Introduction

In the dynamic world of manufacturing, the role of a supplier quality engineer is pivotal in ensuring that products meet stringent quality standards. These professionals are not just gatekeepers; they actively engage in various inspection types and techniques to uphold quality control checks throughout the production process. By doing so, they contribute significantly to maintaining compliance with QA standards and enhancing overall product reliability.

Understanding the Role of Supplier Quality Engineers

A supplier quality engineer plays a crucial role in bridging the gap between suppliers and manufacturers, ensuring that every component meets quality specifications before it reaches the assembly line. Their responsibilities involve executing final inspections and utilizing machine inspection techniques to identify defects early on, ultimately preventing costly rework or recalls. This proactive approach to quality checking in the garment industry—and beyond—ensures that only the best materials are used in production.

Importance of Quality Control in Manufacturing

Quality control is not merely a checkbox on a list; it’s an essential practice that can make or break a manufacturing operation. The implementation of rigorous quality control checks helps mitigate risks associated with defective products, which can lead to significant financial losses and damage to brand reputation. By prioritizing QA compliance through systematic inspection techniques, manufacturers can ensure their products consistently meet customer expectations.

The Impact of Quality on Customer Satisfaction

The direct link between product quality and customer satisfaction cannot be overstated; consumers today are more discerning than ever before. When companies invest in thorough inspection types and maintain high-quality standards, they foster trust and loyalty among their customer base. A commitment to excellence not only enhances brand reputation but also translates into repeat business—a win-win for both manufacturers and consumers alike.

Key Responsibilities of a Supplier Quality Engineer

Supplier Quality Engineers play a pivotal role in ensuring that products meet stringent quality standards throughout the manufacturing process. Their responsibilities encompass various aspects of quality control checks, inspection types, and compliance with QA standards. By effectively managing these elements, they contribute significantly to customer satisfaction and overall product integrity.

Overseeing Quality Control Checks

One of the primary responsibilities of a supplier quality engineer is overseeing quality control checks at different stages of production. This includes monitoring processes to ensure that they adhere to predefined specifications and tolerances. By conducting regular audits and assessments, they can identify potential issues early on, preventing costly defects from reaching the final inspection stage.

Quality control checks are not merely a box-ticking exercise; they are essential for maintaining high standards in the garment industry and beyond. The supplier quality engineer must ensure that all materials and components meet required specifications before they proceed further down the line. This proactive approach not only enhances product reliability but also strengthens relationships with suppliers by fostering transparency and collaboration.

Executing Various Inspection Types

Executing various inspection types is another critical responsibility for supplier quality engineers. They employ diverse inspection techniques tailored to specific products or processes, ensuring comprehensive coverage of potential quality issues. Whether it’s visual inspections or machine inspections, each method plays a vital role in confirming that products meet rigorous industry standards.

In the garment industry, for example, effective quality checking involves assessing fabric integrity, stitching accuracy, and overall design adherence during multiple stages of production. The supplier quality engineer must be well-versed in different inspection types to adapt their approach based on unique challenges presented by each project or supplier relationship. By doing so, they help maintain consistent product quality while minimizing waste and rework costs.

Implementing QA Compliance Standards

Implementing QA compliance standards is crucial for any supplier quality engineer aiming to uphold product excellence throughout the manufacturing process. These standards serve as benchmarks against which all products are measured before reaching consumers’ hands—ensuring safety and satisfaction alike. Supplier quality engineers must stay updated on regulatory changes that may affect these compliance requirements.

The process often involves developing detailed documentation outlining QA protocols while training team members on best practices for adhering to these guidelines during production runs. In addition to ensuring compliance with internal policies, supplier quality engineers frequently liaise with external regulatory bodies to guarantee alignment with industry expectations as well as legal obligations—especially in sectors like automotive or aerospace where safety is paramount.

By diligently implementing QA compliance standards across all operations—from initial material sourcing through final inspection—they help cultivate an environment focused on continuous improvement within their organizations.

The Ins and Outs of Inspection Techniques

When it comes to maintaining high standards in manufacturing, inspection techniques are the backbone of quality control checks. Supplier quality engineers employ a variety of inspection types to ensure that products meet established QA compliance standards before they reach consumers. Understanding these techniques is crucial for enhancing product reliability and customer satisfaction.

Understanding Final Inspection Procedures

Final inspection procedures serve as the last line of defense in the quality assurance process. This stage involves thorough checks that verify whether a product meets all specifications and requirements before it is shipped out. Supplier quality engineers meticulously conduct these inspections, ensuring that any defects are identified and addressed, thus minimizing returns and improving customer trust.

Final inspections typically include visual assessments, functional tests, and measurements against defined criteria. By implementing robust final inspection protocols, manufacturers can significantly reduce the risk of defective products reaching the market. Ultimately, this attention to detail helps uphold a company's reputation for quality.

Utilizing Machine Inspection for Quality Assurance

Machine inspection has revolutionized how supplier quality engineers approach quality control checks in manufacturing environments. Automated systems are employed to perform detailed assessments faster and more accurately than manual methods could achieve alone. This not only increases efficiency but also allows for consistent monitoring across production lines.

By utilizing advanced machine inspection techniques, manufacturers can detect minute discrepancies that might otherwise go unnoticed during human-led inspections. These automated systems often incorporate data analytics to track performance trends over time, enabling proactive adjustments to maintain QA compliance standards continuously. As a result, machine inspections become an invaluable tool in ensuring product integrity throughout the manufacturing process.

The Role of Quality Checking in the Garment Industry

In the garment industry, quality checking plays a pivotal role in delivering products that satisfy consumer expectations while adhering to stringent regulations. Supplier quality engineers focus on various inspection types tailored specifically for textiles—ranging from fabric checks to finished garment evaluations—to ensure every piece meets established guidelines. This meticulous approach not only enhances brand reputation but also fosters long-term customer loyalty.

Quality checking processes within this sector often involve assessing color consistency, stitching accuracy, and overall construction integrity before garments hit retail shelves. By emphasizing rigorous QA compliance measures throughout production stages, companies can mitigate risks associated with defective apparel entering the market. Ultimately, effective quality checking leads to reduced waste and increased profitability while satisfying discerning customers.

Collaborating with Suppliers for Quality Improvement

Collaboration between supplier quality engineers and suppliers is crucial for enhancing product quality and ensuring compliance with industry standards. By fostering strong partnerships, organizations can not only streamline their inspection types but also improve the overall quality control checks throughout the supply chain. This teamwork ultimately leads to better quality checking in the garment industry, resulting in happier customers.

Establishing Clear Communication Channels

Establishing clear communication channels is fundamental for effective collaboration between supplier quality engineers and their suppliers. Regular updates about inspection techniques and QA compliance requirements can help prevent misunderstandings that might compromise product integrity. By utilizing various communication tools—such as email, video calls, and collaborative platforms—teams can ensure everyone is on the same page regarding expectations and responsibilities.

Moreover, open lines of communication facilitate prompt feedback on inspection results from final inspections or machine inspections carried out by suppliers. This immediate exchange of information allows both parties to address any issues swiftly, thereby minimizing delays in production timelines. In essence, a well-structured communication framework lays the groundwork for a productive relationship focused on continuous improvement.

Providing Training and Support

Providing training and support to suppliers is essential for elevating their understanding of quality standards and inspection techniques. Supplier quality engineers should organize workshops or training sessions that cover critical topics such as QA compliance requirements and effective execution of various inspection types. These initiatives empower suppliers to implement best practices that enhance their ability to meet established quality control checks.

Additionally, ongoing support helps build confidence among suppliers when it comes to conducting their own inspections effectively. By sharing expertise in areas like final inspections or machine inspections, supplier quality engineers can cultivate a culture of excellence that resonates throughout the supply chain. Ultimately, this investment in training pays off through improved product consistency and reduced defect rates.

Conducting Supplier Audits

Conducting supplier audits is a vital component of maintaining high-quality standards across the board. Supplier quality engineers should regularly evaluate suppliers' processes to ensure they adhere to QA compliance guidelines while also assessing their effectiveness at implementing various inspection types. These audits provide insights into areas where improvements are needed, fostering an environment where continuous enhancement becomes part of everyday operations.

During these audits, it's important to focus on specific aspects such as final inspection procedures and machine inspection capabilities employed by the supplier. Identifying gaps or inconsistencies during these evaluations allows teams to collaborate more effectively on corrective actions that drive better outcomes over time. In turn, this proactive approach not only strengthens relationships but also elevates overall product quality within the garment industry.

Data Analysis and Reporting

In the realm of quality control, data analysis and reporting are crucial components that ensure a supplier quality engineer can effectively oversee inspection types and techniques. By meticulously analyzing inspection results, engineers can identify trends, pinpoint issues, and develop strategies to enhance overall product quality. This process not only helps maintain QA compliance but also boosts customer satisfaction through improved product reliability.

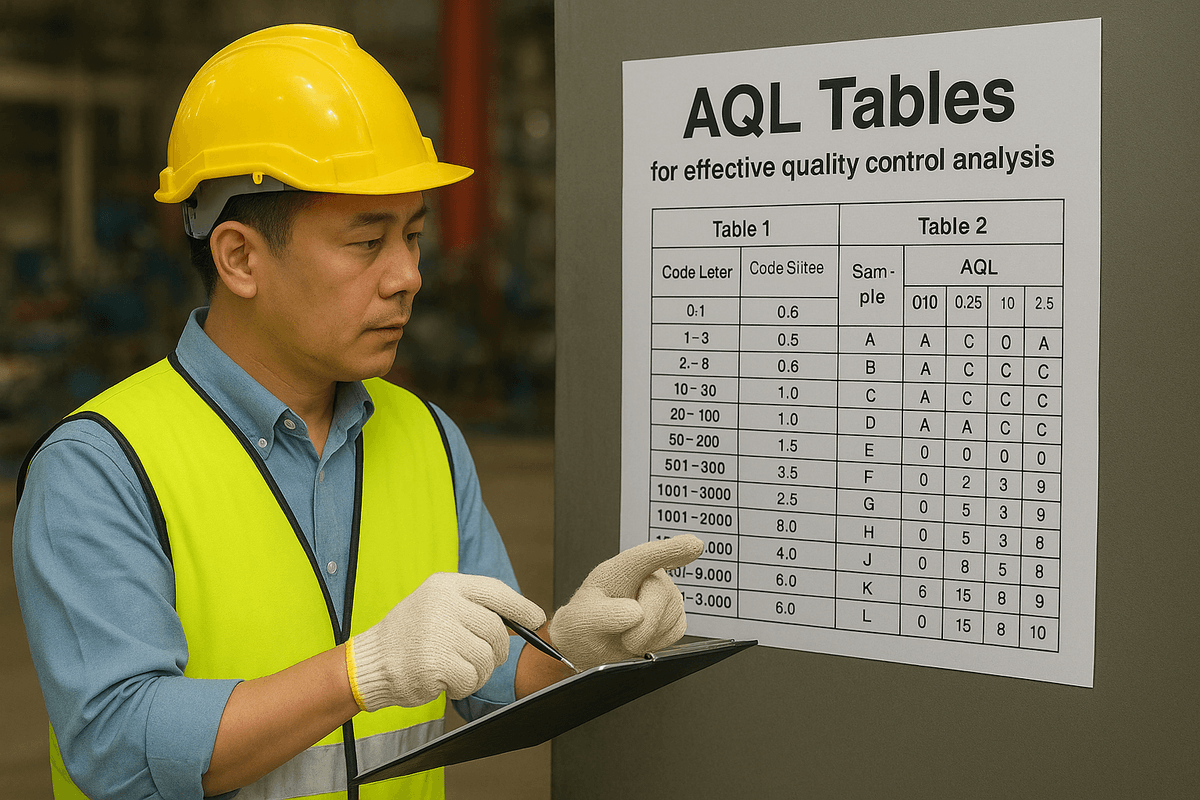

Analyzing Inspection Results

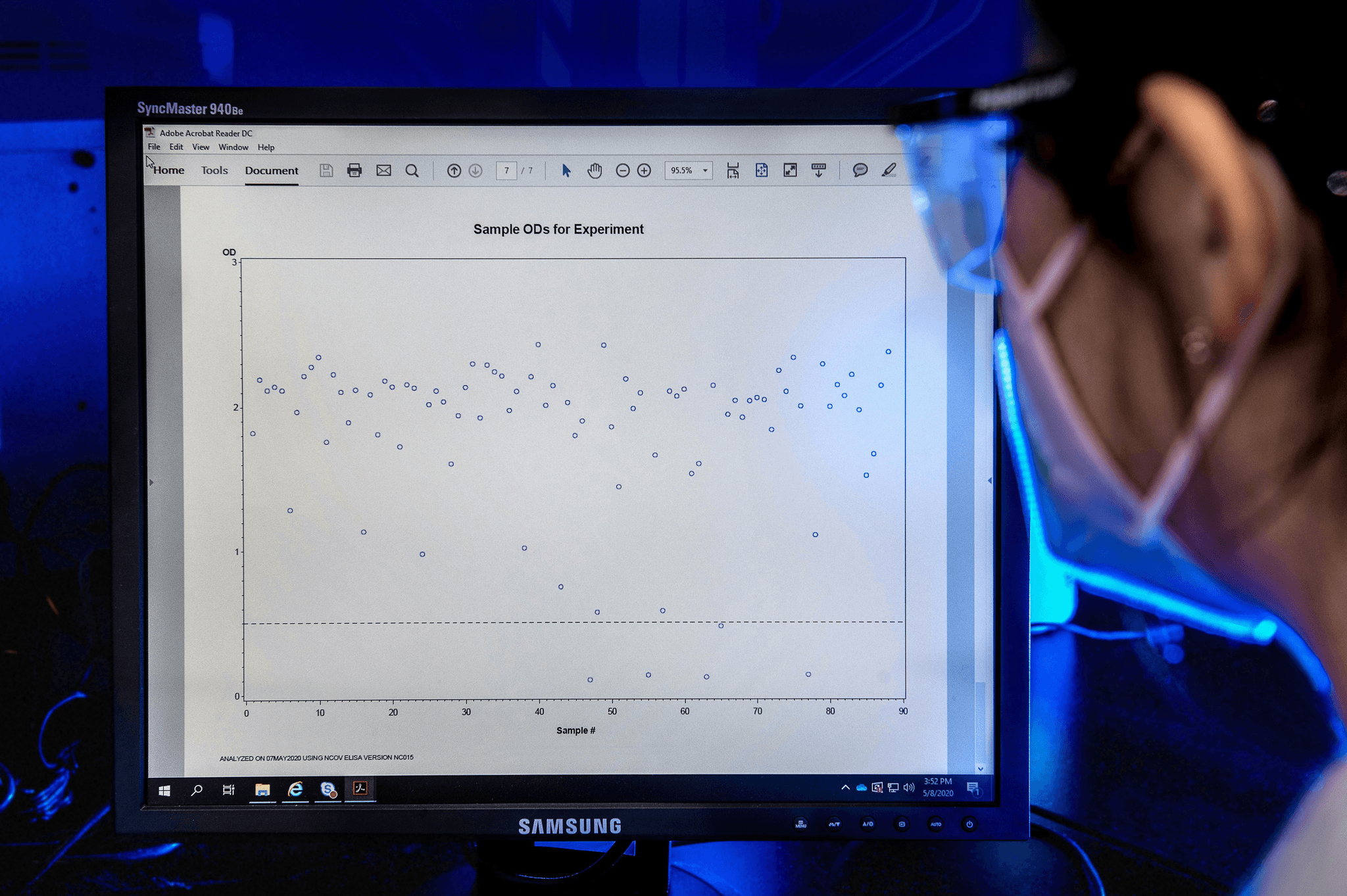

Analyzing inspection results is a vital task for any supplier quality engineer tasked with maintaining high standards in manufacturing. By reviewing various inspection types—such as final inspections and machine inspections—engineers can extract valuable insights into product performance and adherence to specifications. This thorough analysis allows for the identification of recurring defects or areas needing attention, which is essential for effective quality control checks.

The garment industry is particularly reliant on rigorous quality checking; thus, the role of data analysis takes on added significance here. Through careful examination of inspection results, suppliers can better understand how their processes impact end products, leading to more informed decisions about adjustments or improvements needed in production lines. Ultimately, this analytical approach fosters a culture of continuous improvement within the organization.

Developing Actionable Quality Improvement Plans

Once inspection results have been analyzed, the next step for a supplier quality engineer is to develop actionable quality improvement plans based on those findings. These plans should be specific and targeted towards addressing identified issues while incorporating best practices from various inspection techniques used across industries. For instance, if machine inspections reveal consistent problems with specific components in garments, engineers can create tailored action plans that focus on redesigning those elements or refining manufacturing processes.

Moreover, these improvement plans should not only aim at rectifying existing problems but also proactively prevent future issues from arising during production cycles. Engaging stakeholders in this process ensures that everyone involved understands their roles in implementing changes effectively while adhering to QA compliance standards. By fostering collaboration among teams during plan development and execution phases, organizations can significantly enhance overall product quality.

Reporting Findings to Stakeholders

Reporting findings to stakeholders is an essential aspect of the supplier quality engineer's role that ties together data analysis and actionable plans into a cohesive narrative about product integrity. Effective communication ensures all parties are aware of current performance metrics related to various inspection types and understand how these metrics influence customer satisfaction levels directly. Reports should highlight key insights derived from final inspections and machine inspections while providing context around their implications for ongoing operations.

Transparency is paramount when sharing findings; stakeholders must feel confident that they are receiving accurate information regarding product quality checks within the garment industry or other sectors involved in manufacturing processes. Regular updates help maintain accountability across teams while reinforcing a commitment to continuous improvement initiatives established previously through actionable plans developed post-analysis phase.

In conclusion, effective data analysis and reporting empower supplier quality engineers to uphold high standards across all facets of production by ensuring thorough understanding among stakeholders regarding current practices while paving pathways toward enhanced operational efficiency.

Continuous Improvement Strategies

In the fast-paced world of manufacturing, continuous improvement strategies are vital for a Supplier Quality Engineer. These strategies not only enhance quality control checks but also ensure that inspection types and techniques remain effective in identifying defects. By fostering a culture of constant evaluation and adaptation, businesses can maintain high standards in quality assurance.

Implementing Feedback Loops

Feedback loops are essential for refining processes and improving outcomes in quality control checks. A Supplier Quality Engineer can establish these loops by regularly gathering input from various stakeholders involved in the inspection process, including suppliers and internal teams. This collaborative approach helps identify areas needing improvement, ensuring that inspection techniques evolve to meet changing demands.

Moreover, feedback loops allow for real-time adjustments to QA compliance standards based on insights gained from inspection results. For instance, if machine inspections reveal recurring issues with specific materials, immediate corrective actions can be implemented to address these problems before they escalate. Ultimately, this proactive stance enhances overall product quality and customer satisfaction.

Adopting Industry Best Practices

Keeping abreast of industry best practices is crucial for any Supplier Quality Engineer aiming to excel in their role. By adopting proven methods for conducting final inspections and utilizing various inspection types, engineers can streamline processes while maintaining rigorous standards of quality checking in the garment industry. This not only boosts efficiency but also fosters a culture of excellence within the organization.

Incorporating best practices into daily operations also involves training team members on effective inspection techniques that align with current trends and technologies. For example, leveraging advanced machine inspection tools can significantly improve accuracy during inspections while reducing human error. By embracing innovation alongside established practices, companies can stay competitive in an ever-evolving market landscape.

Staying Updated on Regulatory Changes

Regulatory changes are an inevitable part of the manufacturing landscape; hence staying informed is essential for a Supplier Quality Engineer’s success. Regularly reviewing updates related to QA compliance ensures that all processes align with legal requirements and industry standards regarding product safety and quality assurance protocols. Ignoring these changes could lead to costly penalties or reputational damage.

Furthermore, being proactive about regulatory changes allows engineers to adjust their inspection techniques accordingly—whether it’s modifying final inspections or enhancing machine inspections based on new guidelines. Continuous education through workshops or industry conferences can be instrumental in keeping up with these shifts while fostering relationships with regulators who provide valuable insights into upcoming changes. Thus, remaining vigilant about regulations ultimately supports sustained operational excellence.

Conclusion

In wrapping up our exploration of the vital role played by supplier quality engineers, it’s essential to recognize their multifaceted responsibilities in ensuring that products meet rigorous standards. These professionals oversee quality control checks, execute various inspection types, and implement QA compliance measures that are crucial for maintaining high-quality manufacturing processes. Their work not only safeguards the integrity of products but also enhances customer satisfaction and trust in the brand.

Recap of Supplier Quality Engineer Responsibilities

Supplier quality engineers are tasked with a plethora of responsibilities that center on maintaining product quality throughout the supply chain. They oversee quality control checks, ensuring that every stage of production adheres to established standards while executing various inspection types to catch any potential defects early on. By implementing QA compliance protocols, these engineers play a pivotal role in fostering a culture of excellence within manufacturing operations.

The Importance of Inspection Types and Techniques

The significance of diverse inspection types and techniques cannot be overstated in the realm of quality assurance. From final inspections to machine inspections, each method serves a unique purpose in identifying issues before they escalate into larger problems. In particular, effective quality checking in the garment industry relies heavily on these techniques to ensure that every piece meets customer expectations and regulatory requirements.

The Future of Quality Control in Manufacturing

Looking ahead, the future of quality control in manufacturing is poised for transformation through technological advancements and innovative practices. As industries evolve, supplier quality engineers will increasingly leverage data analytics and machine learning to enhance inspection techniques and streamline processes like never before. This evolution will not only improve efficiency but also reinforce the importance of thorough quality control checks as we strive for excellence across all sectors.