Introduction

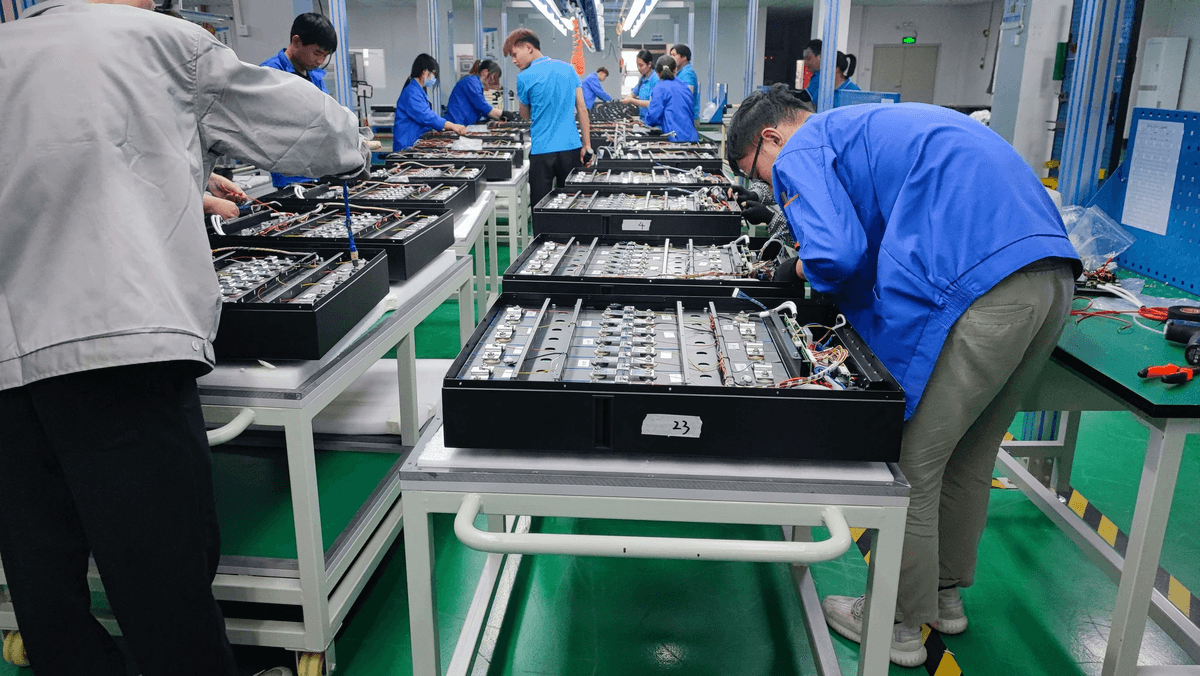

In the bustling world of global trade, Chinese inspection services have emerged as a cornerstone for businesses looking to ensure quality and compliance. With China being a manufacturing powerhouse, understanding the nuances of Quality Control in China is vital for any company sourcing products from this region. This introduction will delve into the importance of these inspection services, the pivotal role that quality control plays, and provide an overview of the product inspection process.

Importance of Chinese Inspection Services

Chinese inspection services are essential for mitigating risks associated with sourcing products from overseas manufacturers. They not only help businesses maintain high standards but also safeguard their reputation by ensuring that products meet international quality benchmarks. By engaging in effective inspections, companies can avoid costly mistakes and enhance their market competitiveness.

The Role of Quality Control in China

Quality Control in China is not merely a buzzword; it’s an integral part of the manufacturing landscape. It encompasses various processes designed to ensure that products meet specific requirements before they reach consumers. Understanding what QC in China entails can significantly impact your bottom line, as it influences everything from production efficiency to customer satisfaction.

Overview of the Product Inspection Process

The product inspection process is a structured approach aimed at identifying defects and ensuring compliance with safety and quality standards. It typically involves several stages, including pre-production checks, during production assessments, pre-shipment evaluations, and container loading inspections—collectively answering the question: What are the 4 types of inspection? Each stage plays a crucial role in maintaining product integrity and adhering to regulations such as what is the product safety law in China? By grasping this process, businesses can better navigate challenges associated with importing goods.

Understanding Quality Control in China

Quality Control (QC) in China is a critical component of manufacturing, ensuring that products meet specified standards before they reach consumers. With the rapid growth of Chinese manufacturing, understanding what QC in China entails is essential for businesses looking to maintain quality and compliance. The significance of effective quality control cannot be overstated; it safeguards brand reputation and ensures customer satisfaction.

Definition and Significance

Quality Control in China refers to the systematic process of maintaining standards in manufactured products by testing them for defects and ensuring they meet predetermined specifications. The significance of QC lies not only in preventing defective products from reaching the market but also in fostering trust between manufacturers and consumers. In an era where product recalls can tarnish reputations overnight, understanding what is QC in China becomes vital for brands aiming for longevity.

Key Players in Quality Control

The landscape of quality control involves various key players, including manufacturers, inspection agencies, and regulatory bodies that enforce compliance with standards such as China's Product Safety Law. Manufacturers must adhere to these laws while partnering with reliable Chinese inspection services to ensure their products pass necessary inspections throughout the production process. Additionally, third-party inspectors play a crucial role by providing objective assessments that help businesses navigate what are the 4 types of inspection available during various stages of production.

How QC Affects Your Business

The impact of quality control on your business can be profound; effective QC practices lead to higher customer satisfaction and reduced returns due to defects. When companies invest time and resources into understanding how QC affects their operations, they often see improved efficiency and cost savings over time. Furthermore, navigating the complexities of what is the product inspection process can help mitigate risks associated with non-compliance or poor-quality goods entering international markets.

What Are the 4 Types of Inspection?

In the realm of Quality Control in China, understanding the various types of inspections is crucial for ensuring product quality and compliance. Each inspection type serves a unique purpose within the product inspection process, helping businesses mitigate risks and maintain standards. So, let's dive into the four primary types of inspections that every importer should know about.

Pre-Production Inspection

Pre-Production Inspection (PPI) is the first line of defense in the Quality Control in China landscape. This inspection occurs before manufacturing begins and focuses on verifying that raw materials meet specified standards and that production processes are set up correctly. By identifying potential issues early on, businesses can avoid costly mistakes down the line, making it an essential step in what is the product inspection process.

During a PPI, inspectors assess samples from suppliers to ensure they align with specifications provided by buyers. This includes checking materials for quality and compliance with safety regulations like what is the product safety law in China? The outcome of this inspection sets a solid foundation for successful production runs.

During Production Inspection

The During Production Inspection (DPI) takes place while products are actively being manufactured. This type of Chinese inspection focuses on monitoring production quality at various stages to ensure that everything remains on track with predefined standards. DPI helps catch defects early when they are easier—and less expensive—to rectify.

Inspectors will check a sample size representative of current production output to evaluate workmanship, functionality, and conformity to specifications. As part of what is QC in China?, DPI not only enhances product quality but also boosts supplier accountability throughout the manufacturing process.

Pre-Shipment Inspection

Pre-Shipment Inspections (PSI) occur just before goods leave the factory and head towards their final destination—this is where you want everything to be perfect! PSI serves as a final check to confirm that products meet all agreed-upon specifications before shipment, thereby reducing risks associated with international trade disputes or returns due to faulty merchandise.

During this stage, inspectors will verify packaging integrity, labeling accuracy, and overall product condition while also conducting functional tests if necessary. Essentially, this step ensures compliance with both customer expectations and regulations like what is the product safety law in China? It’s your last chance to catch any discrepancies before your products hit store shelves!

Container Loading Inspection

Container Loading Inspections (CLI) are often overlooked but play an essential role in ensuring safe transportation of goods across borders. This type of Chinese inspection involves examining how products are loaded into shipping containers to prevent damage during transit—a critical aspect given how rough transport can be sometimes!

Inspectors will monitor loading procedures closely while checking for proper securing methods that minimize movement within containers during shipping journeys. After all, you wouldn't want your carefully inspected products arriving at their destination damaged or misaligned; therefore understanding what are the 4 types of inspection becomes vital for maintaining your brand's reputation.

Navigating Product Safety Laws in China

These regulations are designed to protect consumers and ensure that products meet specific standards before they can be sold. This section will delve into the intricacies of China's product safety law, compliance requirements for foreign businesses, and the potential consequences of non-compliance.

Overview of China's Product Safety Law

What is the product safety law in China? At its core, this law establishes a framework for ensuring that products are safe for consumers. It encompasses various regulations, including mandatory testing and certification processes that manufacturers must adhere to before their goods hit the market. This law not only applies to domestic companies but also imposes strict guidelines on foreign businesses looking to sell their products in China.

The Chinese government has ramped up efforts to enforce these laws in recent years, reflecting a growing commitment to consumer protection. For anyone involved in Quality Control in China, familiarizing themselves with these regulations is paramount. Ignoring them could lead to severe repercussions not just for your business but also for consumer trust.

Compliance Requirements for Foreign Businesses

Foreign businesses must navigate a complex web of compliance requirements when entering the Chinese market. Understanding what QC in China entails is crucial; this includes adhering to local standards and obtaining necessary certifications before launching any products. Companies must conduct thorough due diligence on local laws and engage reliable Chinese inspection services that can guide them through this process.

Additionally, documentation plays a key role in compliance; businesses should maintain accurate records of inspections and certifications as proof of adherence to product safety laws. Regular audits may also be required, depending on the type of products being manufactured or imported into China. By staying informed about these compliance requirements, foreign companies can avoid pitfalls associated with non-compliance.

Consequences of Non-Compliance

What happens if you fail to comply with China's stringent product safety laws? The consequences can be dire: from hefty fines and legal action against your company to complete bans on selling your products within Chinese borders. Non-compliance may also tarnish your brand's reputation and lead consumers to distrust your offerings—an outcome no business wants.

Moreover, without proper adherence to Quality Control in China practices, you risk having subpar products enter the market that could harm consumers or lead to significant recalls down the line. Engaging professional Chinese inspection services can help mitigate these risks by ensuring all aspects of production align with legal standards before they become an issue.

In summary, navigating product safety laws in China requires diligence and proactive engagement with quality control measures throughout your supply chain process—including understanding what are the 4 types of inspection? By prioritizing compliance and engaging trusted partners for inspections, businesses can thrive while maintaining high standards of consumer protection.

The Product Inspection Process Explained

When it comes to ensuring product quality, understanding the product inspection process is crucial for businesses engaging in Chinese manufacturing. This process not only safeguards your investment but also helps maintain your brand's reputation in a competitive market. So, let’s dive into the nitty-gritty of how inspections work and why they matter.

Steps in the Inspection Process

The product inspection process typically begins with a thorough planning phase where specific criteria are established based on the type of goods being produced and the standards required by buyers. Following this, inspectors conduct various checks at different stages of production—this is where understanding What are the 4 types of inspection? becomes essential. Each type of inspection—pre-production, during production, pre-shipment, and container loading—serves a unique purpose in maintaining Quality Control in China and ensuring that products meet safety regulations.

Once inspections begin, inspectors evaluate products against predefined quality standards to identify any defects or non-compliance issues early on. If discrepancies arise during these checks, corrective action can be taken promptly to prevent larger problems down the line. Ultimately, this proactive approach not only enhances product quality but also minimizes costly delays associated with rework or returns.

How China Inspection Pro Facilitates Inspections

China Inspection Pro plays a pivotal role in streamlining the complex landscape of Quality Control in China by providing expert guidance throughout the inspection process. They offer tailored services that align with international standards while ensuring compliance with local regulations—including insights into What is the product safety law in China? This means businesses can focus on their core operations while leaving the intricacies of inspections to seasoned professionals who know how to navigate both cultural and regulatory nuances.

In addition to coordinating inspections at various production phases, China Inspection Pro ensures that clients receive timely updates and detailed reports about their products' status. Their expertise allows them to identify potential issues before they escalate into significant problems that could jeopardize business relationships or lead to financial losses. By leveraging their extensive network of qualified inspectors across different regions in China, they facilitate efficient communication between manufacturers and clients.

Importance of Documentation and Reporting

Documentation is an often-overlooked aspect of the product inspection process but is vital for maintaining transparency and accountability throughout Quality Control in China. Detailed reports provide essential insights into each stage of inspection—documenting findings related to defects or compliance with What is QC in China? This documentation serves as evidence that products have met necessary quality standards before reaching consumers.

Moreover, proper reporting can protect businesses from legal repercussions related to non-compliance with China's stringent safety laws; failing to document inspections could result in hefty fines or even bans from certain markets if products do not adhere to What is the product safety law in China?. In essence, thorough documentation not only helps companies stay organized but also builds trust among stakeholders by demonstrating a commitment to quality assurance.

Best Practices for Engaging Inspection Services

When it comes to engaging Chinese inspection services, understanding the nuances of Quality Control in China is crucial. The right inspection partner can make or break your product's success in the market. By following best practices, you can streamline the product inspection process and ensure compliance with regulations.

Choosing the Right Inspection Partner

Selecting the right inspection partner is fundamental to effective Quality Control in China. Look for a company with a solid reputation, extensive experience, and expertise in your specific industry. It's also wise to verify their accreditation and ask for references to ensure they understand what is QC in China and how it impacts your products.

Additionally, consider their ability to conduct all four types of inspections: pre-production, during production, pre-shipment, and container loading inspections. This versatility will save you time and resources while ensuring comprehensive oversight throughout the manufacturing process. Remember that a good inspection partner should not just check boxes but offer valuable insights into improving quality standards.

Tips for Effective Communication

Effective communication is vital when working with Chinese inspection services; after all, clarity can prevent costly misunderstandings down the line. Establish regular check-ins to discuss expectations regarding what are the 4 types of inspections performed and any specific concerns you may have about your products or processes.

Moreover, be clear about your quality standards and compliance requirements under China's product safety law; this transparency will help align both parties towards common goals. Utilize technology—like video calls or instant messaging—to maintain open lines of communication throughout the entire product inspection process.

Ensuring Transparency in Inspections

Transparency during inspections fosters trust between you and your Chinese inspection partner while enhancing overall quality control outcomes. Make sure that all findings from inspections are documented thoroughly; this not only helps you understand what is happening on-site but also provides necessary evidence if disputes arise later on.

Encourage inspectors to share real-time updates as they perform their duties; knowing exactly what happens during each stage of the process allows you to react quickly if issues arise related to compliance with China's product safety law or other regulations. Ultimately, fostering an environment of transparency will lead to better decision-making and improved relationships with manufacturers.

Conclusion

In wrapping up our exploration of Chinese inspection services and the vital role they play in quality control, it's essential to recognize their profound impact on businesses engaging with China. The complexities of navigating the landscape of Quality Control in China can be daunting, but understanding the nuances of what is the product inspection process and how it integrates with local regulations can provide a significant competitive edge. By leveraging these services, companies not only enhance product quality but also build stronger relationships with their suppliers.

Key Benefits of Chinese Inspection Services

One major advantage of utilizing Chinese inspection services is the assurance that products meet international quality standards before they reach consumers. Companies can avoid costly mistakes by implementing effective inspections at various stages, including pre-production and pre-shipment phases. Moreover, understanding what are the 4 types of inspection allows businesses to tailor their quality control measures specifically to their needs, ensuring a smoother operational flow.

Another benefit lies in compliance with local laws; knowing what is the product safety law in China is crucial for foreign businesses aiming to maintain market access without legal hiccups. By partnering with experienced inspectors who understand both local regulations and international standards, companies can navigate this complex environment more effectively. Ultimately, these services not only help mitigate risks but also foster long-term partnerships built on trust and transparency.

Common Pitfalls in Quality Control

Despite its importance, many businesses fall into common pitfalls when managing Quality Control in China. One such issue arises from a lack of understanding regarding what is QC in China; many underestimate the cultural differences that can affect communication and expectations during inspections. This misalignment often leads to misunderstandings about product specifications or quality standards, resulting in subpar outcomes.

Additionally, neglecting to perform thorough inspections at every stage—especially during critical points like container loading—can lead to significant financial repercussions down the line. Businesses should be wary of cutting corners by skipping inspections or relying solely on supplier assurances without verifying through independent checks. Such oversights can compromise product integrity and ultimately damage brand reputation.

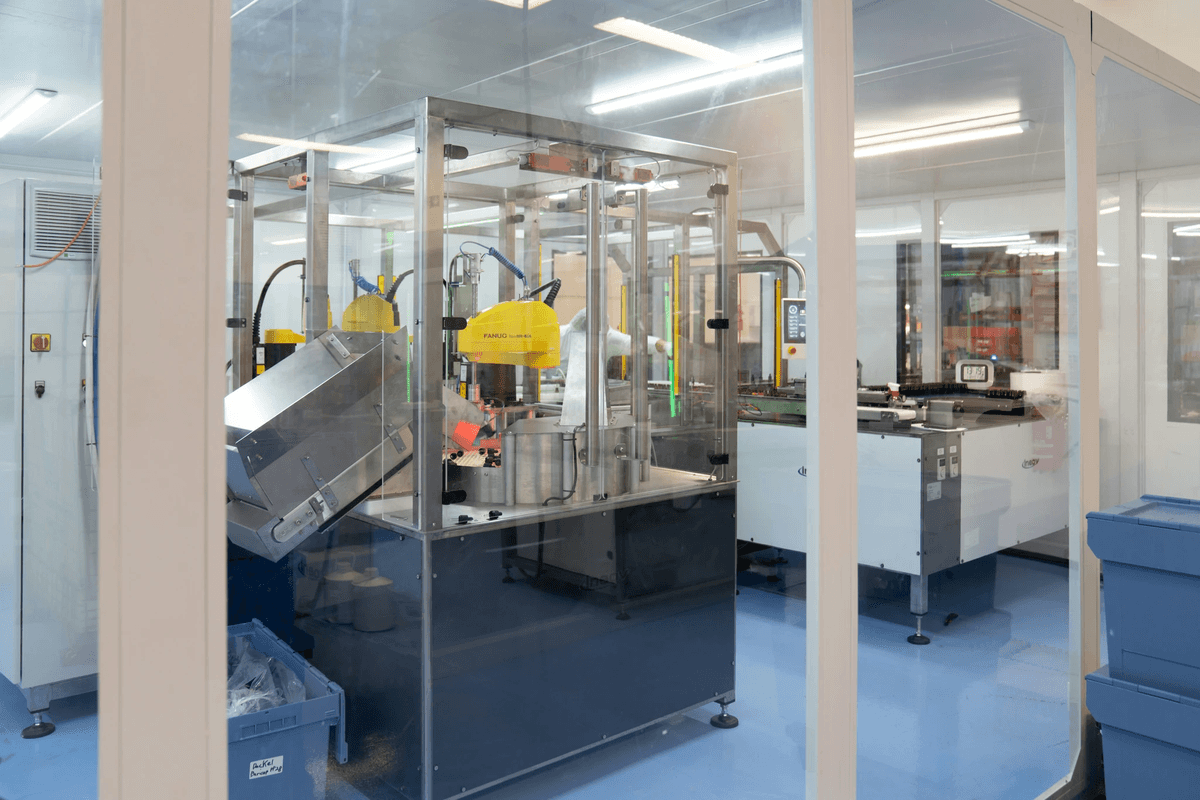

Future Trends in Product Inspections

As we look ahead, several trends are shaping the future landscape of product inspections within China’s dynamic market environment. Increasingly sophisticated technology will play a pivotal role; tools like AI-driven analytics will enhance efficiency throughout what is the product inspection process by providing real-time data insights for better decision-making. This evolution promises not only faster inspections but also greater accuracy and reliability across all four types of inspection.

Furthermore, sustainability will become an integral focus within Quality Control in China as global consumers demand higher ethical standards from brands they support. Companies that prioritize eco-friendly practices during production will likely find themselves at an advantage when it comes to consumer loyalty and regulatory compliance alike—especially as awareness surrounding environmental issues continues to grow worldwide. Embracing these changes now will prepare businesses for success amid shifting market demands.