Introduction

In the ever-evolving landscape of construction, quality control is the backbone that supports successful projects. It encompasses a range of practices designed to ensure that every aspect of a construction project meets specific standards and regulations. Understanding quality control in construction projects is crucial not only for compliance but also for delivering structures that stand the test of time.

Understanding Quality Control in Construction

Quality control in construction is more than just a checklist; it’s a commitment to excellence throughout every phase of a project. This process aims to identify defects, manage risks, and ensure that all materials and workmanship meet predetermined criteria. By establishing clear quality control measures, stakeholders can significantly reduce costly rework and enhance overall project efficiency.

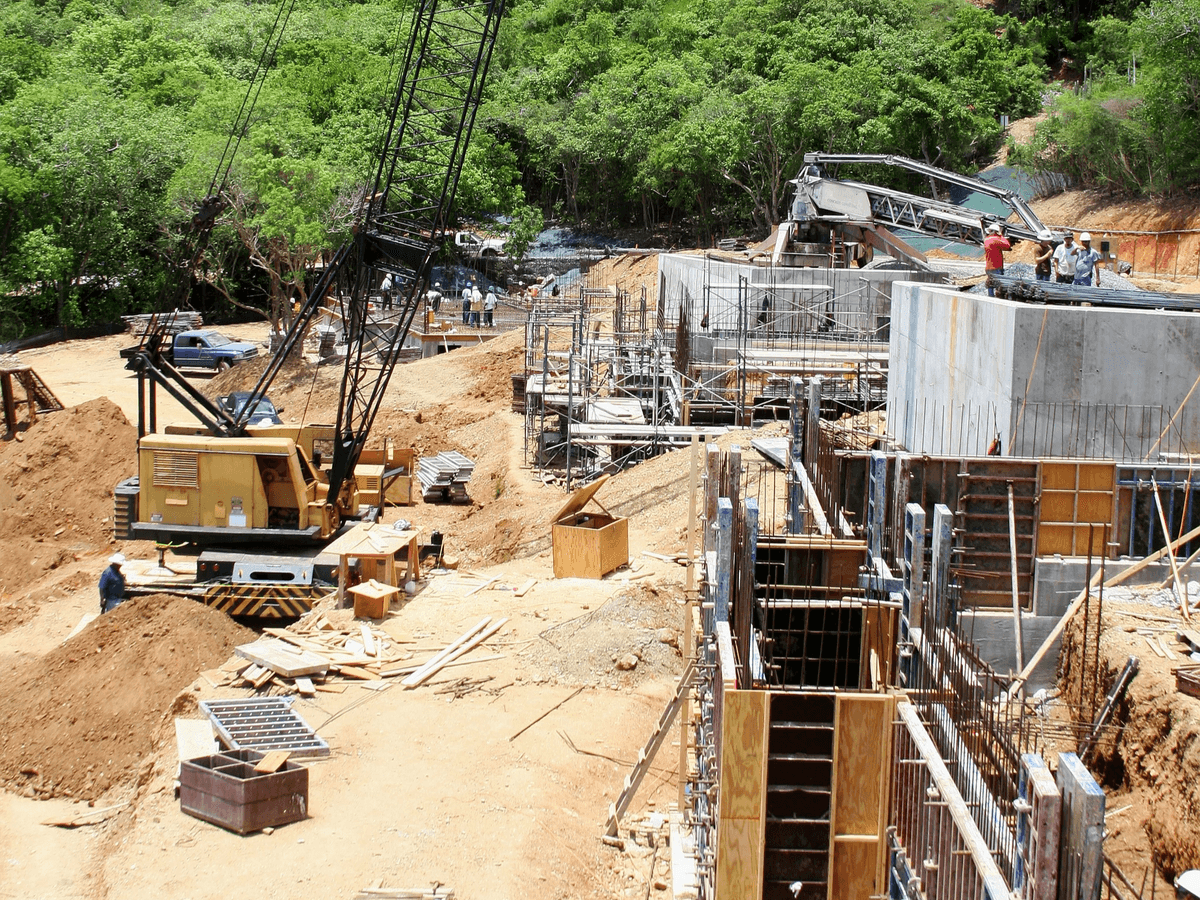

The Role of Inspections in Building Projects

Inspections serve as a vital component in maintaining quality control within building projects. They provide an objective assessment of work completed, ensuring compliance with established standards and specifications. Whether through internal teams or engaging a third party inspection company, regular inspections help identify potential issues early on, preventing delays and additional costs down the line.

Benefits of Ensuring Quality in Construction

The benefits of robust quality control practices are manifold; they extend beyond mere compliance to foster trust among clients and stakeholders alike. Consistent quality enhances safety, reduces liability issues, and ultimately leads to satisfied customers who are likely to recommend your services. Additionally, implementing effective inspection and quality control measures can significantly improve the reputation of companies involved in both construction and manufacturing sectors.

What is Quality Control in Construction?

Quality control in construction projects is the backbone of successful building endeavors. It encompasses a series of systematic processes aimed at ensuring that every aspect of a project meets predetermined quality standards. By focusing on quality control, construction teams can prevent defects, reduce waste, and ultimately deliver safer and more reliable structures.

Definition and Purpose of Quality Control

Quality control in construction refers to the measures taken to ensure that all materials, workmanship, and processes meet specific requirements and standards throughout a project. The primary purpose is to identify any deviations from expected quality levels before they escalate into larger issues that could compromise safety or performance. Effective quality control not only enhances the final product but also fosters trust among stakeholders, including clients and third party inspection companies.

Importance of Consistency in Construction Projects

Consistency is paramount in construction projects; it guarantees that every component aligns with the overall design intent and functional requirements. When consistency is maintained through rigorous quality control measures, it minimizes the risk of errors that can lead to costly rework or delays. Moreover, maintaining high consistency levels improves client satisfaction—a crucial factor when considering long-term relationships with clients or partners involved in inspection and quality control in manufacturing.

Overview of Quality Control Standards

Quality control standards serve as benchmarks for assessing the quality of work within construction projects. These standards are established by various organizations and regulatory bodies to ensure compliance with safety regulations and industry best practices. Familiarity with these standards equips construction professionals with the knowledge needed for effective implementation of quality control processes while also guiding third party inspection companies during their evaluations.

The Process of Quality Control in Construction Projects

Quality control in construction projects is a systematic approach to ensuring that the materials, processes, and final outputs meet specified requirements. It involves a series of steps designed to assess and enhance the quality of construction work while minimizing defects and rework. By implementing effective quality control measures, project stakeholders can significantly improve overall project outcomes.

Steps to Implement Quality Control Measures

The first step in implementing quality control measures is establishing clear quality standards based on relevant codes and regulations. These standards should be communicated effectively to all team members involved in the construction process. Next, regular inspections should be scheduled throughout the project lifecycle to monitor compliance with these standards, ensuring that any deviations are promptly addressed.

Documentation plays a crucial role in quality control construction; it helps track progress and identify areas needing improvement. Additionally, involving a third party inspection company can add an extra layer of scrutiny, providing unbiased feedback on adherence to quality standards. Finally, conducting training sessions for workers on how to conduct inspection of defective equipment can empower them to identify issues before they escalate.

Role of Quality Control Personnel

Quality control personnel serve as the backbone of any successful construction project by overseeing compliance with established standards and procedures. Their responsibilities include conducting regular inspections, analyzing test results, and coordinating with various teams to ensure everyone is aligned with quality objectives. They also play an essential role in training staff on best practices related to quality control in civil engineering.

These experts are not just inspectors; they are proactive problem solvers who anticipate potential issues before they arise. By fostering open communication between different departments, they help create a culture where everyone prioritizes quality from day one. Ultimately, their efforts contribute significantly to reducing costs associated with rework and enhancing overall project efficiency.

Using Technology for Quality Assurance

In today's digital age, technology plays an increasingly vital role in enhancing quality assurance processes within construction projects. Various software solutions enable real-time monitoring of materials and workmanship through data collection and analysis tools designed specifically for the industry. This technological integration allows teams to pinpoint problems early on—before they lead to costly delays or safety hazards.

Moreover, utilizing drones for aerial inspections offers a bird's-eye view that traditional methods simply can't match when assessing large sites or complex structures. Mobile applications also facilitate easier reporting and documentation during inspections—making it simpler than ever for teams involved in inspection and quality control in manufacturing processes as well as construction projects alike. By embracing these technological advancements, companies can elevate their approach toward achieving top-notch quality control across all facets of their operations.

Third Party Inspection Companies: Why They Matter

In the realm of quality control in construction projects, third party inspection companies play an indispensable role. These organizations provide an unbiased perspective, ensuring that standards are met without the influence of internal biases or conflicts of interest. Their involvement not only enhances the integrity of inspections but also fosters trust among stakeholders involved in the project.

The Value of a Third Party Perspective

A third party inspection company offers a fresh set of eyes on your construction project, which can be invaluable. They bring expertise and objectivity to the table, allowing for a thorough evaluation of quality control construction practices without being swayed by personal relationships or company politics. This impartiality is crucial for identifying potential issues early on, ensuring that any defects are addressed before they escalate into costly problems.

Moreover, their findings can serve as a critical benchmark against industry standards and regulations. By providing an independent assessment, these companies help maintain accountability among all parties involved in the project. Ultimately, this leads to enhanced overall quality control in civil engineering and helps ensure that the final product meets all necessary compliance requirements.

Choosing the Right Inspection Company

Selecting a reputable third party inspection company is essential for effective quality control in construction projects. Start by researching firms with proven track records and relevant certifications to ensure they adhere to industry standards. Look for companies that specialize not only in general inspections but also have experience with specific types of projects you are undertaking.

Additionally, consider their approach to communication and reporting; clear documentation is vital when you learn how to conduct inspection of defective equipment efficiently. A good inspection company should provide detailed reports outlining their findings along with actionable recommendations for improvement. Finally, client testimonials can offer insights into their reliability and effectiveness—after all, satisfied clients often indicate a company's commitment to excellence.

How China Inspection Pro Enhances Project Confidence

China Inspection Pro stands out as a leader among third party inspection companies due to its comprehensive services tailored specifically for various industries including construction and manufacturing. Their team employs cutting-edge technology combined with traditional methods to deliver precise evaluations that enhance quality control construction efforts significantly. This blend ensures that every aspect from materials used to workmanship meets stringent quality benchmarks.

Moreover, China Inspection Pro places great emphasis on transparency throughout the inspection process; clients receive timely updates and detailed reports which help build confidence in project outcomes. As they focus on continuous improvement strategies within their operations, clients benefit from innovative solutions designed to mitigate risks associated with defective equipment or subpar workmanship during inspections. By choosing China Inspection Pro, stakeholders can rest assured knowing their projects are being scrutinized by seasoned professionals dedicated to upholding high-quality standards.

How to Conduct Inspection of Defective Equipment

In the realm of construction, ensuring that equipment functions optimally is crucial for maintaining quality control in construction projects. Defective equipment can lead to delays, increased costs, and safety hazards, making inspections a vital part of any project. By understanding how to conduct inspection of defective equipment, teams can mitigate risks and uphold the standards expected in quality control construction.

Identifying Common Defects in Construction

Identifying common defects in construction is the first step toward effective quality control in civil engineering. These defects may include structural weaknesses, improper material use, or mechanical failures that can compromise safety and functionality. Recognizing these issues early allows teams to address them promptly, ensuring that the overall integrity of the project remains intact.

Common defects often stem from inadequate maintenance or poor workmanship during installation. For instance, cracks in concrete or misaligned components can signal deeper issues that require immediate attention. By familiarizing yourself with these potential pitfalls, you set the stage for a more thorough inspection process.

Techniques for Effective Defective Equipment Inspection

When it comes to how to conduct inspection of defective equipment effectively, employing systematic techniques is essential for success. Visual inspections should be complemented by functional tests and measurements to ensure all aspects are thoroughly evaluated. Utilizing checklists tailored specifically for quality control construction helps inspectors stay organized and focused on critical areas.

Additionally, leveraging technology can enhance inspection accuracy; tools such as drones or thermal imaging cameras allow for comprehensive evaluations without compromising safety or access. Engaging a third-party inspection company can also provide an unbiased perspective on equipment performance and condition—an invaluable resource when striving for excellence in quality control in civil engineering.

Regular training sessions for personnel conducting inspections are equally important; this ensures they remain up-to-date with industry standards and best practices while reinforcing their skills over time. A well-trained team is better equipped to identify defects efficiently and accurately.

Importance of Documentation and Reporting Findings

Documentation plays a pivotal role in inspection and quality control in manufacturing as well as construction projects—it's not just about identifying flaws but also about tracking them over time. Accurate records provide insight into recurring issues and help establish patterns that may indicate systemic problems within processes or equipment usage. This information becomes invaluable when presenting findings to stakeholders or when making decisions about repairs or replacements.

Reporting findings should be clear and concise; detailed reports enhance communication among team members while ensuring everyone understands the current state of equipment conditions related to quality control construction efforts. Additionally, proper documentation serves as a reference point during future inspections—making it easier to compare current conditions against historical data.

Ultimately, effective documentation fosters accountability within teams while promoting transparency across all levels of project management—a key element needed to build trust among stakeholders involved in any project focused on maintaining high-quality standards.

Quality Control in Civil Engineering: Best Practices

Quality control in civil engineering is crucial for ensuring that construction projects meet the highest standards of safety, functionality, and longevity. By adhering to established principles and implementing effective strategies, engineers can significantly enhance the quality of their work. This section explores the key principles of quality control, presents successful case studies, and outlines strategies for continuous improvement in construction projects.

Key Principles of Quality Control in Civil Engineering

The foundation of quality control in civil engineering rests on several key principles that guide project execution. First, consistency is paramount; maintaining uniformity across all aspects of construction helps prevent defects and ensures reliability. Second, thorough documentation is essential; detailed records allow for traceability and accountability throughout the project lifecycle, which is particularly important when collaborating with a third party inspection company.

Another critical principle is proactive risk management—identifying potential issues before they arise can save time and resources down the line. Regular inspections and adherence to quality control standards ensure that materials and workmanship meet required specifications. Lastly, fostering a culture of continuous improvement encourages teams to learn from past experiences, thereby enhancing overall project outcomes.

Case Studies of Successful Quality Control Implementation

Examining real-world examples can provide valuable insights into effective quality control practices in construction projects. One notable case involved a large infrastructure project where rigorous quality control measures were implemented from the outset. By employing a third party inspection company to oversee compliance with industry standards, the team was able to identify defects early on—ultimately saving significant costs associated with rework.

Another example comes from a residential development where innovative technology was utilized for inspection and quality control in manufacturing processes related to prefabricated components. This approach not only streamlined production but also ensured that every piece met stringent quality standards before reaching the construction site. These case studies illustrate how strategic implementation of quality control measures can lead to successful outcomes across various types of civil engineering projects.

Strategies for Continuous Improvement in Projects

To foster ongoing success within quality control in civil engineering, it’s essential to adopt strategies focused on continuous improvement. One effective approach involves regular training sessions for personnel involved in inspections; equipping them with updated knowledge about best practices ensures they remain vigilant against potential defects or issues during construction projects.

Additionally, utilizing feedback mechanisms—such as post-project reviews—can help teams identify areas needing enhancement while celebrating successes achieved through effective inspection processes. Another strategy includes leveraging modern technology; tools like drones or advanced imaging software can provide invaluable insights during inspections by identifying hidden flaws that traditional methods might miss.

By embracing these strategies for continuous improvement alongside established principles of quality control construction, engineering teams can elevate their performance while minimizing risks associated with defective equipment or materials.

Conclusion

Quality control in construction projects is not just a box to check; it’s a cornerstone of successful building practices. By ensuring that every aspect of construction meets established standards, stakeholders can mitigate risks and enhance the durability of structures. The long-term impact of quality control extends beyond immediate project success, fostering a culture of excellence that resonates throughout the industry.

The Long-Term Impact of Quality Control

Implementing rigorous quality control in construction projects can significantly reduce costs associated with repairs and rework down the line. A proactive approach to quality ensures that potential issues are addressed before they escalate into major problems, ultimately saving both time and money. Moreover, consistent adherence to quality standards builds a reputation for reliability and excellence, which can lead to more business opportunities in the future.

Building Trust Through Consistent Quality

In an industry where trust is paramount, consistent quality acts as a powerful currency. Clients are more likely to engage with contractors who demonstrate commitment to quality control construction practices, knowing that their investments are safeguarded. This trust is further reinforced through third party inspection companies which provide an unbiased assessment, enhancing credibility and confidence in the project's outcomes.

Steps to Elevate Your Quality Control Practices

To elevate your quality control practices, begin by integrating advanced technology into your inspection processes for improved accuracy and efficiency. Regular training for teams on how to conduct inspections of defective equipment will also ensure everyone is equipped with the latest knowledge and techniques for identifying issues early on. Lastly, establishing partnerships with reputable third party inspection companies can provide valuable insights into best practices while reinforcing your commitment to maintaining high standards in all aspects of construction.