indispensable part of ensuring you partner with trustworthy manufacturers who can meet your expectations. Start by requesting documentation such as certifications that validate their compliance with industry standards; this could include ISO certifications or safety compliance records relevant to your products. These credentials not only reflect their commitment to quality but also provide peace of mind when considering potential risks associated with product defects.

Don't overlook financial stability either; reviewing financial statements or credit reports can shed light on whether a supplier is capable of fulfilling long-term commitments without compromising on quality or service levels.

The Role of Reviews and Ratings

In today's digital age, reviews and ratings serve as invaluable resources during the supplier selection process—think of them as modern-day testimonials that reveal what others have experienced firsthand. Platforms like Alibaba allow buyers to leave feedback on suppliers based on their interactions, providing insights into reliability, communication skills, and overall satisfaction levels—all crucial elements for minimizing product defects down the line.

However, it's essential not just to rely solely on high ratings but also consider patterns in feedback over time; consistent positive reviews indicate reliability while occasional negative comments may warrant further investigation into those specific issues raised by buyers. By taking both quantitative scores and qualitative comments into account, you'll be better equipped to make informed decisions about which suppliers align best with your business values and objectives.

Sampling Process Explained

Product samples serve as a tangible representation of what you can expect from a supplier, allowing you to assess quality before committing to larger orders. By taking this step seriously, you set the stage for better outcomes in your supply chain.

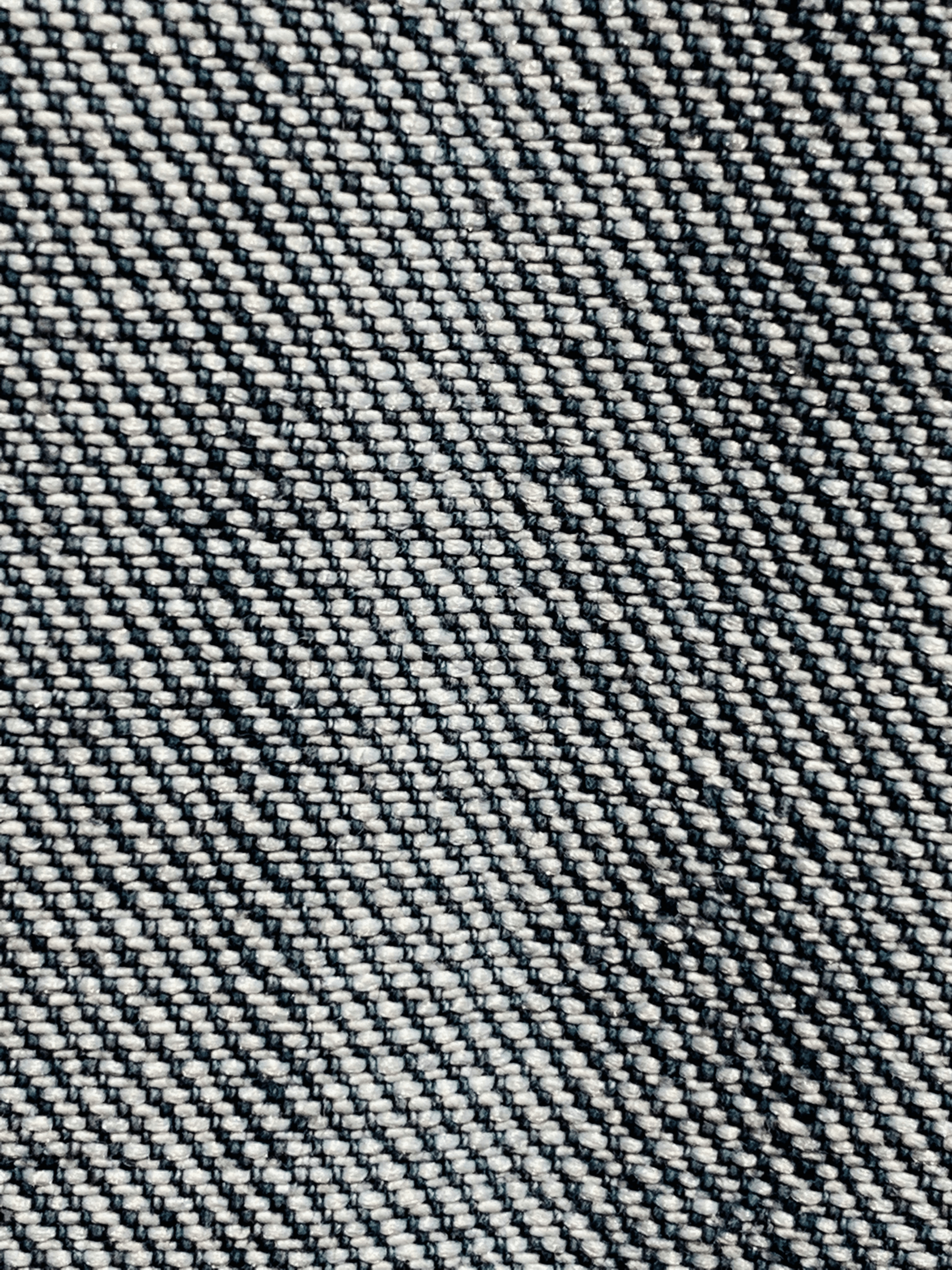

Importance of Product Samples

Product samples are vital for anyone looking to ensure quality and consistency in their offerings. They provide an opportunity to evaluate materials, craftsmanship, and adherence to specifications without the risk of a full order's financial loss. Moreover, these samples serve as a benchmark for assessing future batches, making them essential in your strategy for minimizing product defects.

How to Request Samples on Alibaba

Requesting samples on Alibaba is more straightforward than one might think, but it requires some finesse in communication with potential suppliers. Start by clearly outlining your needs and expectations when reaching out; this sets the tone for effective dialogue and helps suppliers understand what you're looking for in terms of quality and design. Don’t hesitate to ask about costs associated with shipping or any other fees involved—transparency here will aid you in making informed decisions during your supplier selection process.

Analyzing Sample Quality

Once you've received the samples, it's time for some serious analysis—this is where you'll really see if your efforts in arranging a visit or communicating effectively have paid off! Examine each sample closely: check materials, finishes, dimensions, and overall craftsmanship against your specifications. By conducting thorough evaluations now, you'll be one step closer to minimizing product defects later on when you move forward with bulk orders.

Arranging a Visit to Suppliers

When it comes to supplier selection, arranging a visit to your potential suppliers can be a game-changer. While emails and video calls have their place, nothing quite beats the insights gained from an in-person interaction. Not only does it provide a clearer picture of the operation, but it also helps in building trust—an essential element for minimizing product defects.

Benefits of On-Site Visits

On-site visits allow you to assess the manufacturing environment firsthand, which is crucial for minimizing product defects. You can observe the production processes, quality control measures, and even employee morale—all factors that impact product quality. Moreover, meeting suppliers face-to-face fosters stronger relationships and opens up more honest lines of communication for future negotiations.

Another significant advantage is that you can directly evaluate their capabilities against your specific needs during the sampling process. By seeing how they operate, you can better gauge whether they align with your expectations in terms of quality and reliability. Plus, if any issues arise later on, having established personal rapport can make resolving them much smoother.

How to Plan Your Visit

Planning your visit involves more than just booking a flight; it's about setting clear objectives for what you want to achieve during your time there. Start by researching the supplier's location and logistics—knowing how long it takes to get there will help avoid any last-minute surprises. Create an itinerary that includes meetings with key personnel and time allocated for observing production lines.

Don't forget to prepare questions related to minimizing product defects; this shows you're serious about quality control right from the start! Additionally, consider scheduling visits around peak production times so you can see their operations in action rather than during quieter periods when they might not be fully engaged. Lastly, ensure that you have all necessary documentation ready—like contracts or agreements—to facilitate discussions on future collaborations.

What to Look for During Your Visit

During your visit, focus on several key areas that will give you insight into both their capabilities and commitment to quality assurance. Pay close attention to cleanliness and organization within their facilities; these are often indicative of overall operational standards that impact product quality directly related to minimizing product defects.

Additionally, take note of how employees interact with one another as well as with machinery; high morale typically correlates with better productivity levels and lower defect rates in products produced through effective sampling processes. Finally, don't hesitate to ask about their quality control protocols—understanding these systems will help ensure consistency in what you'll receive down the line.

Effective Communication with Suppliers

Effective communication is the backbone of any successful supplier relationship, especially when it comes to minimizing product defects. Clear and open dialogue ensures that both parties are on the same page regarding expectations, timelines, and quality standards. By honing your communication skills, you can navigate the complexities of supplier selection and enhance your overall experience on platforms like Alibaba.

Setting Clear Expectations

Setting clear expectations is crucial in the supplier selection process to minimize misunderstandings that could lead to product defects. Begin by outlining your requirements in detail—this includes specifications, delivery timelines, and quality standards. When both you and your supplier have a mutual understanding of what is expected, it significantly reduces the chances of surprises down the line.

Moreover, don’t hesitate to document these expectations in writing. This serves as a reference point for both parties throughout the sampling process and beyond, allowing for smoother interactions during negotiations or when arranging a visit. If issues arise later on, having a clear set of agreed-upon terms can help resolve disputes more efficiently.

Negotiation Tips for Better Deals

Negotiation is an art form that can make or break your business relationships while impacting your bottom line significantly. To secure better deals during the supplier selection phase, start by doing thorough research on market prices and competitor offerings; knowledge is power! This preparation allows you to make informed decisions when discussing costs with potential suppliers.

When negotiating, aim for win-win outcomes; express what you need while also considering their constraints. This approach will not only help you get favorable pricing but also foster goodwill—an essential ingredient for long-term partnerships that minimize product defects over time. Remember to be flexible; sometimes offering larger orders or longer contracts can yield better pricing without compromising quality.

Overcoming Language Barriers

In global trade scenarios like those found on Alibaba, language barriers can pose significant challenges during communication with suppliers. However, overcoming these hurdles is entirely feasible with a few strategic approaches! Utilize simple language and avoid jargon when discussing technical specifications or requirements; clarity should always be your goal.

Consider using translation tools or hiring professional translators if necessary—this investment can pay off by ensuring that critical details are accurately conveyed during negotiations or while arranging a visit to inspect facilities firsthand. Additionally, establishing strong relationships through consistent communication helps build trust over time despite any initial language challenges you may encounter.

Utilizing Quality Inspection Services

When it comes to minimizing product defects, quality inspection services are your safety net in the vast ocean of global sourcing. These services help ensure that what you receive matches your expectations and specifications, making them a crucial part of the supplier selection process. By integrating these inspections into your workflow, you can significantly reduce the risk of costly mistakes.

Role of China Inspection Pro

China Inspection Pro plays a pivotal role in the quality assurance landscape by providing comprehensive inspection services tailored to various industries. They specialize in evaluating products before shipment, ensuring that suppliers meet agreed-upon standards and specifications during the sampling process. By leveraging their expertise, you can identify potential issues early on, allowing for timely interventions that minimize product defects.

Benefits of Professional Inspections

Professional inspections offer numerous benefits that go beyond mere compliance checks; they serve as a proactive approach to maintaining high-quality standards. First and foremost, they provide peace of mind by verifying that your products are manufactured according to your requirements and industry standards. Moreover, these inspections can uncover hidden flaws that might not be apparent during initial evaluations or even during on-site visits.

Ensuring Consistency in Quality

Regular quality inspections help establish a benchmark for product standards while fostering trust between you and your suppliers. This ongoing relationship ensures that every batch meets expectations, effectively minimizing product defects over time and reinforcing the importance of diligent supplier selection.

Conclusion

In the world of global trade, finding trusted suppliers is not just a luxury—it's a necessity. The journey from supplier selection to ensuring product quality can be complex, but with the right strategies in place, you can mitigate risks and foster fruitful partnerships. By focusing on key areas such as the sampling process and arranging visits, businesses can significantly enhance their chances of success while minimizing product defects.

Final Thoughts on Trusted Suppliers

Supplier selection should be approached like dating; you want to know their history, values, and how they handle challenges before committing long-term. A reliable supplier will not only meet your expectations but also become an integral part of your business strategy.

Strategies for Minimizing Product Defects

Minimizing product defects starts with a robust supplier selection process that emphasizes quality over cost. Implementing a thorough sampling process allows you to assess products before making large purchases—think of it as a dress rehearsal before the big show! Additionally, arranging a visit to your potential suppliers can provide invaluable insights into their operations and quality control measures.

Importance of Ongoing Supplier Relationships

Building strong relationships with your suppliers is crucial for long-term success in any business endeavor. Ongoing communication fosters trust and transparency, making it easier to address issues related to product defects when they arise. Remember that supplier selection is just the beginning; nurturing these relationships will ensure consistency in quality and help you navigate challenges together.