Introduction

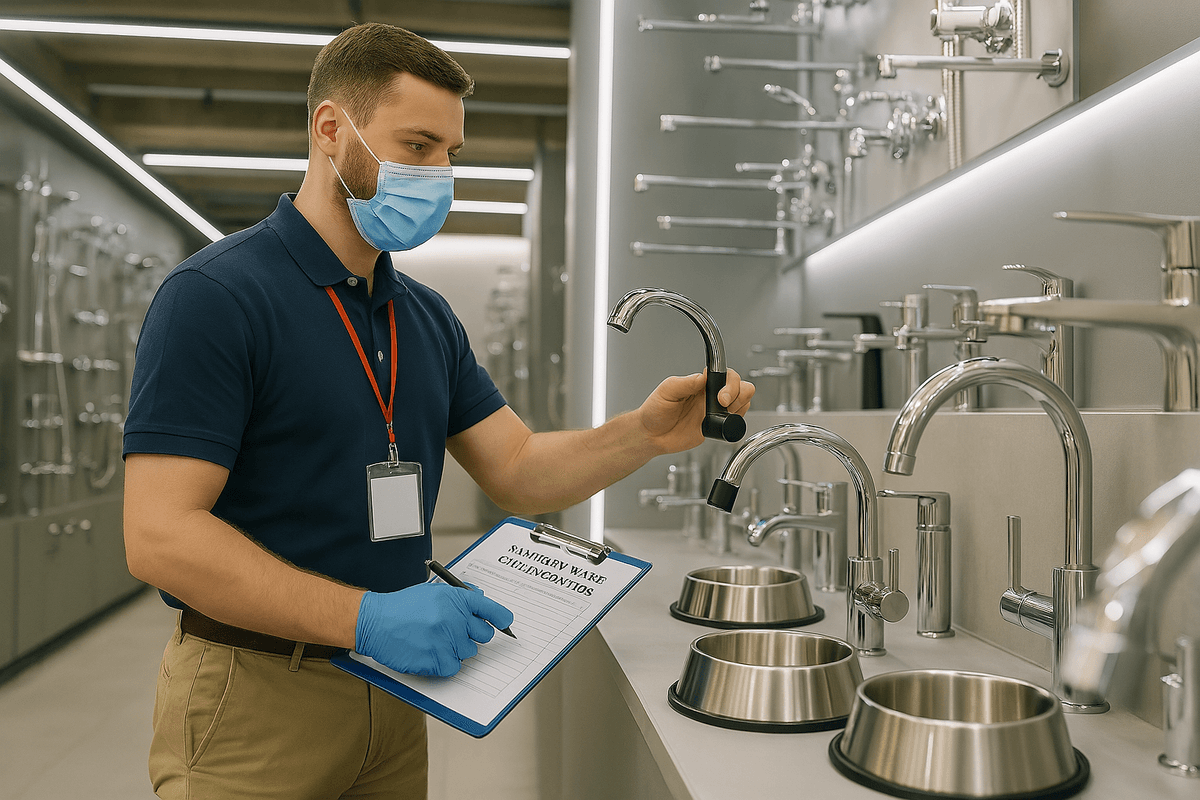

In the fast-paced world of global sourcing, the role of QC inspectors has never been more critical. With a growing emphasis on quality assurance, businesses are increasingly reliant on these professionals to ensure that products meet stringent standards before they reach consumers. Understanding the importance of QC inspectors is essential for anyone looking to navigate the complexities of product inspection in China effectively.

Understanding the Importance of QC Inspectors

QC inspectors serve as the guardians of quality in the manufacturing process, ensuring that products not only meet specifications but also align with buyer expectations. Their expertise allows them to identify issues early, which is vital for maintaining product integrity and avoiding costly recalls or returns. By performing thorough inspections and providing actionable feedback, these inspectors enhance buyer confidence and contribute significantly to a company's reputation.

The Sourcing Landscape in China

China remains a powerhouse in global manufacturing, attracting businesses seeking cost-effective solutions without compromising quality. However, navigating this landscape requires an understanding of local practices and potential pitfalls associated with sourcing products from overseas. As companies engage with suppliers, it becomes imperative to schedule the inspection date strategically to allow ample time for any necessary adjustments before shipment.

Overview of Quality Control Processes

Quality control processes are designed to ensure that every product meets predefined standards throughout its lifecycle—from production through delivery. This involves a series of checks and balances where QC inspectors perform quality inspections at various stages, identifying defects or non-conformities early on. By implementing robust quality control and assurance strategies, businesses can mitigate risks associated with poor-quality products while fostering long-term relationships with their sourcing partners.

The Role of QC Inspectors

Their expertise ensures that products meet specific standards and specifications before they are shipped, thereby safeguarding both the supplier's and buyer's interests. By acting as the final line of defense against defects, QC inspectors help maintain a seamless flow in the supply chain.

Ensuring Product Quality Before Shipment

The primary responsibility of QC inspectors is to ensure product quality before shipment, which is crucial for maintaining brand integrity and customer satisfaction. They meticulously examine products against established quality control and assurance benchmarks, identifying any discrepancies that could lead to customer dissatisfaction down the line. By conducting thorough inspections, they help companies avoid costly returns and enhance their reputation in the marketplace.

Scheduling inspections effectively is crucial for ensuring that these quality assessments occur at optimal times during production. When you schedule the inspection date wisely, it allows for adjustments to be made if defects are discovered early on. This proactive approach not only saves time but also reinforces the importance of quality control throughout the manufacturing process.

Spotting Defects Early in the Process

One of the most significant advantages of having QC inspectors on-site is their ability to spot defects early in the process. Early detection can prevent minor issues from escalating into major problems that could jeopardize entire shipments or even long-term business relationships. By implementing rigorous checks during various stages of production, QC inspectors contribute significantly to overall product quality.

Moreover, these inspections often reveal systemic issues within manufacturing processes that may not be apparent without a thorough examination. When companies prioritize quality control and assurance strategies by integrating regular inspections into their workflow, they foster a culture of continuous improvement that benefits everyone involved—from manufacturers to end consumers. This proactive stance ultimately leads to more reliable products reaching market shelves.

Enhancing Buyer Confidence

The presence of skilled QC inspectors enhances buyer confidence significantly by assuring them that their products will meet or exceed expectations upon delivery. Buyers can rest easy knowing that rigorous standards have been applied through effective product inspection in China before shipment occurs—this builds trust between suppliers and buyers alike. When clients see consistent adherence to quality control measures, they’re more likely to establish long-term partnerships with manufacturers.

Furthermore, transparent reporting from QC inspectors regarding findings enhances communication between all parties involved in sourcing decisions. Clear documentation not only highlights areas for improvement but also showcases commitment toward maintaining high-quality standards throughout production processes—an invaluable asset when negotiating future contracts or expanding business relationships globally.

The role of QC inspectors cannot be overstated; they are essential for ensuring product integrity while fostering trust within international trade dynamics.

Scheduling Inspections Effectively

When it comes to product inspection in China, scheduling is key to ensuring a smooth quality control process. A well-planned inspection date can save time, reduce costs, and enhance overall efficiency. To make the most of your inspection efforts, it’s essential to understand how to effectively schedule inspections and navigate any potential hiccups along the way.

How to Schedule the Inspection Date

To schedule the inspection date effectively, start by coordinating with your manufacturer to identify a suitable timeframe that allows for adequate preparation. Consider aligning your inspection with production timelines; this ensures that products are ready for evaluation without unnecessary delays. Additionally, it's wise to factor in travel time and local holidays in China when planning your visit for product inspection.

Once you’ve pinpointed a tentative date, confirm it with your QC partner and communicate clearly about expectations for the quality control and assurance processes involved. This proactive approach will help ensure everyone is on the same page and ready for action when the day arrives. Remember, clear communication can be the difference between a seamless experience and a chaotic one!

Best Practices for Timely Inspections

Timeliness is crucial when it comes to performing quality inspections in China; after all, delays can lead to costly setbacks down the line. One best practice is to establish a buffer period before shipment—this gives you ample time to address any issues that may arise during inspections without jeopardizing delivery schedules. Make sure all parties involved are aware of these timelines so everyone can work towards meeting them.

Another effective strategy is utilizing digital tools or platforms designed specifically for scheduling inspections; they can help streamline communication and track progress more efficiently than traditional methods. Furthermore, always have contingency plans in place—unexpected challenges often arise during product inspections in China due to various factors like weather or transportation issues. Being prepared will help you adapt quickly while maintaining quality control standards.

Dealing with Last-Minute Changes

Last-minute changes are an inevitable part of sourcing products from overseas; however, how you handle them can significantly impact your quality control efforts. When faced with sudden alterations in production schedules or shipment dates, remain calm and assess the situation logically—understanding what adjustments need to be made will allow you to respond effectively without losing sight of your goals.

Communicate promptly with both your QC partner and manufacturer about any changes affecting scheduled inspections or product readiness dates. This open dialogue helps manage expectations on all sides while ensuring that everyone remains aligned on priorities related to quality assurance processes as they evolve over time.

Lastly, flexibility is essential when navigating last-minute changes; being adaptable means you're better equipped not only for unexpected hurdles but also for seizing new opportunities as they arise within this dynamic sourcing landscape.

Performing the Quality Inspection

When it comes to ensuring that your products meet the highest standards, performing the quality inspection is crucial. This process not only identifies potential issues before they reach your customers but also helps maintain a solid reputation for your brand. By understanding the key steps involved, you can streamline your product inspection in China and ensure a smoother operation.

Key Steps in the Inspection Process

The first step in performing the quality inspection is to schedule the inspection date well in advance. This allows both parties to prepare adequately, ensuring that all necessary resources are available on-site. Once you arrive at the factory, a comprehensive review of product specifications and requirements should be conducted to establish a clear baseline for what constitutes acceptable quality.

Next, QC inspectors will conduct visual checks and functional tests on samples taken from production batches. During this phase, they meticulously examine each item against predetermined criteria—looking for defects such as color mismatches or functional failures. After completing these checks, inspectors compile their findings into detailed reports that will serve as critical documentation for both you and your sourcing partners.

Finally, it's essential to follow up on any corrective actions suggested during inspections. This ensures that any identified issues are addressed promptly and effectively, preventing recurrence in future production runs. By adhering to these steps diligently, you can enhance your overall quality control and assurance strategy.

Common Issues QC Inspectors Identify

In their quest for excellence during product inspection in China, QC inspectors often encounter common issues that can derail even the best-laid plans. One of the most frequent problems is defective materials or components used in manufacturing; this can lead to significant flaws down the line if not caught early enough. Additionally, variations from approved samples—whether in size, color, or functionality—can also surface during inspections.

Another issue frequently identified involves packaging irregularities; improper packaging can result in damage during transit or misrepresentation of products upon delivery. Inspectors may also notice inconsistencies with labeling requirements that could lead to compliance challenges later on. By spotting these common pitfalls early on through diligent inspections, buyers can avoid costly mistakes and maintain a strong market presence.

Moreover, QC inspectors often find discrepancies between production timelines and actual output rates; this misalignment can affect delivery schedules and customer satisfaction levels adversely. Addressing these concerns proactively ensures smoother operations throughout your supply chain while reinforcing trust with partners involved in sourcing processes.

Reporting Findings and Recommendations

Once inspections are performed thoroughly, it's time to report findings and recommendations effectively—a critical aspect of maintaining robust quality control and assurance practices. A well-structured report should highlight any defects found during inspections alongside photographic evidence when possible; this adds an extra layer of credibility to your claims about product quality issues encountered during assessments.

Moreover, reports should include actionable recommendations tailored specifically for each identified problem area; this empowers manufacturers with clear guidance on how best to rectify issues moving forward while preventing similar occurrences down the line from rearing their ugly heads again! Timely communication regarding these findings fosters collaboration between buyers and suppliers alike—strengthening partnerships built around mutual goals focused on producing high-quality goods consistently over time.

Lastly—and perhaps most importantly—regularly reviewing past reports allows businesses to identify trends over time affecting overall performance metrics related directly back into customer satisfaction levels achieved through effective product inspection procedures implemented throughout various stages within supply chains across industries worldwide!

Quality Control and Assurance Strategies

Quality control and assurance are essential components of a successful sourcing strategy in China. With the right techniques and processes, businesses can mitigate risks associated with product quality, ensuring that they receive goods that meet their specifications. By employing effective quality control strategies, companies can not only enhance their reputation but also foster long-term relationships with suppliers.

Quality Control Techniques Used in China

In the bustling manufacturing landscape of China, various quality control techniques are employed to ensure products meet international standards. Techniques such as Statistical Process Control (SPC) and Six Sigma are often utilized to monitor production processes and identify variations that could lead to defects. Additionally, implementing regular product inspections at different stages allows QC inspectors to catch issues early, giving businesses the confidence they need when they schedule the inspection date.

The focus on proactive measures means that manufacturers in China are increasingly adopting Total Quality Management (TQM) practices. This holistic approach encourages continuous improvement across all aspects of production, from raw material sourcing to final assembly. By prioritizing these quality control techniques, companies can significantly reduce costs associated with returns or rework due to poor-quality products.

Importance of Documentation and Traceability

Documentation plays a crucial role in maintaining high standards of quality control and assurance throughout the supply chain in China. It ensures that every step—from initial design specifications to final product inspection—is recorded meticulously for accountability purposes. This traceability not only aids in identifying potential issues but also serves as a valuable resource during audits or disputes.

Moreover, maintaining accurate documentation helps businesses quickly respond to any problems that arise during the product inspection process. When QC inspectors perform the quality inspection thoroughly and document their findings effectively, it creates a transparent environment where both buyers and suppliers can address concerns collaboratively. In an ever-evolving market landscape, this level of transparency is essential for building trust between partners.

Role of Technology in Quality Assurance

Technology has revolutionized how quality assurance is approached within China's manufacturing sector. From automated inspection systems using artificial intelligence (AI) to advanced data analytics tools that predict potential defects before they occur, technology enhances the efficiency of product inspections dramatically. By integrating these technologies into their operations, companies can streamline processes while ensuring adherence to stringent quality standards.

Additionally, digital platforms facilitate real-time communication between buyers and QC inspectors during inspections—making it easier than ever to schedule the inspection date effectively and manage expectations on both sides. As technology continues to advance, its role in enhancing quality control will become even more significant; businesses must stay ahead by embracing innovative solutions tailored for their specific needs in product inspection china.

Choosing the Right Inspection Partner

Finding the right inspection partner is crucial for ensuring your products meet quality standards before they reach your customers. The right QC partner can help streamline your operations, enhance buyer confidence, and ultimately save you money by preventing costly defects. In the vast landscape of product inspection in China, making an informed choice can set you up for success.

What to Look for in a QC Partner

When selecting a QC partner, consider their experience and expertise in product inspection in China. Look for companies that have a proven track record with businesses similar to yours; this ensures they understand your specific needs and challenges. Additionally, prioritize partners who offer comprehensive services that include not just inspections but also quality control and assurance strategies tailored to your industry.

Communication is another key factor when choosing a QC partner; they should be responsive and transparent about their processes. It's essential that they can effectively schedule the inspection date to align with your production timeline. Finally, check if they provide detailed reporting on their findings so you can make informed decisions based on their insights.

Benefits of Working with China Inspection Pro

Choosing China Inspection Pro as your QC partner comes with several advantages that can elevate your sourcing efforts. They specialize in product inspection in China and have extensive experience working with various industries, which means they understand the nuances of different products and markets. Their team is well-equipped to perform the quality inspection efficiently while identifying potential issues early on.

Another significant benefit is their commitment to transparency and communication throughout the process. They ensure you're always updated about inspections, findings, and recommendations—allowing you to make timely decisions without unnecessary delays. Plus, their use of technology enhances documentation accuracy and traceability, making it easier for you to maintain compliance with international standards.

Comparing Costs vs. Quality of Services

When evaluating potential QC partners, it's vital to strike a balance between cost-effectiveness and service quality—especially in the realm of product inspection in China where prices can vary significantly. While it might be tempting to choose the cheapest option available, remember that lower costs may come at the expense of thoroughness or expertise during inspections. Investing slightly more upfront could save you from costly mistakes down the line.

Consider what each potential partner offers beyond just price: do they provide comprehensive reporting? Are they flexible enough to accommodate last-minute changes or urgent requests? By weighing these factors against costs, you'll find a partner who not only fits within budget but also meets high-quality standards essential for effective quality control and assurance.

Conclusion

In the fast-paced world of international trade, effective quality control is not just a luxury; it’s a necessity. Businesses that prioritize quality control and assurance can significantly reduce risks associated with defective products, thus safeguarding their reputation and financial health. By investing in thorough product inspection in China, companies ensure that they receive goods that meet their standards and customer expectations.

The Value of Effective Quality Control

Effective quality control is the backbone of any successful sourcing operation. By implementing rigorous quality control and assurance measures, businesses can pinpoint issues before they escalate into costly problems. Furthermore, consistent product inspection in China fosters a culture of excellence among manufacturers, driving them to maintain high production standards.

Building Trust with Sourcing Partners

Trust is paramount when dealing with sourcing partners across borders. When companies schedule the inspection date well in advance and adhere to agreed timelines, it demonstrates reliability and professionalism. This proactive approach not only enhances relationships but also instills confidence among partners that their investments are protected through diligent oversight during the perform the quality inspection phase.

Future Trends in Product Inspection in China

As technology continues to evolve, so do practices surrounding product inspection in China. Innovations such as AI-driven inspections and real-time reporting tools are set to revolutionize how inspections are conducted, making them more efficient than ever before. Companies will need to adapt by embracing these advancements while maintaining robust quality control and assurance strategies to stay competitive in an increasingly global market.