Introduction

In today's global marketplace, quality control has never been more crucial. With the rise of international sourcing, particularly in regions like China, maintaining high standards can mean the difference between success and failure for your business. Effective quality assurance strategies are not just optional; they are essential to safeguard your investment and reputation.

Importance of Quality Control

Quality control is the backbone of any successful product launch or ongoing production process. It ensures that products meet specified standards and customer expectations, reducing the risk of returns and complaints. By emphasizing quality control, businesses can build trust with their customers while minimizing costly errors that could arise from subpar goods.

Understanding the Risks of Sourcing

Sourcing from countries like China presents unique challenges that can jeopardize product quality if not managed properly. Language barriers, cultural differences, and varying manufacturing standards all contribute to potential risks in the supply chain. Understanding these risks allows businesses to implement proactive measures such as conducting inspections in China or hiring a third party inspection agent to mitigate issues before they escalate.

Overview of Quality Assurance Strategies

Quality assurance strategies encompass a range of practices designed to ensure that products meet required specifications throughout the manufacturing process. These may include actual checking by yourself during factory visits, asking your manufacturer or supplier to check for you, or engaging professional services for thorough evaluations. By adopting a multi-faceted approach to quality assurance, businesses can enhance their confidence in sourcing while ensuring consistent product excellence.

Conducting Your Own Inspection in China

When sourcing products from overseas, particularly in China, conducting your own inspection can be a game-changer. While you might consider hiring a third-party inspection agent or asking your manufacturer to check for you, there’s something uniquely valuable about being physically present. By engaging in actual checking by yourself, you gain firsthand insights into the production process and quality of goods that no report can fully convey.

Benefits of Actual Checking by Yourself

One of the most significant benefits of conducting an inspection in China is the ability to see everything with your own eyes. You’re not just relying on someone else's observations; you're experiencing the environment and processes directly, which can highlight issues that may otherwise go unnoticed. Additionally, being there allows for immediate communication with your supplier—clarifying expectations and standards right on the factory floor.

Another advantage is building relationships with suppliers through face-to-face interaction. These connections can lead to better negotiations and increased trust, which is crucial when you're relying on them for quality control. Plus, it gives you peace of mind knowing that you've taken proactive steps to ensure product quality rather than just trusting others to do it for you.

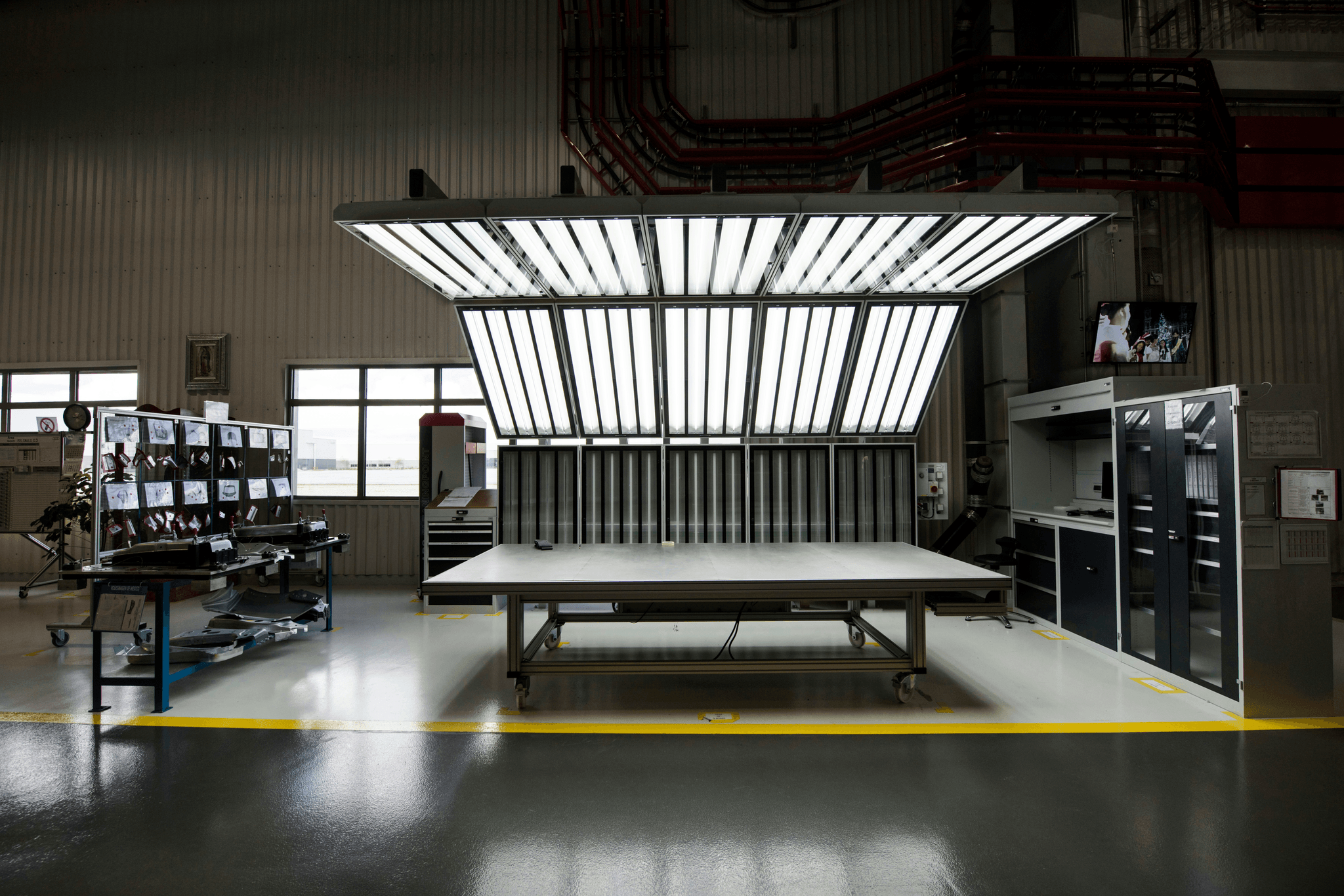

Essential Tools for On-Site Inspections

Before embarking on your journey for an inspection in China, it's essential to equip yourself with the right tools. A good camera is invaluable; capturing high-quality images of production processes or any discrepancies can serve as evidence later if needed. Additionally, having a checklist tailored to your specific product will help keep you focused during your visit—ensuring that nothing slips through the cracks.

Don’t forget about measurement tools! Calipers and gauges are handy for verifying dimensions and ensuring they match specifications precisely. Lastly, consider bringing along a portable device like a tablet or smartphone loaded with relevant documentation; this way, you can reference contracts or quality standards while on-site.

Key Areas to Focus on During the Visit

During your inspection in China, there are several key areas that deserve special attention to ensure quality control remains top-notch. Start with examining raw materials—are they up to par? Next up is checking production processes; observe how workers handle machinery and whether safety protocols are followed diligently.

Quality assurance also involves scrutinizing finished products before they leave the factory floor; inspect packaging methods and labeling accuracy since these elements impact customer satisfaction significantly. Finally, engage with workers during your visit—ask questions about their processes and challenges they face daily; this insight could reveal potential issues down the line if left unaddressed.

Hiring a Third Party Inspection Agent

When it comes to ensuring quality control in your sourcing journey, hiring a third party inspection agent can be a game changer. While you might be tempted to do all the legwork yourself—perhaps even considering the benefits of actual checking by yourself—there are compelling reasons to bring in the pros. These professionals not only save you time and effort but also provide an unbiased assessment that can catch issues you might overlook.

Why You Should Consider Professionals

Hiring a professional inspection agent is like having an extra set of eyes that are trained specifically for quality assurance. They possess the expertise and experience necessary to identify potential problems that may arise during production, which can save you from costly mistakes down the line. Plus, while asking your manufacturer or supplier to check for you the quality of the goods may seem convenient, their vested interest could cloud their judgment; professionals have no such bias.

Another advantage is access to specialized tools and methodologies that enhance the inspection process. A third party inspection agent typically uses advanced techniques and equipment that ensure thorough evaluations of products before they leave the factory floor. This means you're not just relying on surface-level checks but getting comprehensive insights into your product’s quality.

How China Inspection Pro Ensures Quality

China Inspection Pro stands out as a leader in providing reliable third-party inspections tailored specifically for businesses sourcing from China. Their team consists of seasoned inspectors who understand local manufacturing practices and standards, ensuring compliance with international quality benchmarks. By leveraging their expertise, you can rest assured knowing that your products undergo rigorous checks before reaching your doorstep.

Furthermore, they offer a range of services including pre-production inspections, during production checks, and final random inspections—all crucial phases where potential defects could sneak in unnoticed. Their systematic approach allows them to catch issues early on, minimizing risks associated with poor-quality goods entering your supply chain. This proactive stance makes them an invaluable partner in maintaining high-quality standards throughout your sourcing process.

Tips for Choosing the Right Inspection Agency

Selecting an inspection agency isn’t just about picking one off a list; it requires careful consideration and research to find the right fit for your needs. Start by looking for agencies with solid reputations backed by positive client testimonials and case studies demonstrating their effectiveness in conducting inspections in China. Remember that experience matters; agencies with years of practice are more likely to navigate potential pitfalls effectively.

Next, assess their range of services—ensure they offer comprehensive inspections tailored specifically to your product type and industry requirements. It's also beneficial if they provide clear communication channels so you can easily discuss findings or concerns after inspections take place; transparency is key when you're entrusting someone else with such critical tasks as checking product quality.

Lastly, don’t shy away from asking about certifications or affiliations with recognized industry bodies; these credentials often indicate professionalism and adherence to best practices within the field of inspection china services. By following these tips, you'll be well on your way to hiring a third party inspection agent who aligns perfectly with your business goals.

Communicating with Your Supplier

Effective communication with your supplier is crucial for ensuring quality control in your sourcing process. This aspect often gets overlooked, but it can make all the difference between receiving subpar products and maintaining high standards. By establishing a clear dialogue, you can address potential issues before they escalate and ensure that your expectations are met.

Effective Ways to Discuss Quality Standards

When discussing quality standards, clarity is key. Make sure to articulate your expectations explicitly, using specific language that leaves no room for misinterpretation—this is especially important when dealing with suppliers in China where cultural differences may exist. Utilize visual aids like charts or product samples to help illustrate your points; sometimes a picture really is worth a thousand words!

In addition, consider setting up regular check-ins or progress updates to keep the lines of communication open. This not only reinforces the importance of quality but also helps build a relationship based on trust and transparency. Remember, effective communication isn't just about talking; it's about listening too—be receptive to feedback from your supplier regarding the feasibility of your quality demands.

Asking Your Manufacturer to Check for You

One practical approach is to ask your manufacturer or supplier to check for you the quality of the goods before they ship them out. This can serve as an additional layer of assurance that what you receive aligns with what you expect. However, be mindful that this method relies heavily on the integrity and reliability of the manufacturer.

To make this request effective, provide them with detailed specifications and guidelines so they know exactly what you're looking for during their inspection process in China. It’s also wise to follow up after they've conducted their checks—this shows that you’re serious about maintaining high-quality standards and encourages them to take those checks seriously as well.

The Role of Open Communication in Quality

Open communication plays a pivotal role in maintaining product quality throughout the sourcing process. When both parties feel comfortable expressing concerns or suggestions, it fosters an environment where issues can be addressed proactively rather than reactively—saving time and resources down the line!

Moreover, by emphasizing open dialogue, you're more likely to cultivate a partnership mindset rather than just a transactional relationship with your supplier. So don’t shy away from discussing challenges openly; it could lead you toward solutions that improve both product quality and overall satisfaction.

Utilizing Factory Audits

In the world of sourcing, factory audits are a crucial tool for ensuring quality control. These comprehensive evaluations assess a manufacturer's processes, facilities, and compliance with industry standards. By integrating factory audits into your quality assurance strategy, you can significantly reduce risks associated with sourcing from overseas suppliers.

What is a Factory Audit?

A factory audit is an in-depth examination of a manufacturing facility to evaluate its operations and adherence to specified quality standards. This process typically involves reviewing production practices, equipment maintenance, and employee training protocols. Essentially, it's like conducting an inspection in China without the need for you to be physically present—though nothing beats actual checking by yourself when it comes to getting first-hand insights.

How Audits Can Uncover Potential Issues

Factory audits can reveal hidden problems that might not be apparent during regular inspections or through supplier reports. For instance, issues such as inadequate safety measures or sub-standard manufacturing processes can be identified before they lead to larger complications down the line. By hiring a third-party inspection agent who specializes in these audits, you gain access to their expertise and experience in spotting potential pitfalls that could jeopardize your product's quality.

Making Audits Part of Your Quality Assurance

Incorporating factory audits into your overall quality assurance strategy is essential for maintaining high standards consistently. Regularly scheduled audits help ensure that suppliers are adhering to established guidelines while also providing opportunities for improvement based on findings from previous evaluations. Additionally, always remember that asking your manufacturer or supplier to check for you the quality of the goods can further reinforce a culture of accountability within their operations.

Setting Clear Quality Specifications

When it comes to ensuring quality in your products, setting clear quality specifications is absolutely crucial. These guidelines act as a roadmap for both you and your supplier, helping to align expectations and reduce the risk of misunderstandings. Without well-defined specifications, you might find yourself navigating a minefield of potential issues during your inspection in China.

Importance of Clear Guidelines

Clear guidelines serve as the backbone of effective quality control. They not only inform your supplier about what you expect but also provide a reference point for any inspections—whether you're conducting the inspection yourself or hiring a third-party inspection agent. When everyone is on the same page, it minimizes discrepancies and fosters a more productive relationship with your manufacturer.

Creating a Comprehensive Product Checklist

Creating a comprehensive product checklist is an essential step in setting those clear guidelines. This checklist should detail every aspect of the product, from dimensions and materials to packaging requirements and labeling standards. By having this list in hand during inspections—whether you're doing actual checking by yourself or asking your manufacturer or supplier to check for you—you can ensure that nothing slips through the cracks.

How Specifications Help in Quality Control

Specifications play an integral role in quality control by providing measurable criteria against which products can be evaluated. They help streamline the inspection process, making it easier for both you and any third-party inspection agents to identify potential issues before they escalate into bigger problems. Ultimately, well-defined specifications not only enhance product quality but also save time and resources by reducing rework or returns.

Conclusion

In conclusion, maintaining high-quality standards in sourcing products from China is paramount for any business. Throughout this guide, we've explored various quality assurance methods, including conducting your own inspection in China, hiring a third-party inspection agent, and fostering open communication with your suppliers. Each of these strategies plays a crucial role in ensuring that the products you receive meet your expectations and standards.

Recap of Quality Assurance Methods

To recap, there are several effective quality assurance methods to consider when sourcing from China. First, the option to conduct actual checking by yourself allows you to see firsthand the conditions under which your products are made. Alternatively, hiring a third-party inspection agent provides expertise and an unbiased perspective on quality control, while asking your manufacturer or supplier to check for you can help establish trust and accountability.

Long-Term Benefits of Effective Quality Control

Implementing robust quality control measures offers significant long-term benefits for your business. By investing time and resources into thorough inspections—whether through personal visits or professional services—you reduce the risk of costly errors and returns down the line. Furthermore, maintaining high-quality standards helps build a solid reputation with customers who value reliability and excellence in their purchases.

Final Thoughts on Maintaining Quality from Suppliers

Ultimately, the key to successful sourcing lies in proactive communication and clear expectations with your suppliers. Whether you choose to conduct actual checking by yourself or hire a third-party inspection agent, remember that consistent dialogue about quality is essential for long-lasting partnerships. So go ahead—ask your manufacturer or supplier to check for you; it’s not just about receiving goods but ensuring they meet the high standards that reflect well on your brand.