Introduction

In the fast-paced world of valve manufacturing, a Quick On-Site Inspection is not just a luxury; it's a necessity. The efficiency of production hinges on timely evaluations that ensure quality and precision at every stage. With the stakes high, manufacturers must prioritize inspections to avoid costly delays and maintain their competitive edge.

The Importance of Quick On-Site Inspection

Quick On-Site Inspections play a pivotal role in safeguarding product integrity before valves leave the factory floor. These inspections help catch potential issues early, minimizing the risk of defects that could lead to significant financial repercussions down the line. By implementing rigorous inspection protocols, companies can enhance their reputation for reliability and quality in an increasingly demanding market.

What to Expect During Valve Inspections

During valve inspections, expect a thorough examination that covers multiple facets of product quality, including Quantity Verification, Visual Inspection, Packing/Marking Verification, and Valve Dimension Verification. Inspectors assess not only the physical attributes but also compliance with industry standards and specifications. This comprehensive approach ensures that each valve meets stringent requirements before it reaches customers.

Key Players in the Industry

In this landscape of quality assurance, key players like China Inspection Pro stand out by providing specialized services tailored to valve manufacturing needs. Their team comprises seasoned professionals who understand the intricacies involved in effective Quick On-Site Inspections. By leveraging advanced methodologies and deep industry knowledge, they offer invaluable support to manufacturers striving for excellence in every aspect of their production process.

Understanding Quick On-Site Inspection

In the fast-paced world of valve manufacturing, Quick On-Site Inspection has become a crucial component for maintaining quality control. As production times shrink and market demands escalate, the speed at which inspections are conducted can significantly influence overall efficiency. This section delves into why swift inspections are not just beneficial but essential in the valve industry.

The Need for Speed in Quality Control

Quality control is no longer a leisurely stroll; it's a sprint! In an industry where delays can result in lost contracts and dissatisfied customers, Quick On-Site Inspection enables manufacturers to identify defects before they become costly issues. The urgency for speed in quality control drives companies to adopt innovative inspection methods that ensure products meet stringent standards without sacrificing time.

Moreover, rapid inspections allow for immediate feedback on production processes, which is vital for continuous improvement. With techniques like Quantity Verification and Visual Inspection being performed on-site, manufacturers can swiftly address any discrepancies or defects found during evaluations. This proactive approach minimizes downtime and maximizes productivity across the board.

How Inspections Impact Valve Production

The ripple effect of effective inspections reaches far beyond the factory floor; it directly impacts valve production timelines and costs. When Quick On-Site Inspections are executed efficiently, manufacturers can avoid bottlenecks that often occur due to faulty products or miscommunications regarding specifications such as Packing/Marking Verification and Valve Dimension Verification. Consequently, these timely evaluations help streamline operations while ensuring compliance with industry standards.

Additionally, thorough inspections foster trust between suppliers and buyers by ensuring that all products meet predefined criteria before shipment. This trust translates into stronger business relationships and repeat orders—a win-win scenario! In a competitive market where margins are tight, every aspect of production counts; hence, effective inspection processes play a pivotal role in maintaining quality without hindering speed.

The Role of China Inspection Pro in Streamlining Processes

Enter China Inspection Pro—your ally in navigating the complexities of Quick On-Site Inspection! With their professional services focused on product excellence, they provide rigorous examinations that leave no stone unturned when it comes to ensuring quality assurance across various metrics including Quantity Verification and Visual Inspection. Their specialists leverage advanced methodologies to transform findings into clear recommendations that enhance decision-making.

By utilizing their expertise in Packing/Marking Verification as well as Valve Dimension Verification, China Inspection Pro helps manufacturers streamline their inspection processes effectively. Their deep experience allows them to guide clients through intricate challenges while meeting both market expectations and regulatory requirements seamlessly. In doing so, they not only elevate product quality but also empower businesses with confidence in their supply chain integrity.

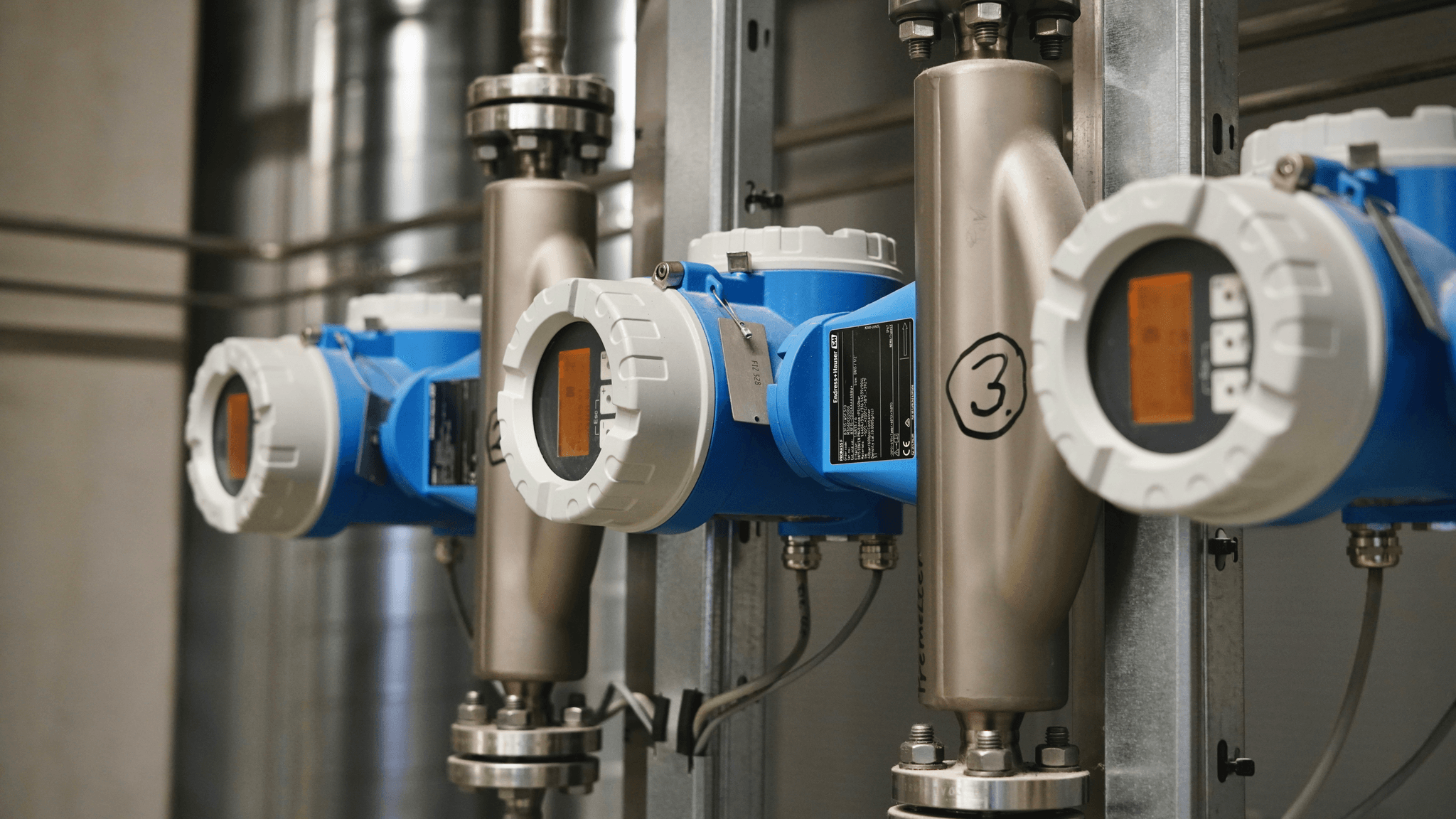

Quantity Verification

In the fast-paced world of valve manufacturing, Quantity Verification is a crucial step that ensures the right number of valves are produced and delivered. Quick On-Site Inspection plays a vital role in this process, as it allows for immediate verification of quantities before they leave the factory floor. Accurate valve counts not only streamline production but also enhance overall efficiency in supply chains.

Ensuring Accurate Valve Counts

Accurate valve counts are essential to maintain optimal inventory levels and avoid costly delays in production schedules. During Quick On-Site Inspections, inspectors meticulously tally the valves to confirm that quantities match purchase orders and shipping documents. This diligence helps prevent discrepancies that could lead to production bottlenecks or customer dissatisfaction.

To ensure accuracy, inspectors often utilize various counting methods, including manual checks and automated systems, which can significantly reduce human error. Moreover, visual aids such as barcodes or RFID tags can enhance tracking during inspections, ensuring each valve is accounted for efficiently. With reliable Quantity Verification practices in place, manufacturers can confidently meet demand without overproducing or underdelivering.

The Impact of Quantity on Supply Chains

Quantity discrepancies can ripple through supply chains, causing delays and financial losses that affect multiple stakeholders. When a manufacturer fails to provide accurate counts during Quick On-Site Inspections, downstream partners may face stockouts or excess inventory situations that disrupt operations. This inefficiency not only affects customer satisfaction but also strains relationships with suppliers and logistics providers.

Furthermore, accurate quantity verification is critical for maintaining cost efficiency across the supply chain; overproduction leads to unnecessary storage costs while underproduction can result in expedited shipping fees to meet urgent demands. By implementing rigorous Quantity Verification protocols during inspections—such as those provided by China Inspection Pro—companies can mitigate these risks effectively. This proactive approach fosters smoother operations and enhances overall supply chain resilience.

Techniques for Effective Quantity Verification

Effective techniques for Quantity Verification include both traditional methods and advanced technologies tailored to streamline the inspection process. Manual counting remains a staple; however, integrating digital tools like barcode scanning systems can significantly enhance accuracy and speed during Quick On-Site Inspections. These tools allow inspectors to quickly verify large quantities of valves with minimal human intervention.

Another useful technique involves cross-referencing physical counts with inventory management software; this dual-check system ensures consistency between what’s physically present and what’s recorded digitally. Additionally, regular training sessions for inspectors on best practices in visual inspection techniques further bolster their ability to identify discrepancies swiftly during packing/marking verification processes as well as quantity checks.

Ultimately, embracing innovative approaches not only improves accuracy but also empowers companies to make informed decisions based on real-time data insights gathered during inspections—an essential component of maintaining high standards in valve manufacturing.

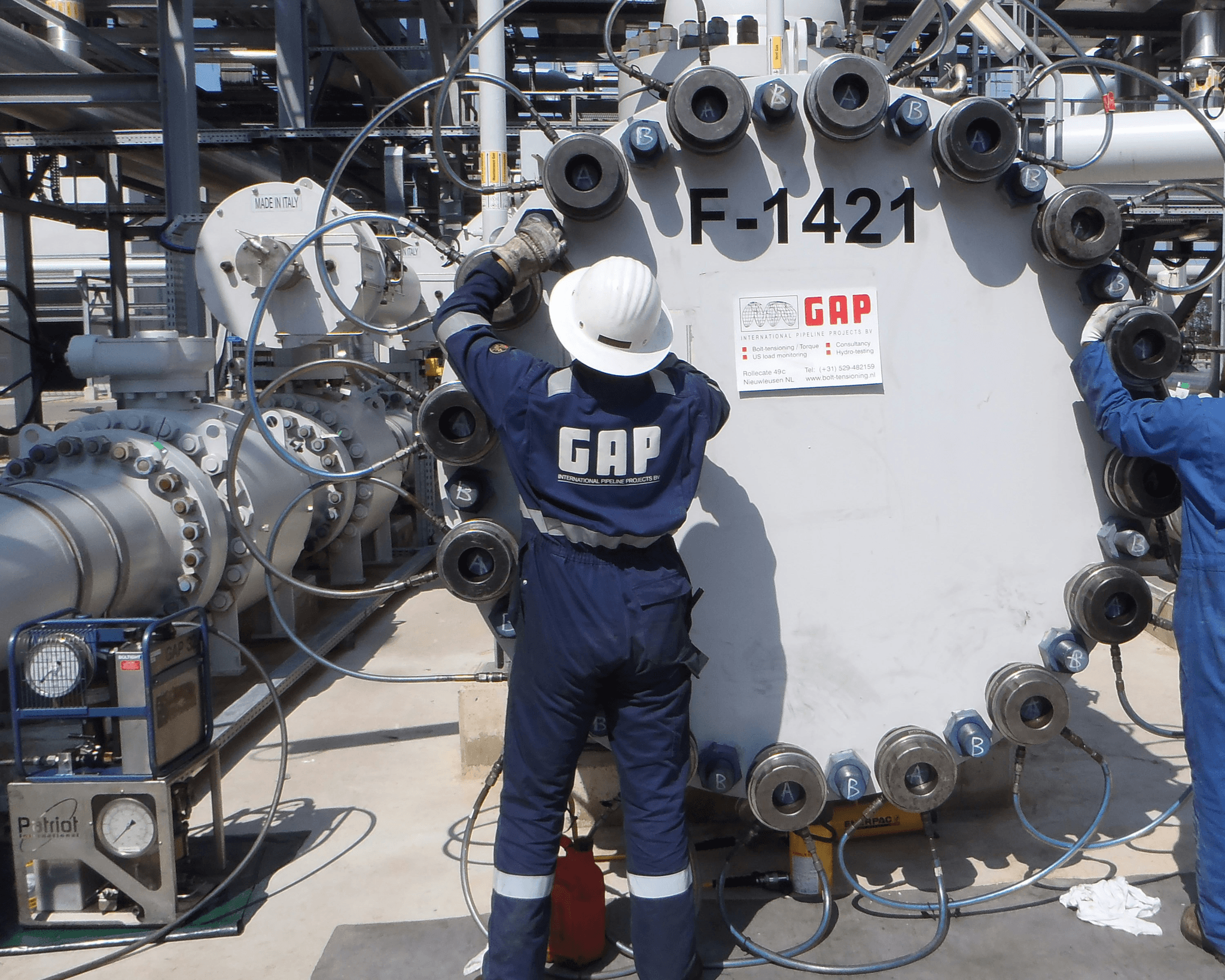

Visual Inspection

In the world of valve manufacturing, visual inspection serves as a critical line of defense against defects that can compromise quality and safety. Quick On-Site Inspection allows for immediate identification of potential issues, ensuring they are addressed before they escalate into larger problems. By integrating visual inspection into the quality control process, manufacturers can maintain high standards and reduce costly rework.

Spotting Defects Before They Escalate

The primary goal of visual inspection is to spot defects early in the production process, preventing them from becoming significant liabilities later on. Whether it’s a minor scratch or a more serious structural flaw, identifying these issues during Quick On-Site Inspection saves time and resources. Early detection not only enhances product integrity but also fosters trust with clients who rely on consistent quality in their valve products.

Tools and Techniques for Effective Visual Inspections

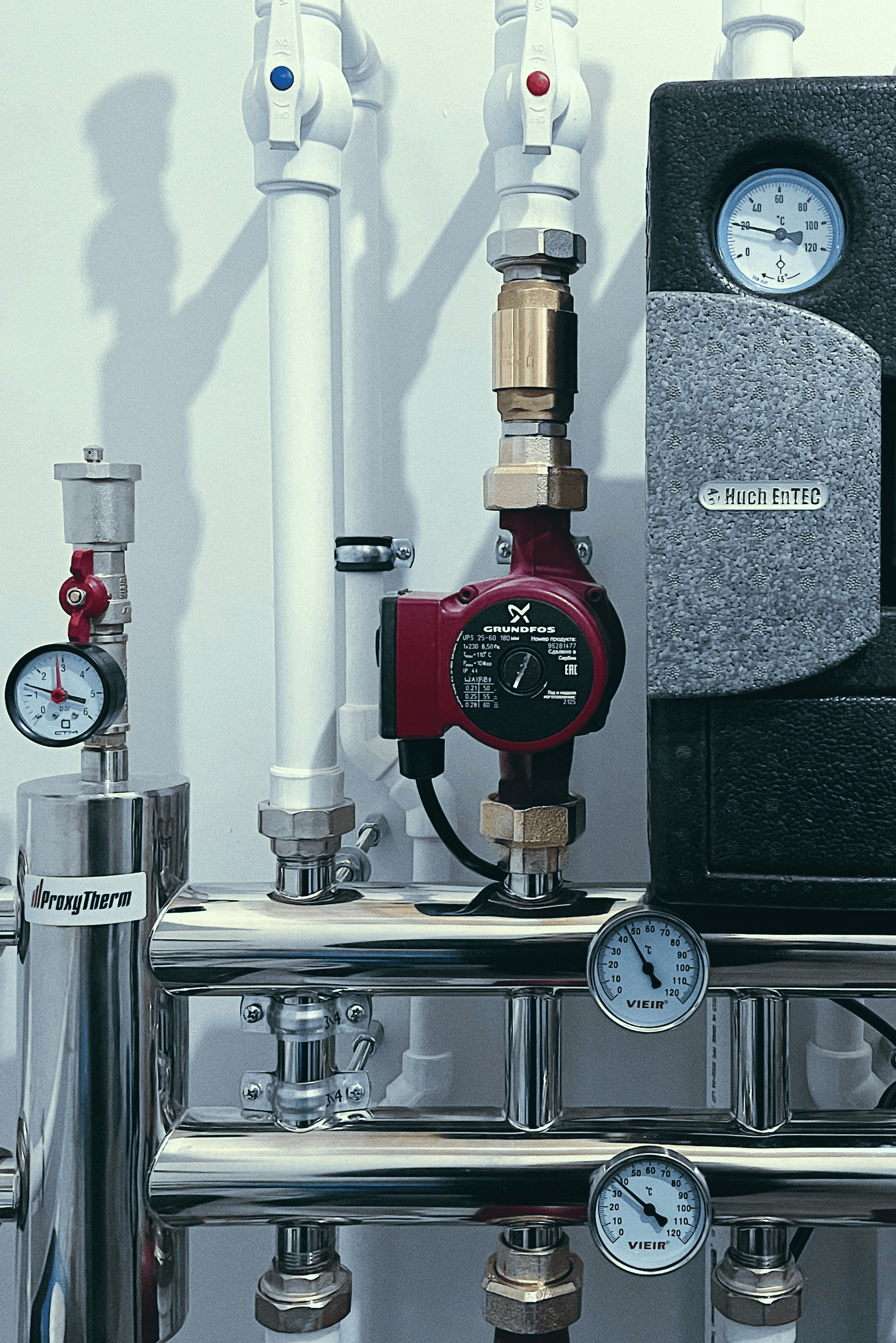

Visual inspections utilize a variety of tools and techniques designed to enhance the accuracy of defect detection. Magnifying glasses, borescopes, and high-resolution cameras are just a few instruments that inspectors employ to scrutinize valves closely during Quantity Verification and Packing/Marking Verification processes. Additionally, employing techniques such as standardized checklists ensures that no detail is overlooked during inspections.

The Importance of Trained Inspectors

While tools are essential for effective visual inspections, the role of trained inspectors cannot be overstated. These professionals bring expertise that enables them to recognize subtle signs of defects that might go unnoticed by untrained eyes. With proper training from organizations like China Inspection Pro, inspectors not only enhance the effectiveness of Valve Dimension Verification but also contribute significantly to overall product quality through their keen attention to detail.

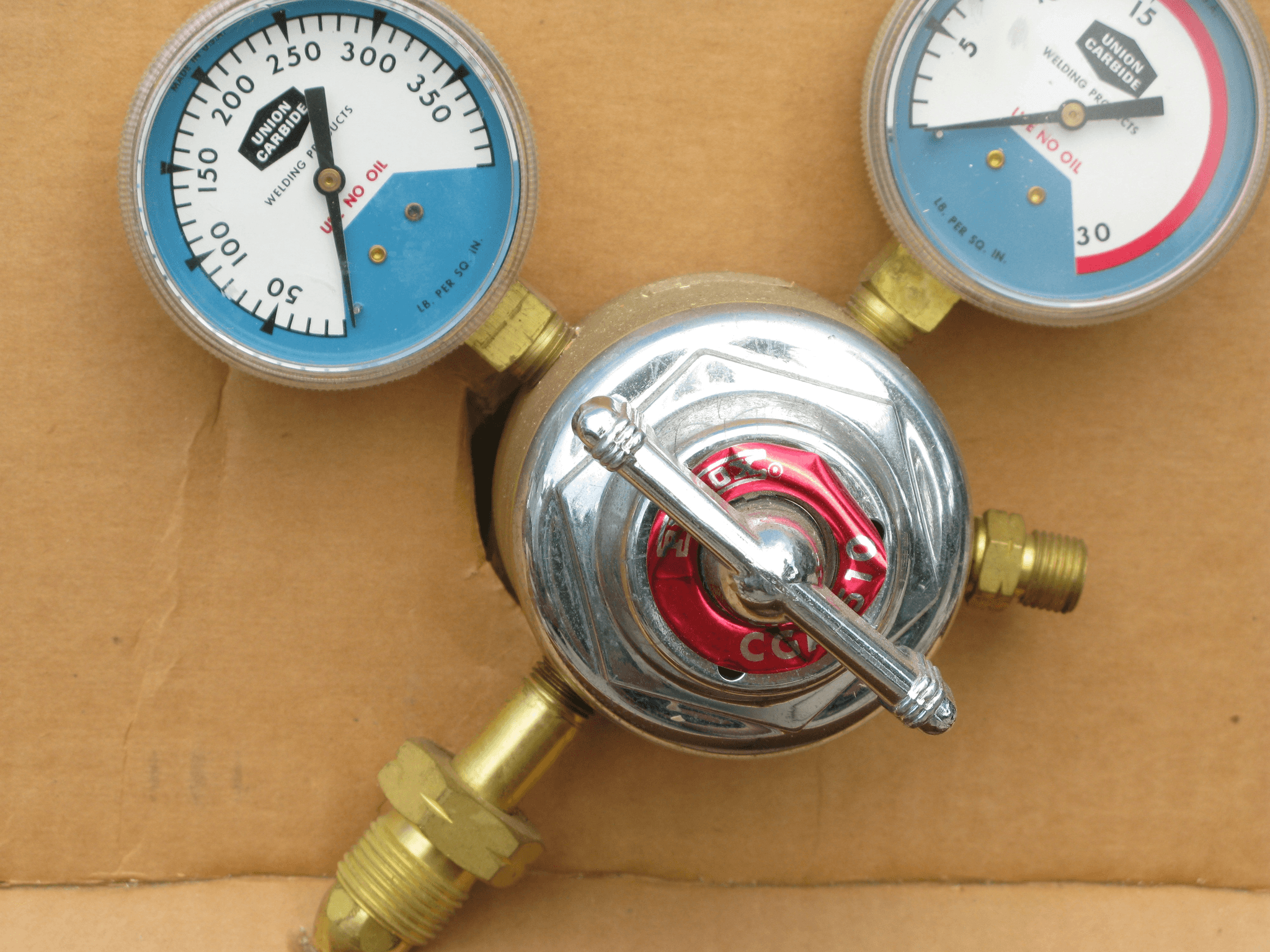

Packing and Marking Verification

Packing and marking verification is a crucial step in the Quick On-Site Inspection process, ensuring that valves are packaged correctly and marked according to industry standards. This phase not only safeguards the integrity of the product but also facilitates seamless logistics and compliance with regulations. Effective packing and marking verification can significantly influence customer satisfaction by preventing mishaps during transportation.

Ensuring Compliance with Industry Standards

Compliance with industry standards is non-negotiable when it comes to packing and marking verification. Adhering to established guidelines ensures that every valve meets safety requirements, which is paramount in industries like oil, gas, and water management. China Inspection Pro plays a pivotal role here by conducting thorough inspections that confirm all packaging materials and labeling meet regulatory expectations.

Moreover, ensuring compliance helps mitigate risks associated with product recalls or legal liabilities due to improper packaging practices. The Quick On-Site Inspection process includes checks for certifications, proper labeling, and adherence to environmental regulations regarding materials used in packaging. By prioritizing compliance, manufacturers can enhance their reputation while fostering trust among clients.

The Role of Packaging in Valve Safety

Packaging serves as the first line of defense against damage during transit; thus, its role in valve safety cannot be overstated. Properly designed packaging protects valves from physical impacts, moisture exposure, and other environmental factors that could compromise their functionality. During Quick On-Site Inspections, visual inspection processes evaluate whether the packaging meets safety standards before products hit the road.

Additionally, effective packing contributes to operational efficiency within supply chains by minimizing delays caused by damaged goods or incorrect labeling. A well-packaged valve not only ensures safe delivery but also simplifies inventory management through clear markings for quantity verification purposes. In essence, robust packing strategies directly correlate with enhanced customer satisfaction rates.

Common Pitfalls in Packing and Marking

Despite best efforts in packing and marking verification processes, common pitfalls often arise that can jeopardize product integrity. One frequent issue is inadequate cushioning or support within packages leading to potential damage during transport—a problem easily caught during a Quick On-Site Inspection if conducted thoroughly through visual inspection techniques as well as quantity verification checks for contents per package.

Another pitfall involves mislabeling or incomplete information on packages; this can result in confusion at distribution centers or even regulatory penalties if discovered post-delivery. It's essential for trained inspectors to be vigilant about these details during their assessments as they play a significant role in maintaining quality assurance throughout the supply chain process—especially concerning valve dimension verification where precise specifications are critical.

Finally, overlooking specific industry standards related to hazardous materials can lead not only to financial loss but also reputational damage for manufacturers involved in valve production sectors such as oil drilling equipment or chemical processing systems—areas where China Inspection Pro excels at providing comprehensive oversight through rigorous inspections tailored specifically for these challenges.

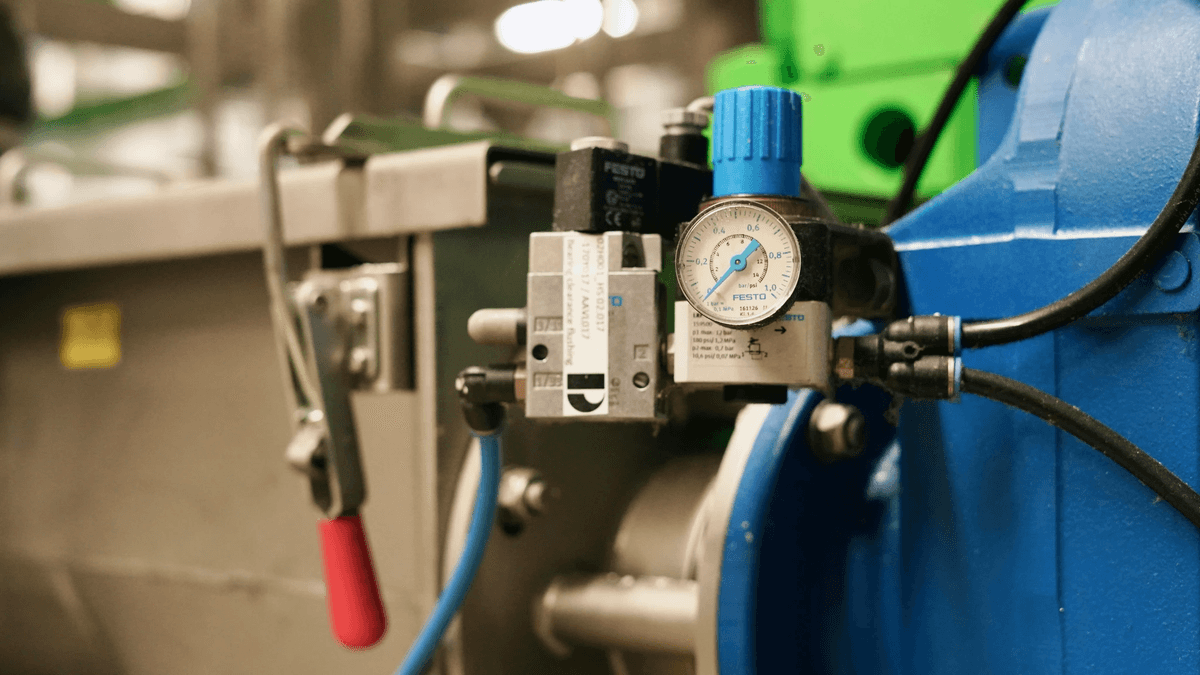

Valve Dimension Verification

In the world of valve manufacturing, precision is not just a luxury; it’s a necessity. When valves are used in critical applications, even the slightest dimensional error can lead to catastrophic failures or inefficiencies. Quick On-Site Inspection ensures that every valve meets stringent specifications, thereby safeguarding both performance and safety.

Why Precision Matters in Valve Manufacturing

Precision in valve manufacturing is crucial for several reasons, primarily related to functionality and safety. Valves must fit perfectly within their systems to prevent leaks and ensure proper flow control; any deviation can compromise operations. Additionally, adherence to precise dimensions during Quick On-Site Inspection protects manufacturers from costly recalls and potential legal liabilities stemming from defective products.

Tools Used for Measuring Valve Dimensions

To achieve accurate measurements during the inspection process, various specialized tools are employed in valve dimension verification. Calipers, micrometers, and laser measurement devices are commonly used to ensure that every aspect of a valve adheres to its specified dimensions. The use of advanced technology not only enhances the accuracy of measurements but also streamlines the Quick On-Site Inspection process by providing immediate feedback.

The Consequences of Dimensional Errors

Dimensional errors can have far-reaching consequences in valve production and application, affecting everything from performance efficiency to safety compliance. If a valve does not meet its specified dimensions due to inadequate Quantity Verification or poor Visual Inspection practices, it may lead to system failures or increased maintenance costs down the line. Furthermore, when packing/marking verification fails due to dimensional inaccuracies, it complicates logistics and can result in significant financial losses for manufacturers.

Conclusion

In the ever-evolving landscape of valve manufacturing, inspections play a pivotal role in ensuring product quality and reliability. Quick On-Site Inspection has emerged as a critical component of the quality assurance process, allowing for immediate identification and rectification of issues before they escalate. By integrating Quantity Verification, Visual Inspection, Packing/Marking Verification, and Valve Dimension Verification into a comprehensive inspection strategy, companies can significantly enhance their operational efficiency and product excellence.

Enhancing Quality Through Inspections

The importance of rigorous inspections cannot be overstated; they are fundamental in enhancing overall quality across the production line. Quick On-Site Inspection allows for real-time feedback, enabling manufacturers to make swift adjustments that prevent defects from reaching customers. Moreover, techniques such as Quantity Verification ensure that the right number of valves are produced and delivered, which is essential for maintaining trust within supply chains.

Visual Inspection techniques add another layer of scrutiny by identifying potential defects early in the process. With trained inspectors utilizing advanced tools, manufacturers can catch issues before they snowball into larger problems that could jeopardize safety or compliance standards. Packing/Marking Verification further ensures that all products meet industry regulations while also safeguarding against damage during transit—essentially wrapping up quality assurance with a neat bow.

The Bottom Line: Why Inspections Matter

When it comes to valve manufacturing, inspections are not just an added step; they are integral to success. The consequences of skipping or skimping on inspections can be dire—not only risking product failure but also damaging reputations and incurring financial losses. By prioritizing thorough inspections like Valve Dimension Verification alongside others mentioned earlier, companies position themselves for long-term success in a competitive market.

Ultimately, efficient inspection processes lead to better decision-making and sharper focus on continuous improvement initiatives within organizations. The investment in Quick On-Site Inspection pays off by reducing waste and ensuring that every valve produced meets stringent quality standards. This commitment to excellence not only fulfills regulatory requirements but also elevates customer satisfaction—a win-win situation for all involved.

Future Trends in Valve Manufacturing Inspections

Looking ahead, we can expect advancements in technology to further revolutionize how inspections are conducted within the valve manufacturing sector. Innovations such as artificial intelligence (AI) and machine learning will likely enhance Quick On-Site Inspection capabilities by enabling predictive analytics that identify potential failures before they occur. As these technologies become mainstream, Quantity Verification will evolve toward automation—reducing human error while increasing efficiency.

Moreover, visual inspection methods will increasingly incorporate high-resolution imaging systems coupled with advanced data analysis tools to provide deeper insights into product integrity than ever before. This shift toward data-driven decision-making will empower manufacturers to maintain high-quality standards consistently while minimizing costs associated with defects or recalls. Additionally, as environmental concerns grow more pressing globally, there will be heightened focus on sustainable practices within packing/marking verification processes.

As we embrace these trends together with established practices like Valve Dimension Verification and other inspection methods outlined here today—it's clear: the future holds exciting possibilities for those committed to maintaining excellence through rigorous inspection protocols.