Introduction

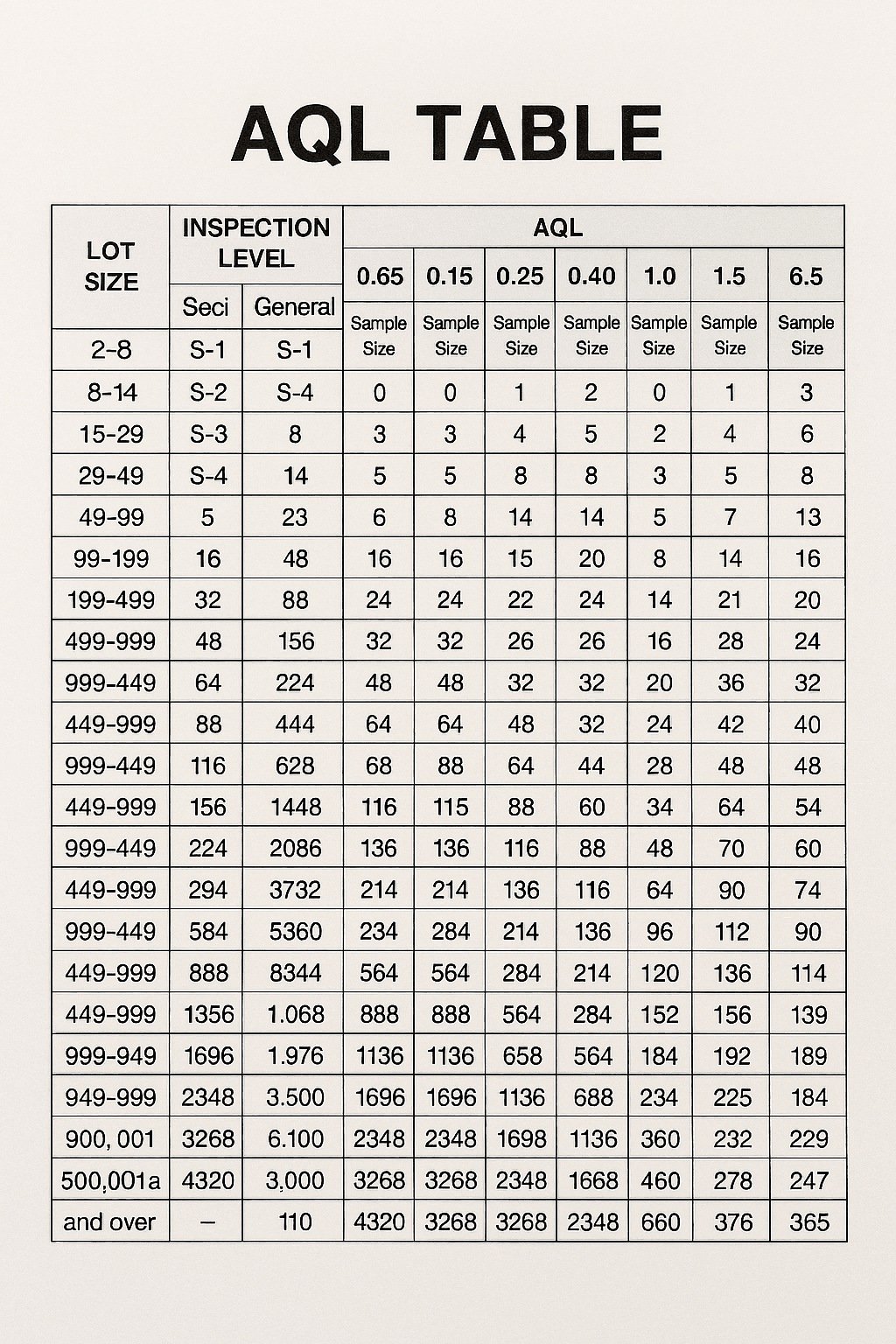

In the fast-paced world of fashion, understanding AQL in garment inspection is paramount. AQL, or Acceptable Quality Level, plays a crucial role in quality control by defining the maximum number of defective items considered acceptable during a quality inspection. As brands strive to meet consumer expectations, knowing what does AQL stand for becomes essential for maintaining high standards in garment production.

Understanding AQL in Garment Inspection

AQL serves as a benchmark in quality control, helping manufacturers and retailers define quality through measurable standards. By setting specific tolerance levels for defects, businesses can ensure that their products meet customer expectations without incurring excessive costs associated with overproduction or rework. Quality assurance inspection processes leverage AQL to systematically evaluate garments, ensuring that only those meeting predefined criteria reach the market.

Importance of Quality Control in Fashion

Quality control is not just a buzzword; it's the backbone of successful fashion brands. In an industry where trends shift rapidly and consumer loyalty can be fleeting, maintaining high-quality standards is vital for brand reputation and customer satisfaction. Effective quality control inspection minimizes returns and enhances overall product reliability, which ultimately translates into better sales performance for companies like China Inspection Pro.

Overview of AQL 2.5 in Garment Quality

AQL 2.5 specifically refers to an acceptable level of defects within a batch—allowing up to 2.5% defective items while still considering the lot acceptable during inspection services. This level strikes a balance between stringent quality requirements and practical acceptance rates that accommodate manufacturing variances without compromising overall garment integrity. Understanding AQL 2.5 is essential for those looking to define quality effectively while navigating the complexities of garment production.

What Does AQL Stand For?

When delving into the realm of quality control, one term that frequently surfaces is AQL, which stands for Acceptable Quality Level. This concept serves as a critical benchmark in quality assurance inspection, allowing manufacturers and inspectors to define quality in measurable terms. Understanding what does AQL stand for helps stakeholders establish standards that ensure products meet specified criteria without overwhelming costs.

Defining AQL in Quality Control

AQL is essentially a statistical measurement used to determine the maximum number of defective items acceptable in a sample batch during quality control inspection. By setting an acceptable threshold, businesses can maintain a balance between product quality and production efficiency. This definition of quality allows brands like China Inspection Pro. to streamline their processes while still delivering garments that meet consumer expectations.

The beauty of AQL lies in its flexibility; it can be tailored based on the type of garment or specific market demands. For instance, a high-end fashion label may opt for a stricter AQL standard compared to mass-market apparel producers. Thus, defining AQL within the context of each business model becomes essential for effective quality control.

Historical Context of AQL

The origins of AQL can be traced back to military and industrial practices during World War II when there was an urgent need for standardized inspections amid increased production demands. Over time, these practices evolved into formalized methodologies utilized across various industries, including fashion and textiles. Understanding this historical context provides insight into how current quality control meaning has developed into a structured approach that emphasizes both reliability and efficiency.

As industries became more globalized, the need for consistent standards grew even more critical; thus emerged organizations like ISO (International Organization for Standardization) which helped formalize these concepts further. Today’s application of AQL reflects decades of refinement aimed at ensuring that products not only meet aesthetic standards but also functional ones through rigorous quality assurance inspection processes.

AQL's Role in Quality Assurance Inspection

In the world of garment production, understanding what does AQL stand for is pivotal as it directly influences how companies conduct their inspections and manage their supply chains effectively. The role of AQL in quality assurance inspection cannot be overstated; it acts as both a guideline and a metric against which all products are evaluated before reaching consumers' hands.

Inspection services leverage these established thresholds to identify non-conforming items swiftly while ensuring compliance with agreed-upon standards between manufacturers and retailers alike. By utilizing an effective AQL strategy, companies like China Inspection Pro, can not only enhance their reputation but also build trust with customers who expect high-quality garments consistently delivered without defects.

In summary, comprehending what does AQL stand for enriches our understanding of how businesses navigate the complexities surrounding garment production while maintaining integrity through diligent quality control measures.

The Significance of AQL 2.5

Understanding AQL 2.5 is critical for anyone involved in quality control within the garment industry. This specific level of Acceptable Quality Level (AQL) signifies a balance between acceptable defects and maintaining high-quality standards in production. It effectively serves as a benchmark for quality assurance inspection, guiding manufacturers and inspectors alike in their quest to define quality.

AQL 2.5 Explained in Detail

AQL 2.5 is a statistical measurement used to determine the maximum number of defective items considered acceptable during quality control inspections. Specifically, it means that out of a sample size, up to 2.5% can be defective without triggering rejection of the entire batch. This level is particularly important for ensuring that garments meet consumer expectations while still allowing for some minor imperfections—because let’s face it, no one’s perfect!

When we talk about what does AQL stand for, we’re essentially diving into the realm where quality meets practicality in garment production. By setting this threshold, businesses can maintain a competitive edge while managing costs effectively—after all, nobody wants to throw away perfectly good clothes just because they have a tiny flaw! China Inspection Pro's commitment to understanding these nuances ensures that your products not only meet but exceed market standards.

Comparison with Other AQL Levels

When comparing AQL 2.5 with other levels like AQL 1 or AQL 4, you’ll notice significant differences in how strict each level is regarding defects allowed per batch during quality inspection processes. An AQL of 1 allows only about 1% defectives, making it much stricter and suitable for high-stakes industries such as aerospace or medical devices where any defect could be catastrophic. On the other hand, an AQL of 4 permits up to 4% defective items—ideal for low-risk consumer goods but potentially unacceptable in fashion where brand reputation hinges on perceived quality.

The choice between these levels ultimately reflects how companies define quality within their operational frameworks and customer expectations. For instance, brands aiming at luxury markets usually opt for lower AQL levels to ensure impeccable craftsmanship, while fast fashion retailers might lean towards higher thresholds without compromising their bottom line too much—this balancing act is where China Inspection Pro's expertise shines through.

Impact on Garment Quality Inspection

The impact of adopting an AQL of 2.5 on garment quality inspection cannot be overstated; it provides a clear guideline that helps streamline processes while ensuring product reliability and satisfaction among consumers. By implementing this standard during inspections, companies can identify defects early on and take corrective actions before garments reach retail shelves—a proactive approach that saves time and money down the line.

Moreover, understanding the significance behind what does aql stand for fosters better communication between manufacturers and inspection services like those offered by China Inspection Pro, promoting transparency throughout the supply chain process regarding potential issues before they escalate into larger problems later on. Ultimately, adhering to an effective quality control system based on established AQL levels not only enhances product integrity but also builds trust with consumers who increasingly demand higher standards from brands.

Quality Control Inspection Process

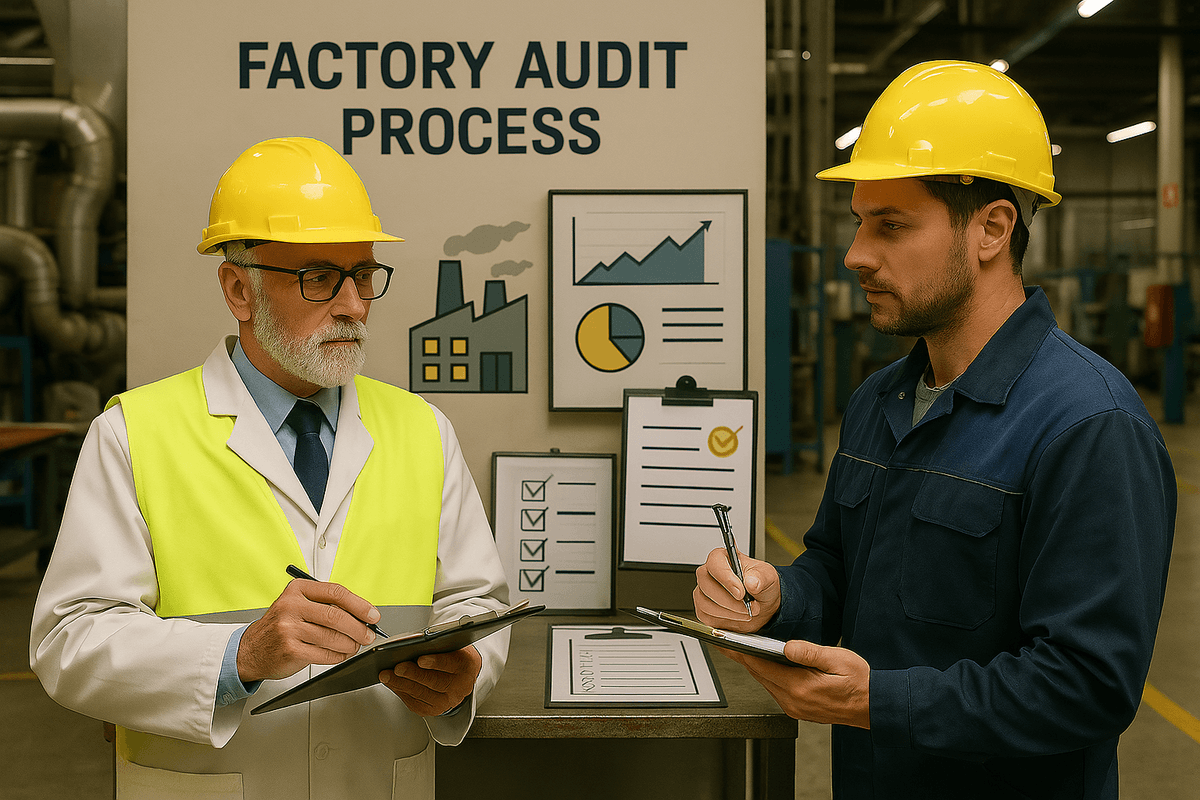

Quality control inspection is the backbone of ensuring that garments meet the desired standards of quality. It encompasses a series of systematic steps designed to evaluate the production process and the final product. Understanding these steps can help in defining quality and ensuring that every piece produced aligns with customer expectations.

Steps in Quality Control Inspection

The quality control inspection process begins with planning, where specific criteria are established based on what does AQL stand for and its significance in garment production. Next, a sample is drawn from the batch, following predetermined statistical methods to ensure that it represents the entire lot adequately. After sampling, inspectors conduct a thorough examination of the garments, checking for defects, inconsistencies, and overall adherence to quality standards.

Following this inspection phase, findings are documented meticulously to maintain transparency and provide actionable insights into any issues discovered during quality control. If defects are identified, corrective actions must be taken before proceeding with further production or shipment. This cyclical process not only helps in maintaining high-quality standards but also aids brands like China Inspection Pro in building trust with their clients through reliable quality assurance inspection.

Tools Used for Quality Assessment

To effectively carry out a quality inspection, various tools are employed that enhance accuracy and efficiency in assessing garment quality. These tools range from simple measuring tapes and rulers to sophisticated electronic devices that can detect flaws invisible to the naked eye. For instance, light booths allow inspectors to assess color consistency under different lighting conditions while fabric testers measure tensile strength and durability.

Additionally, software solutions play an integral role in streamlining data collection during inspections by automating reporting processes, making it easier to analyze trends over time. By utilizing these tools effectively within the framework of quality control meaning, brands ensure they consistently meet or exceed industry standards while minimizing risks associated with poor-quality products.

The Role of Inspection Services

Inspection services serve as an essential partner in achieving optimal garment quality through rigorous assessment processes tailored specifically for each client’s needs. These services not only provide expert evaluations but also help define quality by setting benchmarks based on industry best practices and client specifications. China Inspection Pro, for example, collaborates closely with manufacturers to develop customized inspection protocols that align perfectly with their unique production requirements.

Moreover, employing third-party inspection services enhances credibility since they bring an unbiased perspective into the evaluation process; this is crucial when addressing potential disputes regarding product defects or inconsistencies during production runs. By integrating these services into their operations, companies can significantly improve their overall efficiency while ensuring consistent adherence to AQL standards throughout their supply chain.

Defining Quality in Garment Production

In the world of garment production, defining quality is not just a matter of aesthetics; it encompasses durability, fit, and functionality. When we talk about quality control, we're referring to the systematic processes that ensure each piece meets established standards. But what does aql stand for in this context? It signifies a benchmark for acceptable quality levels that help maintain consistency throughout production.

What Makes Garment Quality?

Garment quality is defined by several key elements including fabric selection, stitching techniques, and overall design integrity. The feel of the fabric against the skin, how well seams are finished, and whether garments hold their shape after washing all contribute to perceived quality. In terms of quality inspection, these factors must be meticulously evaluated during the quality control inspection process to ensure that products meet or exceed customer expectations.

Factors Influencing Quality Standards

Several factors influence what we define as quality in garment production. These include technological advancements in manufacturing processes, consumer preferences for sustainability and ethical sourcing, and compliance with international standards. Understanding these influences helps companies like China Inspection Pro adapt their quality assurance inspection protocols to align with evolving market demands while maintaining high-quality output.

Balancing Cost and Quality in Production

Finding the sweet spot between cost efficiency and high-quality output can be quite challenging in garment production. While it's tempting to cut corners to save money, such practices can lead to inferior products that fail inspections—ultimately hurting brand reputation and customer loyalty. China Inspection Pro's approach emphasizes a balanced strategy where effective inspection services ensure that cost considerations do not compromise product integrity or adherence to established quality control meaning.

Common Challenges in Quality Inspection

Quality inspection is a crucial part of the garment production process, yet it comes with its fair share of challenges. Understanding these challenges is essential for any professional involved in quality control, especially when striving to define quality and ensure consistency. In this section, we will explore the issues faced during quality control, strategies to overcome them, and some inspiring case studies of success in the realm of quality assurance inspection.

Issues Faced During Quality Control

One major issue in quality control is inconsistency in product standards across different manufacturers. When trying to define quality, varying interpretations can lead to discrepancies that complicate the inspection process. Additionally, communication barriers between suppliers and inspectors can result in misunderstandings regarding what constitutes acceptable quality standards.

Another challenge lies in the limitations of traditional inspection methods. Many rely on visual assessments or basic measurements that may not capture all defects effectively. This limitation raises questions about the overall effectiveness of these methods when discussing what does AQL stand for—especially at levels like AQL 2.5 where precision is paramount.

Lastly, time constraints often pressure teams to rush through inspections, compromising thoroughness for speed. This hurried approach can lead to overlooking critical defects or failing to perform a comprehensive quality control inspection. Given that China Inspection Pro prioritizes excellence, addressing these issues head-on is vital for maintaining high-quality production standards.

Strategies to Overcome Inspection Challenges

To tackle inconsistencies in product standards during quality inspections, establishing clear guidelines and expectations is essential. By creating detailed documentation that outlines specific criteria for each garment type, teams can better align their understanding of what defines quality within their context. Regular training sessions also empower inspectors with updated knowledge on industry best practices.

Incorporating advanced technology into the inspection process offers another way to enhance accuracy and efficiency in identifying defects. Automated systems can streamline data collection and analysis while reducing human error—a significant factor affecting traditional methods of quality control meaning today. China Inspection Pro's commitment to leveraging innovative solutions ensures that our clients receive superior results from our inspection services.

Additionally, fostering open communication between all stakeholders involved—from manufacturers to inspectors—can significantly improve clarity around expectations and requirements during inspections. Utilizing collaborative platforms allows teams to share insights quickly and resolve potential issues before they escalate into larger problems during the final stages of production.

Case Studies in Quality Control Success

Examining successful case studies provides valuable insights into effective strategies for overcoming challenges in quality assurance inspection processes. For instance, a renowned fashion brand partnered with China Inspection Pro, implementing a rigorous training program for their inspectors which resulted in a 30% reduction in defect rates over six months—a clear testament to how investing time into education pays off significantly when defining quality expectations.

Another inspiring example involves a manufacturer who adopted automated visual inspection technology after facing persistent issues with manual checks leading to missed defects. Within weeks of implementation, they reported an impressive increase in detection rates by 40%, showcasing how modern tools redefine traditional approaches within the context of what does AQL stand for today.

Lastly, one apparel company improved its communication channels by integrating real-time reporting systems between its production team and inspectors from China Inspection Pro, enabling immediate feedback on any arising concerns during manufacturing processes—ultimately resulting in enhanced product consistency across multiple lines while adhering strictly to established AQL levels throughout their operations.

Conclusion

In the realm of garment production, understanding AQL and its implications for quality is paramount. The term AQL stands for Acceptable Quality Level, which plays a critical role in defining quality standards and ensuring that products meet customer expectations. As we’ve explored, effective quality control is essential not just for compliance but also for fostering brand loyalty and maintaining a competitive edge.

Key Takeaways on AQL and Garment Quality

AQL serves as a benchmark in quality inspection, guiding manufacturers on acceptable defect levels within their garments. It’s crucial to define quality accurately; this encompasses not only the physical attributes of the product but also its durability, functionality, and overall aesthetic appeal. Remember that consistent application of AQL standards can significantly enhance your brand's reputation by minimizing defects and ensuring customer satisfaction.

Future Trends in Quality Assurance Inspection

The future of quality assurance inspection is leaning towards automation and data-driven decision-making processes. As technology advances, we can expect more sophisticated tools that redefine how we understand quality control meaning in garment production. Embracing these innovations will allow brands to optimize their quality control inspection processes while maintaining high standards of excellence.

Why Choose China Inspection Pro for Inspection Services

When it comes to reliable inspection services, China Inspection Pro stands out as a leader in the industry. Our team combines expertise with cutting-edge technology to provide unparalleled insights into your production processes while adhering strictly to AQL guidelines. By choosing us, you’re not just opting for an inspection service; you’re investing in peace of mind knowing your garments are crafted with utmost care and precision.