Introduction

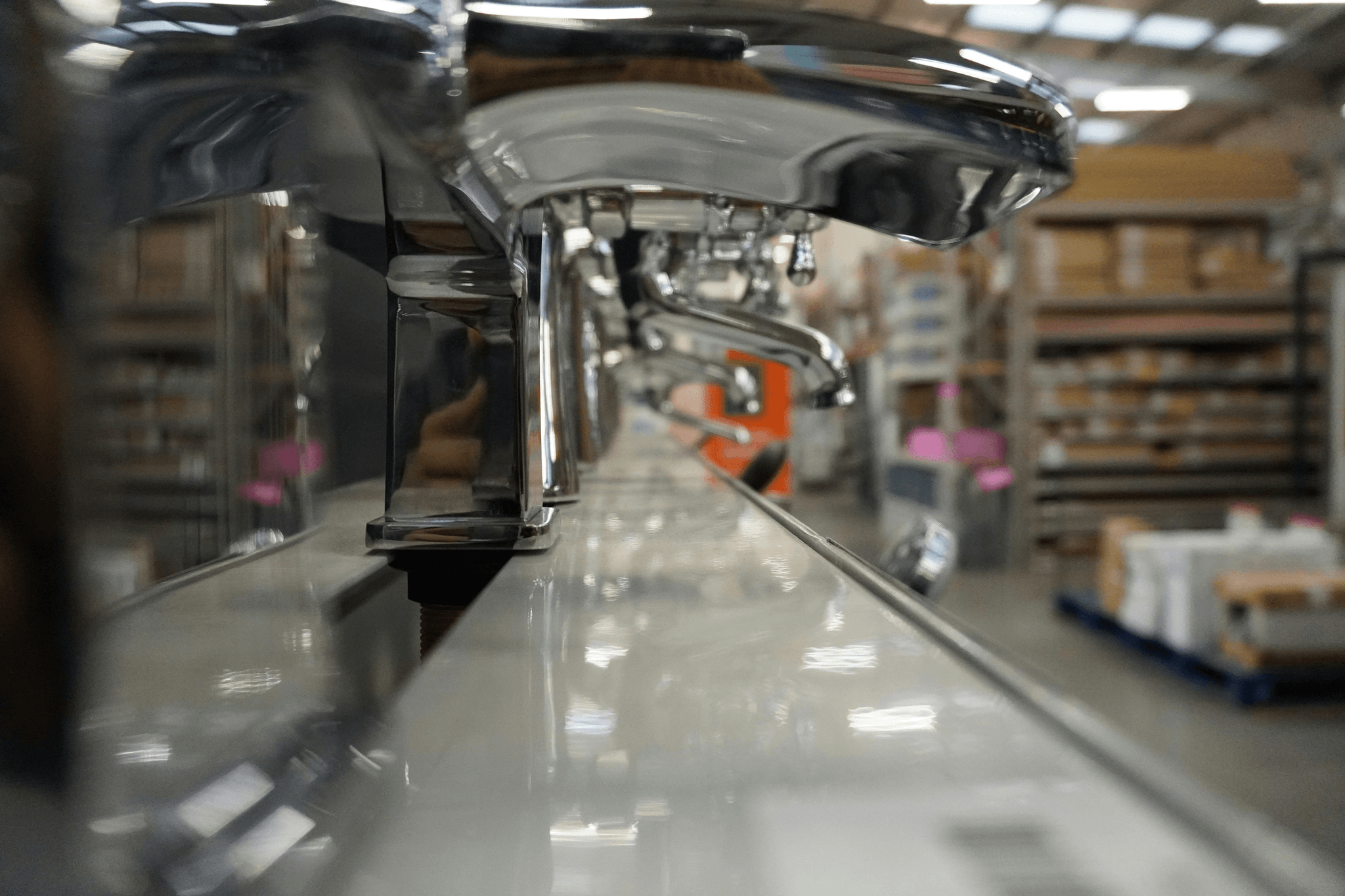

In the world of sanitary ware, quality control is not just a checkbox on a list—it's the foundation upon which consumer trust and product longevity are built. The importance of Sanitary Ware Quality Control cannot be overstated; it ensures that products meet safety standards, function as intended, and stand the test of time. With increasing competition in global markets, particularly from manufacturers in China, understanding how to maintain high-quality standards through effective inspection services is crucial for any business looking to thrive.

Reliable inspection services in China play a pivotal role in maintaining these quality standards. They provide businesses with the assurance that their products are being scrutinized at every stage of production, from raw materials to finished goods. By utilizing professional china factory inspection services, companies can significantly reduce risks associated with defective products and compliance issues before they reach consumers.

Navigating the complex landscape of key standards and regulations is essential for anyone involved in sanitary ware production. Various international guidelines dictate what constitutes acceptable quality; adhering to these regulations not only protects consumers but also enhances a brand's reputation. Understanding these standards will empower businesses to make informed decisions when selecting inspection service providers in China and ensure that their products consistently meet or exceed market expectations.

Understanding Sanitary Ware Materials

Types of Materials Used

Sanitary ware is typically made from a variety of materials, each offering unique benefits and drawbacks. Commonly used materials include ceramic, porcelain, acrylic, and stainless steel. Each material has its own set of characteristics; for instance, ceramic is known for its durability and traditional aesthetics while acrylic offers lightweight flexibility.

In China, where many sanitary ware products are manufactured, understanding these materials is essential for navigating inspection services in China effectively. The choice of material impacts not only the product's appearance but also its longevity and resistance to wear and tear—key aspects that quality control services in China focus on during evaluations. Therefore, knowing what goes into your sanitary ware can make all the difference when it comes to maintaining high standards.

Impact on Quality and Durability

The choice of material directly influences both the quality and durability of sanitary ware products. High-quality materials like porcelain tend to resist staining and chipping better than lower-grade options; this is where diligent china factory inspection becomes invaluable. If inferior materials are used in production, it can lead to premature failures or costly replacements down the line.

Moreover, effective Sanitary Ware Quality Control involves assessing how well these materials hold up under various conditions such as temperature changes or exposure to harsh cleaning agents. Inspection service in China often includes rigorous testing protocols to ensure that manufacturers adhere to international standards regarding material use. This scrutiny helps guarantee that consumers receive durable products that stand the test of time.

Common Material Defects

Despite best efforts in manufacturing processes, defects can still occur with any type of material used in sanitary ware production. Common issues include cracks or chips in ceramic items or discoloration in acrylic surfaces—defects that could easily slip through if not monitored closely by a reliable china inspection company limited during inspections. Such flaws not only affect aesthetic appeal but also compromise functionality.

Additionally, understanding these common defects allows manufacturers to address issues proactively before they escalate into more significant problems affecting supply chain integrity or compliance with international standards. Product inspection services in China play a pivotal role here by identifying these defects early on during production runs—ensuring that what reaches consumers meets expected quality benchmarks consistently. By prioritizing thorough inspections tailored around potential material defects, companies can significantly enhance their overall product reliability.

The Role of Inspection Services in China

When it comes to maintaining high standards in sanitary ware quality control, inspection services in China play a pivotal role. These services ensure that products meet international standards while also adhering to local regulations. By utilizing various types of inspection services, manufacturers can identify potential issues before they escalate, ultimately safeguarding their reputation and bottom line.

Overview of Inspection Service Types

In the realm of sanitary ware quality control, several inspection service types are available to manufacturers and buyers alike. Pre-production inspections help verify materials and components before production begins, while during-production inspections assess the quality at various stages of manufacturing. Finally, the final random inspection ensures that the finished products meet all specified requirements before shipment, making these china factory inspection services indispensable for quality assurance.

Benefits of China Factory Inspection

Engaging in china factory inspections offers numerous benefits that can significantly enhance product integrity and customer satisfaction. First and foremost, these inspections help identify defects early on, allowing for timely corrections that prevent costly rework or returns later on. Additionally, by using reputable product inspection services in China, companies can build trust with their clients by demonstrating a commitment to quality and compliance with international standards.

How to Choose the Right Inspection Company

Selecting the right china inspection company limited is crucial for effective sanitary ware quality control. Look for a company with a solid reputation and extensive experience in conducting inspections specific to your industry needs; this will ensure they understand the nuances of your products and processes. Furthermore, consider factors such as accreditation status, customer reviews, and service offerings when evaluating potential partners—after all, a strong partnership can make all the difference in maintaining high-quality standards.

Quality Control Processes Explained

Quality control is the backbone of any manufacturing process, especially in the sanitary ware industry. Ensuring that products meet specific standards and regulations can significantly impact customer satisfaction and brand reputation. In this section, we will explore the essential steps in the quality control process, best practices for effective quality control, and how technology plays a vital role in these processes.

Steps in the Quality Control Process

The quality control process for sanitary ware typically begins with thorough planning and defining clear quality standards. This involves identifying key specifications that need to be met during production, which sets a benchmark for all subsequent inspections. Following this initial step, inspection services in China conduct routine checks throughout various stages of production to catch any defects early on.

Once production is underway, continuous monitoring is essential to ensure compliance with established standards. This includes conducting random sampling inspections at different intervals to assess product consistency and performance. Finally, after production concludes, a comprehensive final inspection is performed before goods are shipped out—this ensures that only products meeting Sanitary Ware Quality Control standards reach customers.

Best Practices for Effective Quality Control

To achieve optimal results in sanitary ware quality control, implementing best practices is crucial. First and foremost, collaboration between manufacturers and inspection companies can lead to improved outcomes; sharing insights about common defects helps streamline processes and enhances overall product quality. Regular training sessions for staff involved in production can also help maintain high-quality standards by keeping everyone informed about the latest techniques and regulations.

Another best practice involves maintaining detailed documentation throughout the entire inspection process—this creates a transparent trail of compliance with international standards that can be invaluable during audits or when addressing customer concerns. Additionally, utilizing multiple types of inspection services in China allows manufacturers to identify potential issues from various angles rather than relying solely on one method or service provider.

Technology’s Role in Quality Control

In today’s fast-paced manufacturing environment, technology plays an increasingly pivotal role in maintaining Sanitary Ware Quality Control standards. Automated inspection systems equipped with advanced imaging technology can detect flaws more efficiently than manual inspections alone—this not only speeds up the process but also increases accuracy significantly. Moreover, data analytics tools enable manufacturers to analyze trends over time, allowing them to proactively address recurring issues before they escalate into larger problems.

Blockchain technology is also making waves within supply chain management by enhancing transparency among stakeholders involved in product inspections—this ensures that all parties have access to real-time data regarding compliance with established regulations set forth by china factory inspection services or other relevant authorities. Embracing these technological advancements empowers companies to stay ahead of competitors while ensuring their products consistently meet high-quality benchmarks.

Common Challenges in Sanitary Ware Production

Sanitary ware production can be riddled with challenges that impact quality control. Identifying production flaws, addressing supply chain issues, and managing compliance with international standards are just a few hurdles manufacturers face. To ensure high-quality products, effective strategies must be employed to navigate these obstacles.

Identifying Production Flaws

Identifying production flaws is crucial for maintaining high standards in sanitary ware quality control. Common defects may include surface imperfections, incorrect dimensions, or material inconsistencies that can compromise durability and functionality. Regular product inspection services in China help manufacturers catch these flaws early in the process, preventing costly recalls and enhancing customer satisfaction.

To effectively identify production flaws, companies should implement rigorous inspection protocols at various stages of the manufacturing process. Utilizing advanced inspection services in China allows for thorough examinations of products before they leave the factory floor. By engaging a reliable China inspection company limited, businesses can ensure that their sanitary ware meets all necessary quality benchmarks.

Addressing Supply Chain Issues

Supply chain issues can significantly disrupt sanitary ware production and affect overall quality control processes. Delays in raw material delivery or unexpected shortages can lead to rushed manufacturing practices, which often result in compromised product quality. To mitigate these risks, it’s essential for manufacturers to establish strong relationships with suppliers and utilize efficient logistics strategies.

China factory inspection services play a vital role in addressing supply chain challenges by ensuring that materials meet specified standards before they reach the production line. By conducting thorough inspections at various points along the supply chain, companies can prevent subpar materials from entering their manufacturing processes. Moreover, proactive communication with suppliers can help identify potential issues early on and foster smoother operations.

Managing Compliance with International Standards

Managing compliance with international standards is a critical aspect of sanitary ware quality control that cannot be overlooked. Different markets have varying regulations regarding safety and performance requirements for sanitary products; failure to comply could result in hefty fines or product bans. Therefore, staying informed about relevant regulations is essential for any manufacturer aiming to succeed globally.

Utilizing quality control services in China is an effective way to ensure compliance with international standards throughout the production process. These services often include comprehensive audits and inspections tailored to specific market requirements—making it easier for companies to align their products accordingly. Engaging experienced china factory inspection services helps streamline this process while minimizing risks associated with non-compliance.

Case Studies of Successful Quality Control

In the competitive world of sanitary ware production, quality control is not just a nice-to-have; it’s essential for maintaining brand reputation and customer satisfaction. By examining case studies of successful quality control, we can glean valuable insights into effective inspection practices and the benefits of utilizing inspection services in China. These examples showcase how diligent oversight can lead to significant improvements in product quality and compliance with international standards.

Examples of Effective Inspections

One notable example involves a leading manufacturer of sanitary ware that faced challenges with product consistency. By implementing rigorous china factory inspection processes, they were able to identify flaws early in the production cycle, reducing waste and rework costs significantly. This proactive approach to Sanitary Ware Quality Control not only saved money but also enhanced customer trust as their products consistently met high standards.

Another instance highlights a company that utilized product inspection services in China to address issues related to material defects. Through comprehensive inspections at various stages—raw materials, production lines, and final products—they discovered that subpar materials were being used more frequently than anticipated. By switching suppliers based on these findings, they improved both the durability and aesthetic appeal of their sanitary ware offerings.

Lastly, a small startup focused on eco-friendly sanitary ware leveraged china factory inspection services to ensure compliance with environmental regulations. Their commitment to sustainable practices required meticulous attention to detail during inspections, which ultimately positioned them as leaders in the green market segment for sanitary products.

Success Stories from China Inspection Pro

China Inspection Pro has been instrumental in transforming many businesses through its tailored quality control services in China. One success story features a major client who struggled with inconsistent product dimensions leading to increased returns from retailers. After engaging this china inspection company limited for regular inspections throughout production phases, they saw an impressive 30% decrease in return rates within just three months due to enhanced dimensional accuracy.

Another remarkable achievement involved a bathroom fixtures manufacturer that was facing severe delays due to non-compliance with international standards during audits by overseas clients. By employing comprehensive inspection service in China provided by China Inspection Pro prior to shipping their goods, they ensured that all products met necessary certifications ahead of time—effectively streamlining their export process and improving client relationships.

Finally, there’s the story of a mid-sized firm specializing in luxury sanitary ware who sought assistance with quality assurance amidst rapid growth. With the help of product inspection services in China tailored specifically for luxury items, they managed not only to maintain high-quality standards but also received accolades from industry experts for their attention to detail—further solidifying their market position.

Lessons Learned from Inspections

The key takeaway from these case studies is clear: investing in thorough Sanitary Ware Quality Control measures pays off handsomely over time. Companies learned that integrating regular inspections into their production workflow mitigates risks associated with defects while enhancing overall efficiency—a win-win situation! Additionally, engaging reliable china factory inspection services fosters better supplier relationships and encourages accountability throughout the supply chain.

Moreover, these stories emphasize the importance of selecting an experienced china inspection company limited that understands specific industry needs—whether it’s eco-friendliness or luxury finishes—and can adapt its approach accordingly. This tailored strategy ensures that every aspect is covered during inspections without compromising on quality or timelines.

Lastly, embracing technology within quality control processes has proven beneficial across various sectors within sanitary ware manufacturing; automated systems for tracking defects or real-time data analysis have become indispensable tools for achieving excellence consistently across all product lines.

Conclusion

In the realm of Sanitary Ware Quality Control, the importance of meticulous inspection cannot be overstated. Effective quality control processes not only ensure product durability and compliance with international standards but also foster consumer trust. By leveraging reliable inspection services in China, manufacturers can significantly enhance their production quality while mitigating risks associated with material defects and supply chain disruptions.

Key Takeaways on Quality Control

Quality control is a multifaceted process that requires a keen eye for detail and a commitment to excellence. Engaging with reputable inspection services in China can provide invaluable insights into potential production flaws before they escalate into costly issues. Remember, the right China factory inspection services can safeguard your brand’s reputation by ensuring that every product meets established quality benchmarks.

How to Implement Quality Control Best Practices

To effectively implement quality control best practices, start by establishing clear standards based on industry regulations and customer expectations. Regular audits and collaboration with a trusted China inspection company limited will help maintain these standards throughout the production process. Furthermore, integrating advanced technology into your quality control services in China can streamline inspections and enhance accuracy, ultimately leading to improved product outcomes.

Future Trends in Sanitary Ware Quality Control

Looking ahead, we can expect significant advancements in Sanitary Ware Quality Control driven by technology and evolving consumer demands. Automation and AI-driven analytics are set to revolutionize how inspections are conducted, making them faster and more precise than ever before. Additionally, as sustainability becomes increasingly important to consumers, manufacturers will need to adapt their practices accordingly—ensuring that both quality control processes and materials used align with environmentally friendly initiatives.