Introduction

In today's global marketplace, the significance of raw materials testing cannot be overstated. This process ensures that the basic properties of raw materials meet industry standards and specifications, ultimately leading to higher quality products. With the rise of manufacturing in regions like China, understanding the nuances of QC inspection in China has become essential for businesses looking to maintain a competitive edge.

Understanding Raw Materials Testing

Raw materials testing encompasses a variety of analyses aimed at assessing both the physicochemical properties and overall quality of incoming materials. This is crucial not just for product integrity but also for ensuring that these materials perform as intended in their final applications. By conducting thorough testing, companies can identify potential issues before they escalate into costly defects.

Importance of Quality Control

Quality control is the backbone of any successful manufacturing operation, particularly when it comes to raw material testing. Effective QC measures help prevent defects that can compromise product safety and performance, ensuring consumer trust and satisfaction. In an era where consumers are more discerning than ever, maintaining high standards through rigorous testing is paramount.

The Role of QC Inspection in China

QC inspection in China plays a pivotal role in safeguarding product quality amid a bustling manufacturing landscape. With numerous suppliers and manufacturers vying for attention, establishing reliable inspection processes can mean the difference between success and failure. By prioritizing raw material testing and leveraging local expertise, businesses can navigate challenges while maximizing efficiency throughout their supply chains.

What Is Raw Materials Testing?

Raw materials testing is a critical process that ensures the quality and safety of materials before they enter the manufacturing phase. This testing aims to identify any defects or inconsistencies that could compromise product integrity, making it an essential component of quality control in various industries. In the context of qc inspection in China, raw materials testing plays a vital role in maintaining high standards and building consumer trust.

Definition and Purpose

At its core, raw materials testing refers to the evaluation and analysis of raw materials used in production processes to determine their suitability for specific applications. The purpose is not just to meet regulatory requirements but also to prevent costly defects down the line, ensuring that products meet both industry standards and consumer expectations. By conducting thorough assessments, manufacturers can mitigate risks associated with poor-quality inputs, thereby enhancing overall product reliability.

Key Components of Testing

The key components of raw materials testing encompass various methodologies designed to assess the Basic Properties of Raw Materials effectively. This includes evaluating Physicochemical Properties such as pH levels, moisture content, and density—parameters crucial for determining how a material will perform under different conditions. Additionally, tests may involve mechanical properties like tensile strength or thermal stability, all aimed at ensuring that only the best materials make it into production lines.

Common Raw Materials Tested

Common raw materials tested across industries include metals, plastics, textiles, and chemicals—each requiring specific testing protocols tailored to their unique properties. For instance, metals might undergo tensile tests while plastics could be assessed for impact resistance or thermal characteristics; this diversity highlights the Importance of Raw Material Testing in various sectors. Ultimately, rigorous testing not only safeguards against potential failures but also promotes innovation by allowing manufacturers to explore new material combinations confidently.

The Necessity of Raw Materials Testing

In today’s competitive market, the necessity of raw materials testing cannot be overstated. With the increasing complexity of supply chains and the demand for high-quality products, companies must prioritize thorough testing to ensure that their raw materials meet stringent standards. This is particularly true in regions like China, where qc inspection plays a vital role in maintaining product integrity.

Preventing Defects in Products

One of the primary reasons for conducting raw materials testing is to prevent defects in products before they reach consumers. By analyzing the basic properties of raw materials, manufacturers can identify any inconsistencies or anomalies that could lead to product failures down the line. This proactive approach not only saves time and money but also protects brand reputation by ensuring that only high-quality materials are used in production.

Moreover, understanding the physicochemical properties of raw materials helps companies fine-tune their manufacturing processes. When defects are identified early through rigorous qc inspection in China, corrective actions can be taken swiftly, preventing costly recalls and dissatisfied customers. Ultimately, investing in quality control measures leads to enhanced customer satisfaction and loyalty.

Impact on Supply Chain Efficiency

Raw materials testing significantly impacts supply chain efficiency by minimizing delays caused by material non-conformance. When suppliers know that their products will undergo stringent qc inspection procedures, they are more likely to adhere to quality standards from the start. This creates a smoother flow of operations as manufacturers can rely on consistent material quality without unexpected disruptions.

Additionally, effective testing protocols help streamline logistics and inventory management processes. By ensuring that only compliant raw materials enter production lines, companies can reduce waste and optimize resource allocation—leading to cost savings across the board. In essence, robust raw material testing contributes to a well-oiled supply chain machine.

Meeting Regulatory Compliance

Regulatory compliance is another critical aspect of why raw materials testing is essential for businesses operating globally—especially in markets with strict safety regulations like China. Companies must adhere not only to local laws but also international standards that govern product safety and quality assurance practices. Regular qc inspections ensure that all imported or locally sourced raw materials meet these requirements before production begins.

Failing to comply with regulatory standards can result in severe penalties or even legal action against a company, making it imperative for businesses to invest in comprehensive testing protocols early on. Furthermore, maintaining compliance enhances a company's reputation as a responsible entity committed to consumer safety—a significant selling point in today's market where consumers are more informed than ever about what goes into their products.

In conclusion, understanding the necessity of raw materials testing through its roles in defect prevention, supply chain efficiency enhancement, and regulatory compliance is crucial for any business looking to thrive today—and especially within dynamic environments like China where qc inspection practices set industry benchmarks.

Types of Raw Materials Testing

Raw materials testing is a multifaceted process that encompasses various techniques to ensure quality and compliance. Understanding the different types of testing is crucial for manufacturers, especially in the context of qc inspection in China, where adherence to standards can make or break a product's success. This section delves into the primary categories of raw materials testing: chemical analysis techniques, physical properties assessment, and microbiological testing methods.

Chemical Analysis Techniques

Chemical analysis techniques are essential for determining the composition and purity of raw materials. These methods help identify the Basic Properties of Raw Materials, including their elemental makeup and potential contaminants that could affect product quality. In qc inspection in China, chemical analysis plays a significant role in ensuring that materials meet industry standards and regulatory requirements.

Common chemical analysis methods include spectrometry, chromatography, and titration. Each technique has its strengths; for instance, spectrometry is excellent for detecting trace elements while chromatography excels at separating complex mixtures. By employing these techniques during raw material testing, manufacturers can significantly enhance their understanding of Physicochemical Properties which directly influence product performance.

Ultimately, rigorous chemical analysis not only prevents defects but also bolsters supply chain efficiency by ensuring that only high-quality raw materials enter production processes. This proactive approach to quality control aligns seamlessly with the Importance of Raw Material Testing as it safeguards against costly recalls or rework due to subpar inputs.

Physical Properties Assessment

Physical properties assessment evaluates characteristics such as density, viscosity, hardness, and thermal stability of raw materials. These Basic Properties of Raw Materials are critical indicators of how they will perform under various conditions during manufacturing or end-use applications. In qc inspection in China, this type of assessment ensures that physical attributes align with specifications outlined by manufacturers or regulatory bodies.

Techniques used for physical properties assessment include tensile strength tests, impact resistance tests, and thermal conductivity measurements. Such evaluations provide valuable insights into how well a material will withstand stress or environmental factors over time—information that's vital for ensuring durability and safety in final products. By focusing on these aspects during raw material testing processes, businesses can mitigate risks associated with material failure down the line.

Moreover, understanding Physicochemical Properties through physical assessments contributes significantly to optimizing formulations and enhancing overall product performance—an essential factor for gaining consumer trust in today’s competitive market landscape.

Microbiological Testing Methods

Microbiological testing methods are indispensable when it comes to evaluating the safety and suitability of raw materials for consumption or use in sensitive applications like pharmaceuticals or food products. These tests identify harmful microorganisms such as bacteria, fungi, and viruses that could compromise product integrity or consumer health—an aspect increasingly prioritized within qc inspection in China.

Common microbiological tests include total viable counts (TVC), pathogen detection assays (like Salmonella or E.coli), and yeast/mold counts which help ascertain whether a batch meets safety standards before reaching consumers' hands. The Importance of Raw Material Testing cannot be overstated here; effective microbiological assessments prevent contamination issues that could lead to serious health risks or legal repercussions down the line.

Incorporating robust microbiological testing into routine quality control measures not only fortifies brand reputation but also enhances overall supply chain efficiency by reducing instances where contaminated materials disrupt production schedules—a win-win scenario for all parties involved!

The Process of Raw Materials Testing

The process of raw materials testing is a meticulous journey that ensures the quality and safety of products before they reach consumers. It involves several critical steps, each designed to uphold the standards expected in today’s competitive market. By focusing on sample collection, testing procedures, and thorough documentation, companies can significantly enhance their quality control measures, especially in the context of qc inspection in China.

Sample Collection and Preparation

Sample collection is a pivotal first step in the raw materials testing process. It requires careful planning to ensure that samples accurately represent the batch being tested, which is crucial for reliable results. Once collected, samples must be prepared according to established protocols to maintain their integrity; this often includes proper labeling and storage conditions to prevent contamination or degradation.

In qc inspection in China, adherence to these sample preparation guidelines can make all the difference between passing and failing tests. The Basic Properties of Raw Materials are evaluated during this phase, ensuring that each sample meets preliminary specifications before undergoing more extensive analysis. Properly collected and prepared samples set the stage for accurate assessments of Physicochemical Properties later on.

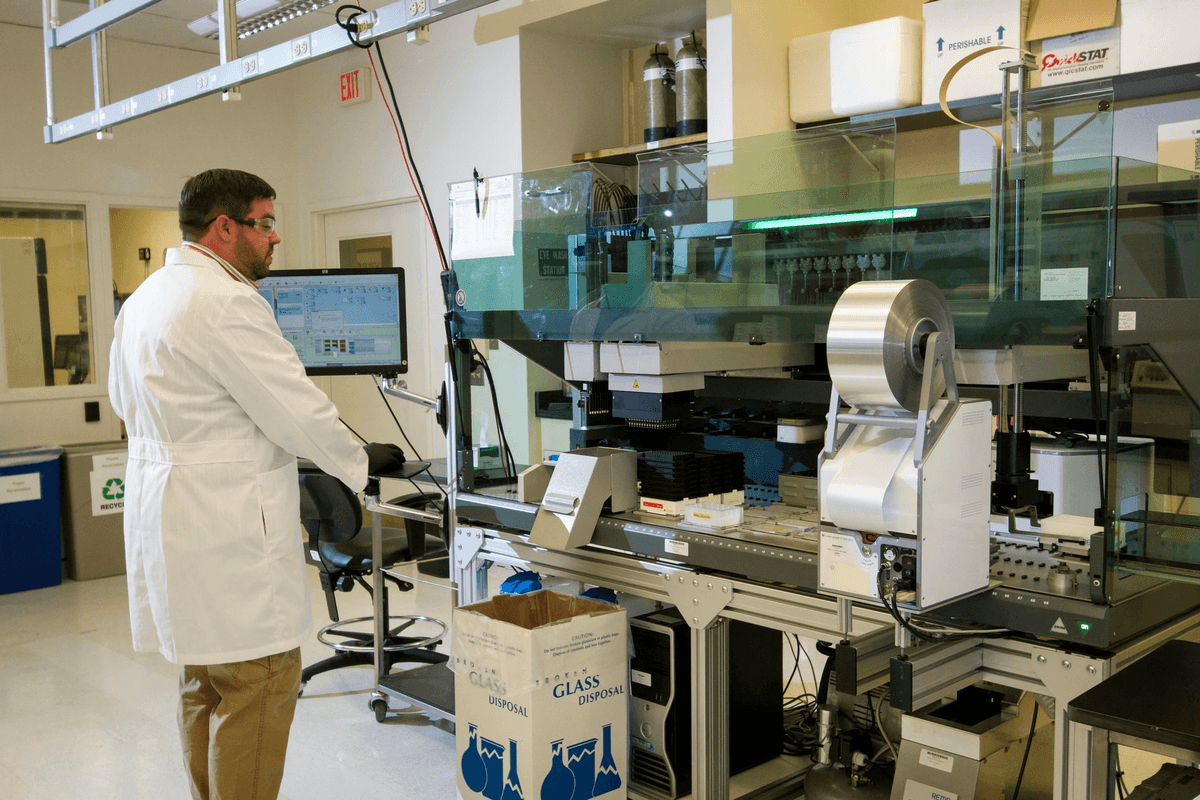

Testing Procedures and Standards

Once samples are prepared, they undergo rigorous testing procedures that adhere to industry standards tailored for various materials. These procedures may involve chemical analysis techniques that identify composition and purity levels or physical properties assessments that measure characteristics like hardness or tensile strength. Each test is conducted following stringent methods outlined by regulatory bodies or industry benchmarks.

The Importance of Raw Material Testing cannot be overstated; these procedures help detect potential defects early on, preventing costly mistakes down the line. In qc inspection in China specifically, understanding local regulations ensures compliance with both domestic and international standards during testing processes. This not only safeguards product quality but also enhances brand reputation among consumers who prioritize safety and reliability.

Reporting and Documentation

After testing concludes, reporting becomes crucial as it provides a detailed account of findings from each assessment performed on raw materials. Comprehensive documentation includes test results alongside any deviations from expected norms or standards observed during testing—a vital component for maintaining transparency with stakeholders involved in supply chains.

Documentation also plays an essential role during qc inspection in China by providing traceability throughout the production process; this helps companies quickly address any issues should they arise post-testing. Additionally, properly archived reports can serve as valuable references for future inspections or audits while reinforcing the Importance of Raw Material Testing as a key element in quality assurance strategies across industries.

Choosing the Right Testing Partner

Choosing a reliable testing partner is crucial for ensuring the quality of raw materials. With the increasing complexity of supply chains and regulatory requirements, organizations must prioritize partnerships that enhance their quality control processes. In particular, QC inspection in China has become essential for businesses looking to maintain high standards while navigating diverse manufacturing landscapes.

Role of Third-Party Inspectors

Third-party inspectors serve as impartial evaluators who provide an objective assessment of raw materials before they enter production lines. Their expertise ensures that the Basic Properties of Raw Materials meet industry standards and specifications, reducing the risk of defects and enhancing overall product quality. By utilizing third-party inspectors, companies can focus on their core operations while resting assured that their materials are being scrutinized by professionals dedicated to upholding quality.

Benefits of Using China Inspection Pro

China Inspection Pro stands out as a premier choice for businesses seeking robust QC inspection in China. This organization offers a comprehensive suite of services tailored to meet various testing needs, including assessments of Physicochemical Properties and microbiological testing methods. By partnering with China Inspection Pro, companies benefit from their vast experience, advanced testing methodologies, and commitment to delivering accurate results that ensure compliance with regulatory standards.

Evaluating Inspector Qualifications

When selecting a testing partner, evaluating inspector qualifications is paramount to achieving effective raw material testing outcomes. Inspectors should possess relevant certifications and experience in assessing the Basic Properties of Raw Materials specific to your industry sector. Additionally, it's wise to check references or case studies demonstrating their success in previous QC inspections in China; this helps ensure you're making an informed decision based on proven expertise.

Conclusion

In the ever-evolving landscape of manufacturing, raw materials testing stands as a cornerstone for ensuring product quality. The importance of raw material testing cannot be overstated; it not only prevents defects but also enhances the overall integrity of products. By implementing rigorous QC inspection in China, companies can significantly elevate their standards and meet consumer expectations.

Enhancing Product Quality Through Testing

The basic properties of raw materials play a crucial role in determining the final product's quality. Effective testing processes assess physicochemical properties to ensure that materials meet specified criteria before they enter production lines. This proactive approach to quality control helps manufacturers avoid costly recalls and reputational damage down the line.

Building Trust with Consumers

Consumers today are more discerning than ever, often scrutinizing product quality before making purchases. By prioritizing raw material testing and showcasing stringent QC inspection in China, companies can foster a sense of trust and transparency with their clientele. When consumers know that thorough testing has been conducted on the basic properties of raw materials, they are more likely to choose those brands over competitors.

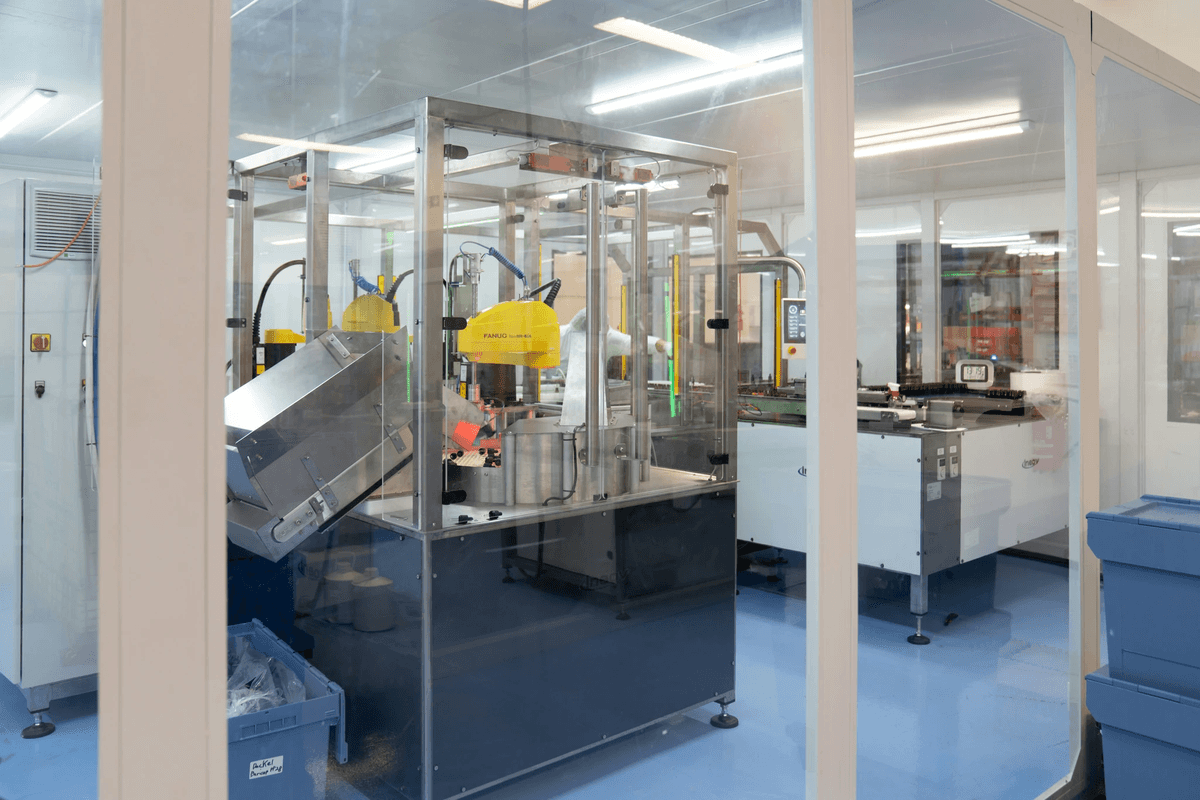

Future Trends in Raw Materials Testing

As industries advance, so too do methodologies for assessing the importance of raw material testing. Emerging technologies such as AI and automation are set to revolutionize how physicochemical properties are analyzed, making processes faster and more accurate than ever before. Moreover, increased globalization will likely drive demand for reliable QC inspection in China, as businesses seek partners who can provide comprehensive testing solutions tailored to their specific needs.